Lead-free and halogen-free solder paste for electronic industry

A technology for the electronics industry and solder paste, applied in the field of flux chemicals for the electronics industry, can solve problems such as weak welding performance, and achieve the effect of reducing defects and improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

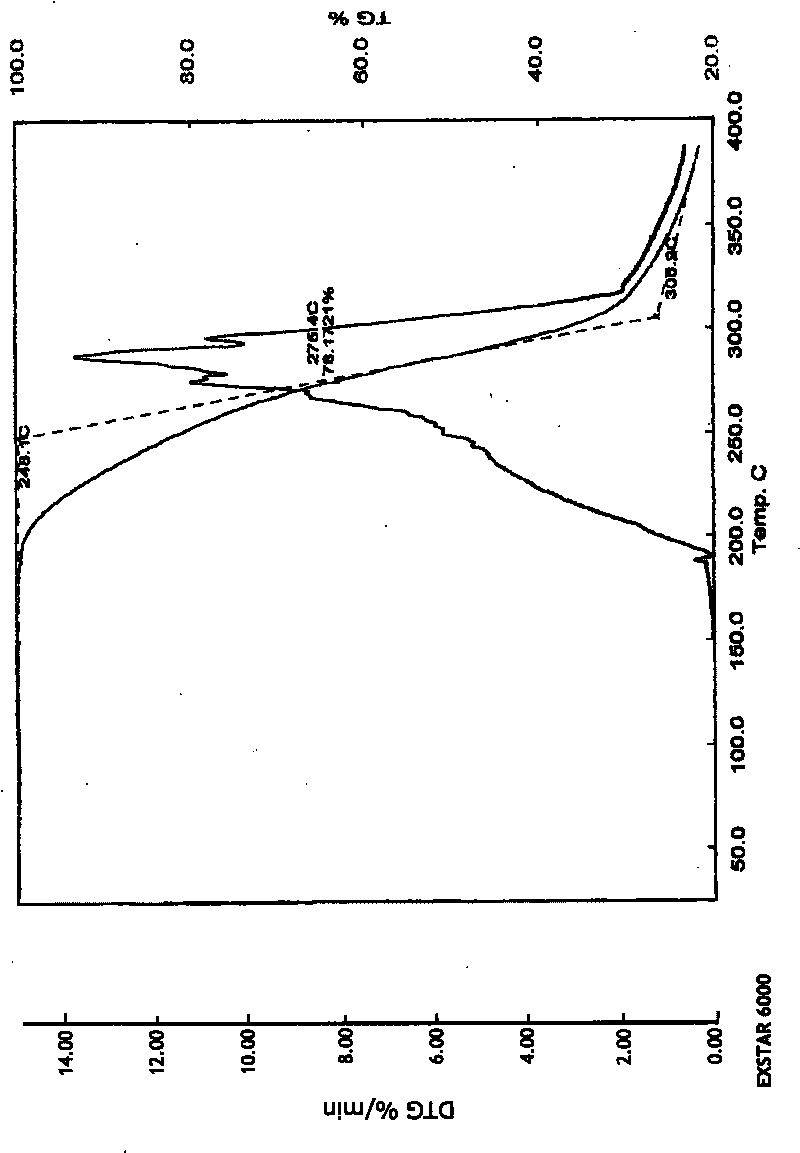

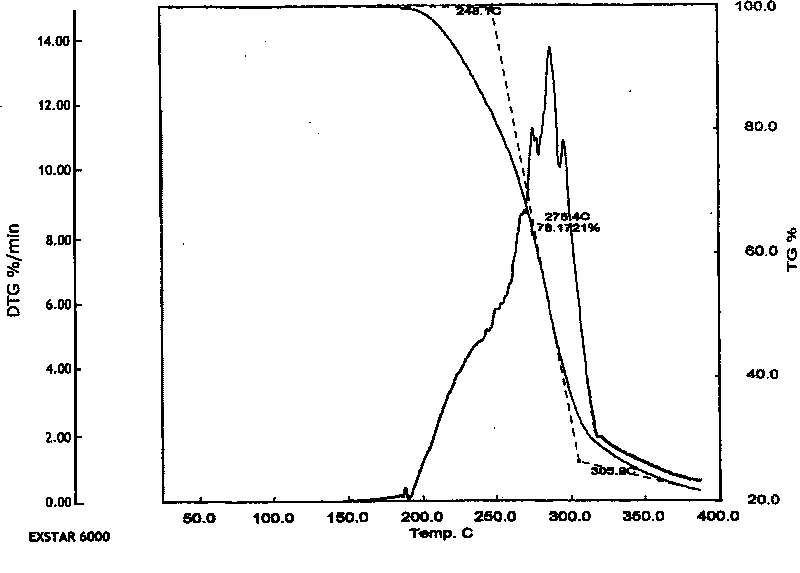

Image

Examples

Embodiment 1

[0034] In this embodiment, the alloy welding portion is alloy solder powder Sn96.5Ag3.0Cu0.5, its content is 88% (mass percentage), and the content of flux is 12% (mass percentage). The components of the flux and the content of each component are shown in Table 1. The solder powder and flux are thoroughly mixed to prepare a solder paste. The product should be refrigerated at 0-10 degrees Celsius.

Embodiment 2-3

[0036] In this embodiment, the alloy welding portion is alloy solder powder Sn99Ag0.3Cu0.7, its content is 88% (mass percentage), and the content of flux is 12% (mass percentage). The components of the flux and the content of each component are shown in Table 1. The solder powder and flux are thoroughly mixed to prepare a solder paste. The product should be refrigerated at 0-10 degrees Celsius.

Embodiment 4-5

[0038] In this embodiment, the alloy welding portion is alloy solder powder Sn96.5Ag3.8Cu0.7, its content is 88% (mass percentage), and the content of flux is 12% (mass percentage). The components of the flux and the content of each component are shown in Table 1. The solder powder and flux are thoroughly mixed to prepare a solder paste. The product should be refrigerated at 0-10 degrees Celsius.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com