Soldering flux composition containing cyclohexane citrate

A technology of cyclohexylamine citrate and cyclohexylamine citric acid is applied in welding medium, welding equipment, welding/cutting medium/material and other directions, which can solve problems such as harm to human health and ecological environment, and achieve low environmental pollution, Enhanced fluxing capability and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

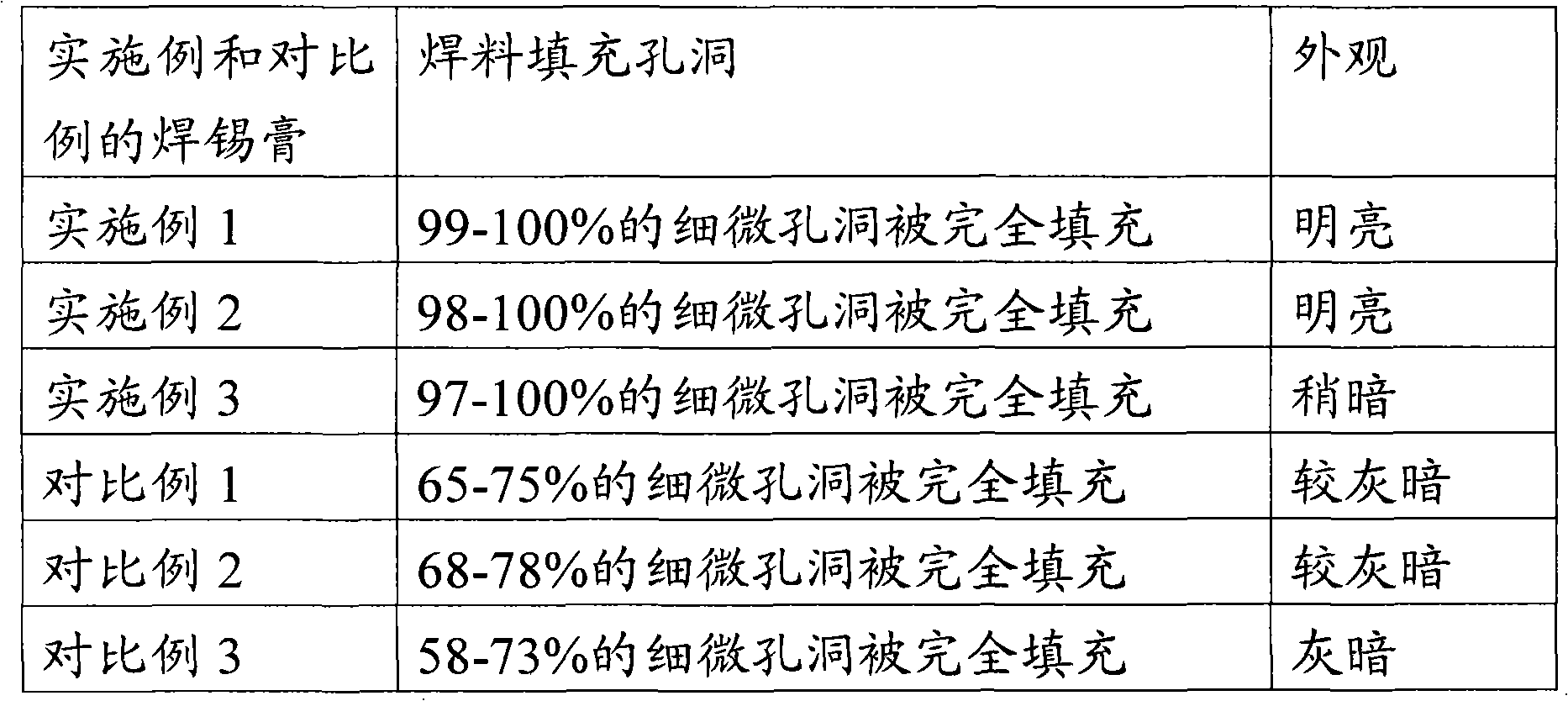

Examples

preparation example 1

[0043] Weigh 210 grams of citric acid monohydrate into a 1000 mL beaker, add 400 mL of pure water and stir to dissolve, filter and clarify for later use. Add 317 grams of cyclohexylamine in another 1000mL beaker, slowly add the filtered and clear citric acid solution under stirring (50r / min), and react completely at 80°C. At this time, the solution is transparent, and the pH of the solution is 8.5. Heat and concentrate until a crystal film appears, pour the concentrated crystals into a clean dish and let cool to form a block, then make small blocks and dry at 85°C for 4 hours to obtain 451.4 g of the product, with a yield of 98.4%. Detection, the content is 99.3 (in (C 6 h 13 N) 3 ·C 6 h 8 o 7 meter), the contents of Cl, F, and Br are all <10ppm.

preparation example 2

[0045] Weigh 210 grams of citric acid monohydrate into a 1000 mL beaker, add 400 mL of pure water and stir to dissolve, filter and clarify for later use. Add 307 grams of cyclohexylamine in another 1000mL beaker, slowly add the filtered and clear citric acid solution under stirring (50r / min), and react completely at 80°C. At this time, the solution is transparent, and the pH of the solution is 7.5. Heat and concentrate until a crystal film appears, pour the concentrated crystals into a clean dish and let cool to form a block, then make small blocks and dry at 80°C for 4 hours to obtain 445.8 g of the product, with a yield of 97.2%. Detection, the content is 99.1 (in (C 6 h 13 N) 3 ·C 6 h 8 o 7 meter), the contents of Cl, F, and Br are all <10ppm.

preparation example 3

[0047]Weigh 210 grams of citric acid monohydrate into a 1000 mL beaker, add 400 mL of pure water and stir to dissolve, filter and clarify for later use. Add 327 grams of cyclohexylamine in another 1000mL beaker, slowly add the filtered and clear citric acid solution under stirring (50r / min), and react completely at 90°C. At this time, the solution is transparent, and the pH of the solution is 9. Heat and concentrate until a crystal film appears, pour the concentrated crystals into a clean dish and let cool to form a block, then make small blocks and dry at 95°C for 3 hours to obtain 453.6 g of the product, with a yield of 98.9%. Detection, the content is 99.3 (in (C 6 h 13 N) 3 ·C 6 h 8 o 7 meter), the contents of Cl, F, and Br are all <10ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com