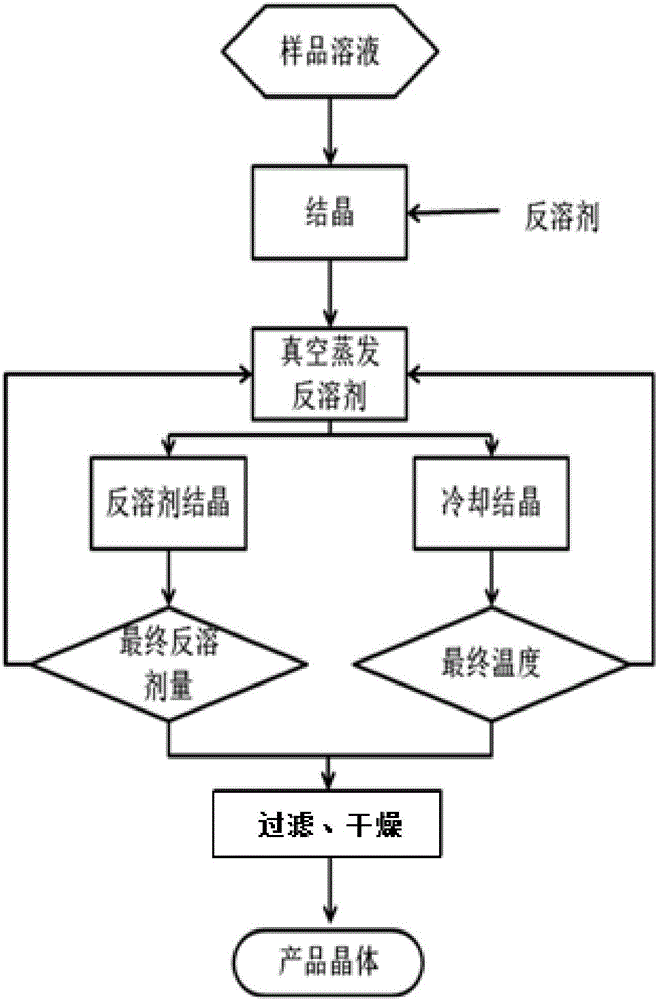

Crystallization method integrating anti-solvent crystallization, vacuum evaporation and cooling or anti-solvent crystallization

A vacuum evaporation and anti-solvent technology, which is applied in the anti-solvent water-soluble amino acid crystallization system, integrated anti-solvent-vacuum evaporation-cooling or anti-solvent crystallization field, can solve the problem of small particles with many crystals, crystallized products with large particle size, and particle size Uneven distribution and other problems, to improve product purity and crystallization process yield, increase particle size, and achieve the effect of particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

