Ultrasonic welding device and ultrasonic welding method

An ultrasonic welding and welding part technology, applied in welding/welding/cutting items, welding equipment, non-electric welding equipment, etc., can solve the problems of low welding yield, loss of foil tab edges, etc., and achieve the effect of avoiding rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

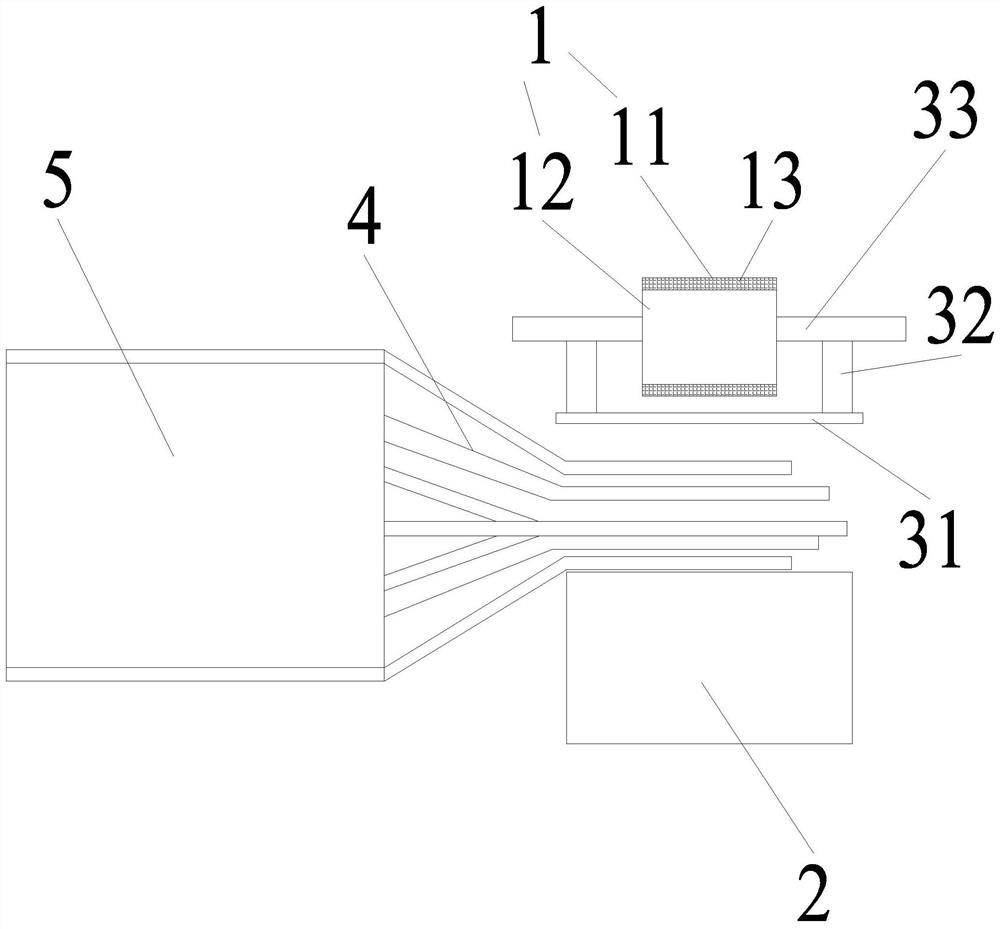

[0030] like Figures 1 to 6 As shown, an ultrasonic welding device includes a welding head 1 and a welding seat 2. The welding head 1 is provided with welding parts 11 on two symmetrical sides, and the welding parts 11 are connected by a connecting part 12. There are several welding teeth 13 arranged at intervals, the welding teeth 13 include a first surface 131 fixedly connected with the welding part 11 and a second surface 132 away from the welding part 11 , the welding teeth 13 are arranged in order to form a gap 14 of straight bars.

[0031] A new ultrasonic welding tooth arrangement design is adopted, and a gap 14 is provided on the originally regularly arranged welding teeth 13, which helps to weaken the welding teeth 13 on the edge of the welding part 11 during the welding process of the welding head 1. The pair of tab foils 4, to avoid the problem of rupture of the tab foil 4, resulting in a low product qualification rate.

