Lithium battery internal short circuit test method

A technology of internal short circuit and test method, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of inability to comprehensively test the performance of lithium batteries, inability to test safety performance, and affect performance, so as to improve the test effect and practicality. Strong performance, reducing the effect of temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

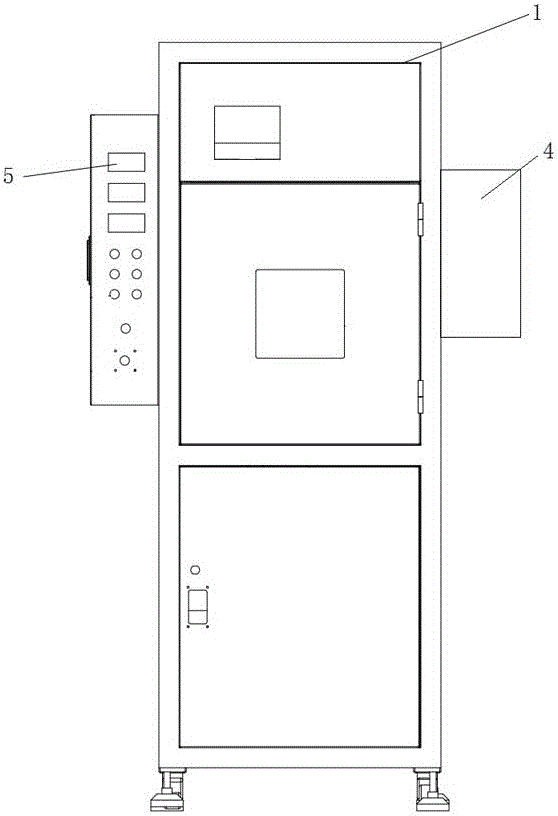

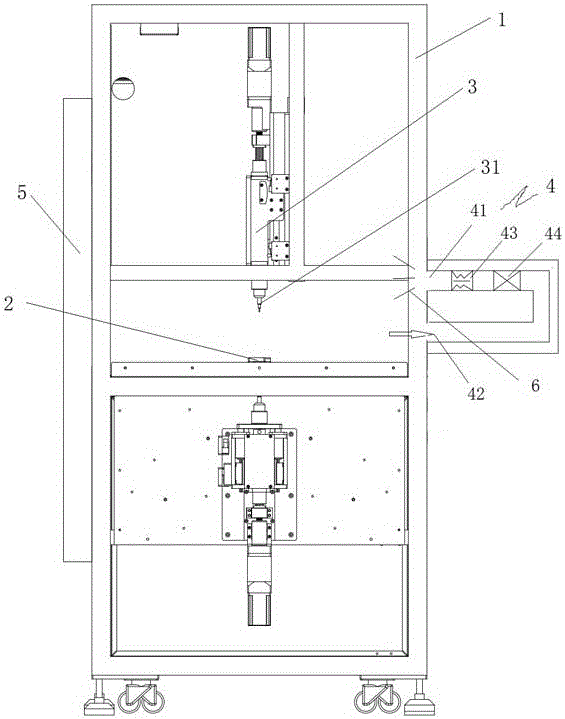

[0030] Such as Figure 1 to Figure 6 As shown, a method for testing the internal short circuit of a lithium battery includes a box body 1, a fixing fixture 2 arranged in the box body for placing the lithium battery, an extrusion device 3 arranged in the box body for testing the lithium battery, and a The heat flow circulation device 4 on the side wall of the box and connected to the box, and the controller 5 for controlling the connection of the fixing fixture, the extruding device and the heat flow circulation device. The box body 1 is provided with an air inlet for the external air to enter the box and an air outlet for the heat flow in the box to flow out of the box, and the air flow in the box and the outside are realized through the air inlet and the air outlet. The box is also provided with an observation port for observing the extrusion changes of the lithium battery, and the observation port is sealed by explosion-proof glass to prevent the lithium battery from explodi...

Embodiment 2

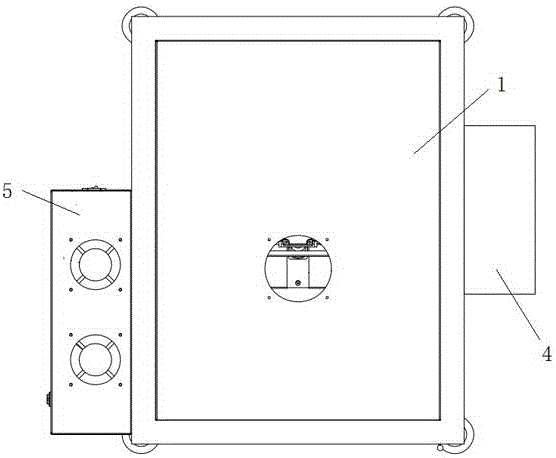

[0045] The mechanism of this embodiment is basically the same as that of Embodiment 1, the difference being that the number of extrusion devices in Embodiment 1 is two, and the number of extrusion devices in Embodiment 2 is three, as Figure 7 and Figure 8 shown. When the number of extruding devices is three, there is one extruding device above the fixing fixture, and the extruding device is arranged directly below the fixing fixture; there are two extruding devices below the fixing fixture, and the The extruding device above the fixing jig and the extruding device below the fixing jig are distributed in a Y-shaped structure between the two. The three extrusion devices move synchronously, and other structures and testing methods are the same as those in Example 1, and will not be described again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com