Patents

Literature

122results about How to "Easy and stable clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

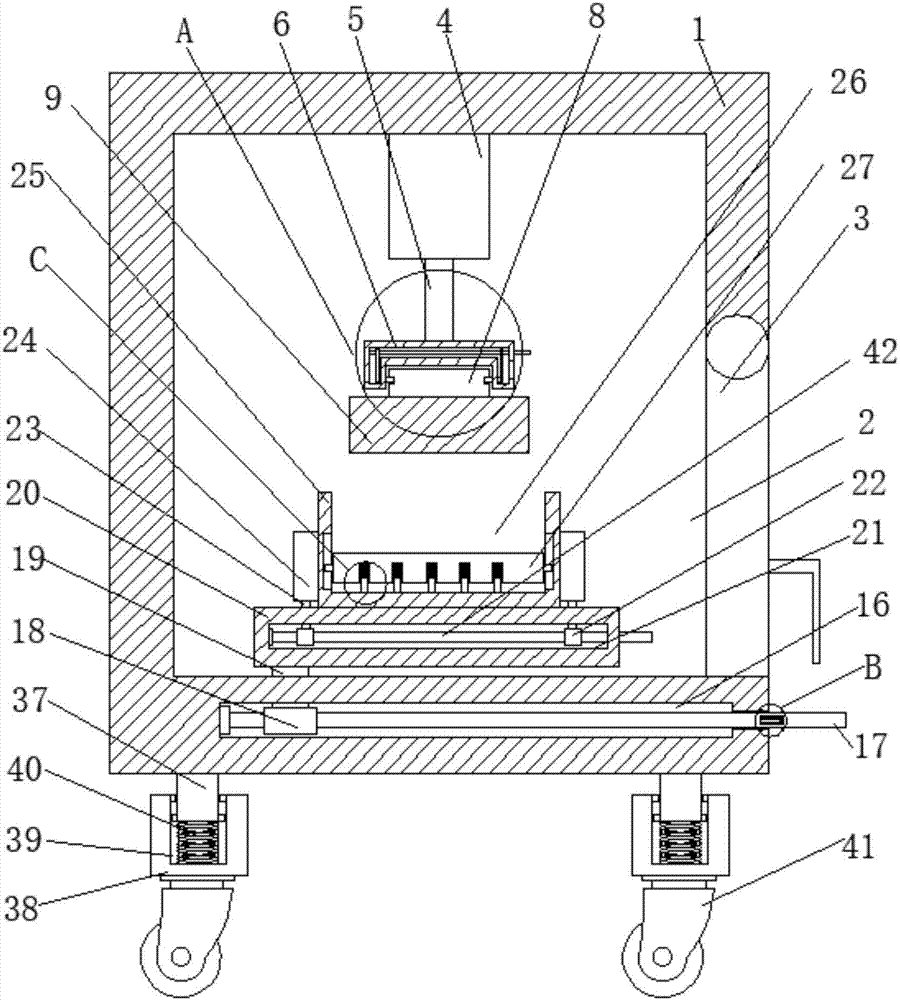

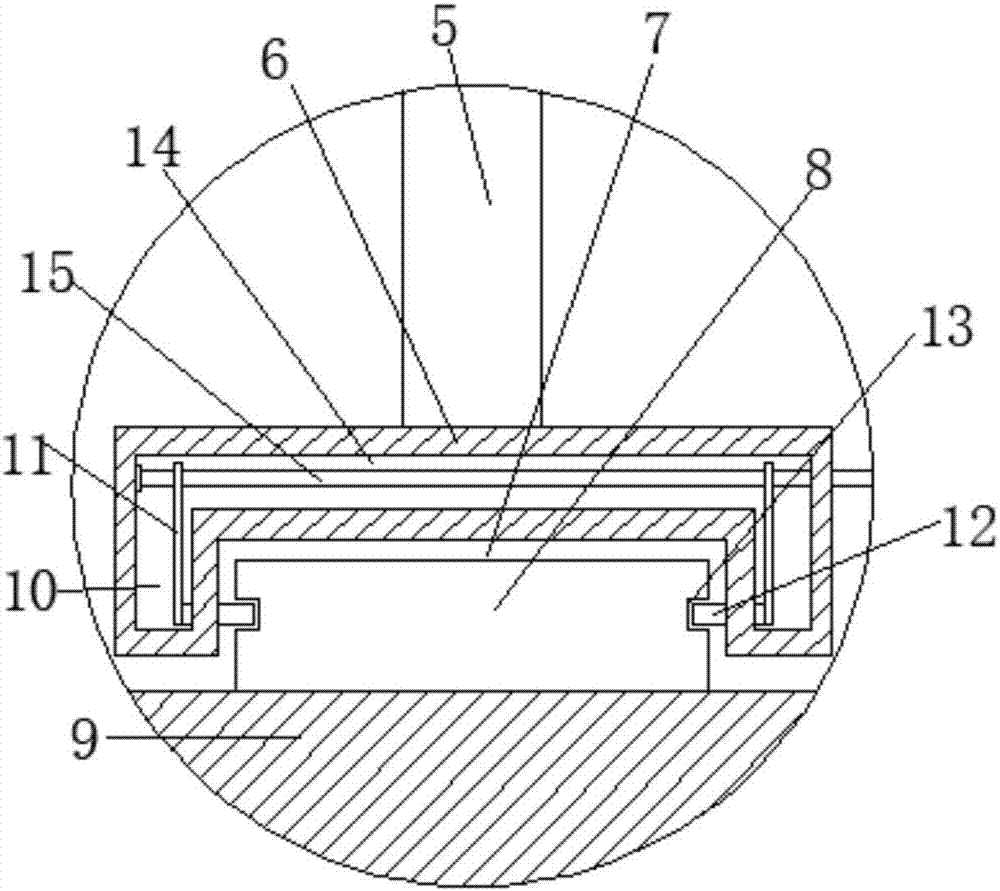

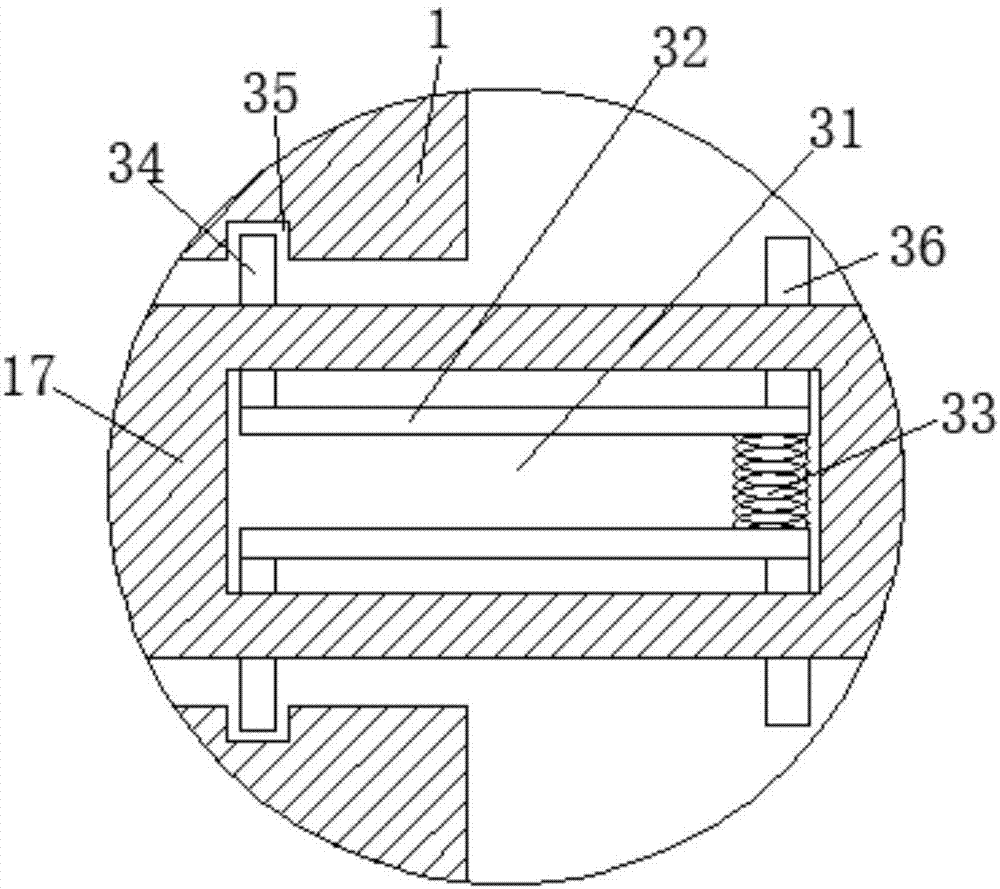

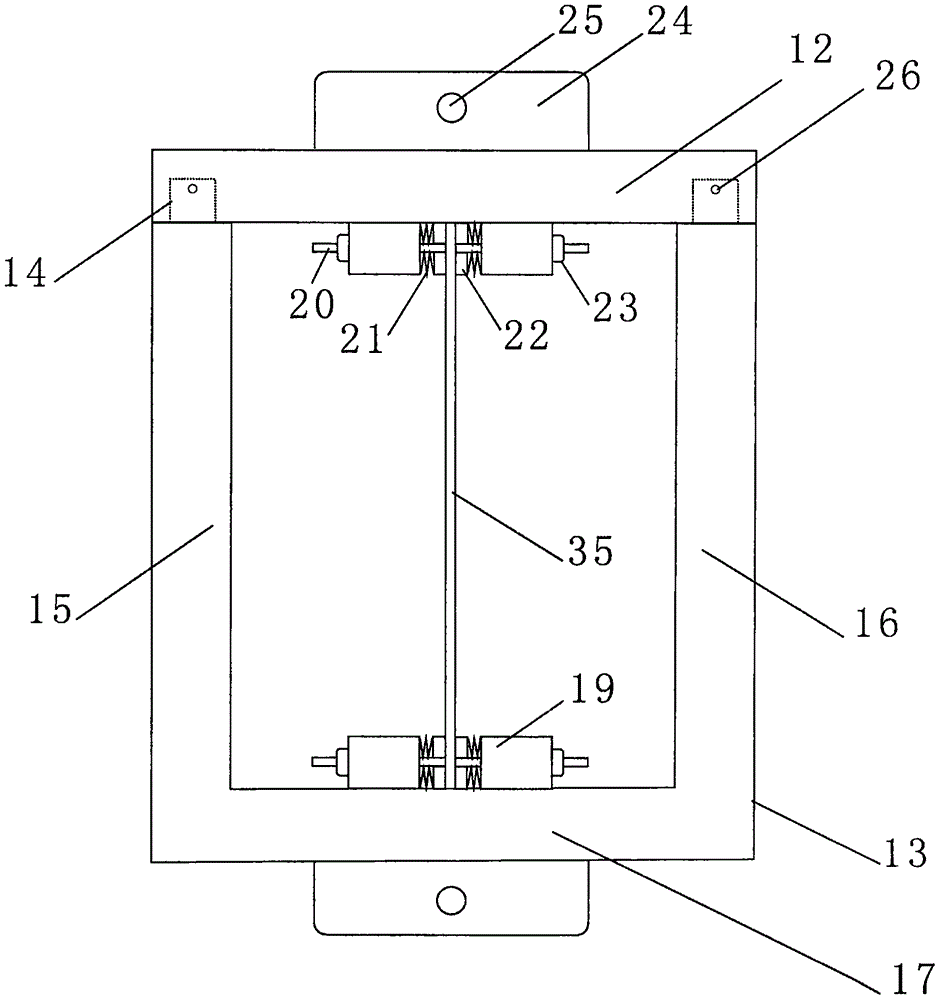

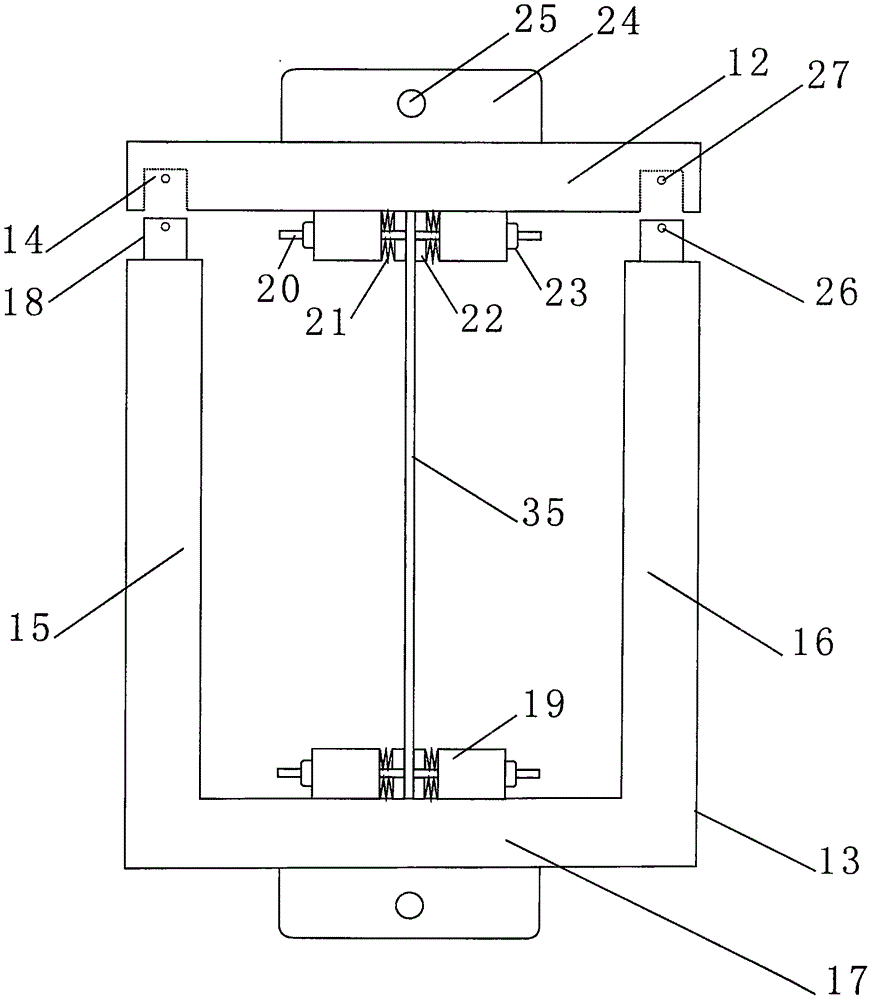

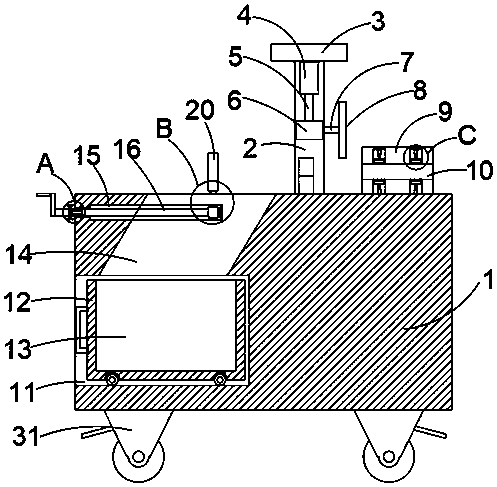

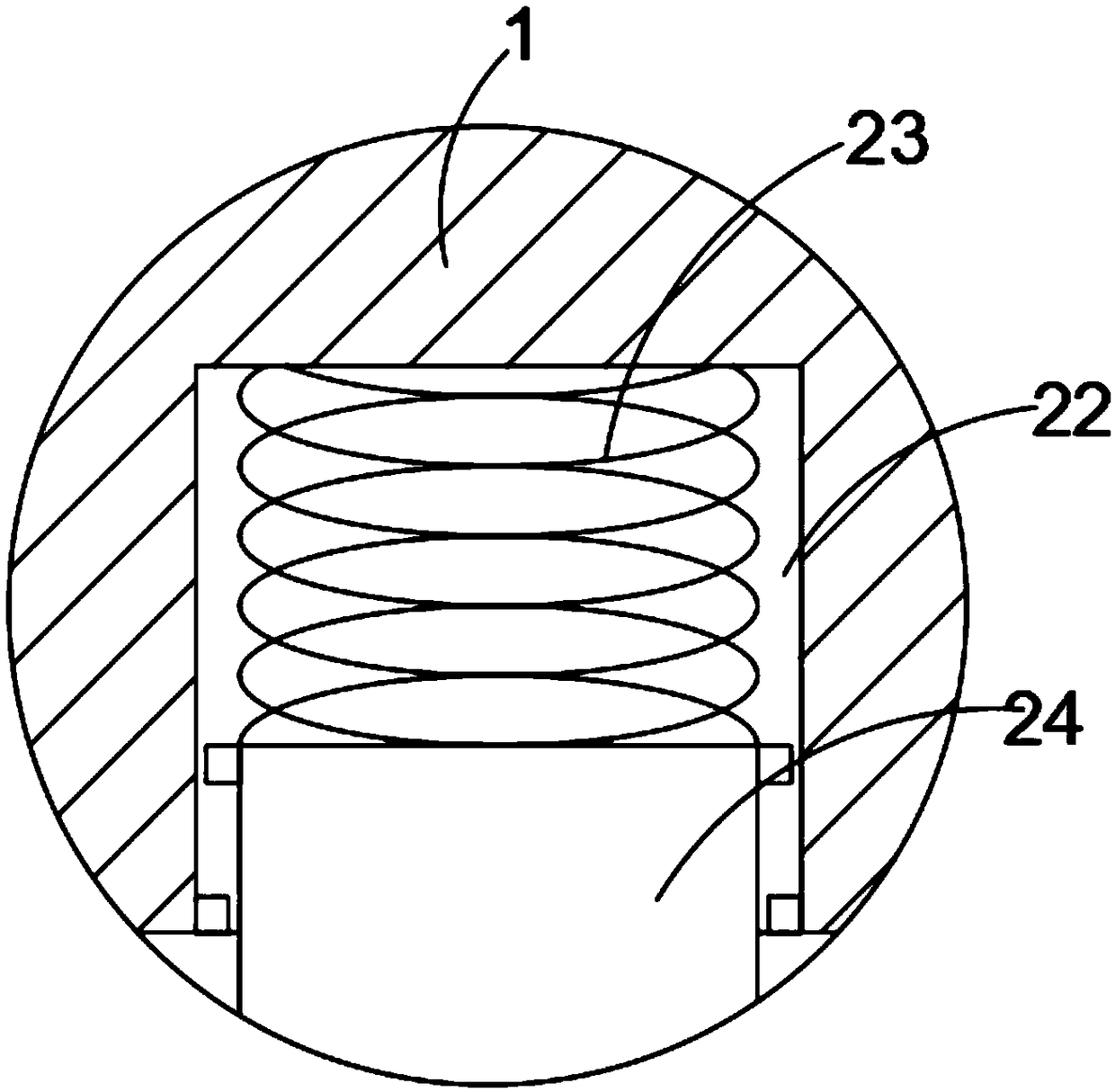

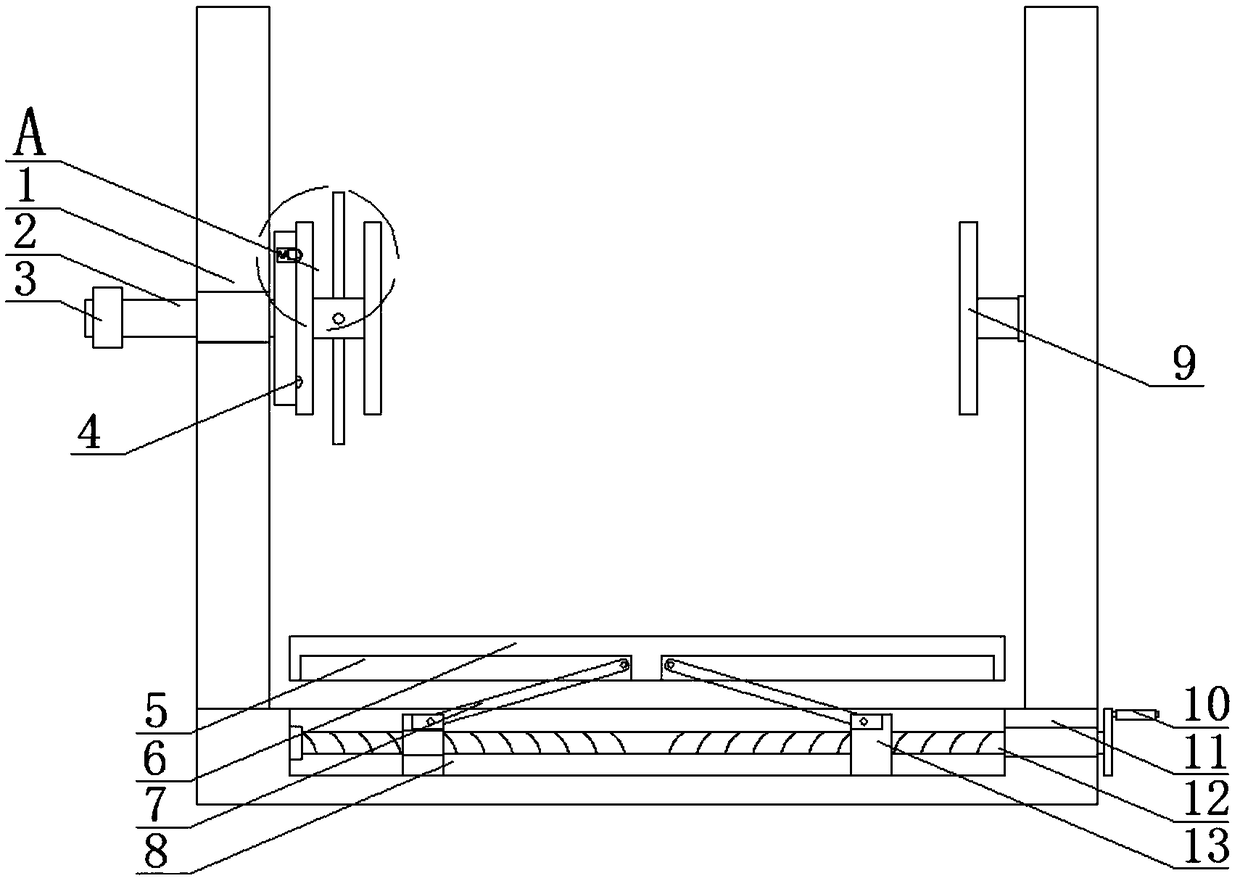

Sand casting die assembly

ActiveCN107876709AAvoid disassembly and replacementEasy to disassemble and replaceMoulding machinesCompression moldingSand casting

The invention discloses a sand casting die assembly comprising a shell which is of a hollow structure. One side wall of the shell is further provided with a feed port of which the opening position isrotatably connected to a cover plate, and the inner wall of the upper side of the shell is fixedly connected to a cylinder; the output end of the cylinder is connected to a piston rod, and the end, far away from the cylinder, of the piston rod is connected to a mounting plate of which the lower end is further provided with a die; the upper end of the die is provided with a mounting block, and thelower side wall of the mounting plate is provided with a mounting groove matched with the mounting block; the mounting plate is internally provide with two cavities arranged symmetrically, and the cavities are internally provided with first slide bars arranged vertically; the opposite side walls of the two first slide bars are both provided with first clamping blocks which penetrate the cavities;and the side wall of the mounting block is provided with a first slot matched with the first clamping blocks. According to the sand casting die assembly disclosed by the invention, a clamping sand mould is simple and firm, and the die for compression molding is easy to remove and displace; and the die assembly is wide in application scope.

