Non-cleaning flux for low temperature paste and preparing method of flux

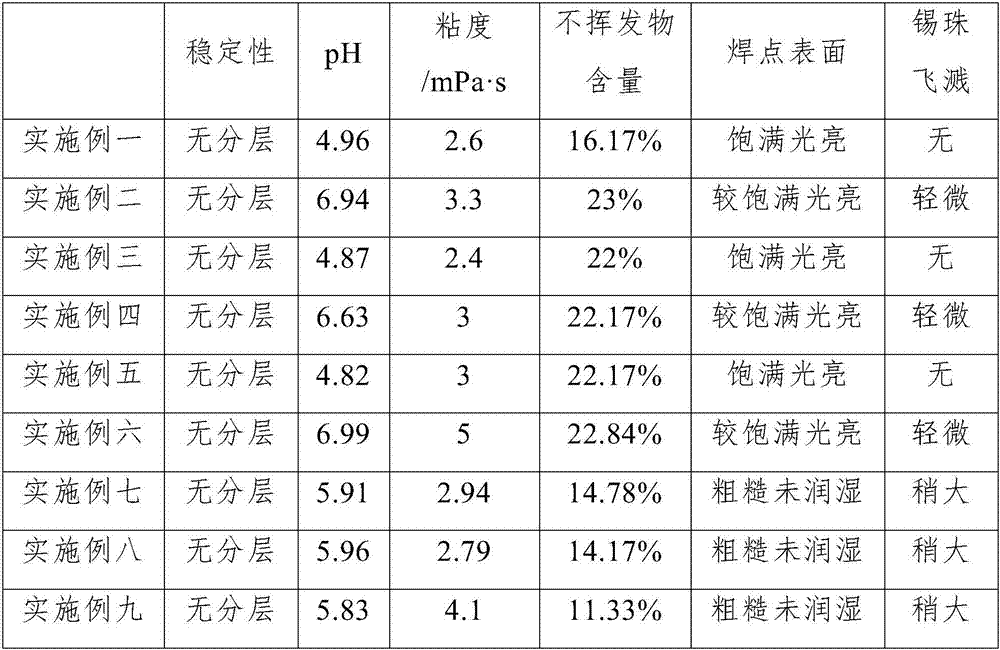

A flux and no-cleaning technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of poor wettability, inability to play a role in fluxing, and many residues, and achieve easy operation, good fluxing effect, The effect of less residue after welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a method for preparing the no-clean flux for low-temperature solder paste as described above, comprising the following steps:

[0035] S0. Mix ethylene glycol, ethylene glycol monobutyl ether, isopropanol and ethanol at a mass ratio of 5:2:(40~95):(0.1~55), and stir at room temperature (25±2°C) until Dissolve completely to obtain compound solvent.

[0036] S1. Heat and stir the compound solvent, thixotropic agent, and film-forming agent at a mass ratio of (79-82):(2-5):0.25 at a temperature of 38° C. to 42° C. until they are completely dissolved to obtain a matrix solution;

[0037] S2. Add 7-14% active agent by mass percentage, 0.5% corrosion inhibitor by mass percentage and 0.1-0.5% antioxidant by mass percentage to the matrix solution obtained in step S1, at 38°C-42°C Stir at a temperature until completely dissolved;

[0038] S3. Add a pH regulator with a mass percentage of 1-8% to the solution obtained in step S2, and stir at a ...

Embodiment 1

[0056] Put 41.95% ethanol, 31.66% isopropanol, 3.96% ethylene glycol, and 1.58% ethylene glycol monobutyl ether in a container with a polytetrafluoro stirring bar, and place the container on a magnetic stirrer and stir at room temperature 3 to 4 hours until it is completely dissolved to obtain the compound solvent; add 0.25% polyethylene glycol 2000 and 5% castor oil to the container containing the compound solvent, place the container in a water bath and heat it to 40°C in a water bath, and stir at a constant speed 2.5 to 3.5 hours to completely dissolve to obtain a matrix solution; after the above stirring is completed, add 13.5% lactic acid, 0.5% benzotriazole, and 0.1% toluate butyrate to the container, and stir at a constant speed for 0.5 to 1.5 hours to Completely dissolve; finally, add 1.5% ethylenediamine into the container, stir for 0.5-1h until completely dissolved, and then you can get the no-cleaning flux.

Embodiment 2

[0058] Put 41.95% ethanol, 31.66% isopropanol, 3.96% ethylene glycol, and 1.58% ethylene glycol monobutyl ether in a container with a polytetrafluoro stirring bar, and place the container on a magnetic stirrer and stir at room temperature 3 to 4 hours until it is completely dissolved to obtain the compound solvent; add 0.25% polyethylene glycol 2000 and 5% castor oil to the container containing the compound solvent, place the container in a water bath and heat it to 40°C in a water bath, and stir at a constant speed 2.5 to 3.5 hours to completely dissolve to obtain a matrix solution; after the above stirring is completed, add 12% lactic acid, 0.5% benzotriazole, and 0.1% toluate butyrate to the container, and stir at a constant speed for 0.5 to 1.5 hours to Completely dissolve; finally, add 3% ethylenediamine into the container, stir for 0.5-1 hour until completely dissolved, and then you can get the no-cleaning flux.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com