[0032] Specifically, the number of welding...

Embodiment 2

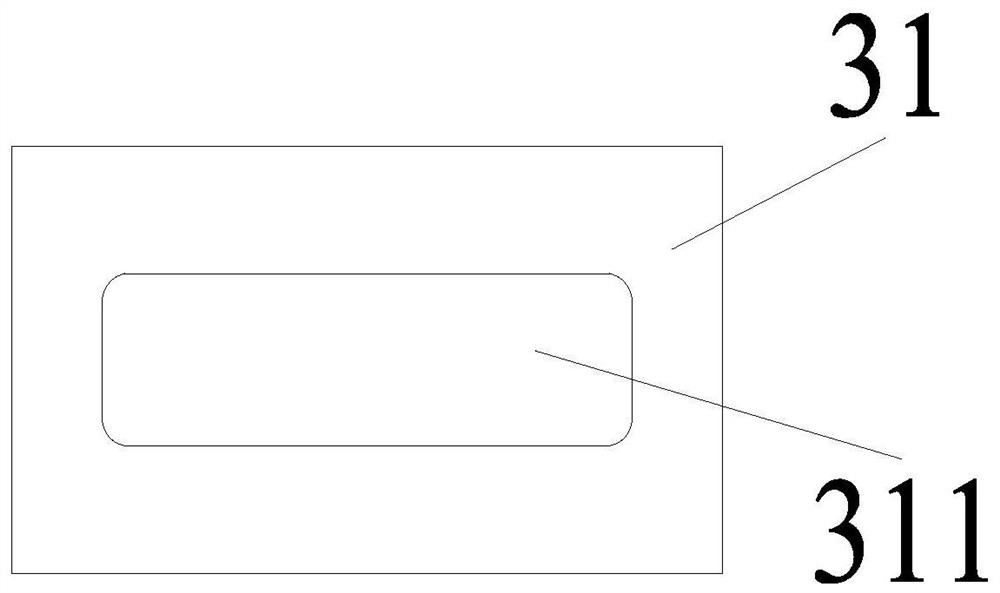

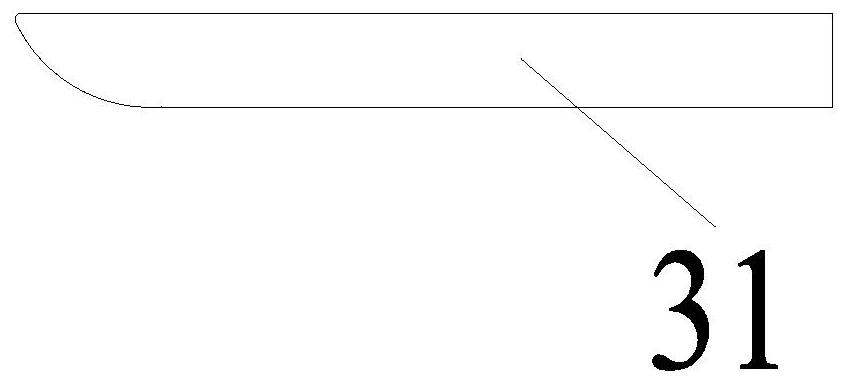

[0043] like Figures 7 to 9 As shown, an ultrasonic welding device includes a welding head 1 and a welding seat 2. The welding head 1 is provided with welding parts 11 on two symmetrical sides, and the welding parts 11 are connected by a connecting part 12. There are several welding teeth 13 arranged at intervals, the welding teeth 13 include a first surface 131 fixedly connected with the welding part 11 and a second surface 132 away from the welding part 11 , the welding teeth 13 are arranged in order to form a gap 14 of straight bars. The welding head 1 is provided with a liftable pressing device. The pressing device includes a pressing plate 31, a telescopic rod 32 and a mounting base plate 33 fixedly connected to the connecting portion 12 of the welding head 1. One end of the telescopic rod 32 is connected to the mounting plate 33. The bottom plate 33 is fixedly connected, and the other end of the telescopic rod 2 is fixedly connected to the pressing plate 31 . The conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com