Owner:马鞍山市海华金属制品有限公司

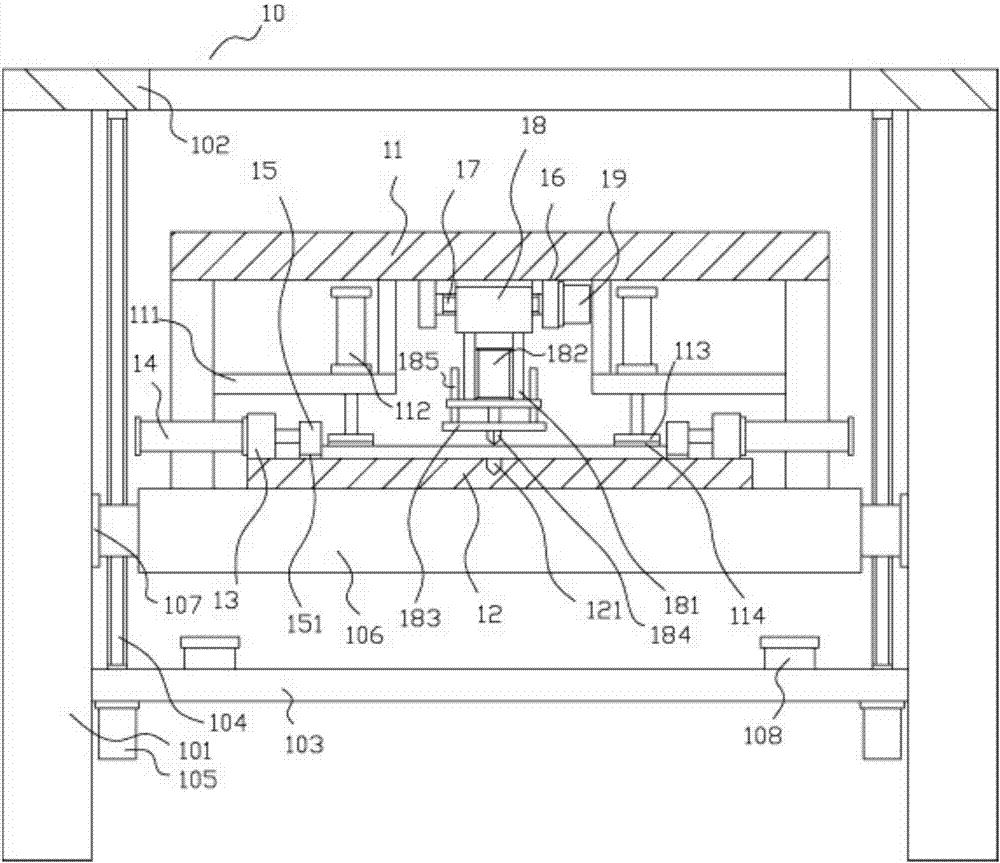

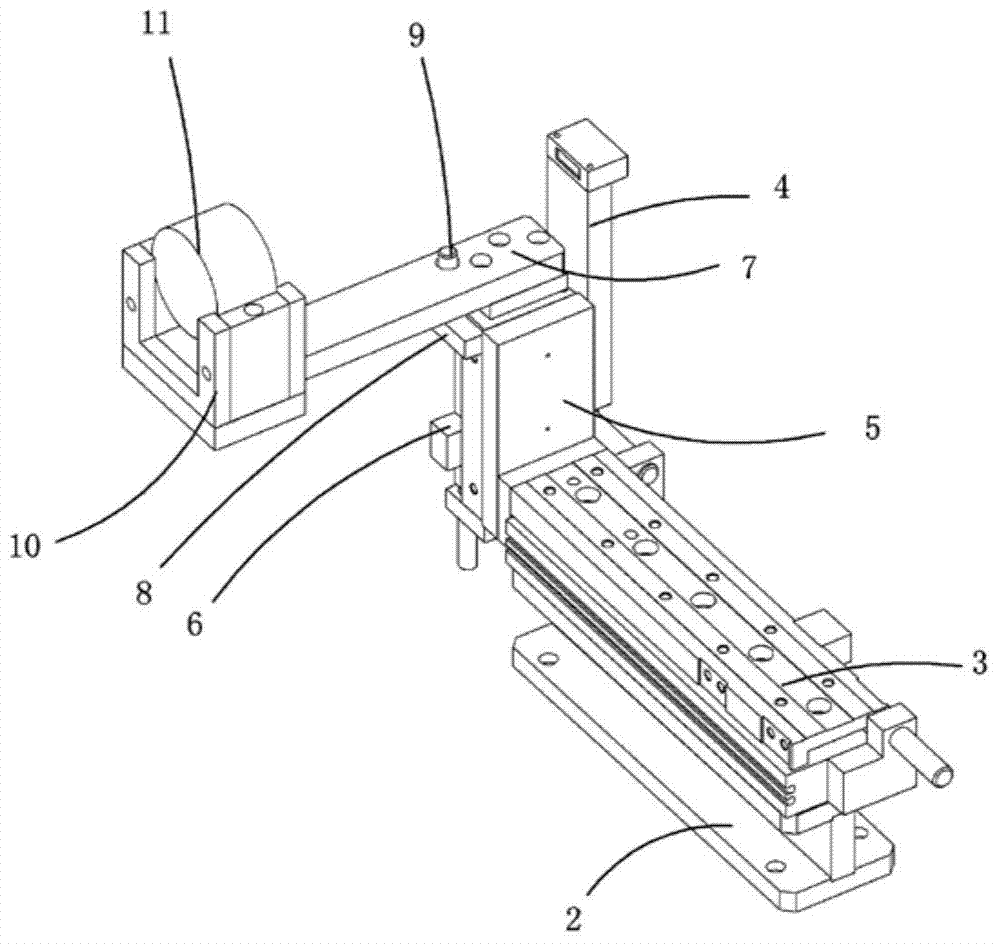

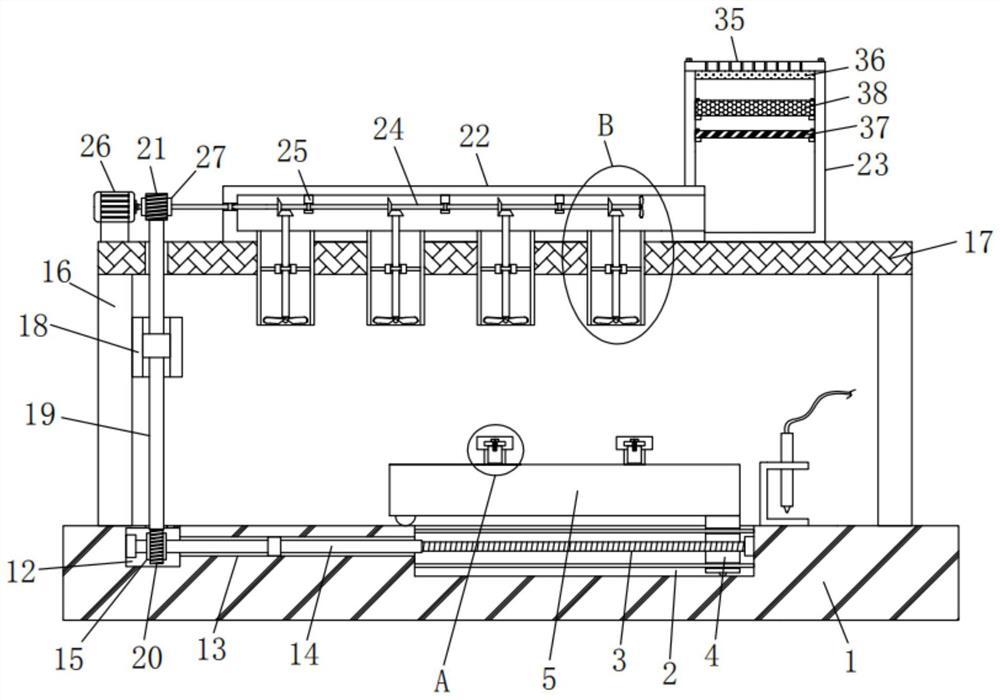

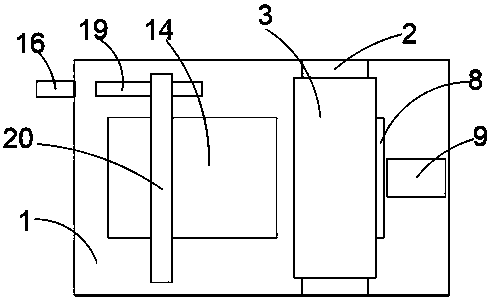

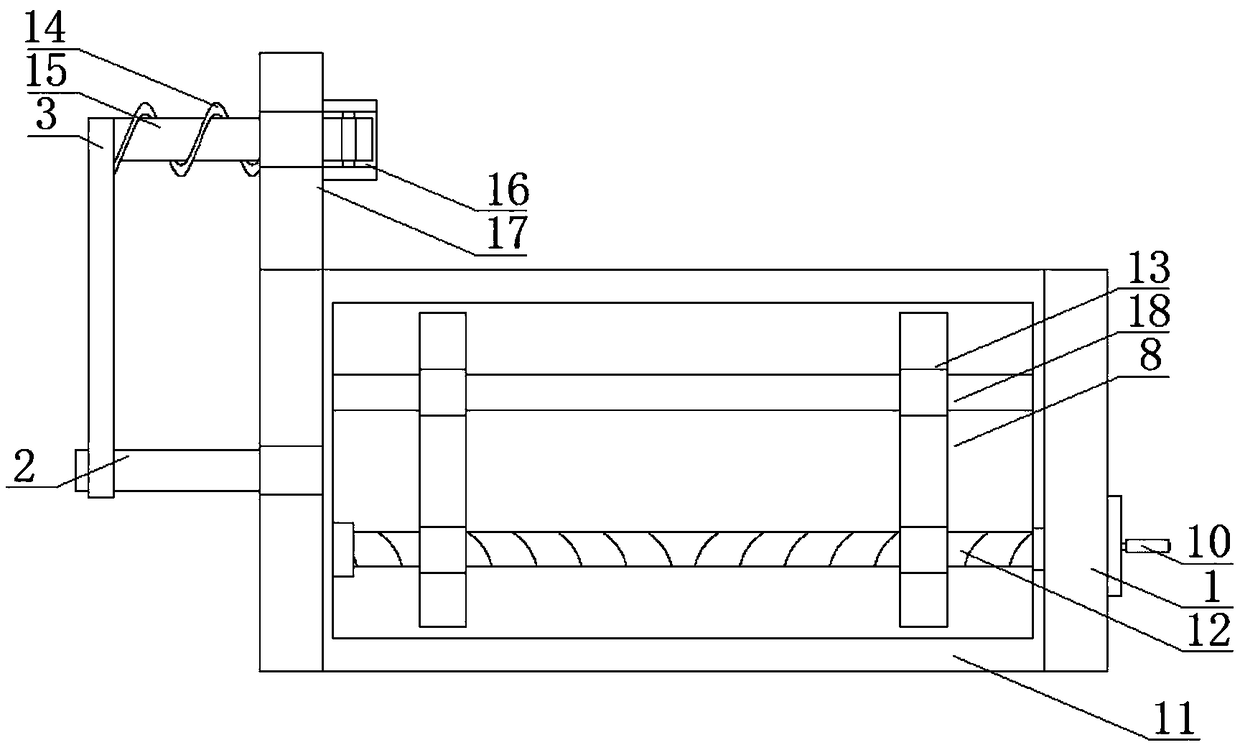

Position-adjustable metal plate punching mechanism

InactiveCN107511420ASimple structureFirm and convenient clampingElectric machineryArchitectural engineering

The invention discloses a position-adjustable metal plate punching mechanism, which includes a frame. The frame includes two main vertical plates and a main top plate. The top ends of the two main vertical plates are fixed on both sides of the bottom surface of the main top plate. side, the lower middle plate is fixed on the inner side walls of the two main vertical plates, the two main vertical screws are on both sides of the lower middle plate, the bottom ends of the main vertical screws are hinged on the lower middle plate, the main vertical screws The top of the main adjustment motor is hinged on the bottom surface of the main top plate, and the two main adjustment motors are fixed on both sides of the lower middle plate. The output shaft of the main adjustment motor is a spline shaft, and the spline shaft is inserted into the bottom of the main vertical screw. It is in the spline hole; it has simple structure, firm and convenient clamping, convenient punching, and is suitable for thin and small-volume sheet materials, and it can adjust the height position of the main moving plate, so as to ensure that it is compatible with the height of the conveying mechanism, so that The installation accuracy requirements are greatly reduced, and the installation is convenient.

