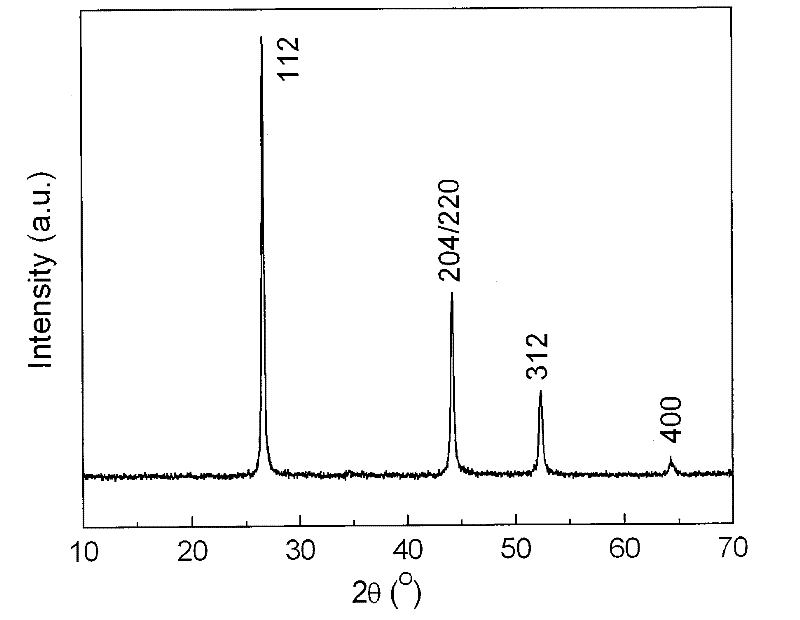

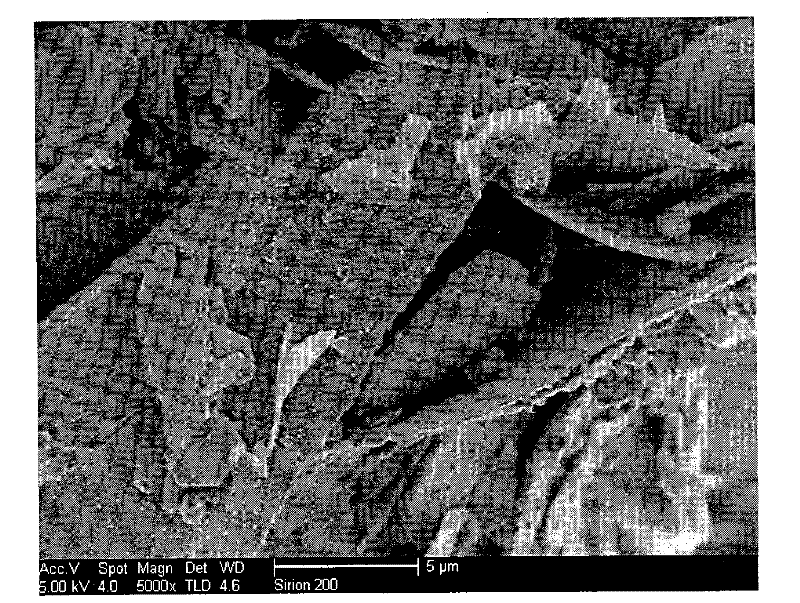

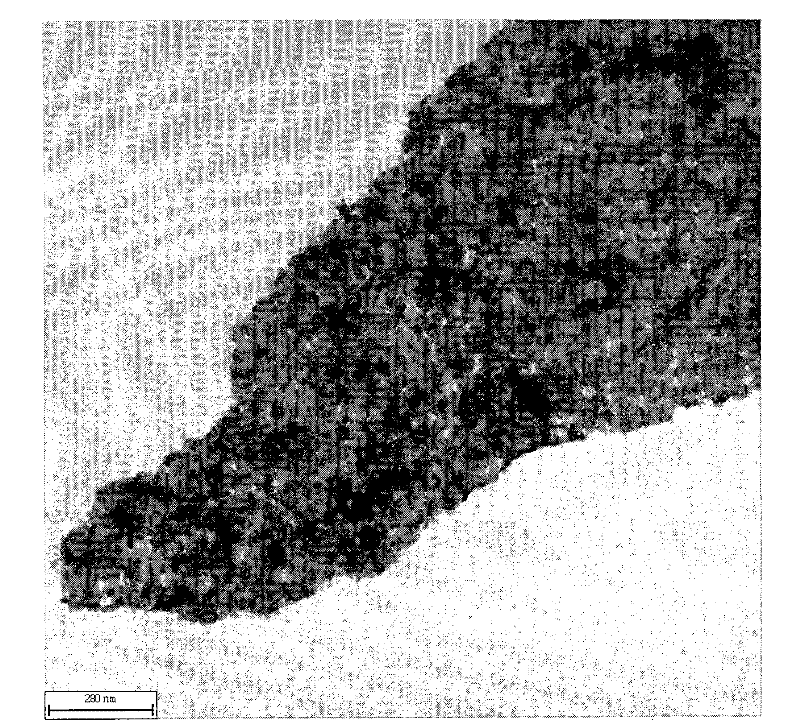

A kind of porous sheet-like cuinse2 nanometer material and preparation method thereof

A technology of nanomaterials and porous sheets, applied in the field of porous sheet CuInSe2 nanomaterials and their preparation, to achieve the effects of simple equipment, novel structure, and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Porous flaky CuInSe of the present invention 2 Nanomaterials were prepared by mixed solvothermal method, that is, with CuCl 2 2H 2 O, InCl 3 4H 2 O and SeO 2 As a raw material, it is formed through a one-step solvothermal reaction in a mixed solvent of ethylene glycol and ethylenediamine. Its specific process steps are as follows:

[0024] (1) According to the volume ratio of ethylene glycol and ethylenediamine, it is 1: 1 to be made into mixed solvent;

[0025] (2) The mixed solvent is filled in the polytetrafluoroethylene liner container of 50 milliliters, and the filling degree is 80%, stirs 10 minutes;

[0026] (3) Add 0.171 g of CuCl in sequence 2 2H 2 O, 0.294 g InCl 3 4H 2 O and 0.111 g SeO 2 , the mixed reactants continued to stir for 30 minutes;

[0027] (4) Put the liner into the stainless steel reaction kettle, tighten and seal;

[0028] (5) Place the reaction kettle in an oven pre-heated to 180°C, and react statically for 30 hours;

[0029] (6)...

Embodiment 2

[0035] The porous sheet-like CISe nanomaterial of the present invention is prepared by a mixed solvothermal method, that is, with CuCl 2 2H 2 O, InCl 3 4H 2 O and SeO 2 As a raw material, it is formed through a one-step solvothermal reaction in a mixed solvent of ethylene glycol and ethylenediamine. Its specific process steps are as follows:

[0036] (1) According to the volume ratio of ethylene glycol and ethylenediamine, it is 1: 1 to be made into mixed solvent;

[0037] (2) The mixed solvent is filled in the polytetrafluoroethylene liner container of 50 milliliters, and the filling degree is 80%, stirs 10 minutes;

[0038] (3) Add 0.170 g of CuCl in sequence 2 2H 2 O, 0.295 g InCl 3 4H 2 O and 0.109 g SeO 2 , the mixed reactants continued to stir for 30 minutes;

[0039] (4) Put the liner into the stainless steel reaction kettle, tighten and seal;

[0040](5) Place the reaction kettle in an oven pre-heated to 180°C, and let it react for 24 hours;

[0041] (6) n...

Embodiment 3

[0045] Porous flaky CuInSe of the present invention 2 Nanomaterials were prepared by mixed solvothermal method, that is, with CuCl 2 2H 2 O, InCl 3 4H 2 O and SeO 2 As a raw material, it is formed through a one-step solvothermal reaction in a mixed solvent of ethylene glycol and ethylenediamine. Its specific process steps are as follows:

[0046] (1) According to the volume ratio of ethylene glycol and ethylenediamine, it is 1: 1 to be made into mixed solvent;

[0047] (2) The mixed solvent is filled in the polytetrafluoroethylene liner container of 50 milliliters, and the filling degree is 80%, stirs 10 minutes;

[0048] (3) Add 0.172 grams of CuCl in sequence 2 2H 2 O, 0.292 g InCl 3 4H 2 O and 0.109 g SeO 2 , the mixed reactants continued to stir for 30 minutes;

[0049] (4) Put the liner into the stainless steel reaction kettle, tighten and seal;

[0050] (5) Place the reaction kettle in an oven pre-heated to 180°C, and react statically for 72 hours;

[0051]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com