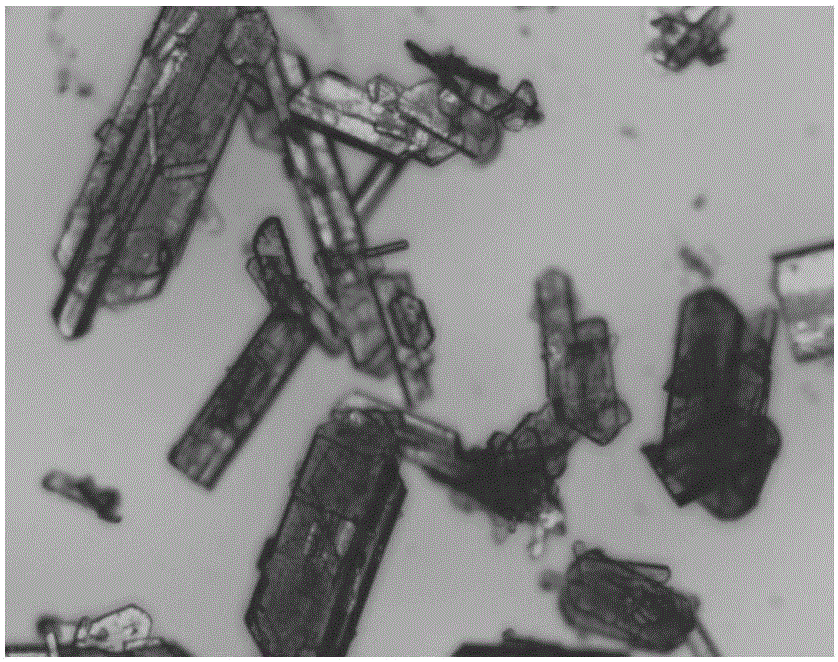

[0034] Weigh 20 g of glycine and measure 100 mL of water in a graduated cylinder. After the two are fully mixed, they are added to the crystallization kettle. The water bath is heated to 60° C. and stirred at a stirring speed of 300 r / min to fully dissolve the glycine. Add 300 mL of anti-solvent absolute ethanol at an addition rate of 3 mL / min, and crystals will precipitate out in the solution. Stir fully for 10 minutes to allow the crystals to grow fully. Reduce the pressure of the system to 45-55kPa, the volume of the volatile liquid is 30mL, and fully stir for 5min to dissolve the small crystal particles. Then, cooling crystallization (ie, cooling to 50°C) or anti-solvent crystallization (ie, continuing to add 170 mL of anti-solvent absolute ethanol at a rate of 3 mL / min) was used to promote crystal growth. Then reduce the pressure of the system to 35-45kPa, the volume of the volatile liquid is 10mL, and fully stir for 5min to fully dissolve the small crystal particles. Gly...

Embodiment 2

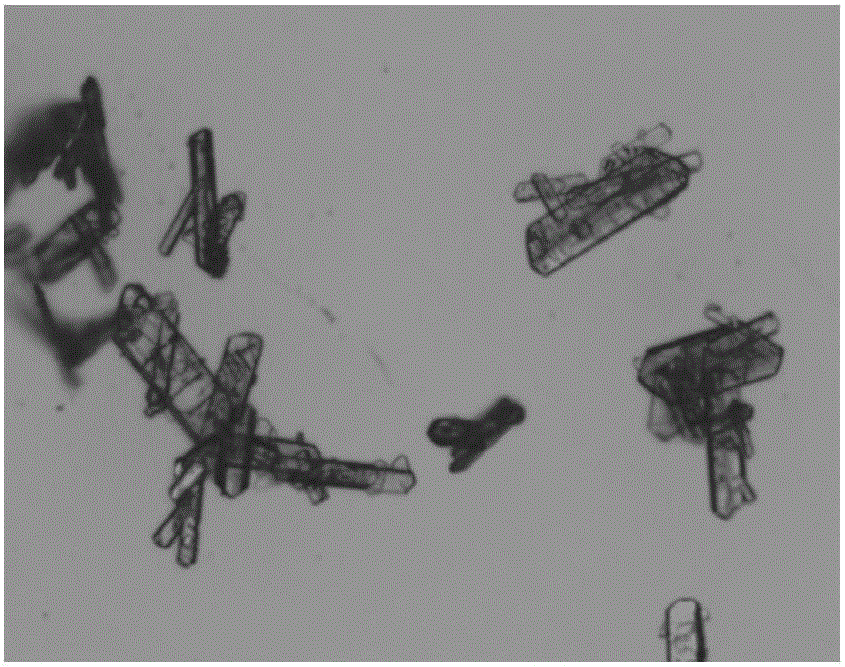

[0037] Weigh 20g of 5'sodium inosinate (IMP), measure 200mL of water in a graduated cylinder, mix the two thoroughly and add to the crystallization kettle, heat the water bath to 60°C, and stir at a stirring speed of 300r / min to fully dissolve IMP. Add 300 mL of anti-solvent absolute ethanol at an addition rate of 3 mL / min, and crystals will precipitate out in the solution. Stir fully for 10 minutes to allow the crystals to grow fully. Reduce the pressure of the system to 40-50kPa, the volume of the volatile liquid is 30mL, and fully stir for 5min to fully dissolve the small crystal particles. Cool down to 50°C, reduce the system pressure to 30-40kPa, and the volume of the volatile liquid is 10mL. Stir fully for 5 minutes to dissolve the small crystal particles. The IMP crystals were obtained by suction filtration under reduced pressure in a Buchner funnel, washed with 30 mL of absolute ethanol, and dried at an absolute pressure of 40 kPa and a temperature of 60° C. for 24 hour...

Embodiment 3

[0040] Weigh 20g of 5'-taste nucleotide disodium (I+G), measure 200mL of water, mix the two thoroughly, add them to the crystallization kettle, heat the water bath to 60°C, and stir at a stirring speed of 300r / min to make I +G is fully dissolved. Add 300 mL of anti-solvent absolute ethanol at an addition rate of 3 mL / min, and crystals will precipitate out in the solution. Stir fully for 10 minutes to allow the crystals to grow fully. Reduce the pressure of the system to 40-50kPa, the volume of the volatile liquid is 30mL, and fully stir for 5min to fully dissolve the small crystal particles. Cool down to 50°C, reduce the system pressure to 30-40kPa, and the volume of the volatile liquid is 10mL. Stir fully for 5 minutes to dissolve the small crystal particles. I+G crystals were obtained by vacuum filtration in a Buchner funnel, washed with 30 mL of absolute ethanol, and dried at an absolute pressure of 40 kPa and a temperature of 60° C. for 24 hours to obtain I+G crystal produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com