Owner:FOSHAN RUIPUDA OPTOELECTRONICS TECH CO LTD

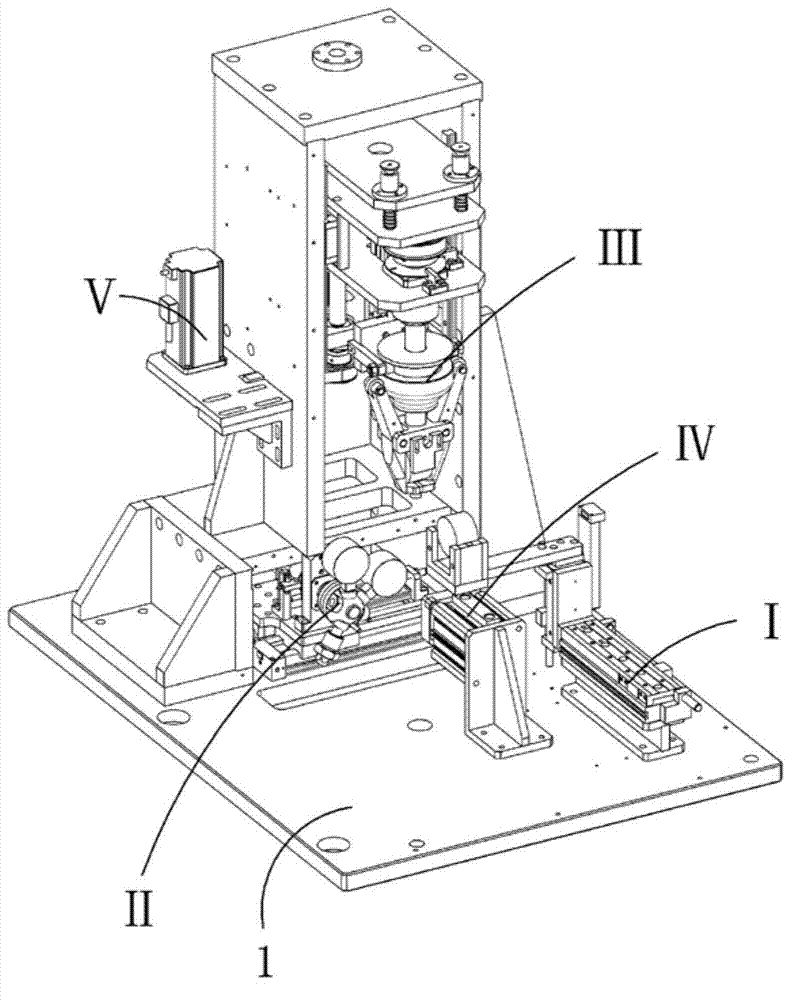

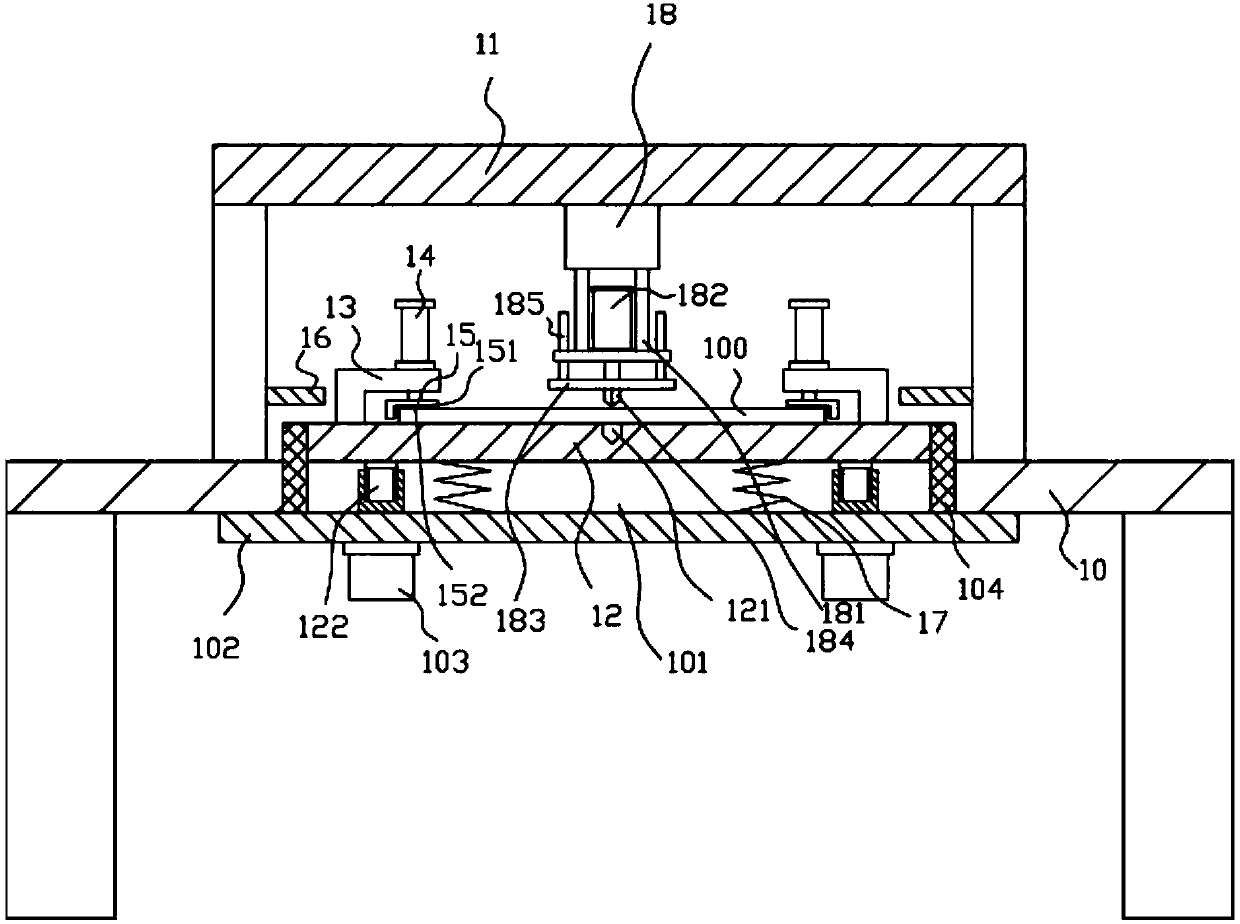

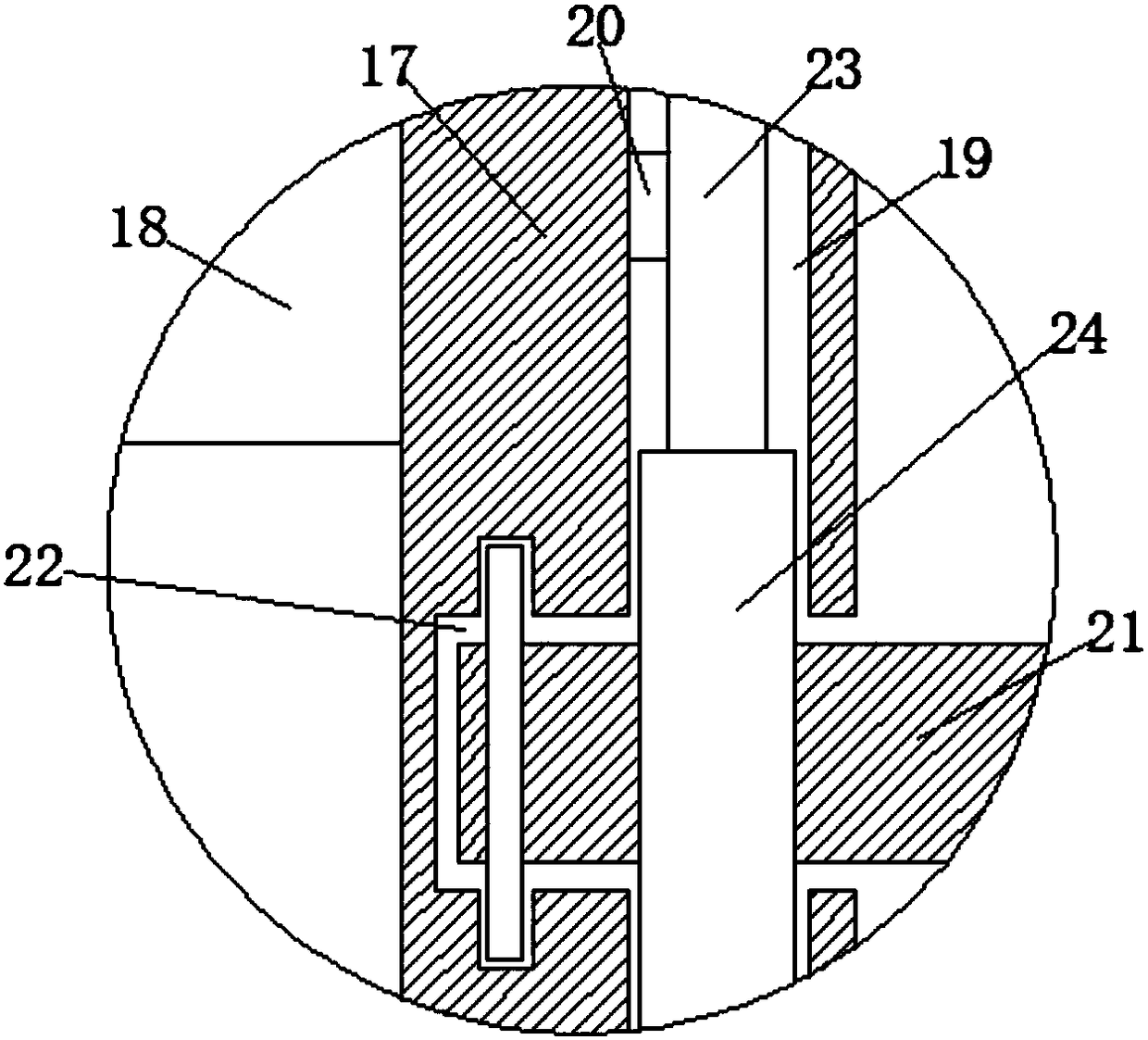

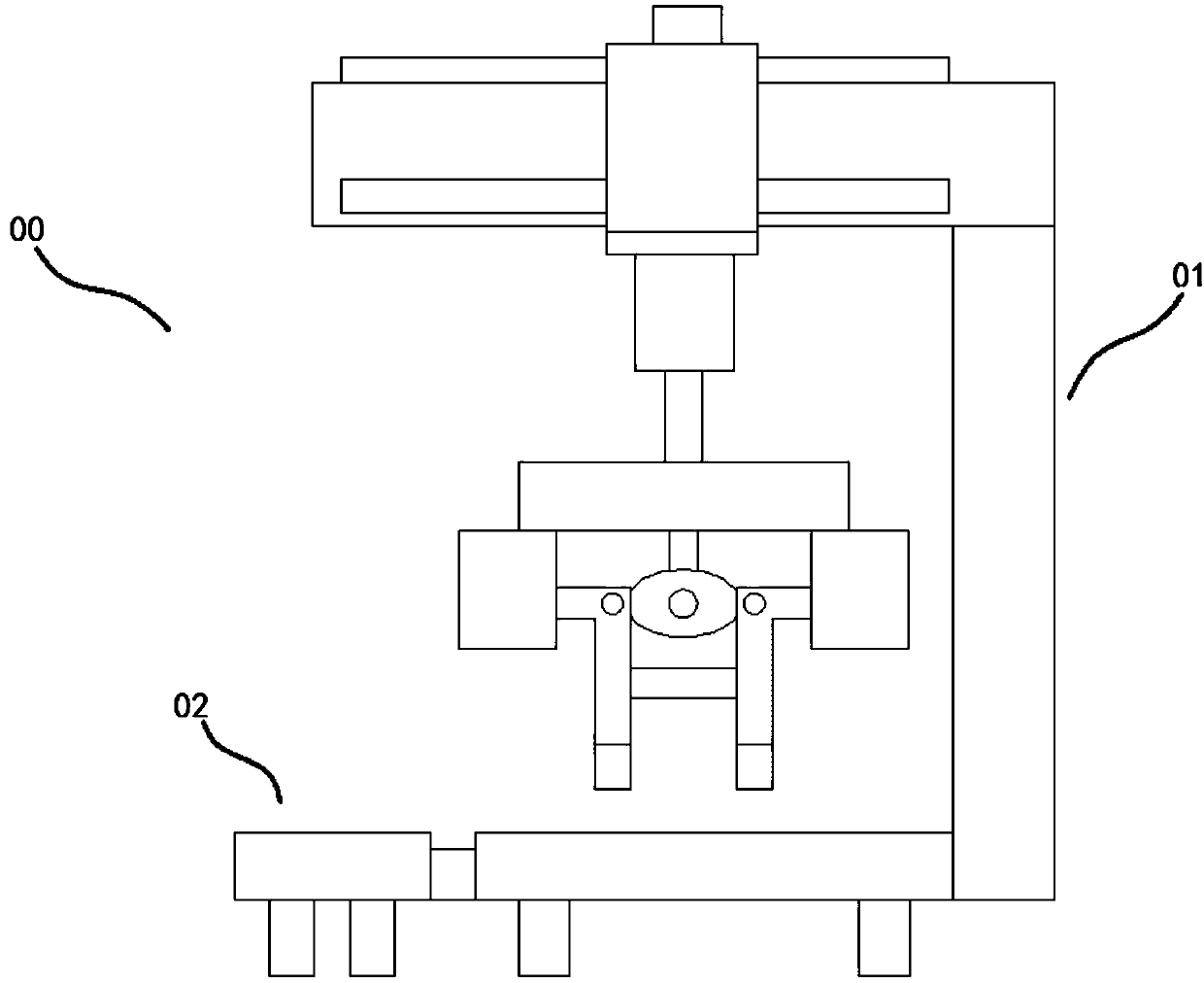

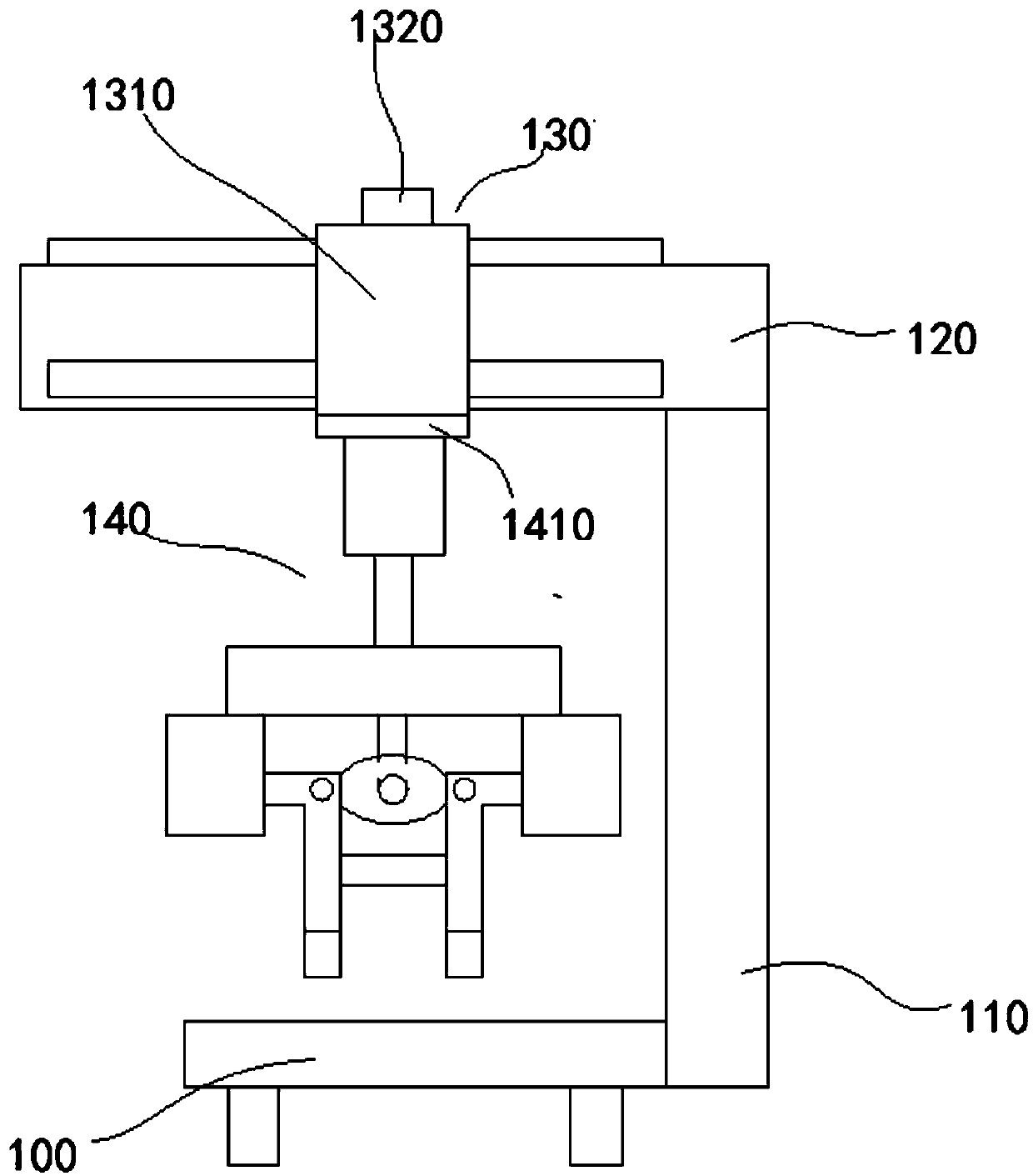

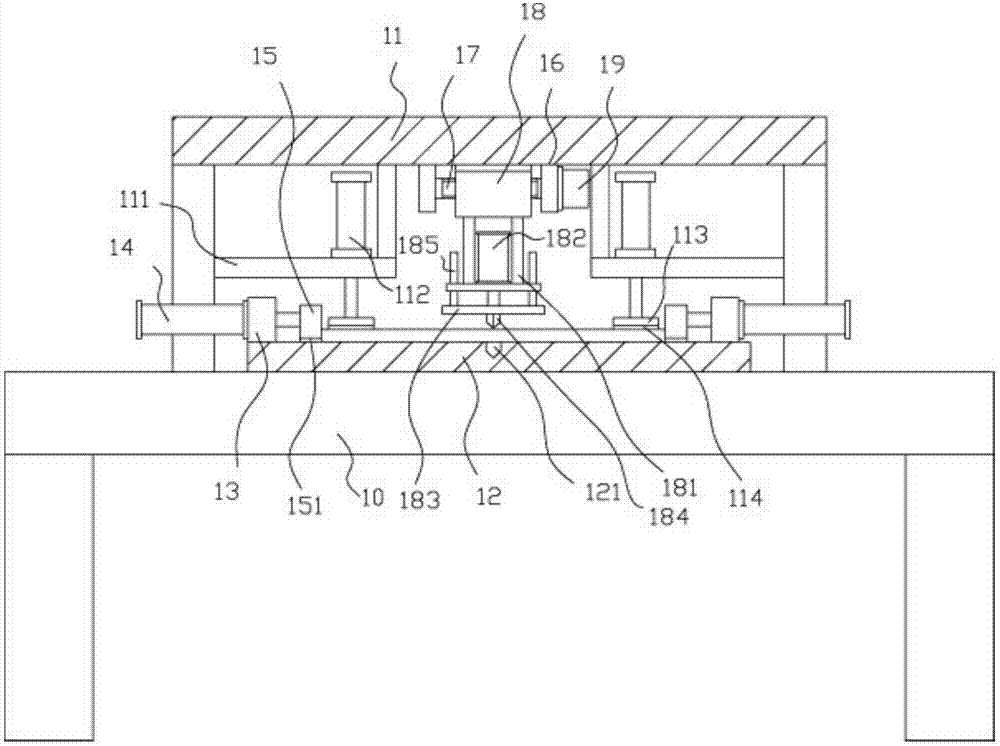

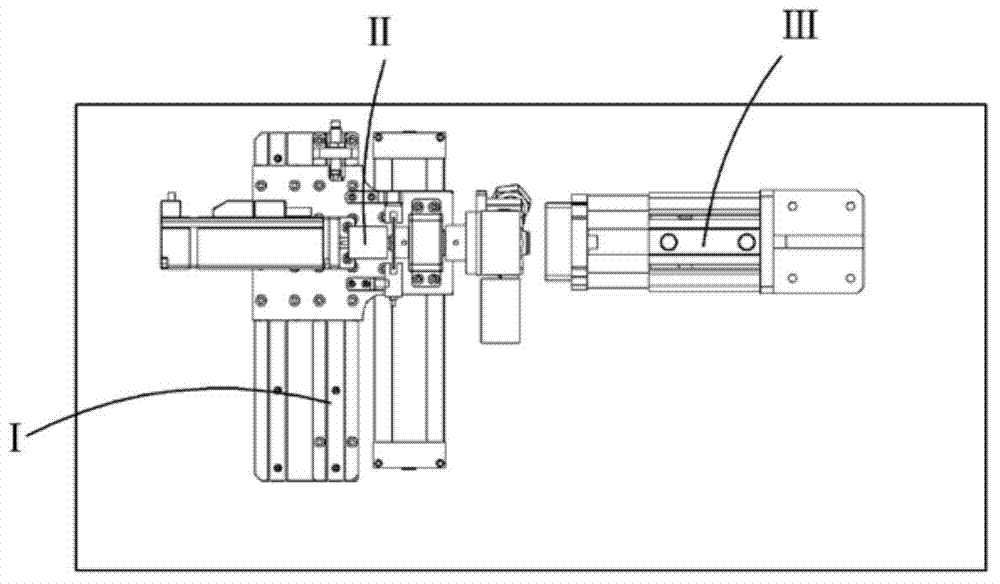

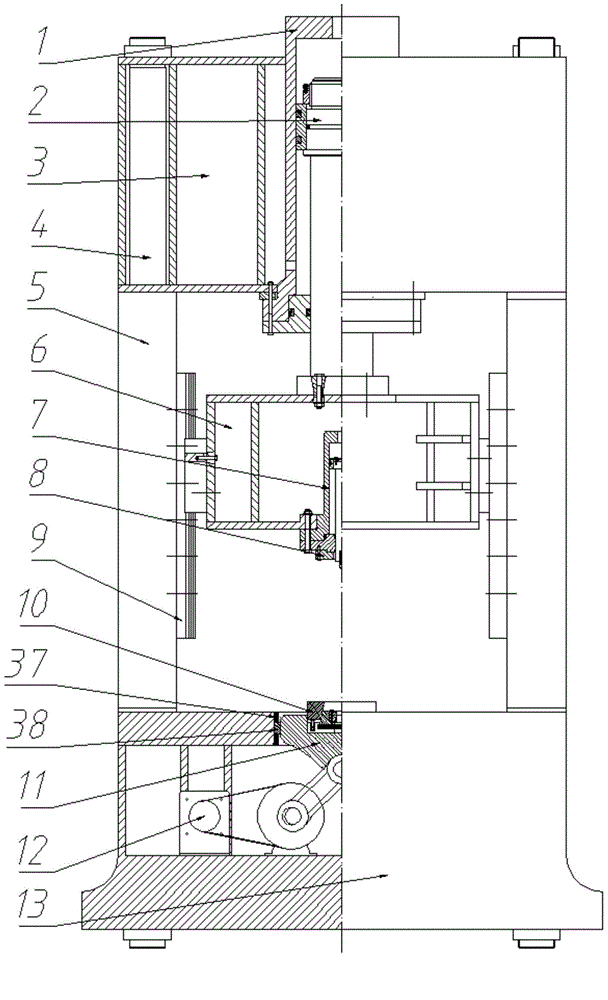

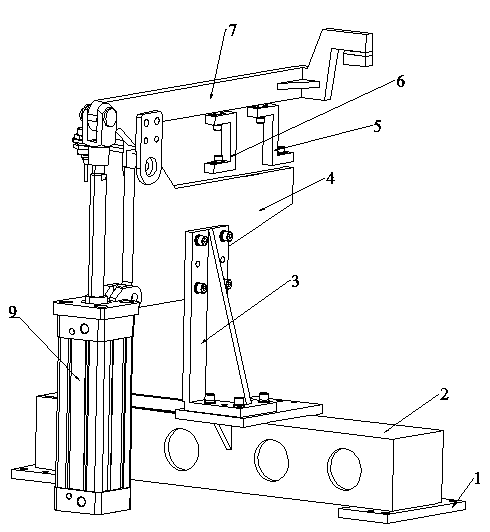

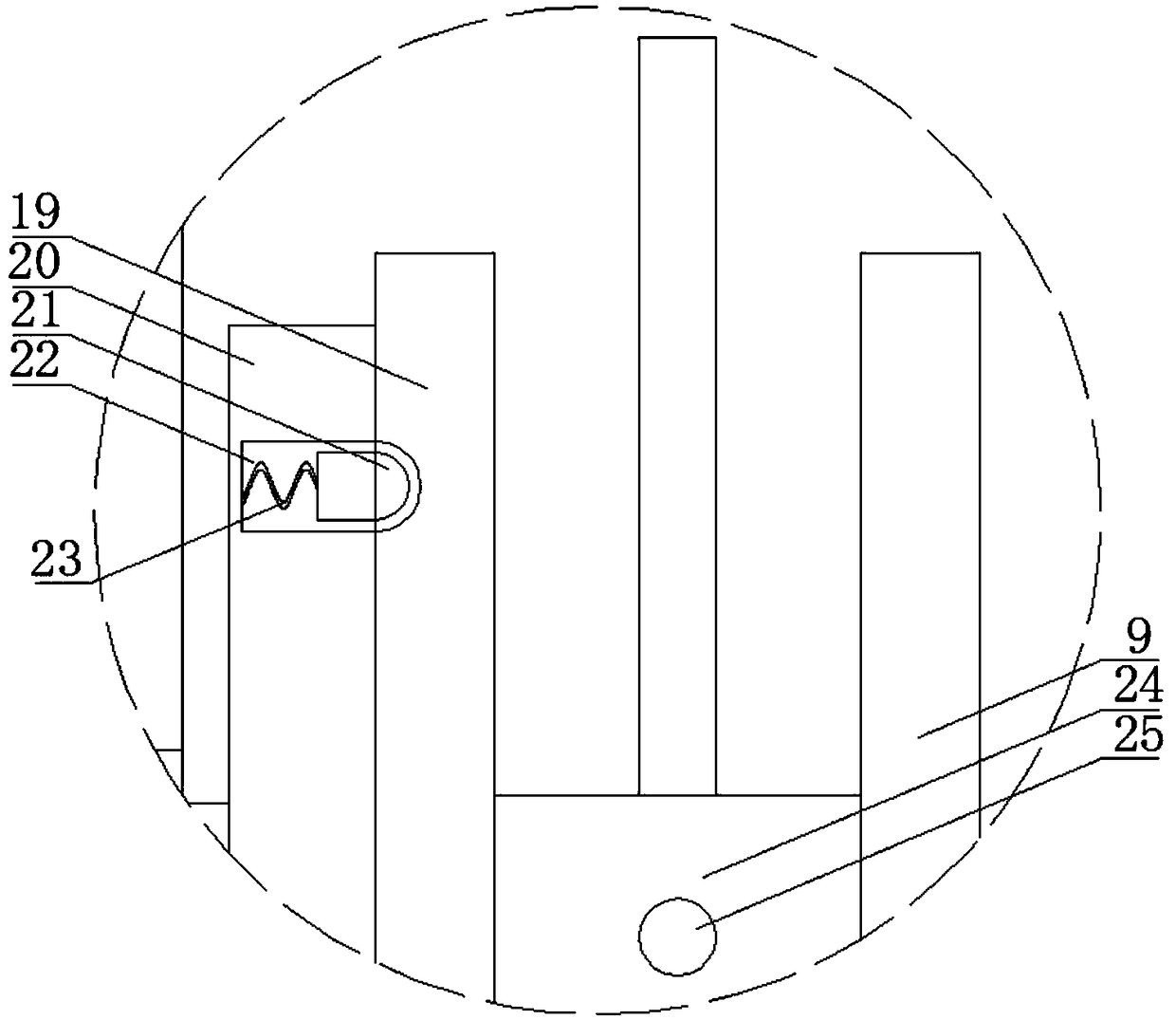

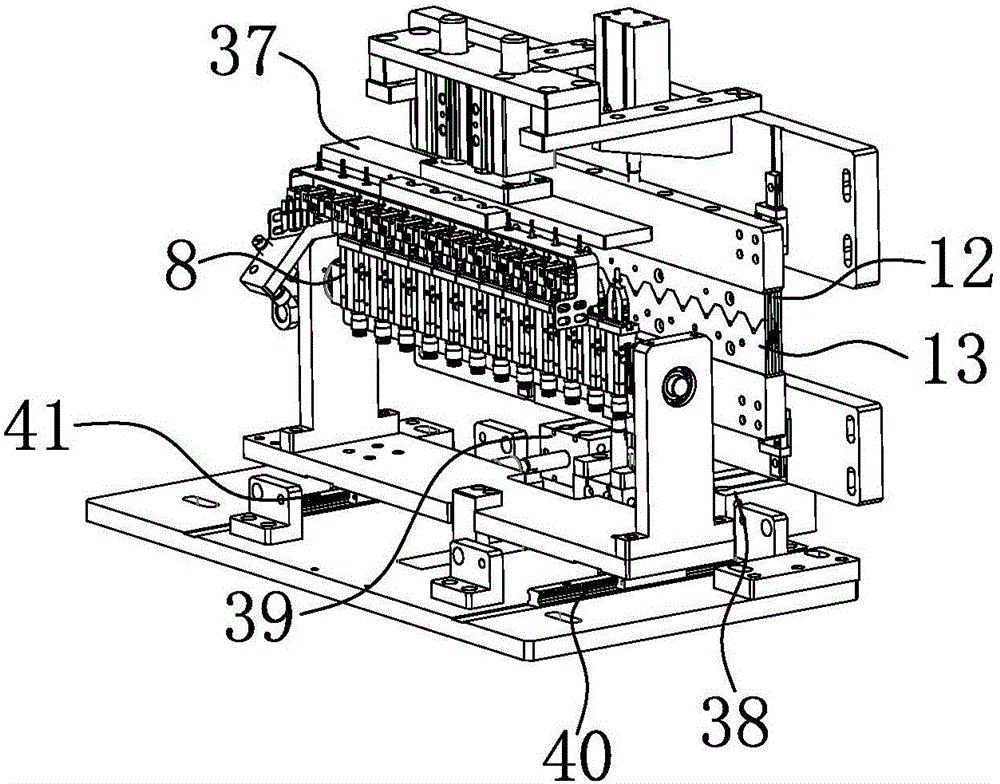

Pressure meter assembling equipment

ActiveCN103692207AGuaranteed not to deviate fromEasy and stable clampingAssembly machinesMetal working apparatusEngineeringCam

The invention relates to pressure meter assembling equipment. A pressure meter is conveyed below a mounting mechanism by a feeding mechanism; a clamping lifting cylinder of the mounting mechanism drives a lifting connection plate to move up and down on a lifting slide rail, a cam is driven to lift, the cam is descended to drive a meter clamping lever to clamp the pressure meter, the cam is ascended to drive the meter clamping lever to loosen the pressure meter, firstly, the meter clamping lever is loosened, a lifting mechanism drives the mounting mechanism to move downwards to clamp the pressure meter, the feeding mechanism returns back to the initial position, then a rotary mechanism is moved to drive a pressure meter seat to move to a place below the mounting mechanism, a compressing mechanism clamps the pressure meter seat, the mounting mechanism is driven by the lifting mechanism to move downwards, and when the pressure meter reaches a place above the pressure meter seat, the mounting mechanism is driven to drive a rotary spindle to rotate, so the pressure meter is rotated and descended to be screwed into the meter seat, and when the torsion achieves a certain value range, the pressure meter stops rotating. The assembly of the pressure meter is full-automatically performed, the labor intensity of operation staff is reduced, and the production cost is reduced.

Owner:BOZHON PRECISION IND TECH CO LTD

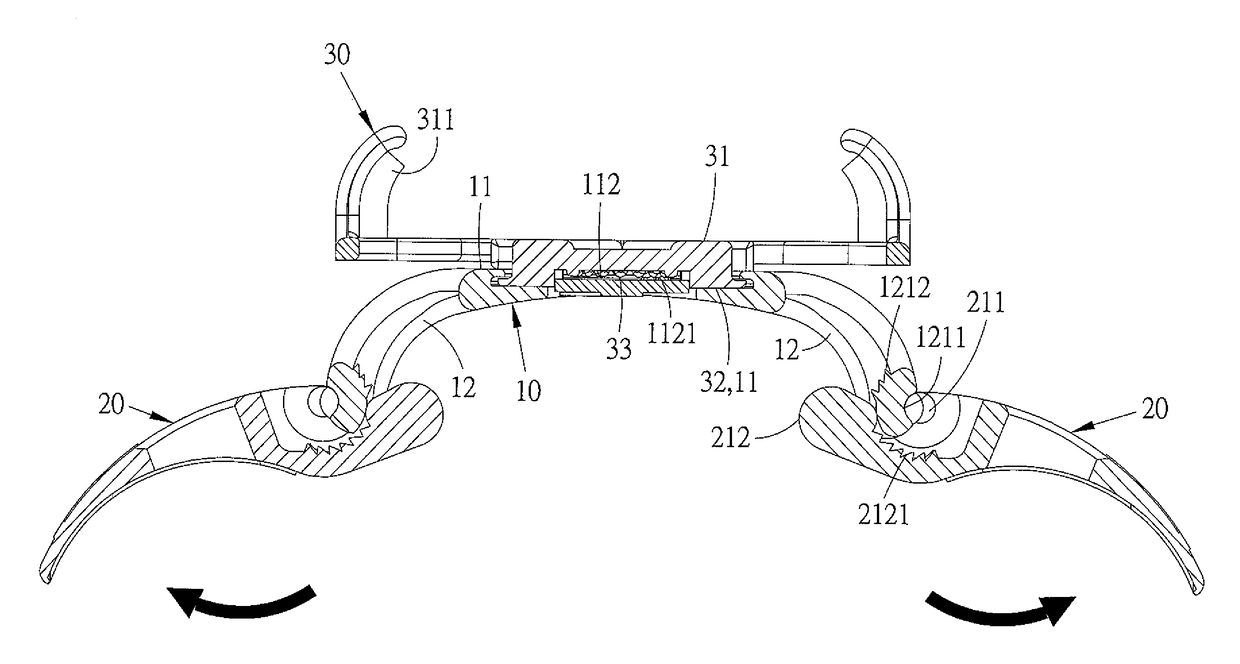

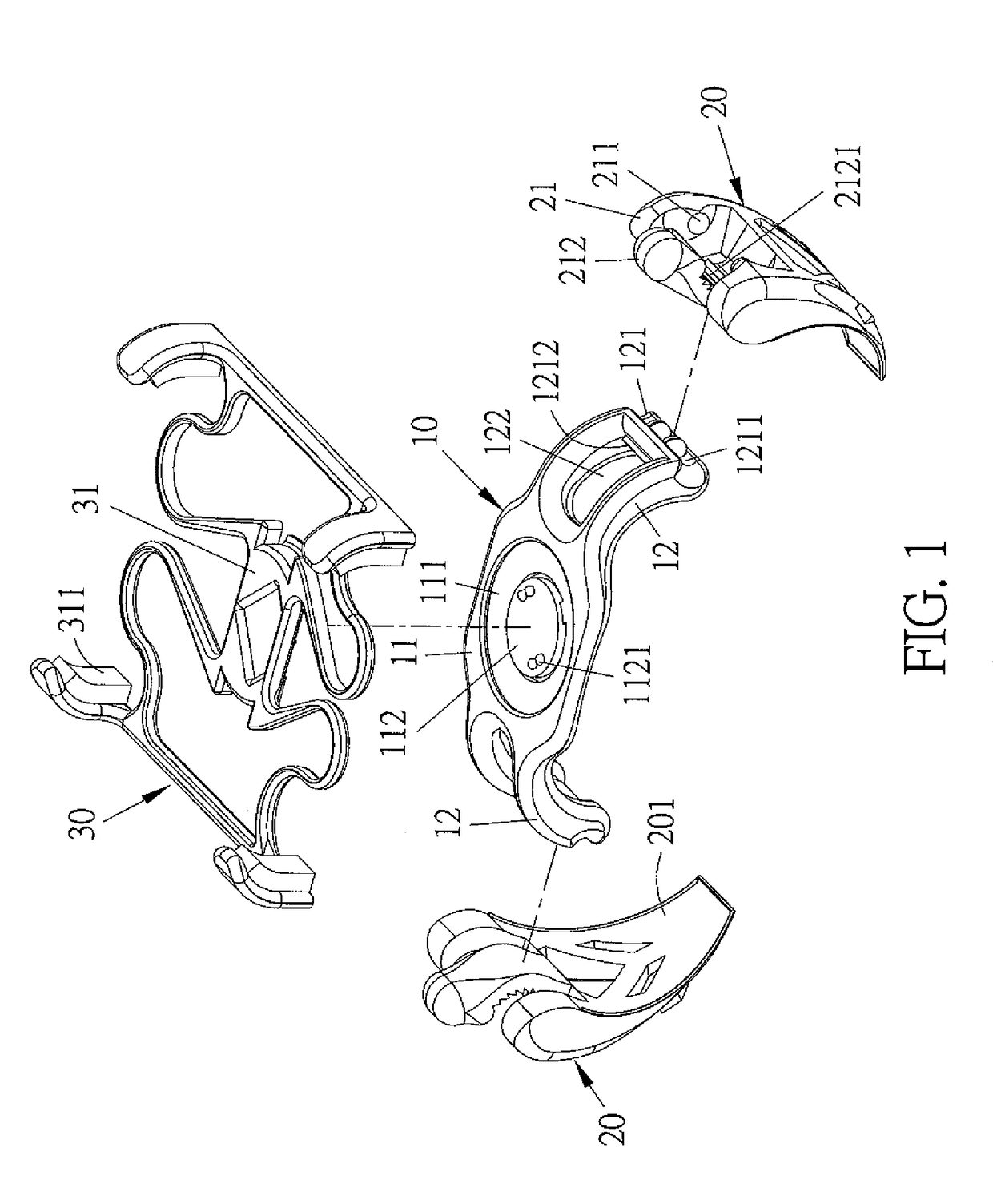

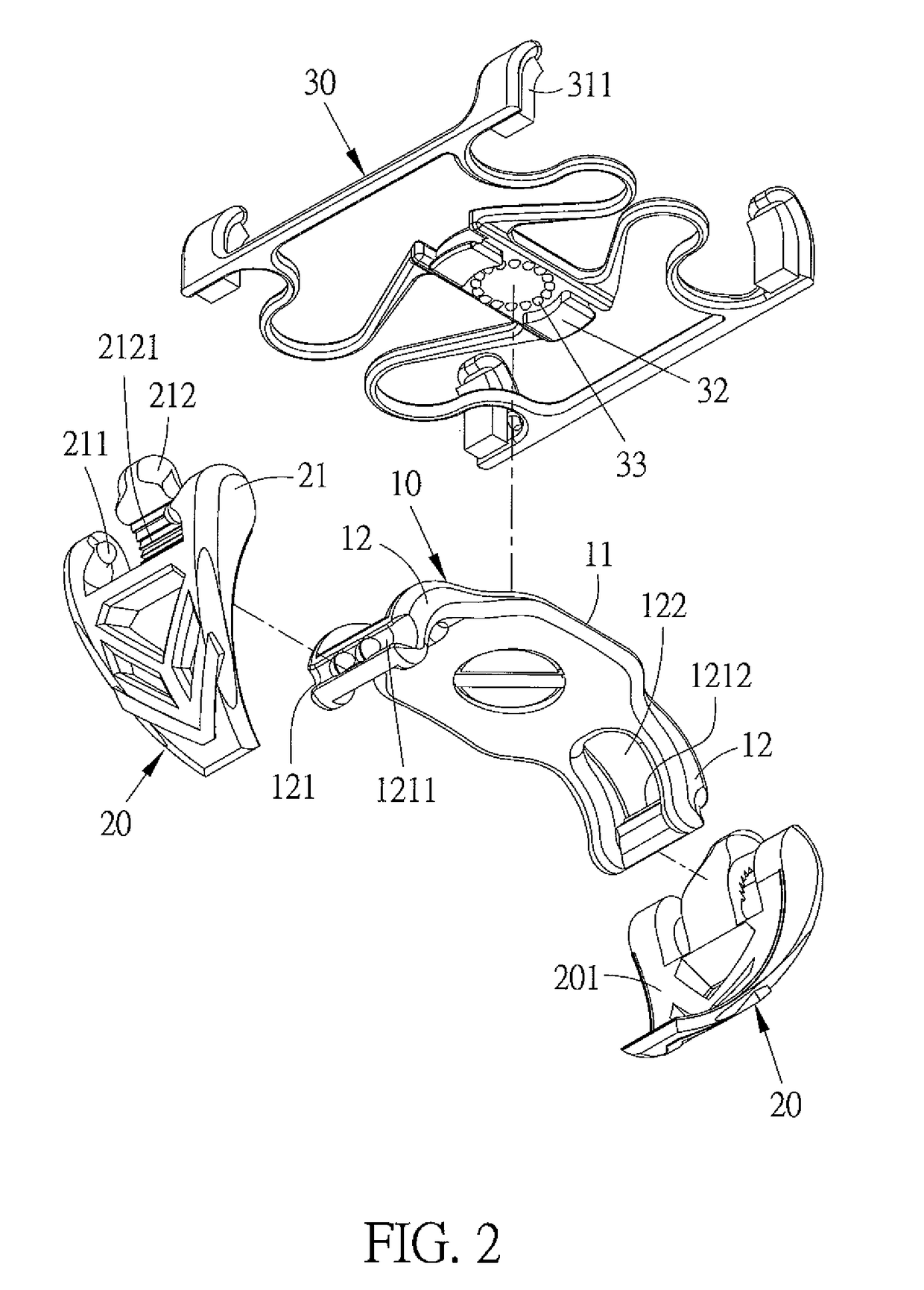

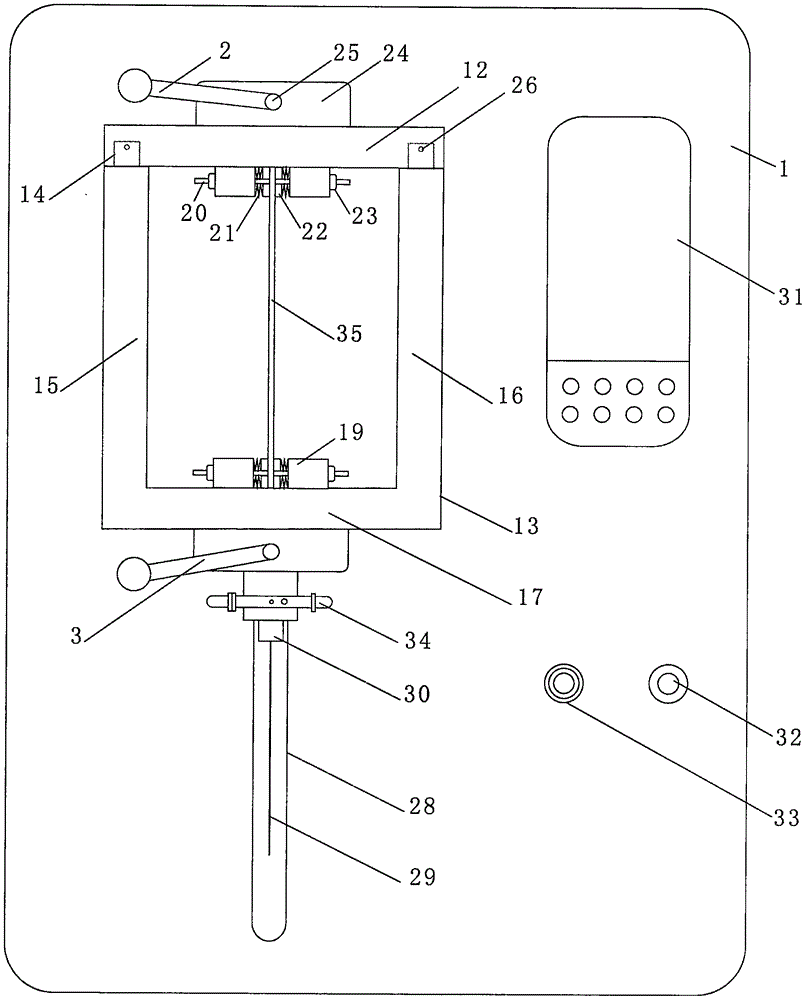

Carrying device for belongings

InactiveUS9661912B1Easily and stablyEasy and stable clampingTravelling carriersHoldersCouplingEngineering

A carrying device for belongings contains: a body and at least one clamper. The body includes a connection portion, the connection portion has at least one curved arm arranged on at least one side thereof respectively, each curved arm has a first rotatable coupling part, and the first rotatable coupling part has at least one first ratchet tooth. Each clamper includes a second rotatable coupling part arranged on one end thereof and rotatably coupled with the first rotatable coupling part, wherein among the at least one clamper and the body forms an adjustable clamping space, the second rotatable coupling part has a flexible column, and the flexible column has a plurality of second ratchet teeth which engage with the at least one first ratchet tooth of the first rotatable coupling part of said each curved arm.

