Rosin halogen-free scaling powder for lead-free soldering paste

A lead-free solder paste, rosin-based technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve problems such as non-cleaning flux, unsuitable lead-free solder paste, residual corrosion, etc. To achieve the effect of excellent quality stability, good flux and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

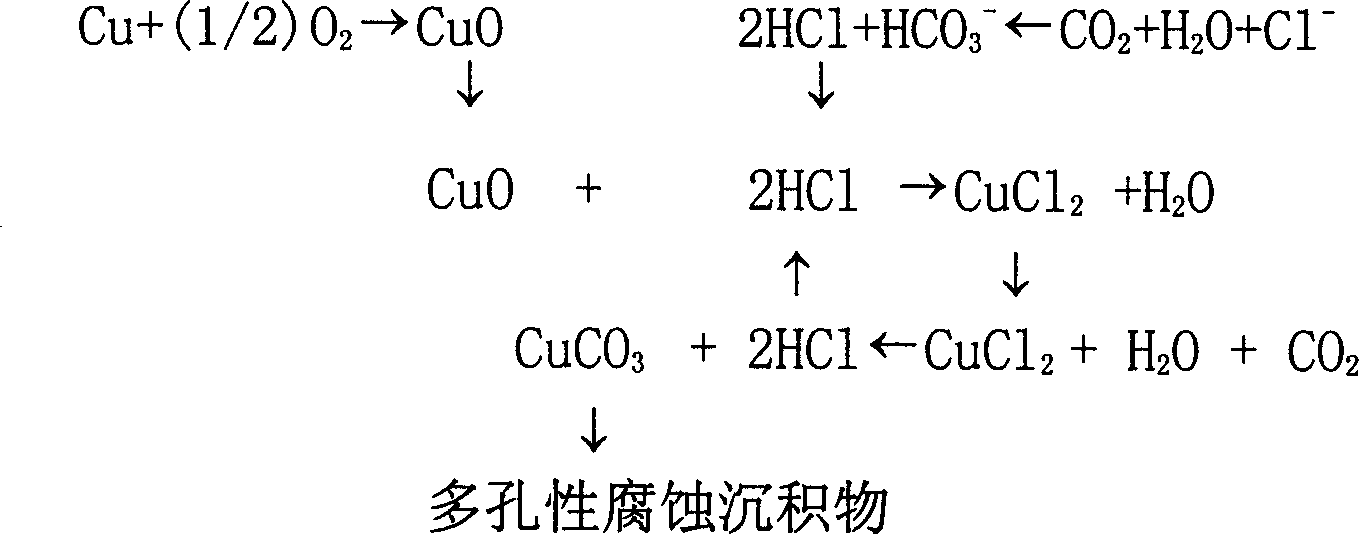

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: This is a rosin-type halogen-free flux for lead-free solder paste that does not contain surfactants, and the mass percentage of each raw material content is:

[0028] polymerized rosin: 67

[0029] Glutaric acid 4

[0030] Polyethylene glycol 2000 1

[0031] Diethylene glycol ether 26.5

[0032] Hydrogenated castor oil 1

[0033] Paraffin 0.5

[0034] Specific preparation method: The specific preparation method is a conventional method, that is, adding an organic solvent into a clean enamel kettle with stirring, then adding polymerized rosin to the solvent, heating, stirring, dissolving, and clarifying, then adding other raw materials in turn, and continuing Stir until the solid matter is completely dissolved, mix evenly, stop stirring, make up the amount of solvent reduced due to volatilization through calculation, mix evenly, let stand, and cool with water, that is, rosin-type halogen-free flux for lead-free solder paste; Mix flux and lead-free solder...

Embodiment 2

[0035] Embodiment 2: This is a kind of rosin-type halogen-free flux for lead-free solder paste containing surfactant and two-component organic acid, and the mass percentage of each raw material content is:

[0036] polymerized rosin: 19

[0037] Hydrogenated rosin 10

[0038] Succinic acid 15

[0039] Glutaric acid 15

[0040] Nonylphenol polyoxyethylene ether 0.5

[0041] Polyethylene glycol 6000 2

[0042] Diethylene glycol butyl ether 22.5

[0043] Hydrogenated castor oil 8

[0044] Paraffin 8

[0045] The preparation method is the same as in Example 1.

Embodiment 3

[0046] Embodiment 3: This is another kind of rosin-type halogen-free soldering flux for lead-free solder paste containing surfactant and single-component organic acid, and the mass percentage of each raw material content is:

[0047] polymerized rosin: 25

[0048] Disproportionated Rosin 15

[0049] Salicylic acid 4

[0050] Octylphenol ethoxylate 10

[0051] Polyethylene glycol 4000 11

[0052] Butyl Cellosolve 25

[0053] Hydrogenated castor oil 5

[0054] Paraffin 5

[0055] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com