A method of testing a tensile property of a single component in a composite fiber

A composite fiber and tensile performance technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, and analyzing materials, can solve the problems of inability to separate the fibers to be tested, insufficient stretching force, and falling off, etc., to achieve It is convenient and reliable to clamp microfiber, not easy to bend or fall off, and reduce the effect of test error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

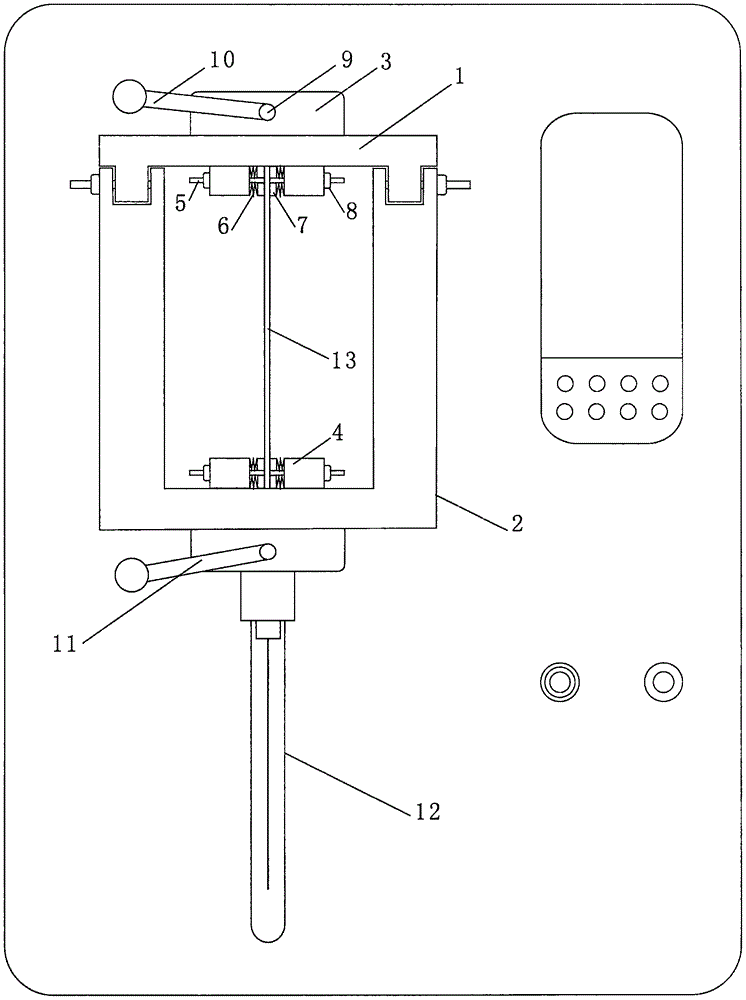

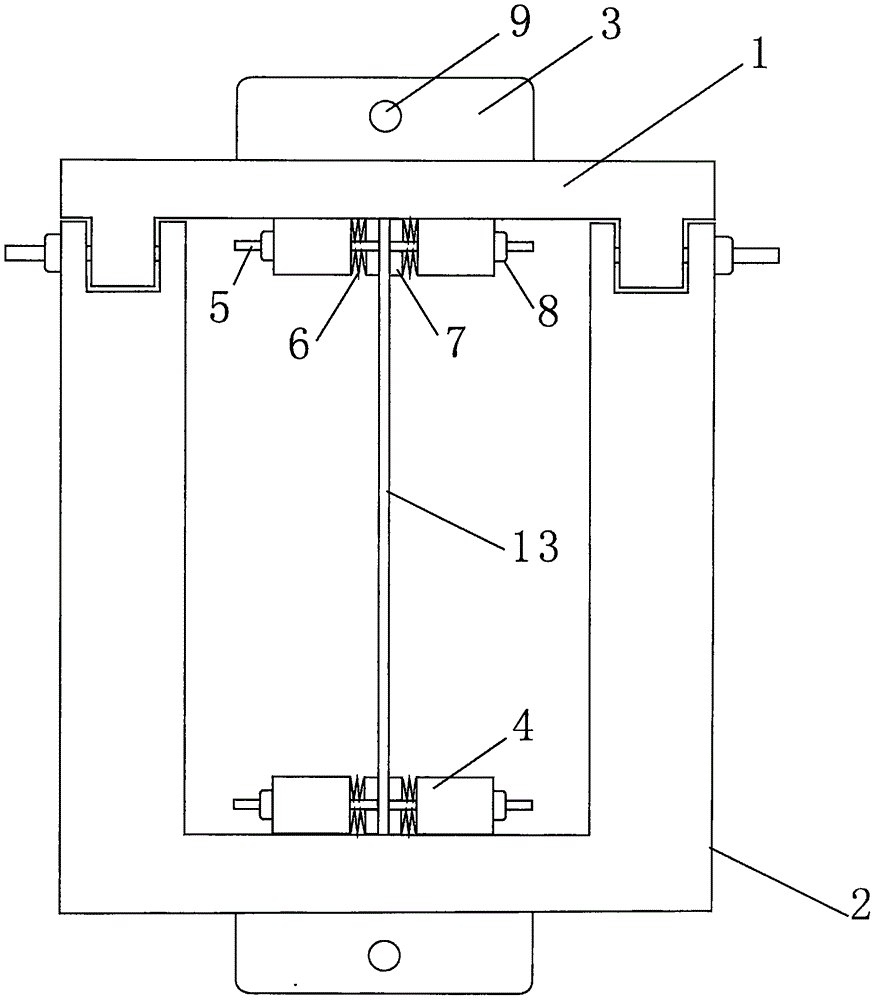

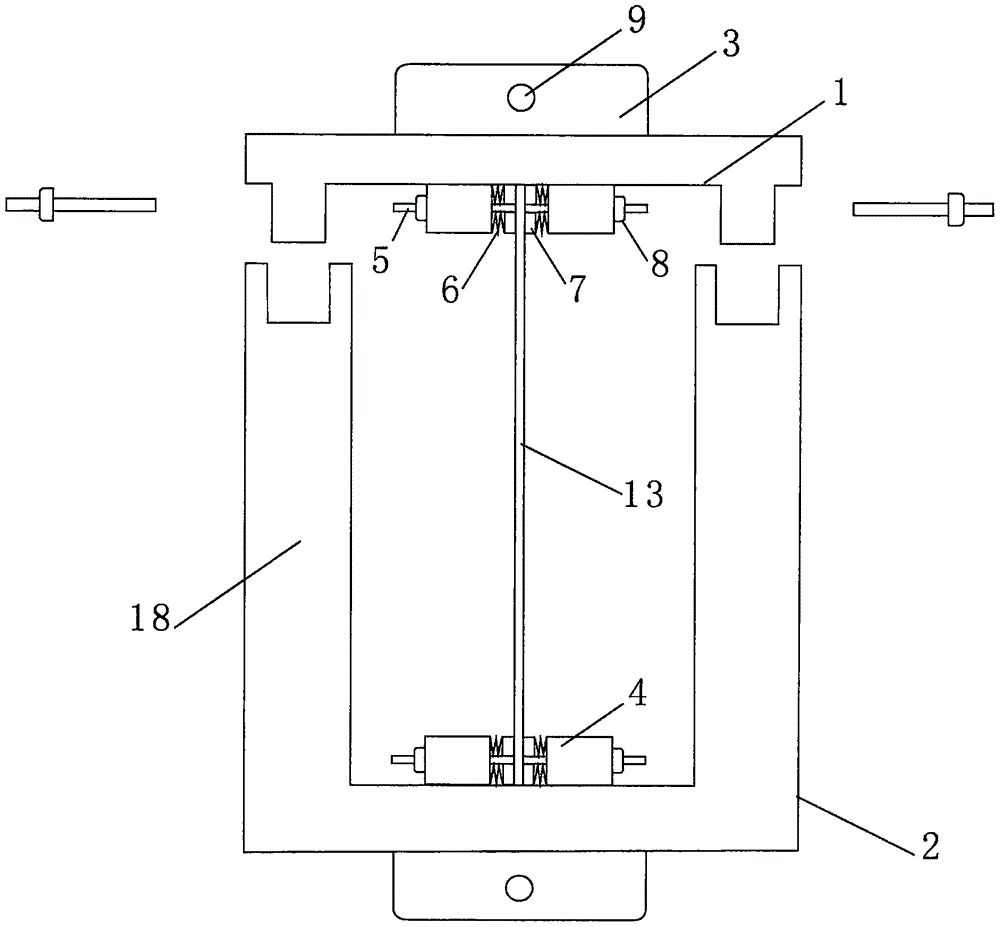

Image

Examples

Embodiment 1

[0039] A method for testing the tensile properties of a single component in a composite fiber, characterized in that it comprises the steps:

[0040] Step S1, selecting: taking a plurality of segment samples from the composite fiber roll, and picking a plurality of single composite fibers in each segment sample;

[0041] Step S2, fixing: each selected composite fiber is respectively fixed on the fixing component through the clamping unit;

[0042] Step S3, dissolving other fiber components in the composite fiber except the fiber component to be tested:

[0043] a. Put a plurality of fixed components clamped with composite fibers into a container containing a fiber dissolving solution, the fiber dissolving solution being one of toluene, dimethylformamide or NaOH;

[0044] b. Heating the container and controlling the temperature at a constant temperature of 95°C, setting the holding time at 30 minutes, dissolving other fiber components in the composite fiber except for the fibe...

Embodiment 2

[0062] A method for testing the tensile properties of a single component in a composite fiber, characterized in that it comprises the steps:

[0063] Step S1, selecting: taking a plurality of segment samples from the composite fiber roll, and picking a plurality of single composite fibers in each segment sample;

[0064] Step S2, fixing: each selected composite fiber is respectively fixed on the fixing component through the clamping unit;

[0065] Step S3, dissolving other fiber components in the composite fiber except the fiber component to be tested:

[0066] a. Put a plurality of fixed components clamped with composite fibers into a container containing a fiber dissolving solution, the fiber dissolving solution being one of toluene, dimethylformamide or NaOH;

[0067] b. Heating the container and controlling the temperature at a constant temperature of 98°C, setting the holding time at 25 minutes, dissolving other fiber components in the composite fiber except for the fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com