Owner:CHUNG WEN LIANG +1

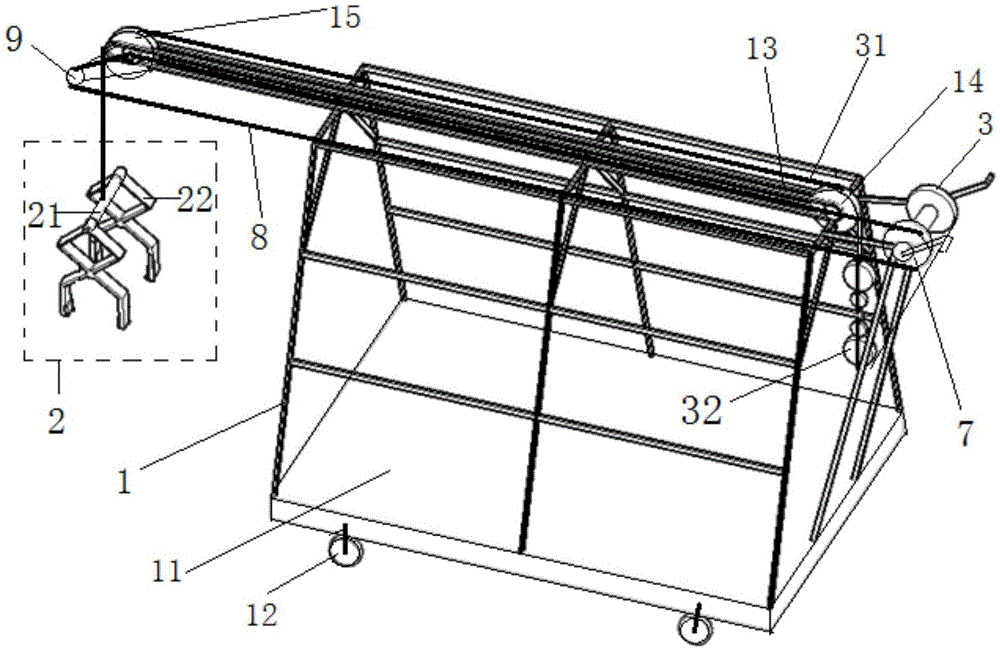

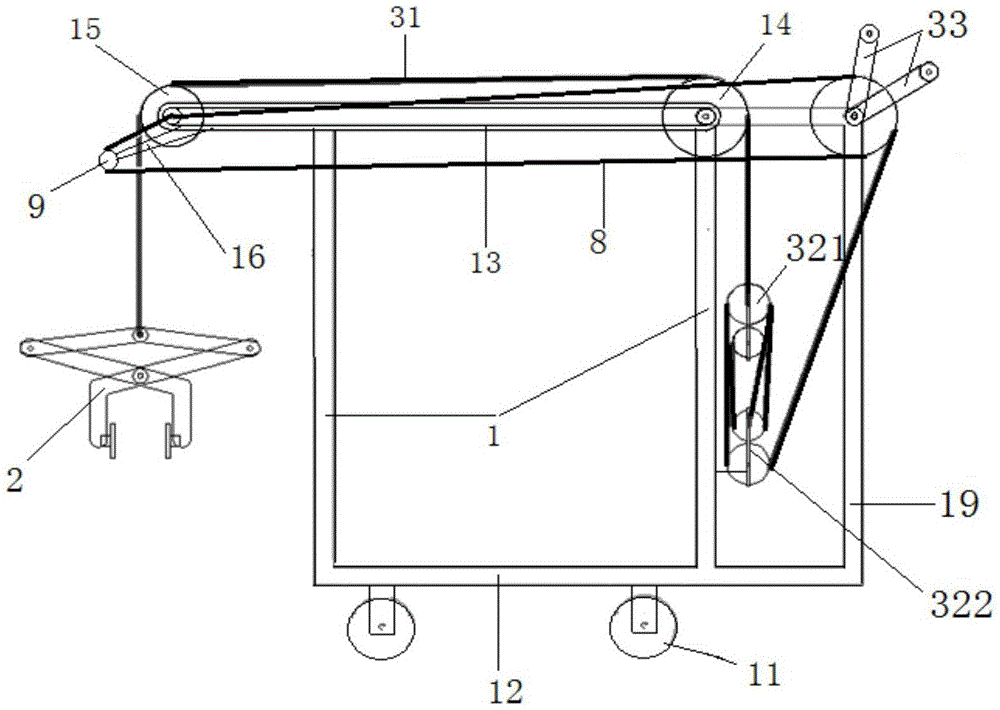

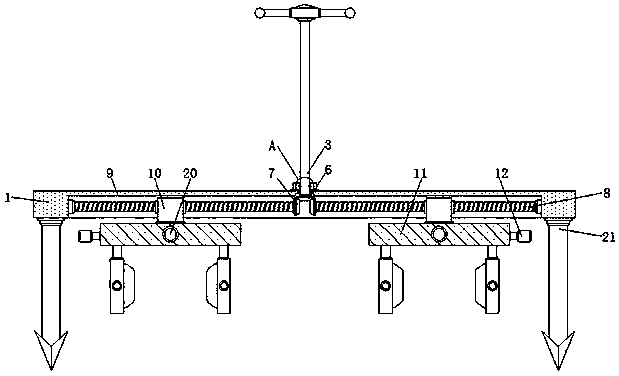

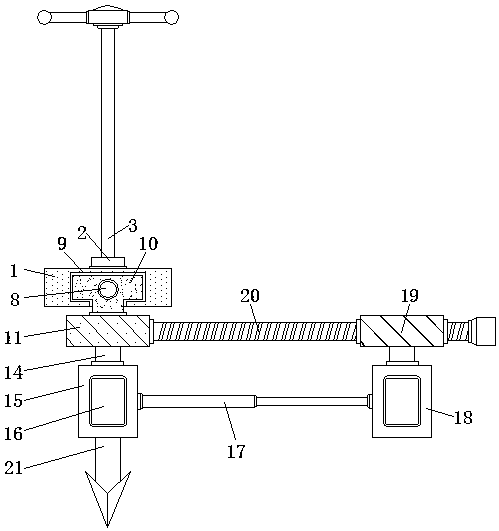

Curbstone construction assisting crane and using method thereof

ActiveCN105544360AEasy and stable clampingRealize lifting movementRoads maintainenceVehicle frameDrive wheel

The invention discloses a curbstone construction assisting crane and a using method thereof. The curbstone construction assisting crane comprises a car frame, wherein a railway is mounted on the car frame, a movable pulley is mounted on the railways, a fixed pulley is mounted at one end of the railway, and is connected with the movable pulley through ropes; a clamp is connected to one ends of the ropes, the other ends of the ropes are connected with a lifting driving wheel through pulley blocks, the lifting driving wheel is mounted on the car frame, a chain wheel is mounted at the tail end of the railway, the chain wheel is connected with a traversing driving chain wheel through a chain, the traversing driving chain wheel is mounted on the car frame, and the movable pulley is fixedly connected to the chain. According to design of the railway, the lifting driving wheel, the fixed pulley, the movable pulley and the clamp, the lifting driving wheel is controlled to rotate and reverse, so that the lifting of the clamp can be realized; according to design of the chain wheel, the traversing driving chain wheel and the chain, the traversing driving chain wheel is controlled to rotate and reverse, so that the horizontal movement of the clamp can be realized; according to design of the special curbstone clamp, curbstones can be more convenient and firm to clamp.

Owner:SHANDONG UNIV

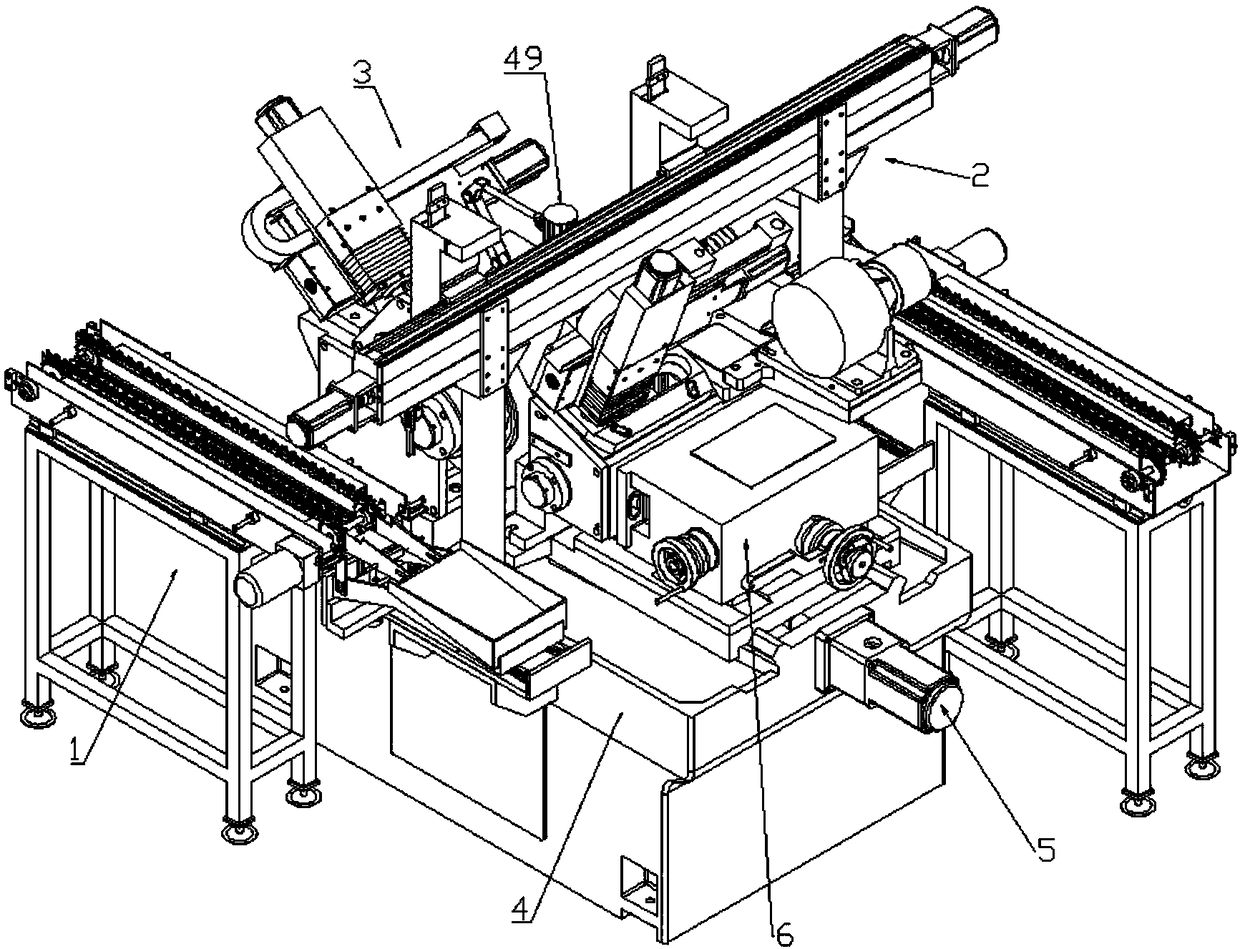

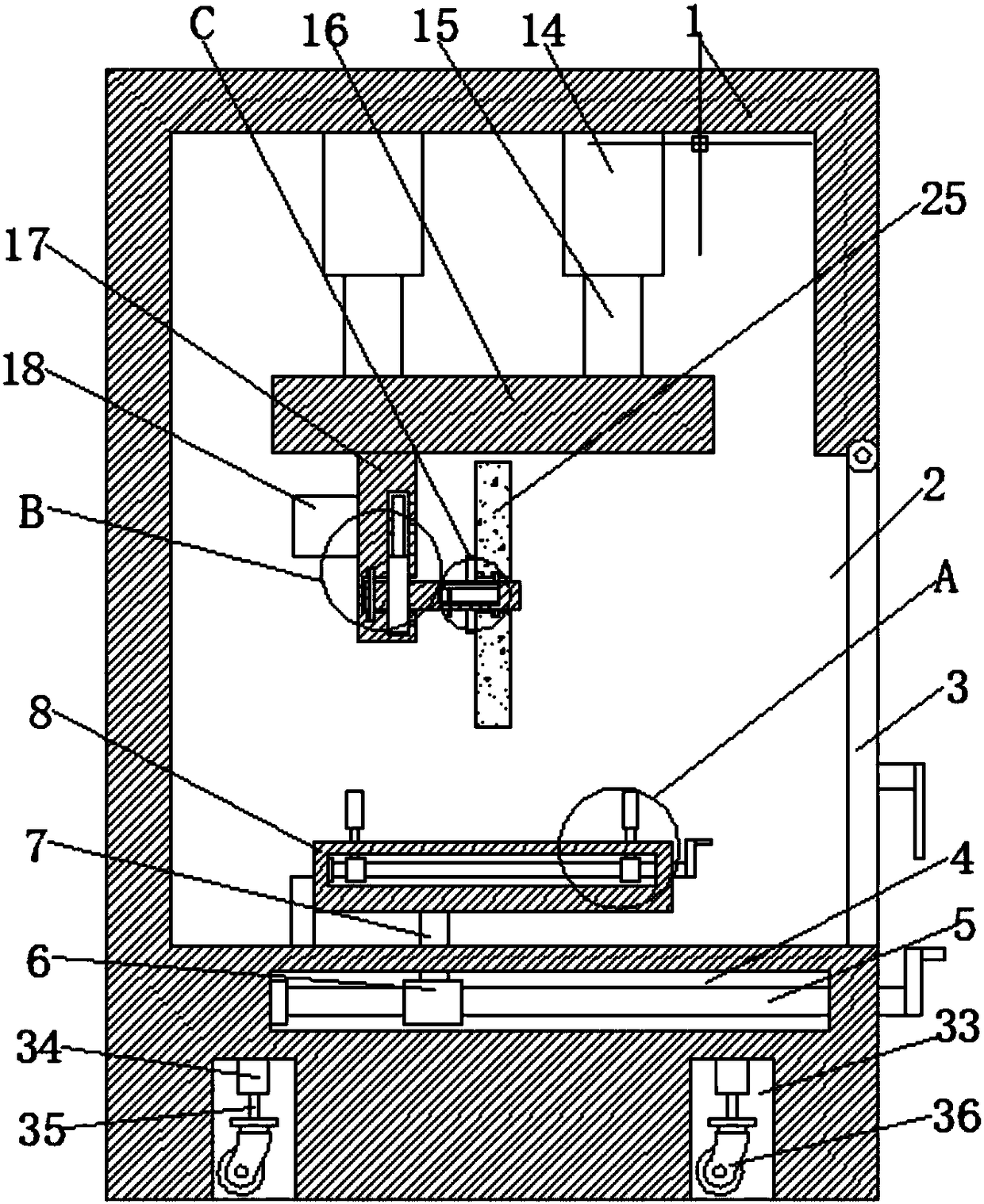

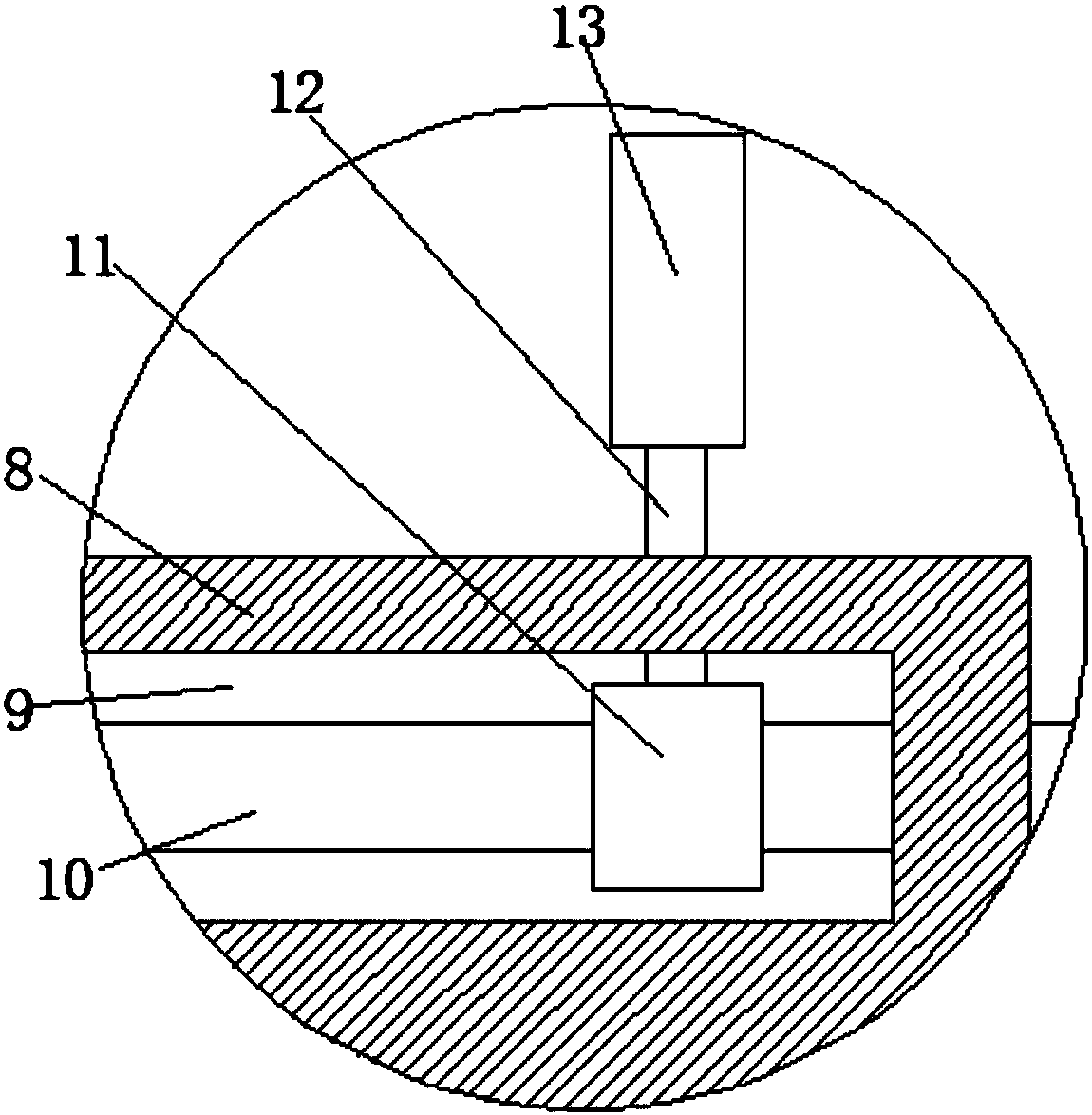

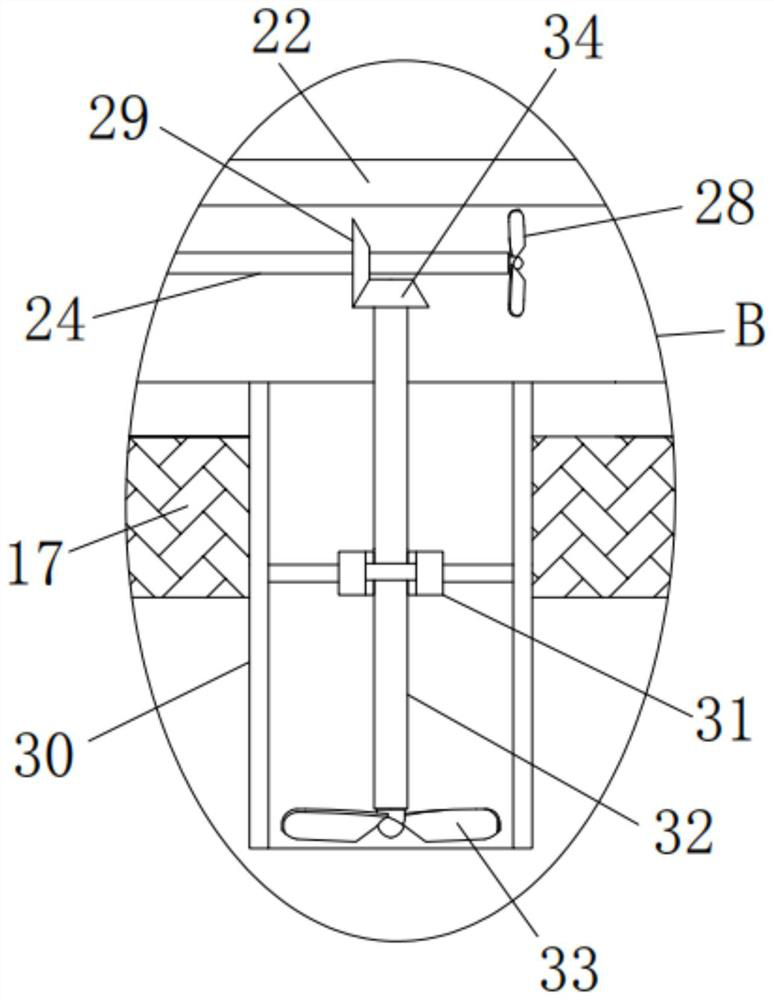

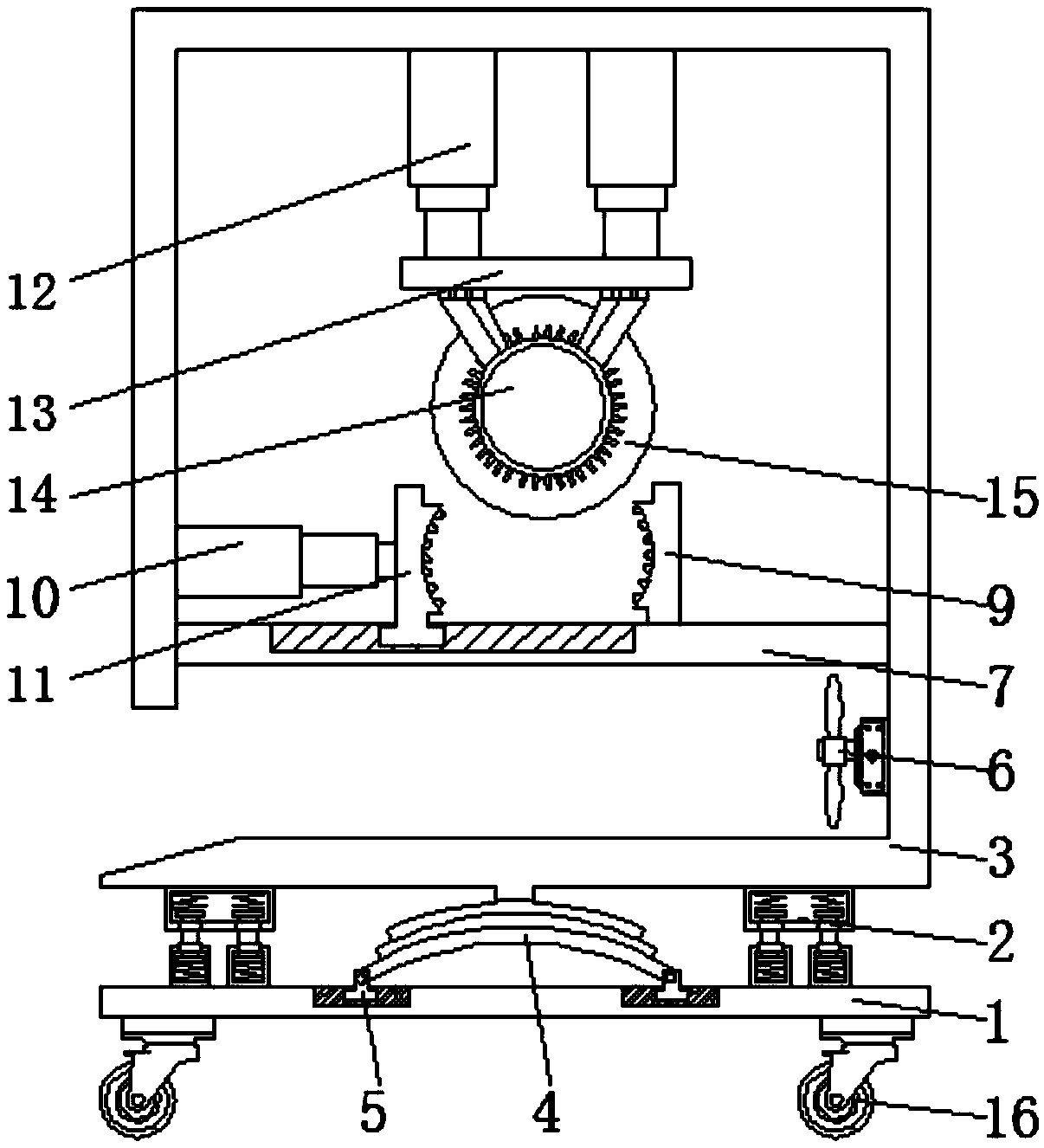

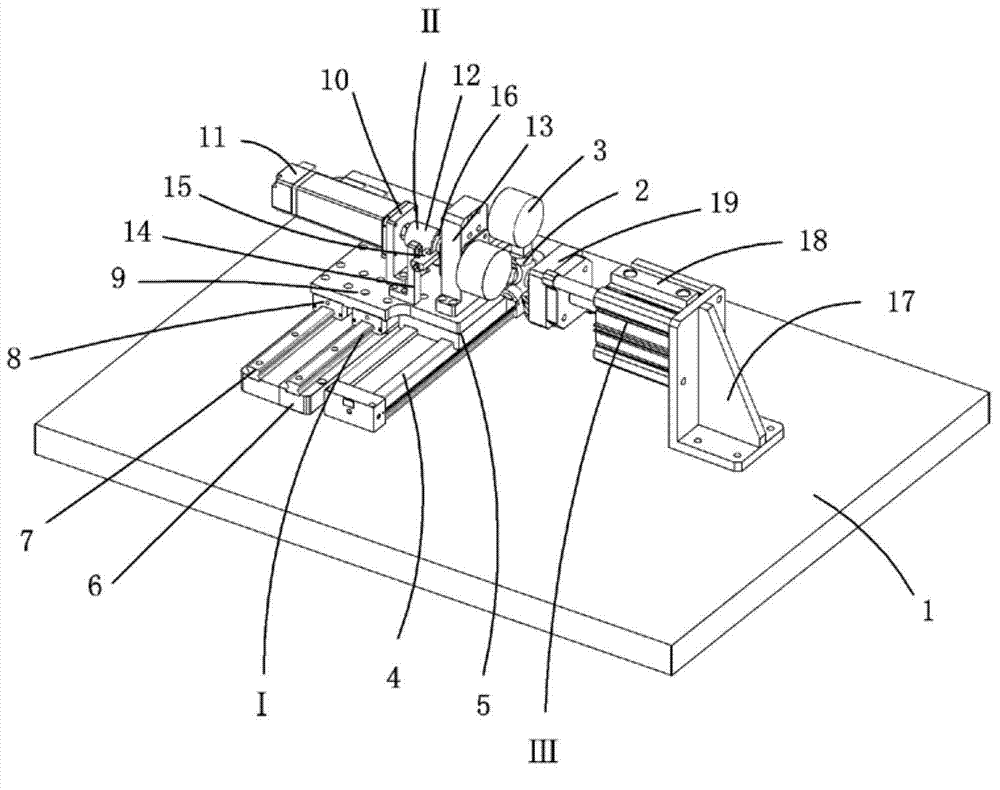

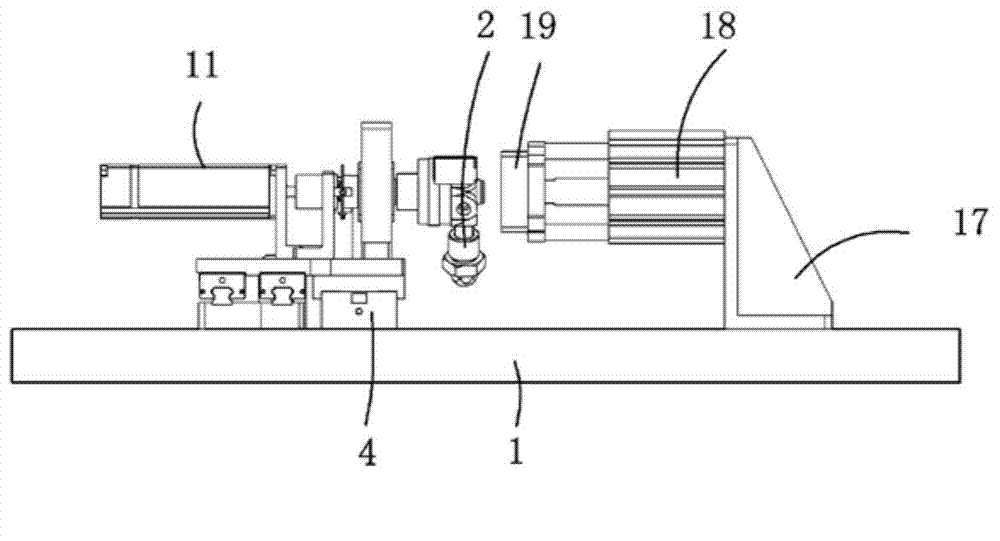

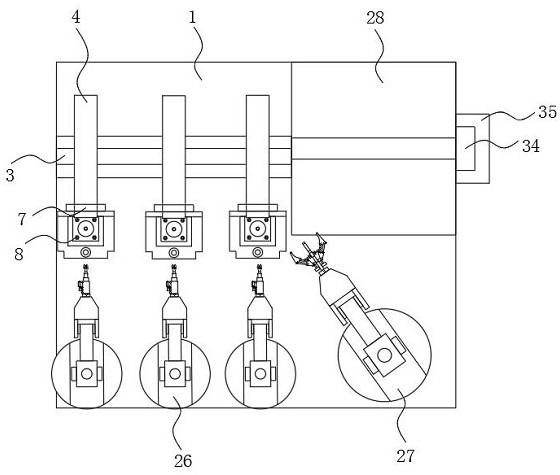

Automatic numerical control grinder

ActiveCN109202560AIncrease flexibilityReduce manual operationsRevolution surface grinding machinesGrinding drivesEngineeringMultiple function

The invention discloses an automatic numerical control grinder and relates to the field of grinder equipment. The automatic numerical control grinder comprises a feeding device, a taking device, a numerical control trimmer, a grinder body, a feed compensating mechanism and a slide box mechanism. When being used for machining a workpiece, the automatic numerical control grinder provided by the invention has the multiple functions of automatic feeding, taking, discharging, grinding wheel surface trimming, grinding wheel feed compensating and the like, automatic machining can be achieved for thewhole process by adopting a PLC, the efficiency is obviously improved, and the machining precision is also high.

Owner:林宗升

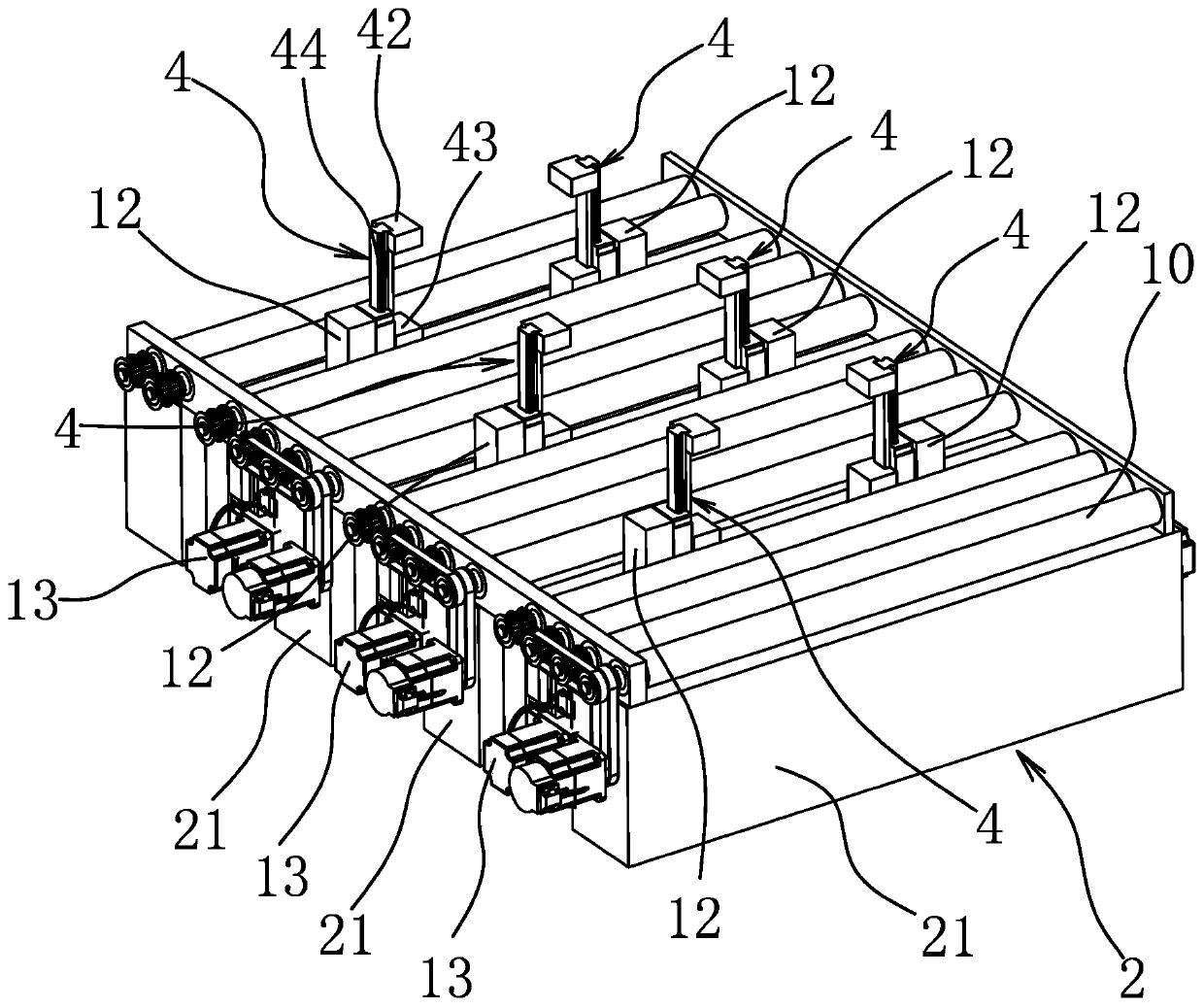

Engraving and milling machine

PendingCN110480377ARealize multi-point clampingImprove stabilityWork clamping meansOther manufacturing equipments/toolsEngineeringMachining

The invention provides an engraving and milling machine, belongs to the technical field of engraving equipment, and solves the problem that it is hard for engraving and milling machines to perform high-precision machining on specially-shaped workpieces in the prior art. The engraving and milling machine comprises a rack and a working platform which is arranged on the rack and used for placing a workpiece; an engraving component which can perform three-dimensional translation relative to the working platform is further arranged on the rack; three or more clamping pieces are arranged on the working platform; any clamping piece is located on one side of the workpiece and can move independently relative to the working platform; and any clamping piece can move in the direction far away from theworkpiece, so that the engraving component can machine contact part, acted by the clamping piece, of the workpiece. The engraving and milling machine has the advantage of high machining precision forthe specially-shaped workpiece.

Owner:吴善旺

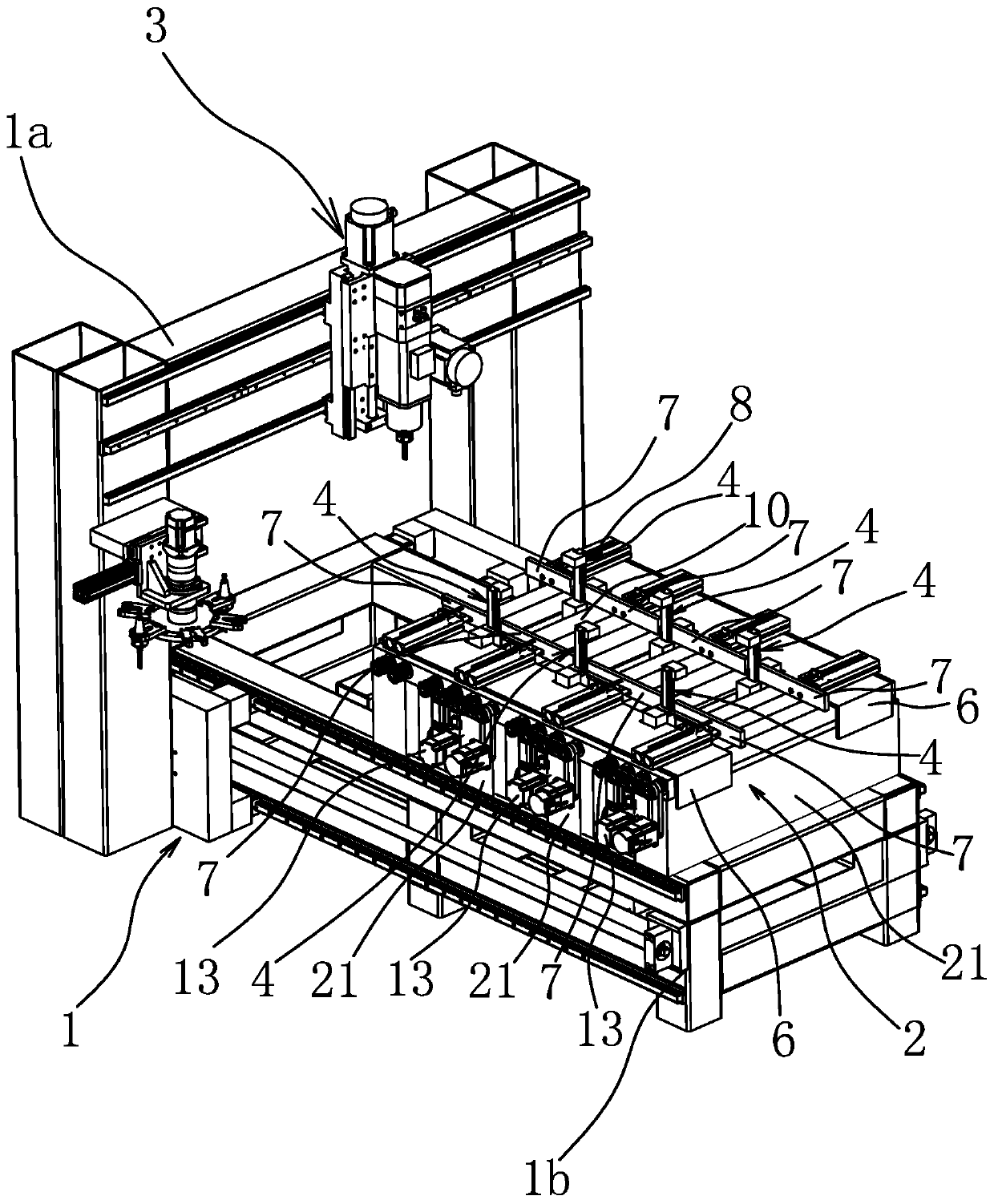

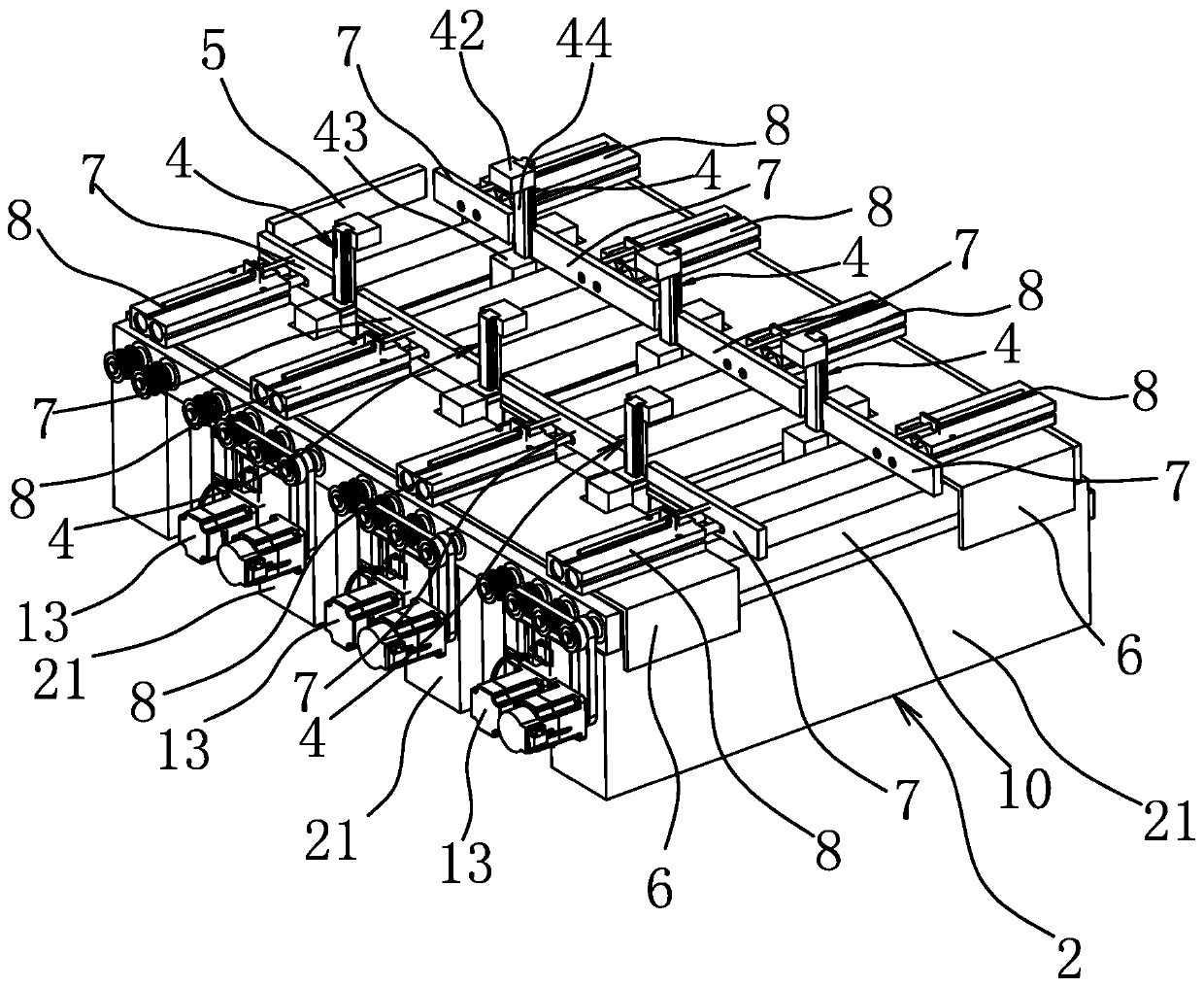

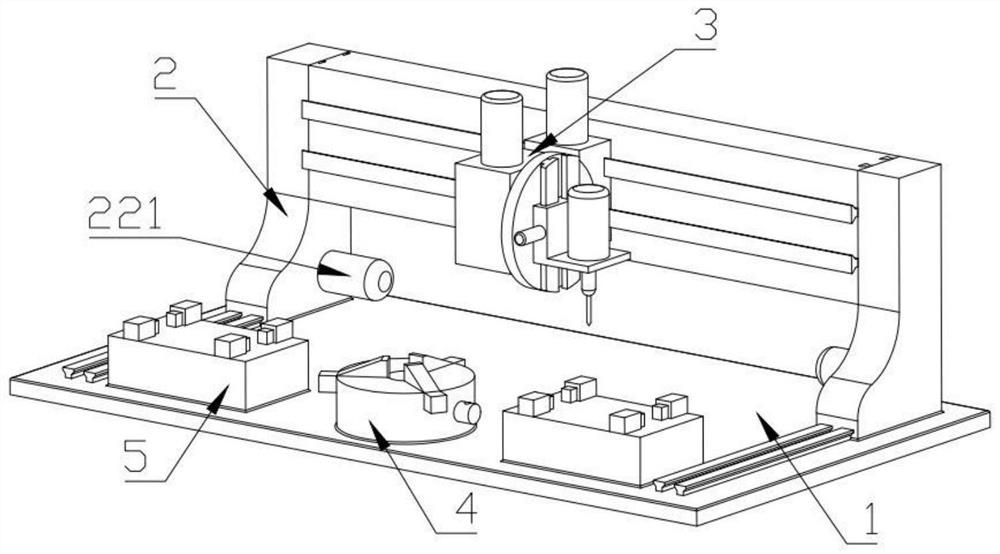

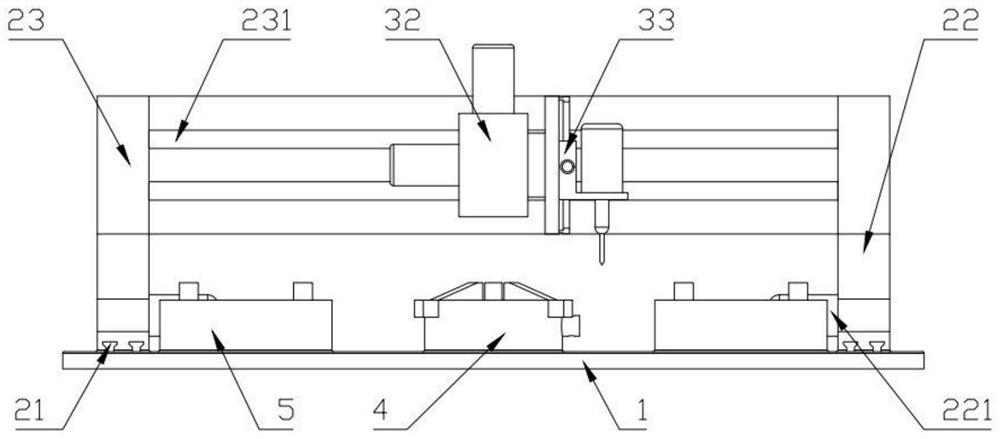

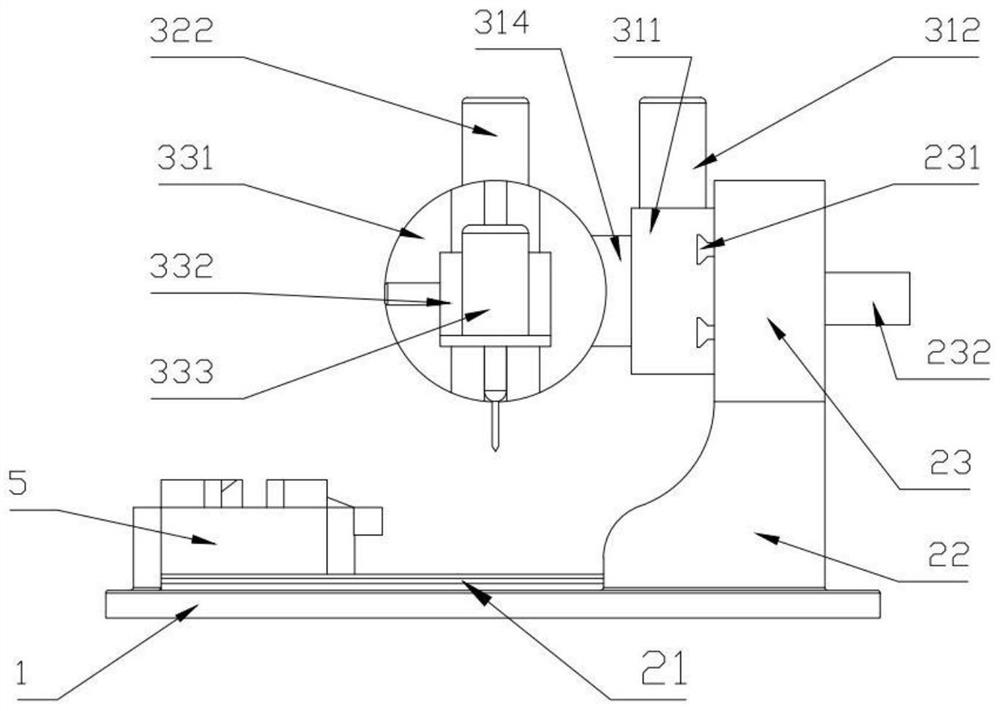

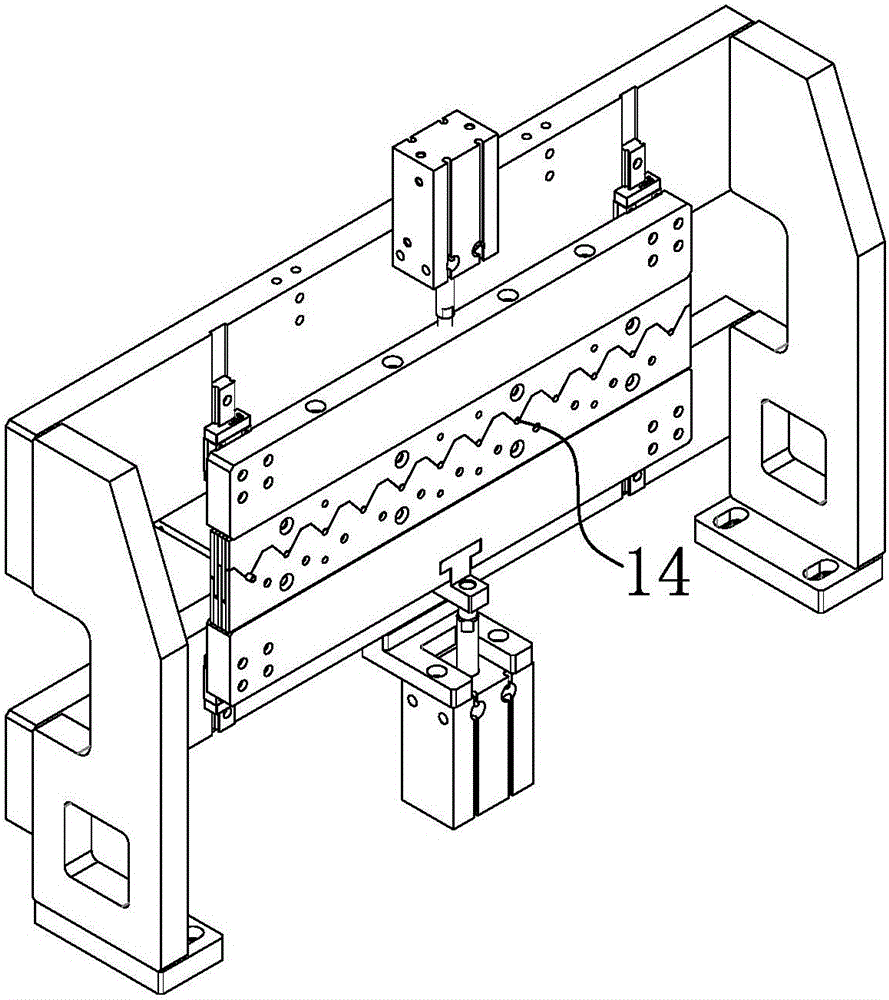

Multi-axis linkage type numerical control drilling and milling machine tool

ActiveCN114226809AEasy and firm clampingReduce the number of clampingFeeding apparatusLarge fixed membersPhysicsEngineering

A multi-axis linkage type numerical control drilling and milling machine tool comprises a base, a portal frame is arranged on the base in the width direction of the base in a sliding mode, the upper end of the portal frame comprises a transverse column arranged in a sliding mode, the sliding direction of the transverse column is vertical, and a drilling and milling system is horizontally arranged at the front end of the transverse column in a sliding mode and used for completing drilling and milling work of workpieces. The drilling and milling system can move front and back, left and right and up and down relative to the base, the clamping frequency of a workpiece to be machined is reduced, the production efficiency is improved, the drilling and milling system is connected with the transverse column through a transverse moving unit, the front end of the transverse moving unit is rotationally connected with a rotating unit, and one side of the rotating unit is rotationally connected with a drilling and milling unit. The drilling and milling unit can rotate around the axis parallel to the length direction of the base and can be driven by the rotating unit to rotate around the axis perpendicular to the length direction of the base, machining work of the upper end, the left, right, front and rear end faces of a workpiece can be achieved only through one-time clamping of the workpiece, machining work of a fixed angle can be completed, and the practicability of the device is improved; and the machining efficiency of the workpiece is improved.

Owner:JINAN ZHANGLI MACHINERY

Simple metal plate punching mechanism

The invention discloses a simple metal plate punching mechanism which comprises a rack. A main supporting frame is fixed on the top surface of a top plate of the rack, a placement fixing plate is placed on the top surface of the middle of the top plate of the rack, a through groove is formed in the middle of the top plate of the rack, a lower connecting plate is fixed in the middle of the undersurface of the top plate of the rack, lifting motors are fixed on two sides of the undersurface of the lower connecting plate, an output shaft of each lifting motor penetrates the lower connecting plateand is inserted into the through groove in a sleeved manner, the top surface of the output shaft of each lifting motor is provided with a threaded connection hole, and adjusting studs are fixed on twosides of the undersurface of the placement fixing plate and connected in the threaded connection holes in a threaded manner; lateral supporting frames are fixed on the top surface of two sides of theplacement fixing plate, a compression oil cylinder is arranged on a top plate of each lateral supporting frame, a push rod of each compression oil cylinder penetrates the top plate of the corresponding lateral supporting frame and is fixed with a compression block, and the lower portions of opposite wall faces of the two compression blocks are provided with lower grooves. The simple metal plate punching mechanism is simple in structure, firm and convenient in clamping and suitable for thin small-size plates.

Owner:FOSHAN RUIPUDA OPTOELECTRONICS TECH CO LTD

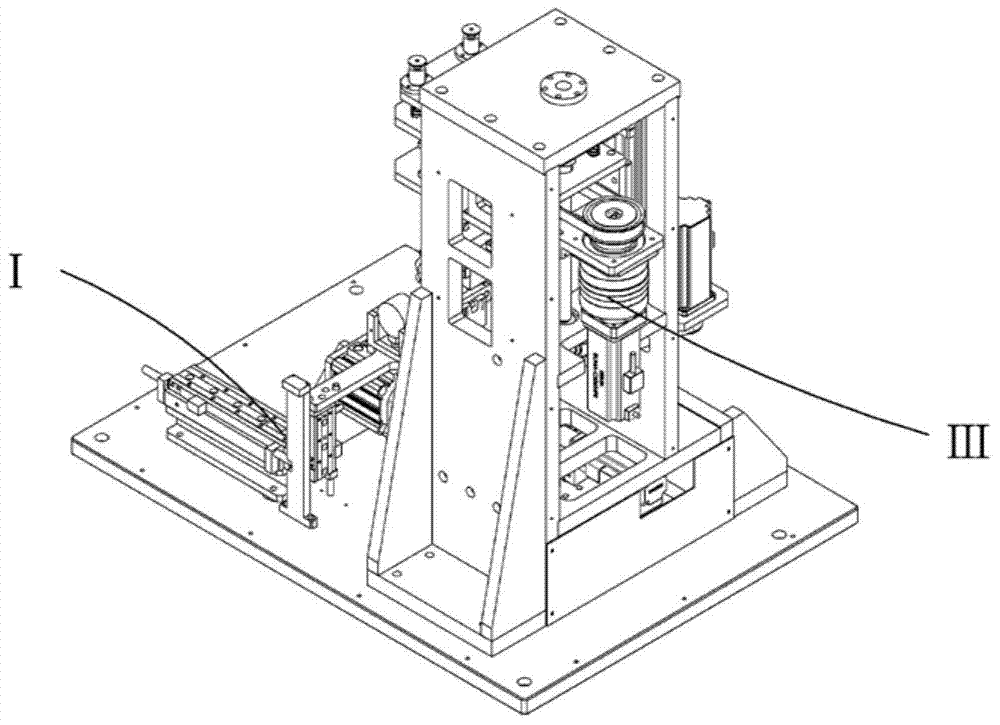

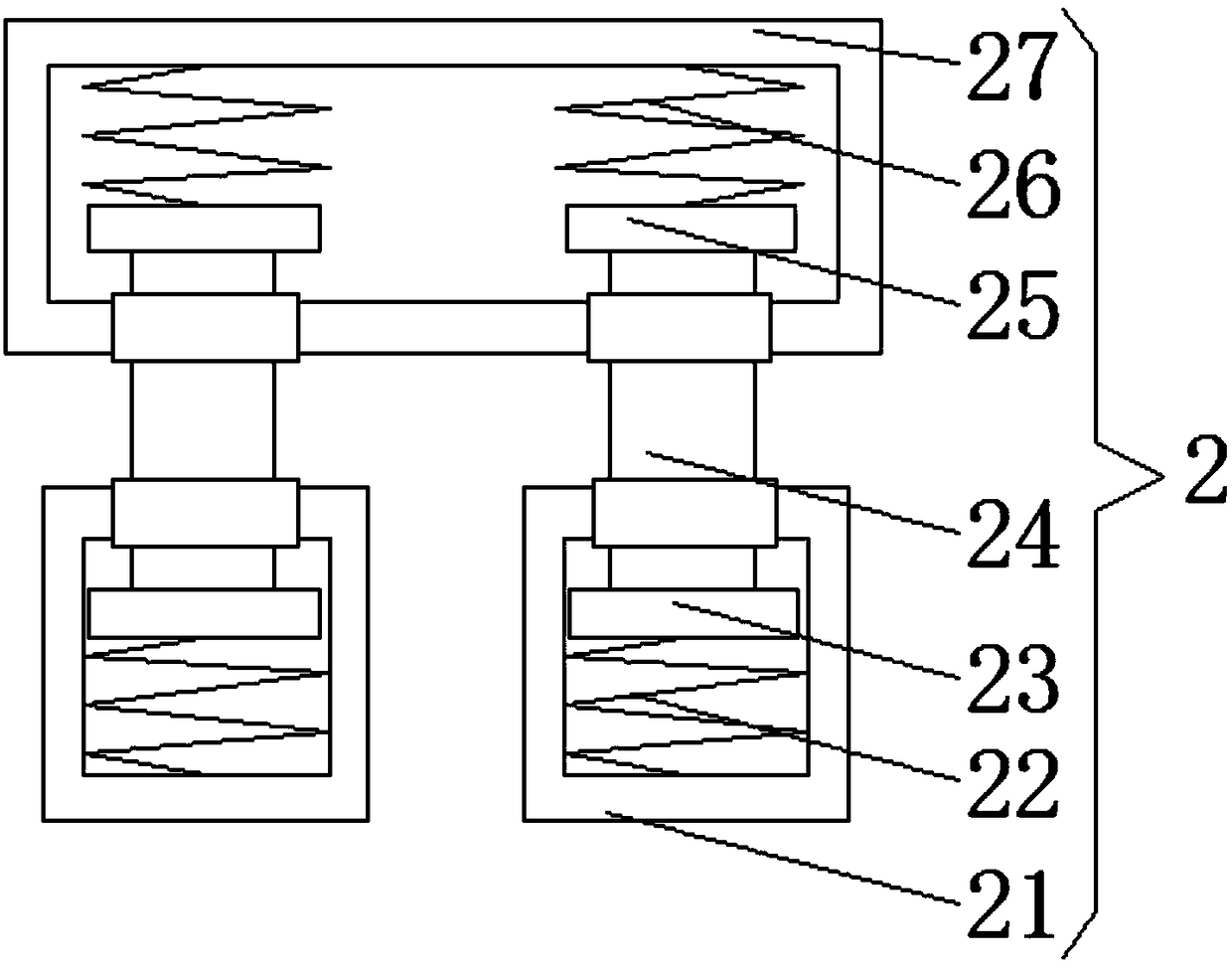

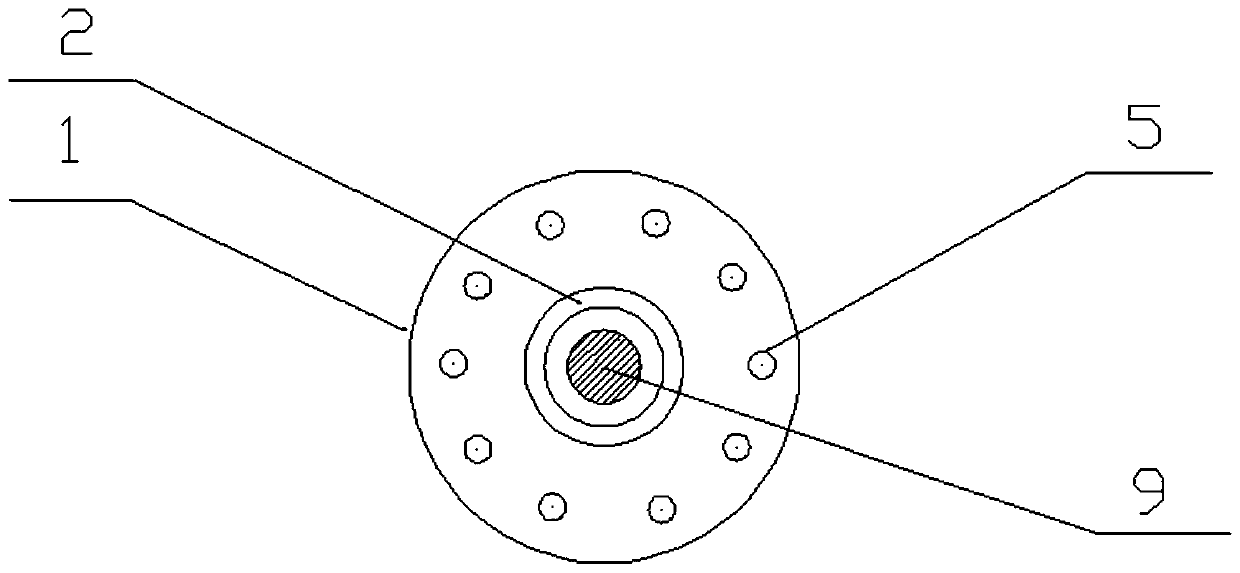

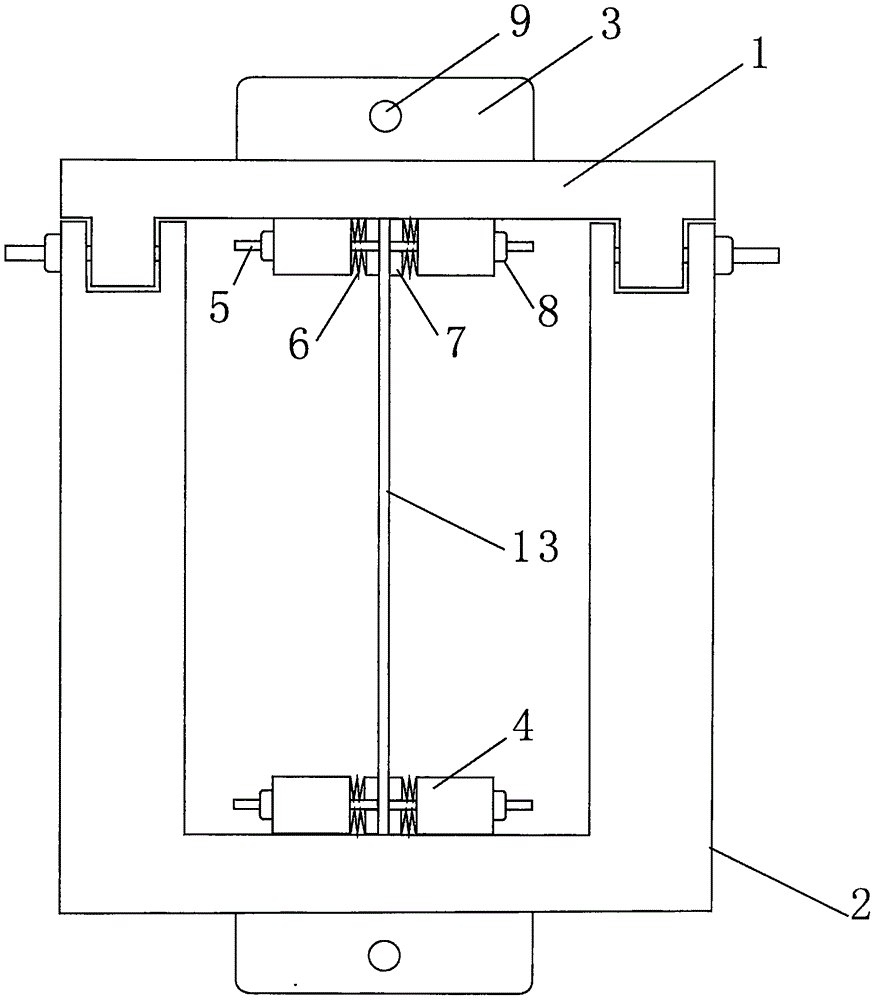

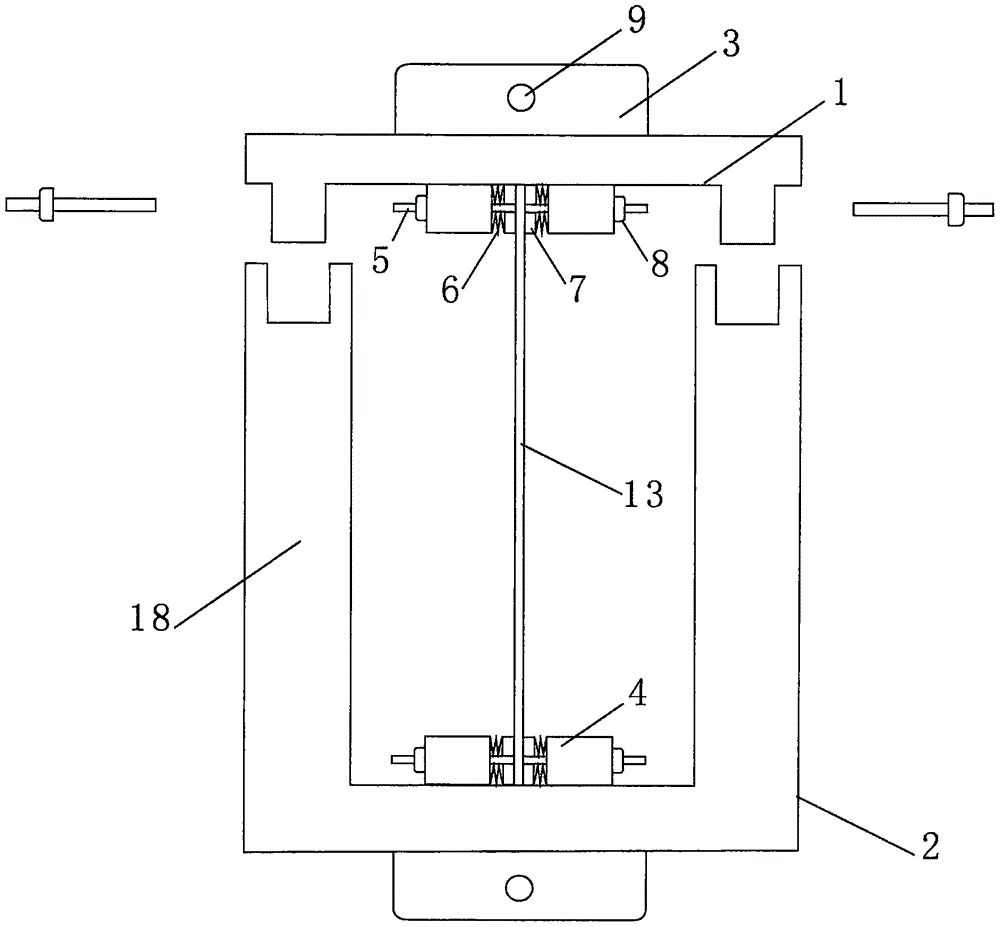

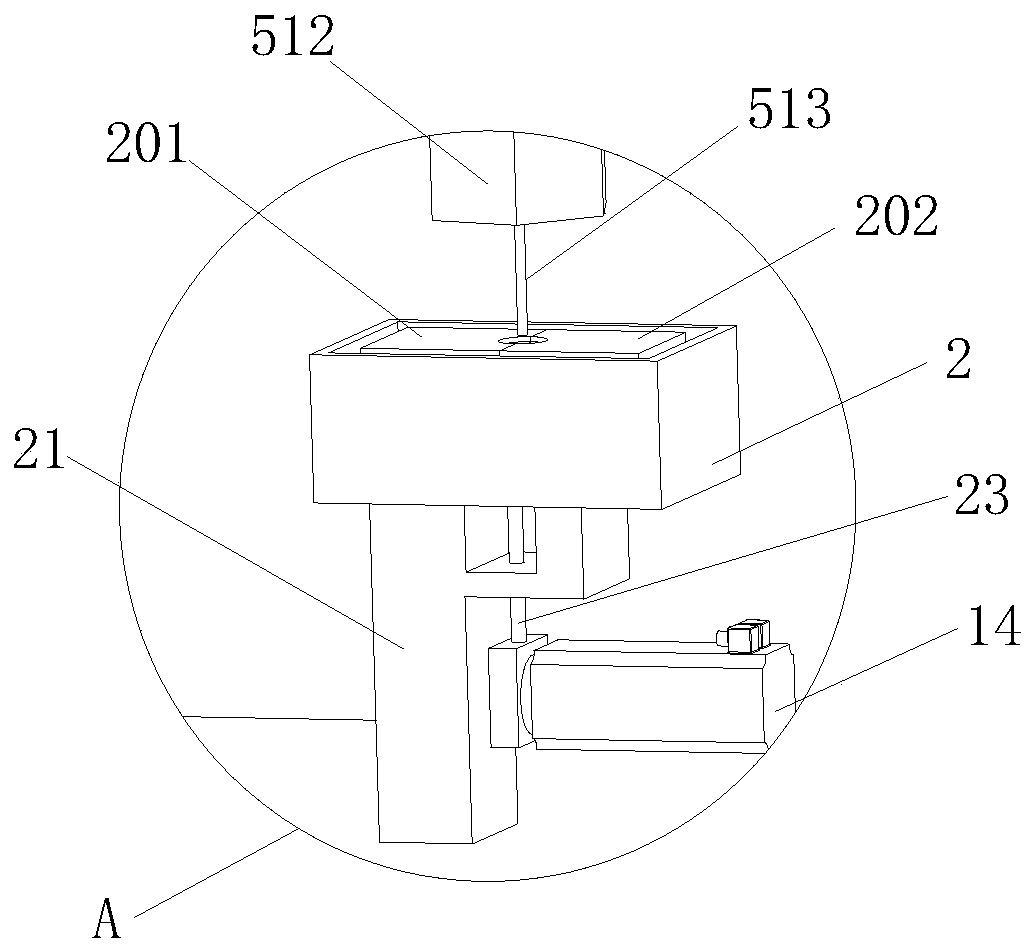

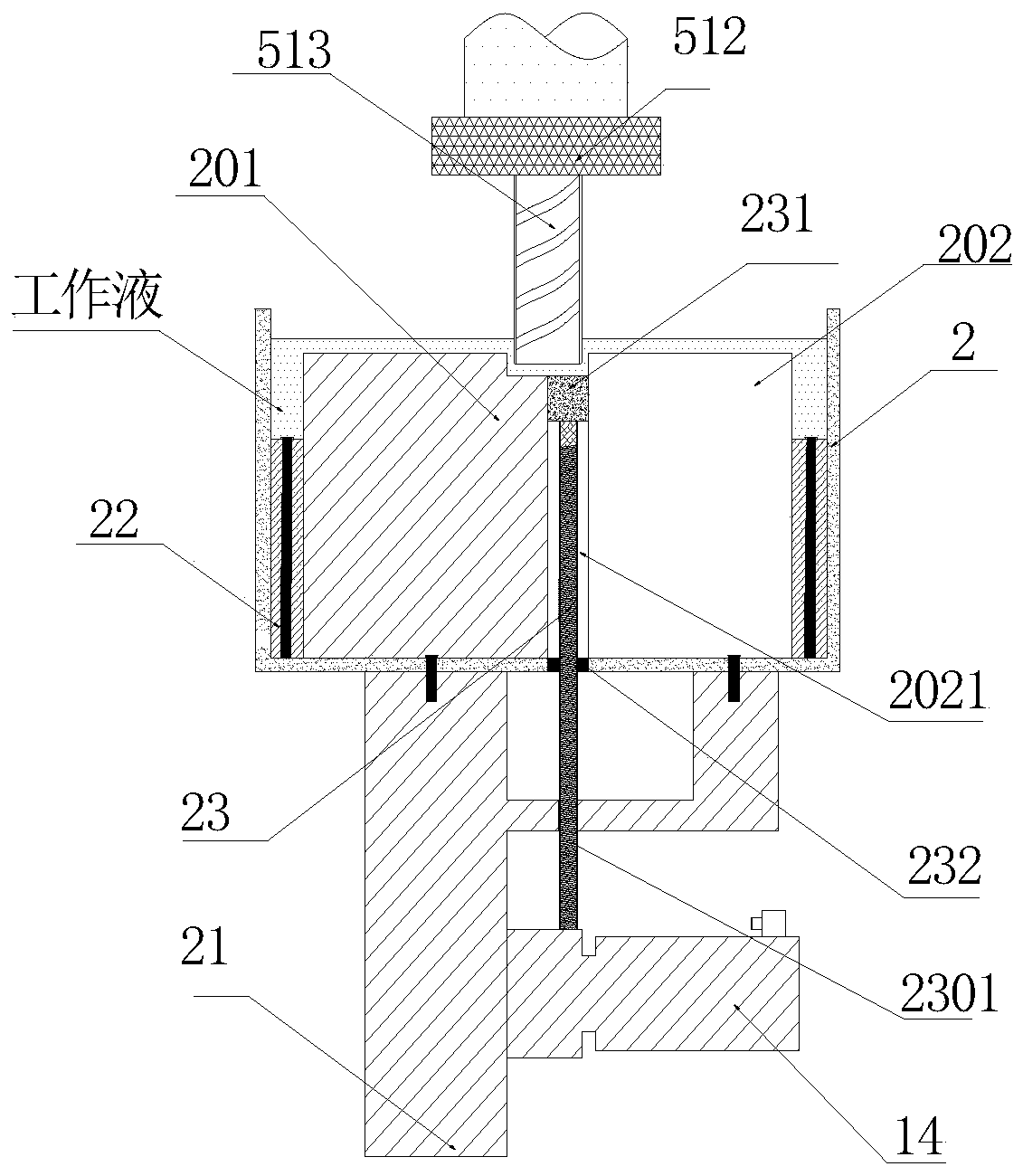

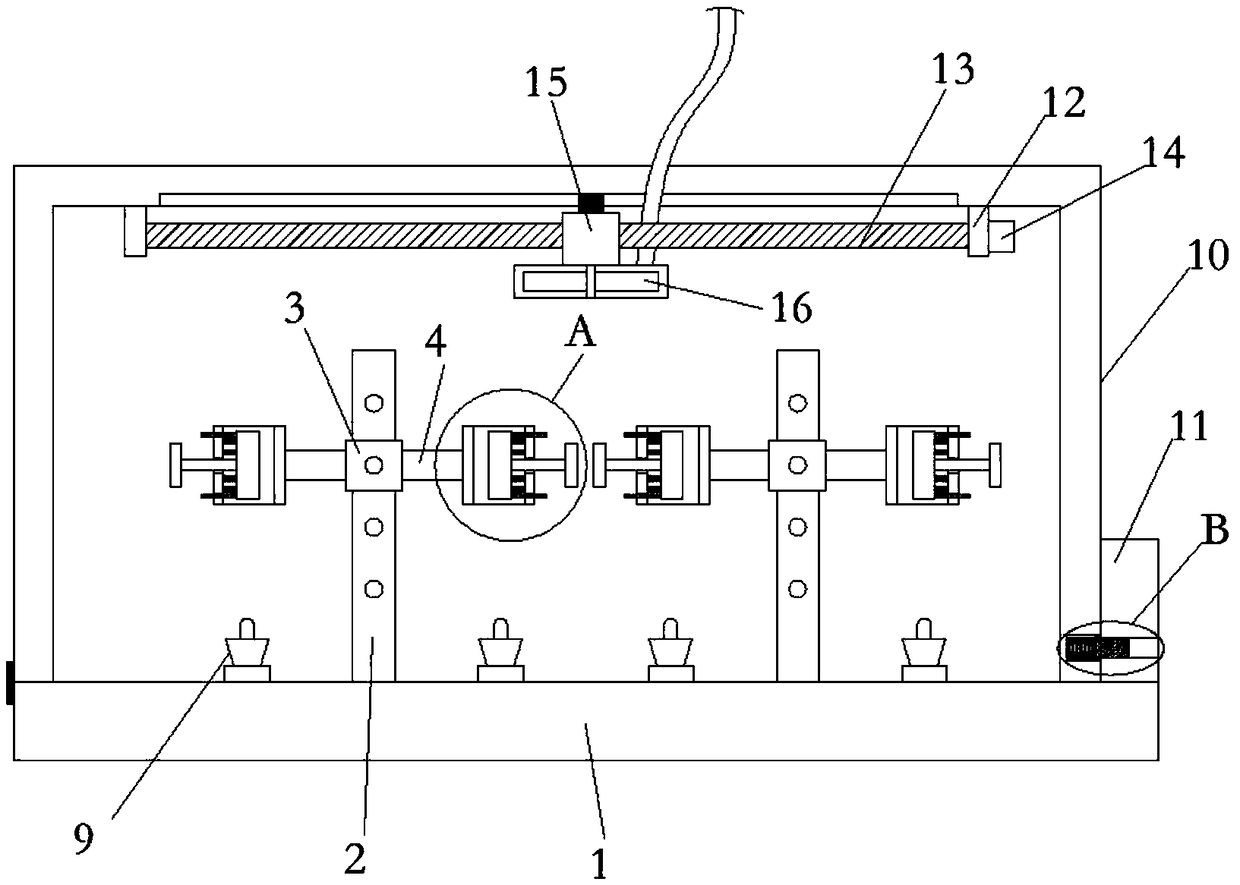

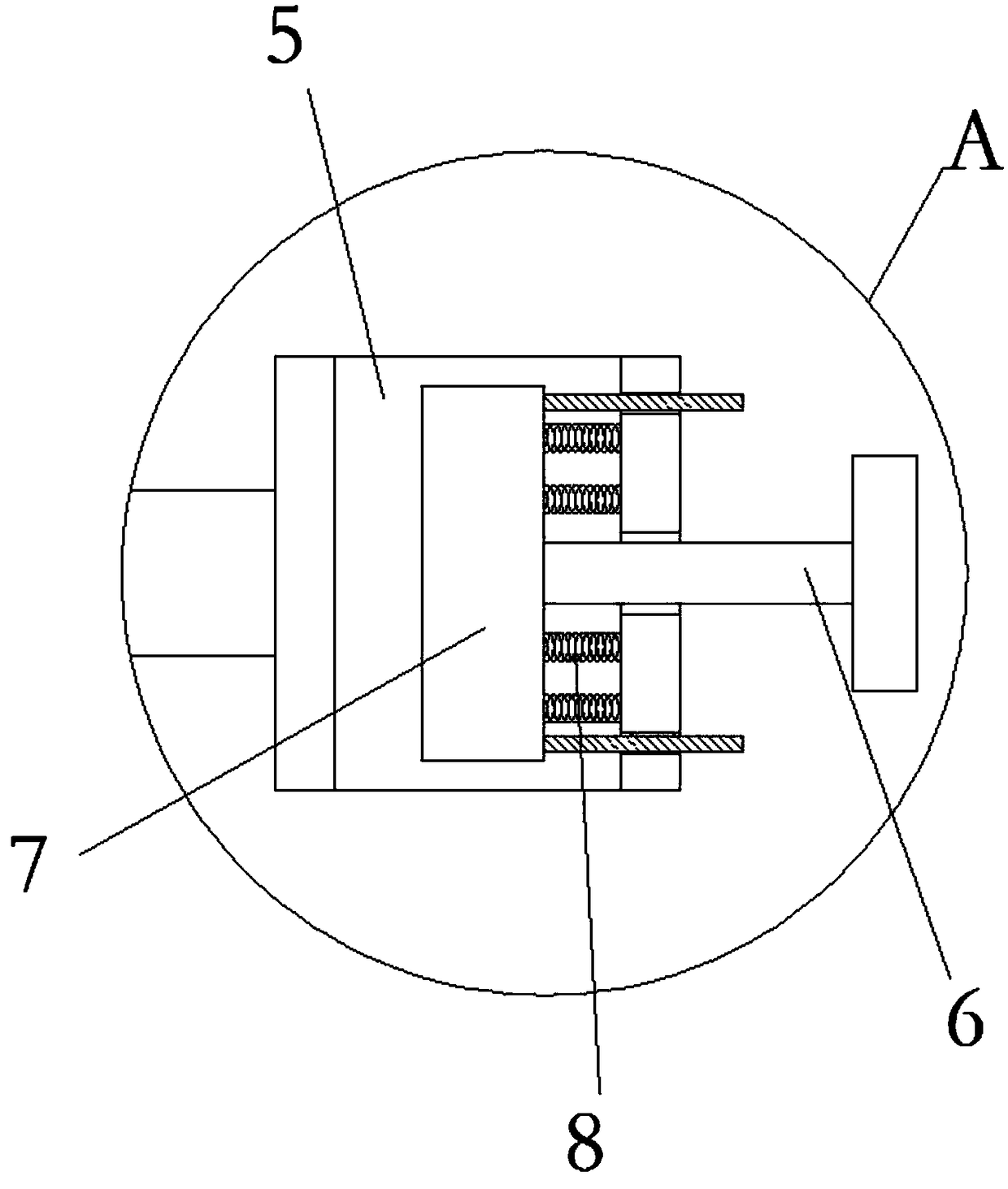

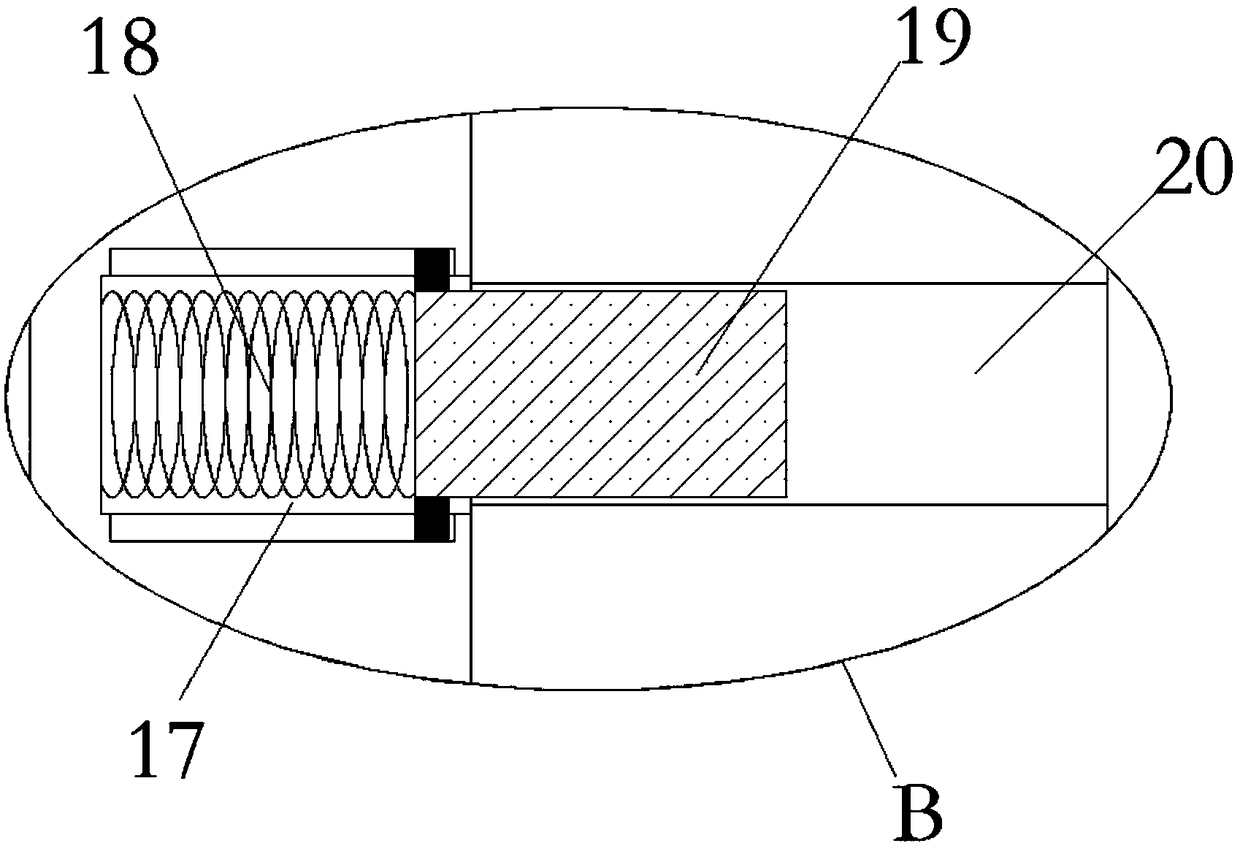

Testing device for tensile properties of single component in composite fibers

ActiveCN106338434AEasy and stable clampingNot easy to bendPreparing sample for investigationMaterial strength using tensile/compressive forcesEngineeringFiber

The invention discloses a testing device for tensile properties of a single component in composite fibers; the device comprises a casing, a lifting mechanism, a clamping device and an electronic control system, wherein the clamping device comprises an upper handle clamper fixed with the casing and a lower handle clamper driven by the lifting mechanism; the upper handle clamper is provided with a stress sensor; the testing device also comprises a dissolving treatment mechanism for dissolving other fiber components except a to-be-tested fiber component in the composite fiber; the dissolving treatment mechanism comprises a container and a fixing assembly. According to the testing device for the tensile properties of the single component in the composite fibers, firstly, the testing device can realize dissolving of the other fiber components except the to-be-tested fiber component in the composite fibers; secondly, the testing device can determine tensile properties of a superfine fiber; and during the testing, the superfine fiber is convenient and reliable to clamp, the phenomenon of bending or falling of the superfine fiber is not easily caused, and the testing precision is high.

Owner:QINGDAO UNIV

Cutting device for plastic product

PendingCN108356890AEasy and secure clampingSimple and quick installation and disassemblyMetal working apparatusEngineeringMechanical engineering

The invention discloses a cutting device for a plastic product. The cutting device comprises a shell, the side wall of one side of the shell is provided with a feeding port communicating with the interior of the shell, and a cover plate is ratably connected to an opening of the feeding port; the shell is internally and rotatably connected with a transversely-formed first rotating groove which is internally and rotatably connected with a first threaded rod, one end of the first threaded rod is arranged to penetrate through the shell, and the first threaded rod is sleeved with a first nut matched with the first threaded rod; the side wall of the first nut is fixedly connected with a first connecting rod, the inner wall of the lower side of the shell is provided with a strip-shaped opening communicating with the first rotating groove, and the first connecting rod is arranged to penetrate through the strip-shaped opening; and the end, away from the first nut, of the first connecting rod isfixedly connected with an object placing plate which is internally provided with a transversely-formed second rotating groove. The cutting device for the plastic product is easy to operate and convenient to use, material clamping is simple and firm, mounting and dismounting of a cutting wheel for cutting is simple, convenient and fast, overhaul and replacement of the cutting wheel is facilitated,and the working efficiency is high.

Owner:邹凡

Welding device for metal devices for electromechanical engineering

InactiveCN111992845AWeld firmlyImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesIndoor air qualityMetal device

The invention discloses a welding device for metal devices for electromechanical engineering. A base is included; a sliding chute is formed in the top of the base; a lead screw is arranged in the sliding chute; a sliding seat sleeves the lead screw in a threaded manner; a platform is fixedly arranged at the top of the sliding seat; and two first electric push rods and two second electric push rodsare fixedly arranged at the top of the platform. According to the welding device, the design is reasonable, the practicability is good, convenience is brought for stably clamping metal devices in different shapes, convenience is brought for welding the metal devices in different shapes, the platform can be controlled to slowly and stably move, welding personnel do not need to walk with electric soldering iron in hand along with the change of welding positions, the welding points of the metal devices can be stably welded, the welding quality is improved, the smoke generated in the welding process can be adsorbed and purified, the indoor air quality is improved, the condition of pollution to indoor environment is greatly reduced, and the harm to human health is reduced.

Owner:周友会

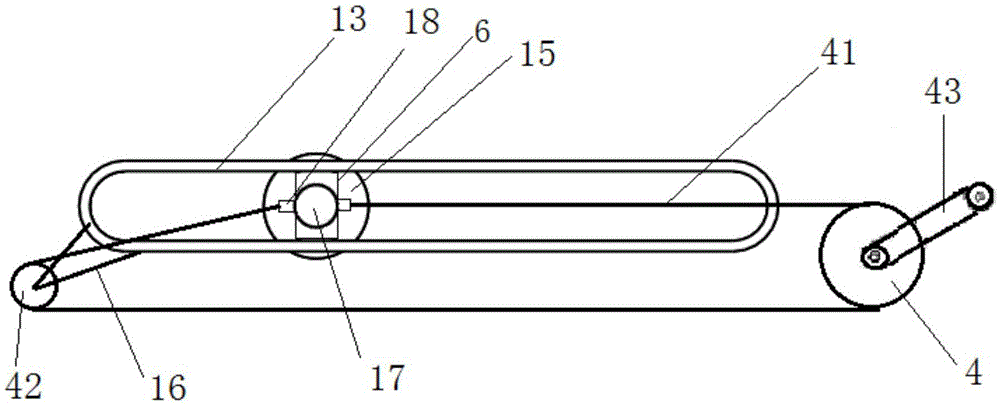

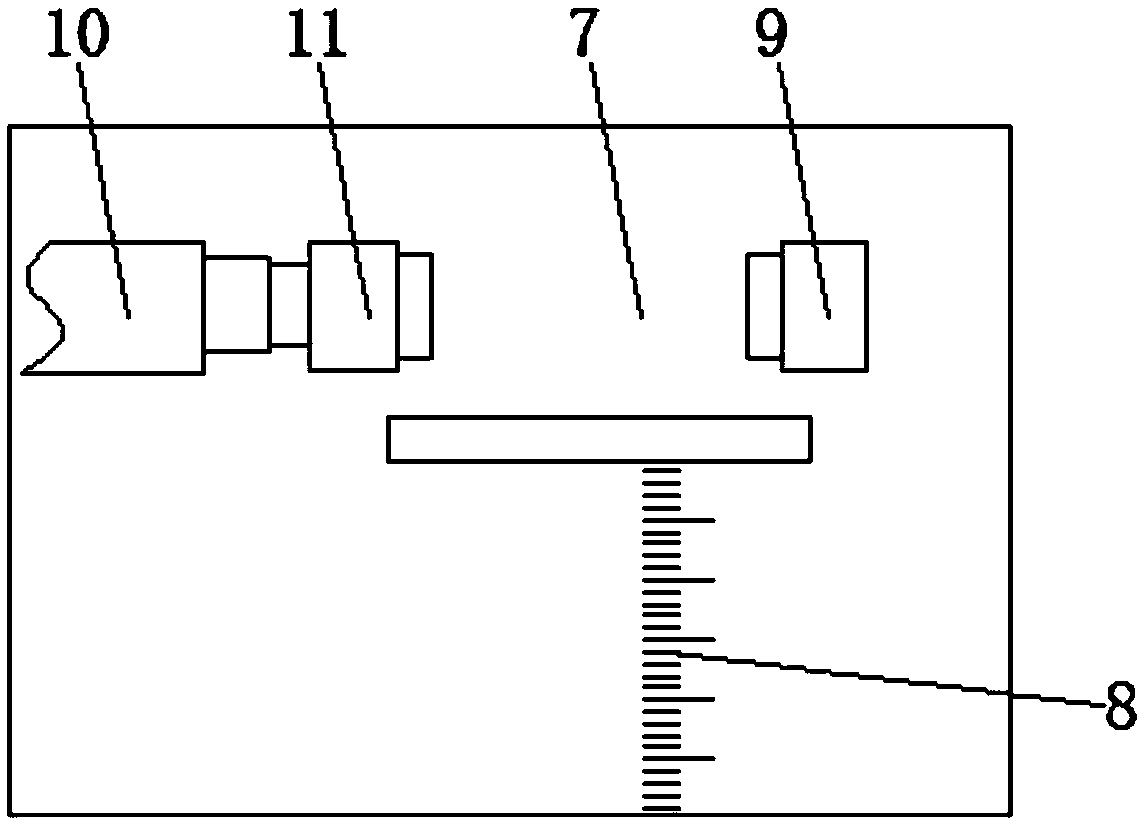

Pipe cutting and blanking mechanism of pipe machining equipment

InactiveCN108838461AEasy to collectEasy to adjustMetal working apparatusPositioning apparatusWire cuttingEngineering

The invention discloses a pipe cutting and blanking mechanism of pipe machining equipment. The pipe cutting and blanking mechanism comprises a base, and the upper end of the base is fixedly connectedwith a fixed plate through a connecting plate. The lower side wall of the fixed plate is fixedly connected with a first air cylinder, and the output end of the first air cylinder is connected with a first piston rod. The end, away from the first air cylinder, of the first piston rod is fixedly connected with a driving motor, and the output end of the driving motor is connected with a rotary shaft.The end, away from the driving motor, of the rotary shaft is fixedly connected with a cutting wheel, and the upper end of the base is fixedly connected with a mounting plate. A transversely formed through hole is formed in the mounting plate, and a clamping device is arranged in the through hole. A sliding groove is formed in the side wall of one side o the base, a collecting box is in sliding connection in the sliding groove, and a collecting groove with an upward opening is formed in the collecting box. According to the pipe cutting and blanking mechanism, a pipe material is clamped easilyand firmly, cut pipes can be collected conveniently, and work efficiency is improved.

Owner:JIANGSU YAFENG TECH GRP CO LTD

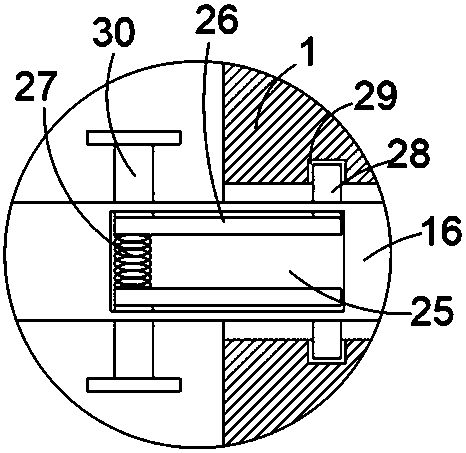

Pipe cutting and processing device

InactiveCN108746814AEasy and stable clampingAccurate cutting lengthShearing machinesLarge fixed membersArchitectural engineeringSpring steel

The invention discloses a pipe cutting and processing device. The pipe cutting and processing device comprises a base, wherein scales are arranged at the top of a workbench, a fixing tooth is fixedlyconnected to the top of the workbench, a sliding tooth is fixedly connected to the working end of a first electric telescopic rod, a movable rod penetrates through the top of a shock absorption frame,a movable plate is fixedly connected to one end, located in the shock absorption frame, of the movable rod, a first spring is fixedly connected between the bottom of the movable plate and the bottomof the inner wall of a damping frame, a top frame sleeves the top end of the movable rod, the movable plate is fixedly connected to one end, located in the top frame, of the movable rod, a second spring is fixedly connected between the top of the movable plate and the top of the inner wall of the top frame, and a spring steel plate is fixedly connected to the bottom of the outer frame. The invention relates to the technical field of cutting. According to the pipe cutting and processing device, the effects of accurate cutting and buffering and damping are achieved, the structure is simple, theuse is convenient, the manual labor is reduced, and the cutting quality and efficiency are improved.

Owner:李文静

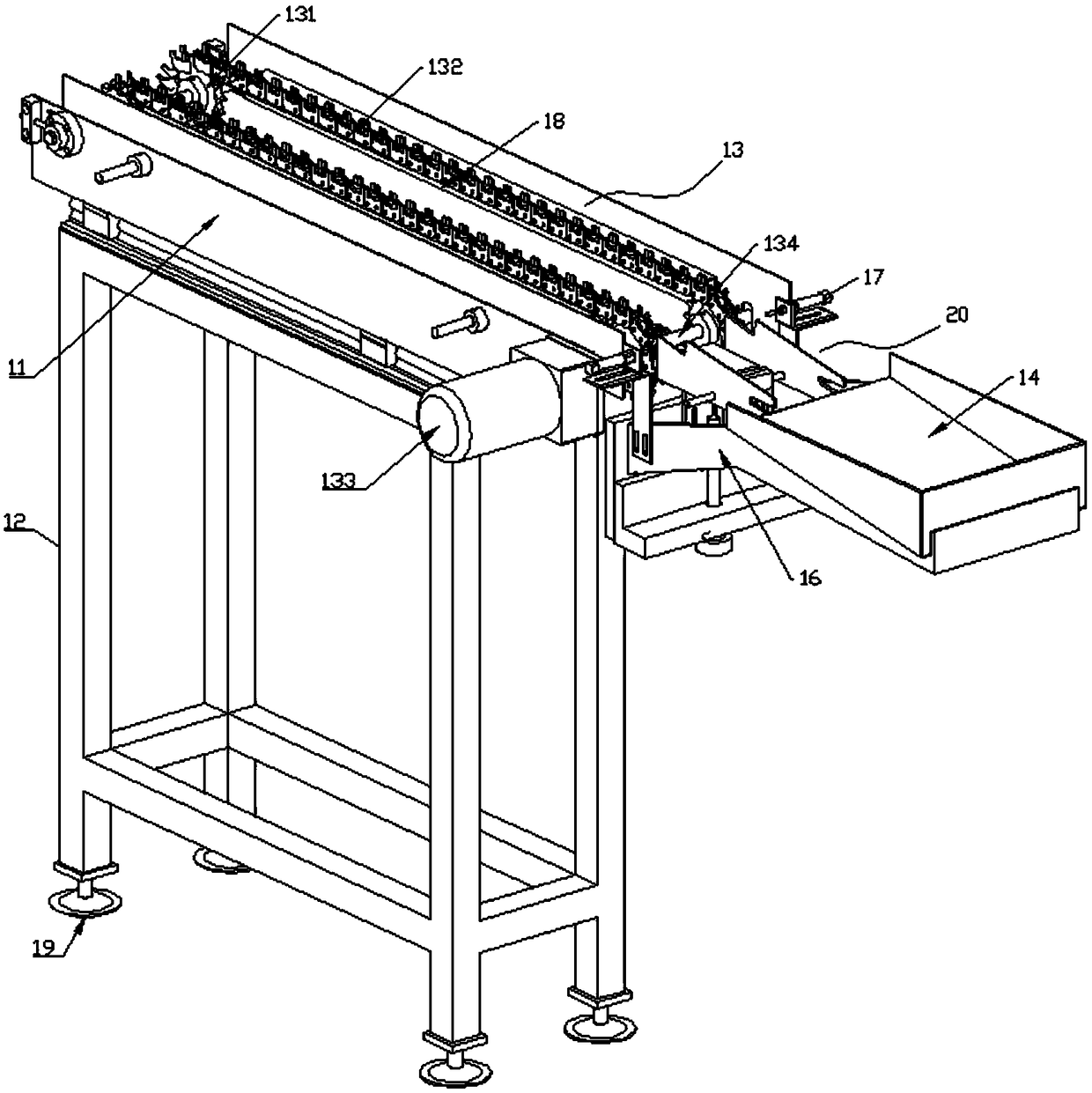

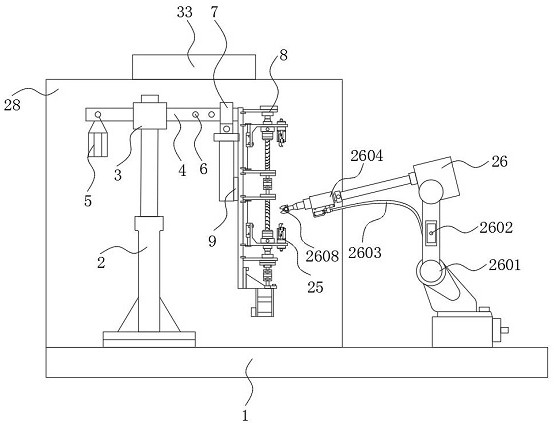

Automatic production line based on intelligent industrial robot

ActiveCN109625915ASmooth and easy movementRealize handlingConveyor partsProduction lineIndustrial engineering

The invention relates to the technical field of production lines, in particular to an automatic production line based on an intelligent industrial robot. The automatic production line comprises a production line body, wherein the production line body is equipped with a carrying mechanism; the carrying mechanism is equipped with an assembly clamping mechanism; the carrying mechanism comprises a conveying table; the right side part of the conveying table is equipped with a supporting post; the top end of the supporting post is equipped with a beam; a first movable device can be arranged on the beam in a left-right sliding mode; a carrying mechanism is arranged below the first movable device; the assembly clamping mechanism comprises a clamp body; the clamp body comprises a first clamp mounting plate, a baffle plate is arranged at one side of the top end surface of the clamp mounting plate, the middle part of the clamp mounting plate is downs sunken to form a mounting slot; a first clamping plate capable of sliding left and right is arranged in the mounting slot; and a second clamping plate capable of turning over is arranged at the inner side of the baffle plate. The automatic production line is simple in structure, is low in manufacturing cost, is good in stability in a carrying process, can automatically regulate according to different workpieces, guarantees assembly quality and improves assembly efficiency.

Owner:义乌市丹航科技有限公司

Sheet metal punching mechanism

The invention discloses a sheet metal punching mechanism, which comprises a frame, a main support frame is fixed on the top surface of the top plate of the frame, a fixed plate is fixed on the middle top surface of the top plate of the frame, and the fixed plate is placed There is a cutting groove on the top surface of the middle part, the top surface on both sides of the fixed plate is fixed with a support plate, the outer wall of the support plate is fixed with a clamping cylinder, the push rod of the clamping cylinder passes through the support plate and is fixed with a clamping block , the two clamping blocks are located on both sides of the top surface of the fixed plate; the middle bottom surface of the top plate of the main support frame is fixed with two connecting plates, the two ends of the fine-tuning screw are hinged on the two connecting plates, and the screw on the fine-tuning screw A moving block is connected, and a fine-tuning motor is fixed on the outer wall of one of the connecting plates, and the output shaft of the fine-tuning motor is a spline shaft. It has simple structure, firm and convenient clamping, convenient punching, and is suitable for thin and small-volume sheet materials.

Owner:FOSHAN RUIPUDA OPTOELECTRONICS TECH CO LTD

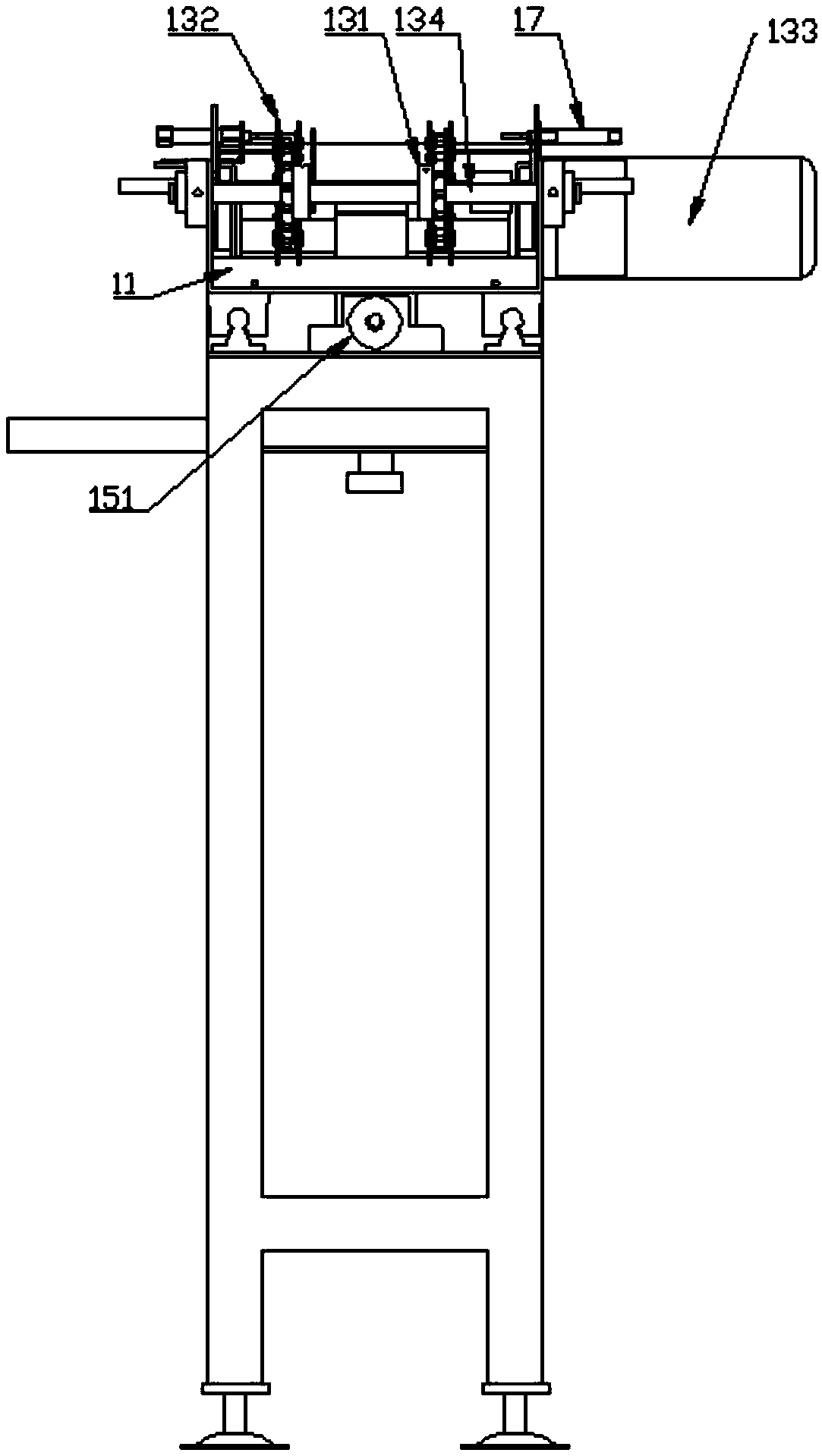

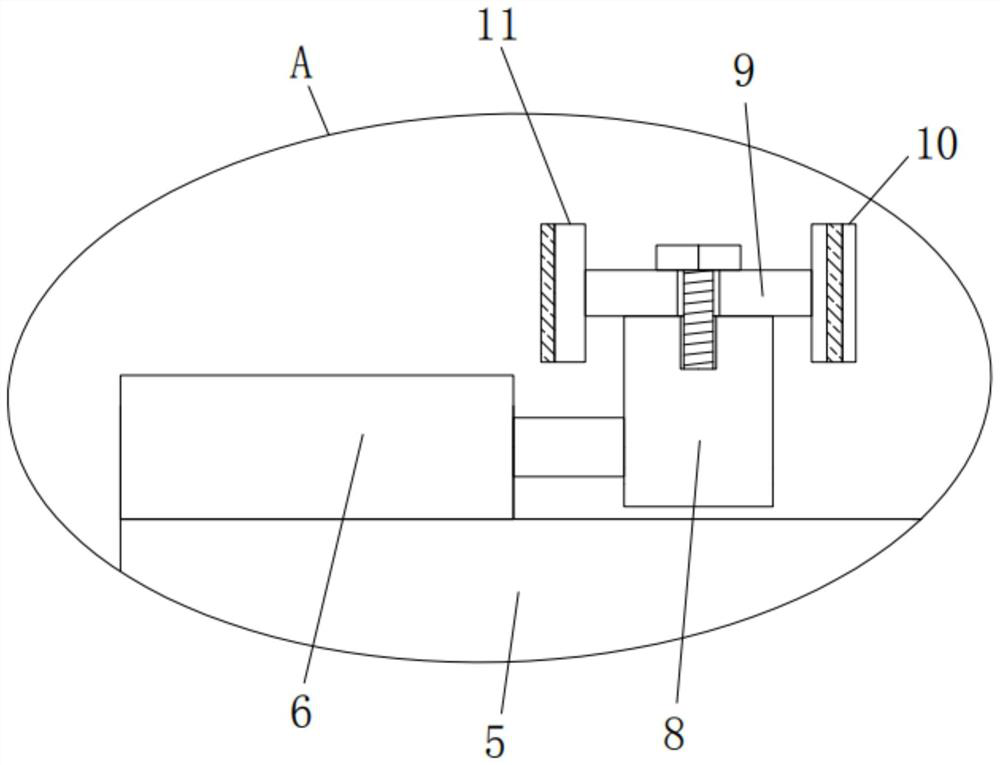

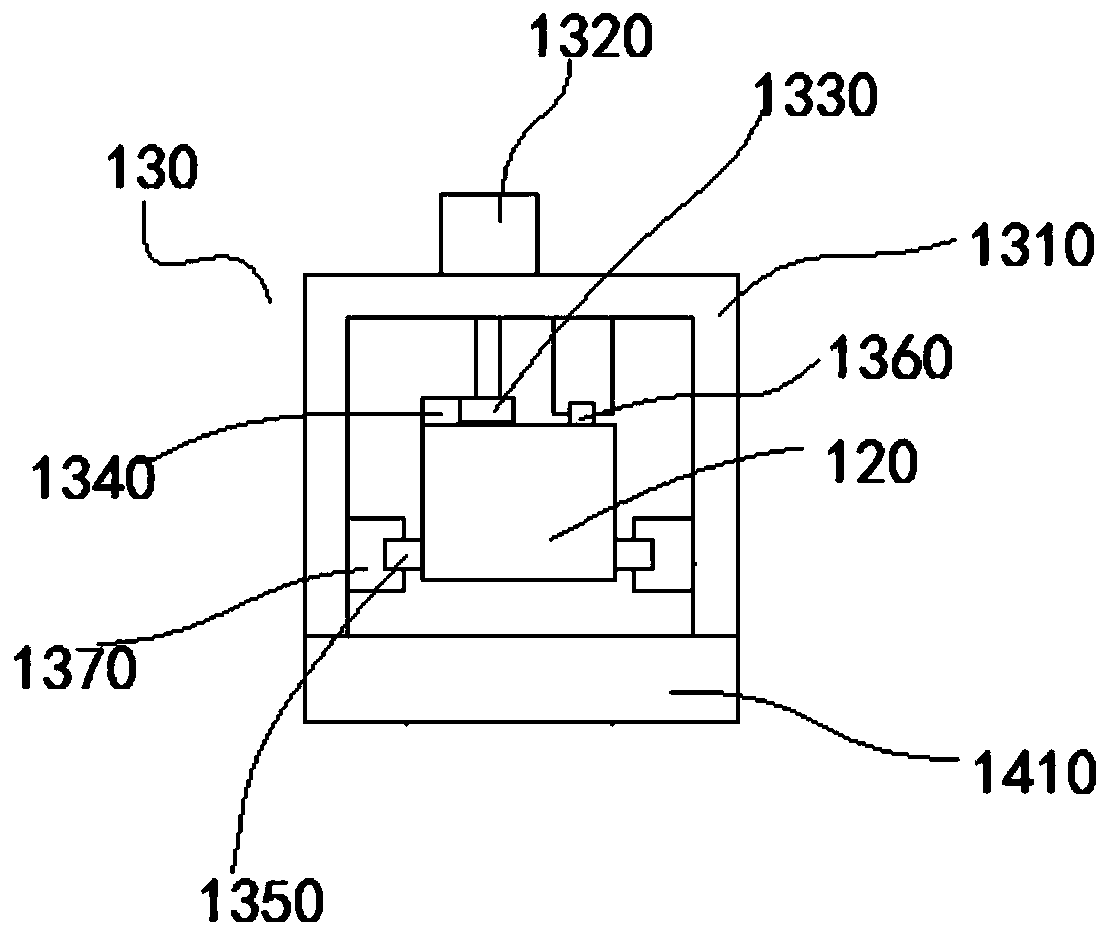

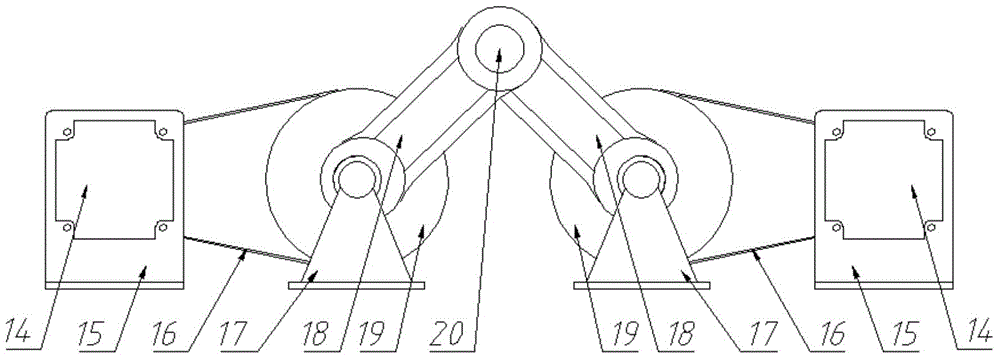

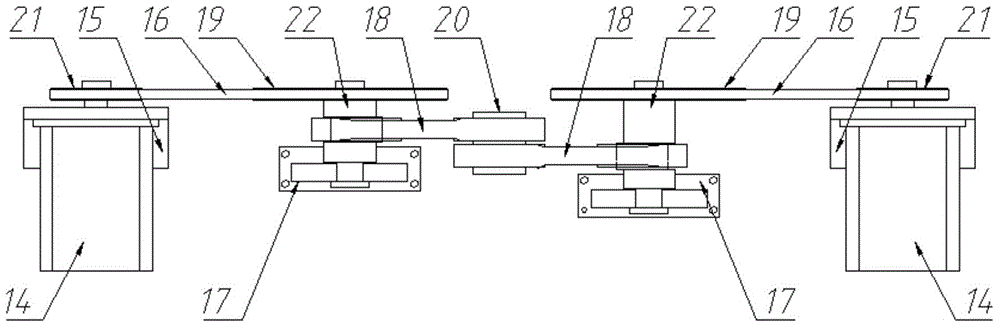

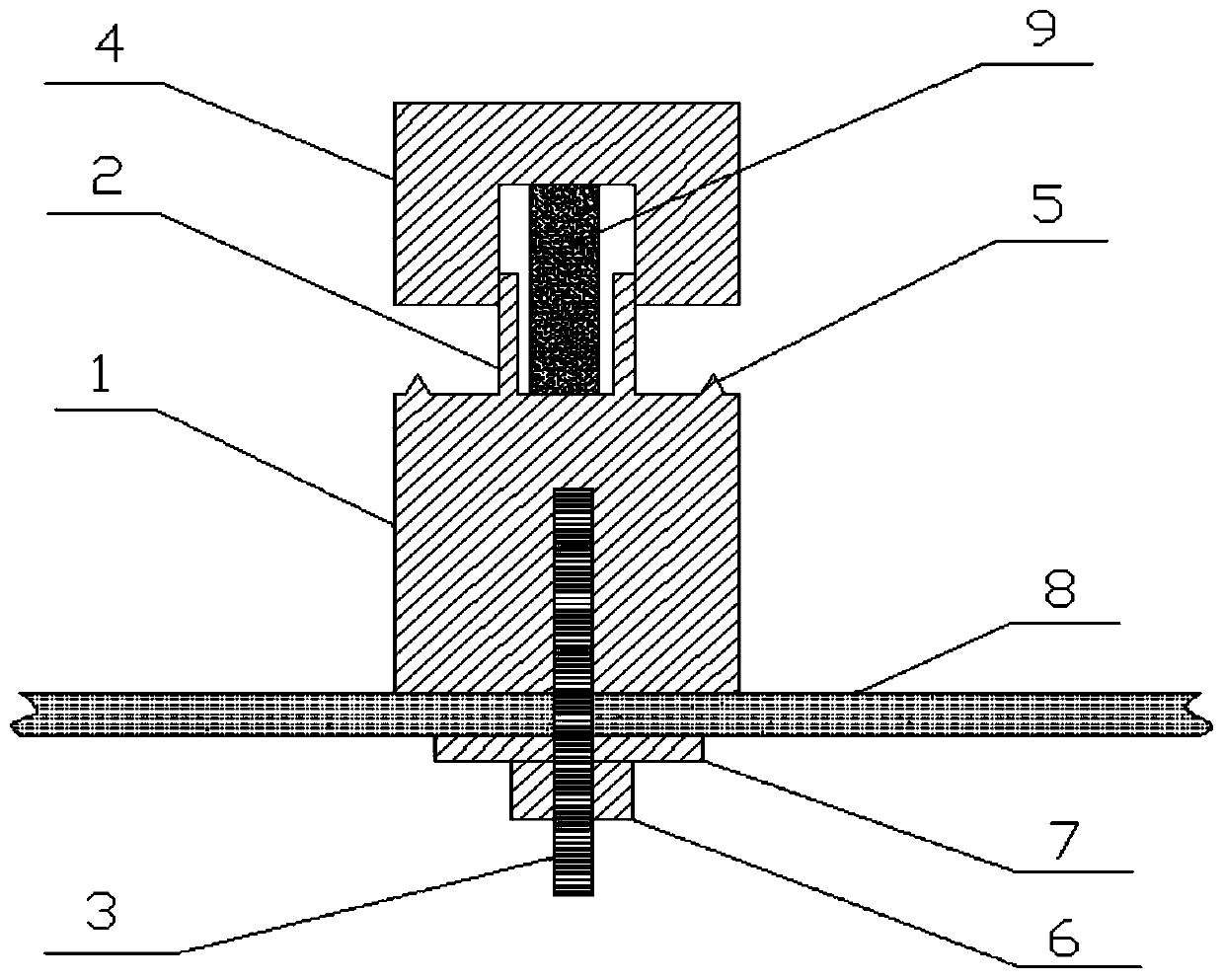

Pressure meter seat moving mechanism

ActiveCN103692181AHigh rotational positioning accuracyEasy and stable clampingMetal working apparatusEngineeringFree rotation

The invention relates to a pressure meter seat moving mechanism, comprising a bottom plate, a mobile module, a rotary module, a clamping module, a pressure meter seat and a pressure meter; the mobile module and the clamping module are arranged on the bottom plate respectively; the rotary module is arranged on the mobile module; the pressure meter seat is positioned on the rotary module by a clamp; the pressure meter is mounted on the pressure meter seat; a mobile cylinder of the mobile module drives the pressure meter seat to a machining position; the direction of the pressure meter seat is rotated to a designated position by the rotary module, then a clamping cylinder clamps the pressure meter seat and ensures that the pressure meter seat is not loosened in the use process, and the pressure meter seat can freely rotate in the rotation process. The pressure meter seat moving mechanism can perform rotation motion while clamping, the rotating positioning precision is high, and a work position is not deviated as a rotary motor of the rotary module can be braked. The labor intensity of operation staff is reduced, and the production cost is reduced.

Owner:BOZHON PRECISION IND TECH CO LTD

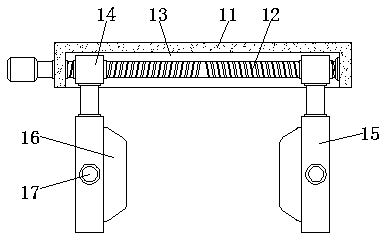

Vertical mechanical vibrating hydraulic extruder

The invention discloses a vertical mechanical vibrating hydraulic extruder, which comprises four pillars, wherein the two ends of the four pillars are respectively connected with an upper cross beam and a base, a first hydraulic cylinder is fixed on the upper cross beam, the end part of a piston rod of the first hydraulic cylinder is matched with a first sliding rail by a first slide block, a second hydraulic cylinder is fixed at the lower part of the first slide block, a mold is connected to the lower part of the second hydraulic cylinder, a vibrating mechanism is fixed in a base and connected with the bottom of a workbench, a clamping mechanism is arranged at the upper part of the workbench, a second slide block connected with the workbench is matched with a second sliding rail, the second sliding rail is connected to the base, the clamping mechanism clamps workpieces, and the vibrating mechanism drives the workbench to vibrate. According to the invention, axial feeding is separated from a vibrating process, therefore, the extruder is easy to control; the structure of the hydraulic cylinder is simplified, and the seal requirements of the hydraulic cylinder are reduced; and the extruder is compact in overall structure, and more stable and reliable in the extrusion process.

Owner:XI AN JIAOTONG UNIV

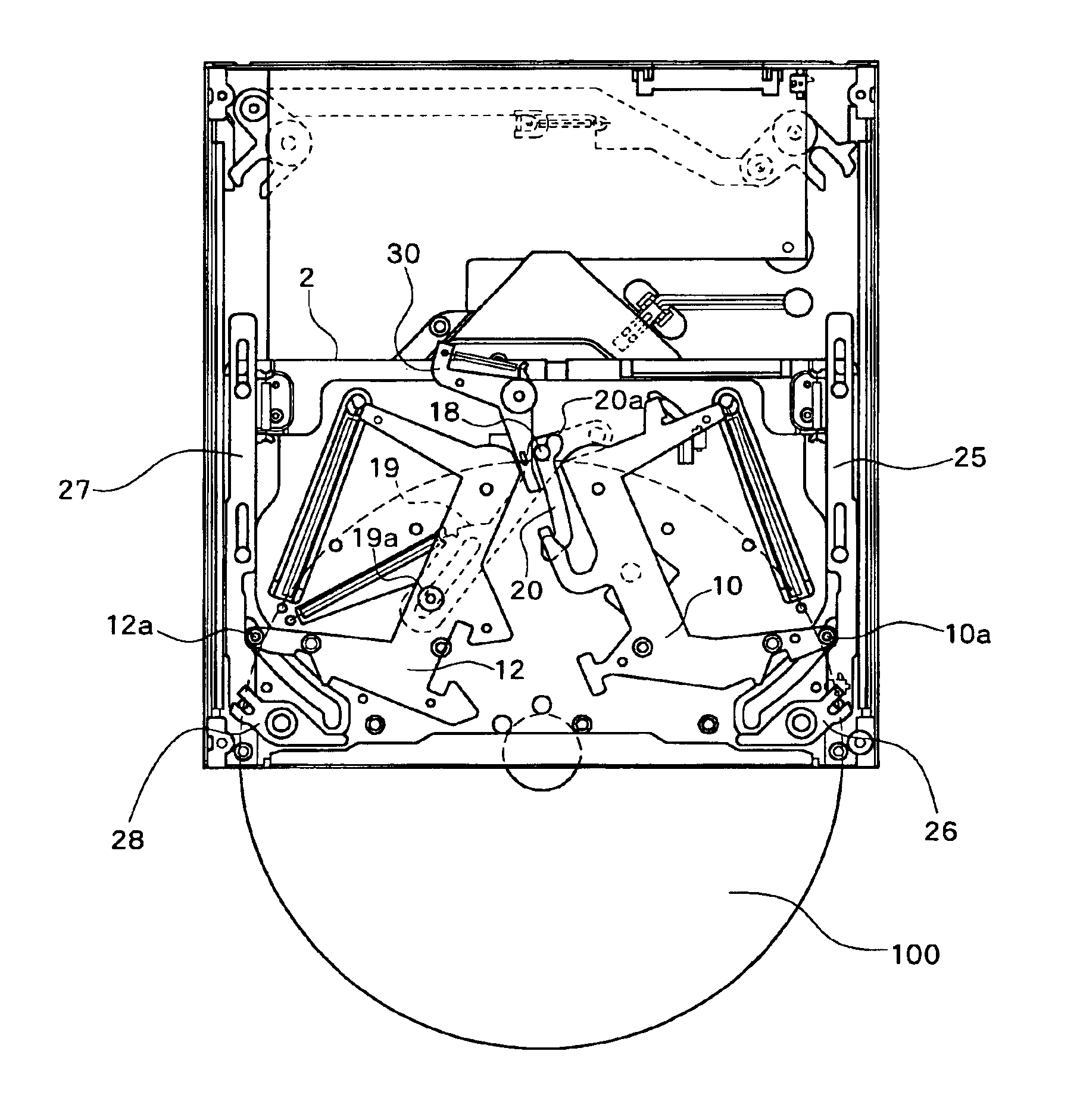

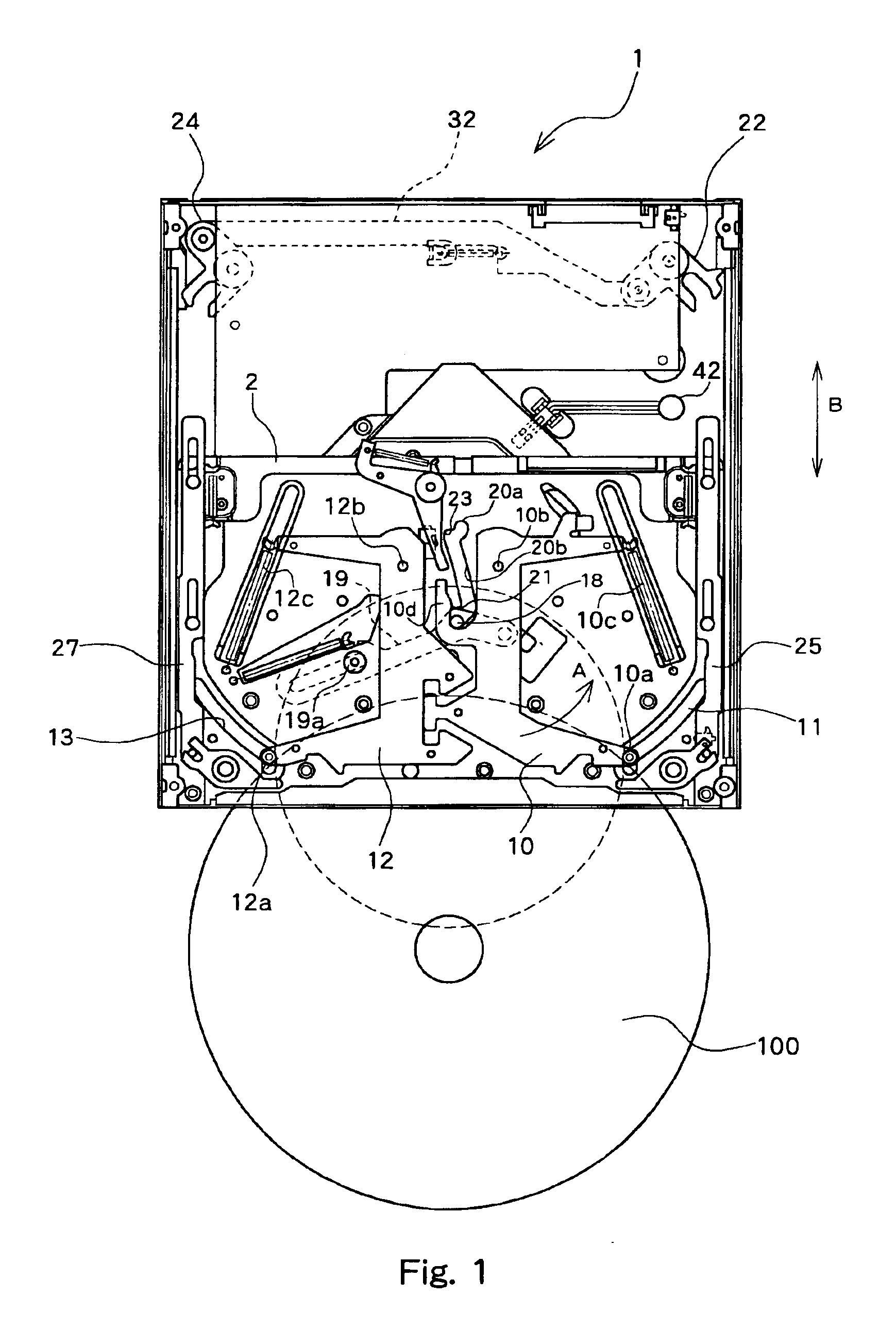

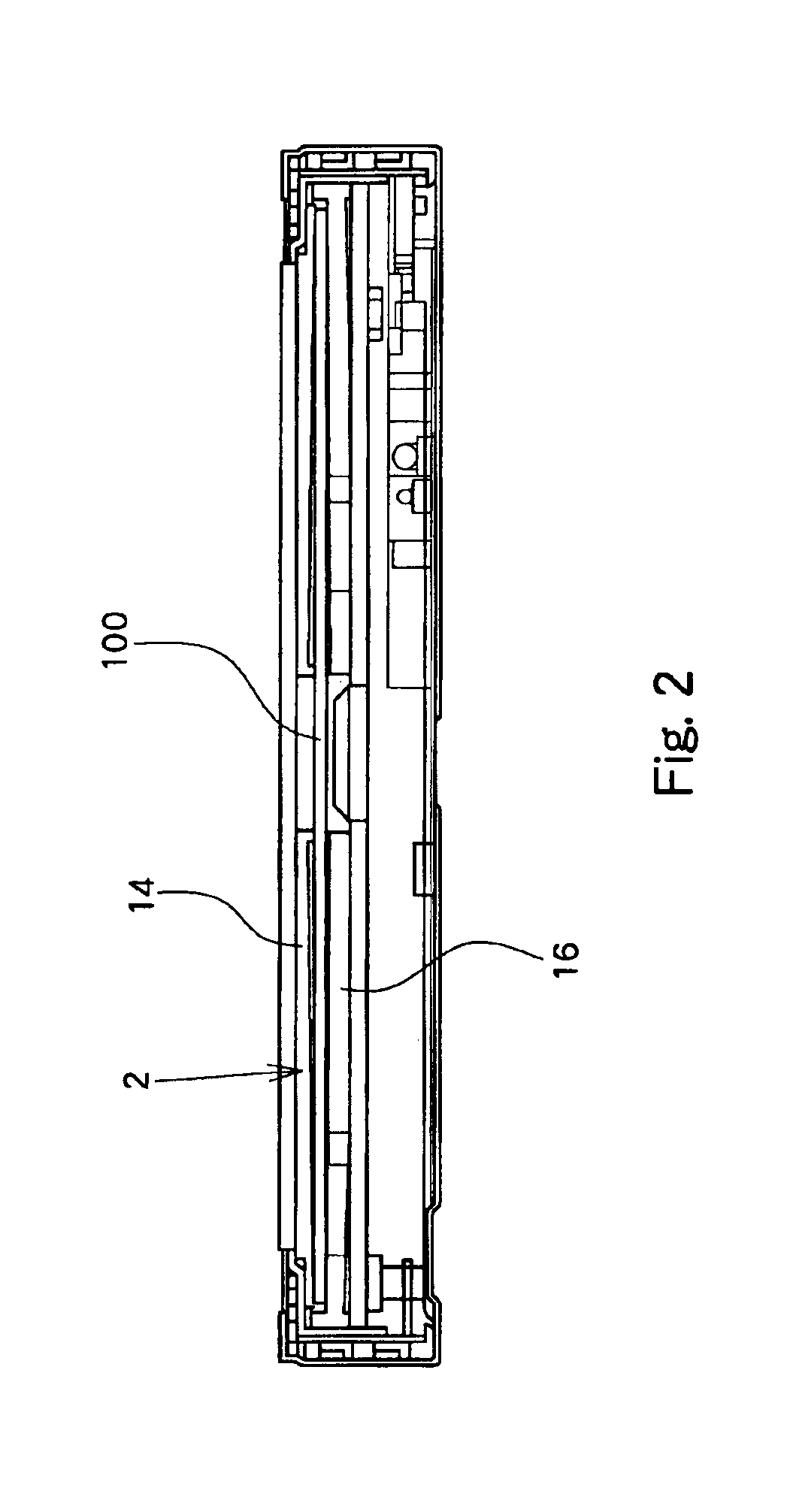

Optical disk device

InactiveUS6964058B2Guaranteed uptimeEasy and stable clampingRecord information storageRecording on magnetic disksOptical pickupEngineering

There is provided a thin optical disk device having a slot-in mechanism which is able to smoothly carry out operations of clamping and releasing an optical disk, including an optical pickup which carries out reading and / or writing from / to the optical disk, a turntable which places the optical disk at an operating position of the optical pickup and rotates the optical disk, a clamper which is arranged at an approximate center of the turntable and can freely advance and retreat in a direction of a diameter of the optical disk, and a device for clamping an inside diameter section of the optical disk at a location directly above the clamper with the optical disk being held by sandwiching the optical disk and for pressing the inside diameter section from the side of a non-writing surface of the optical disk and clamping the inside diameter section to the clamper.

Owner:TEAC CORP

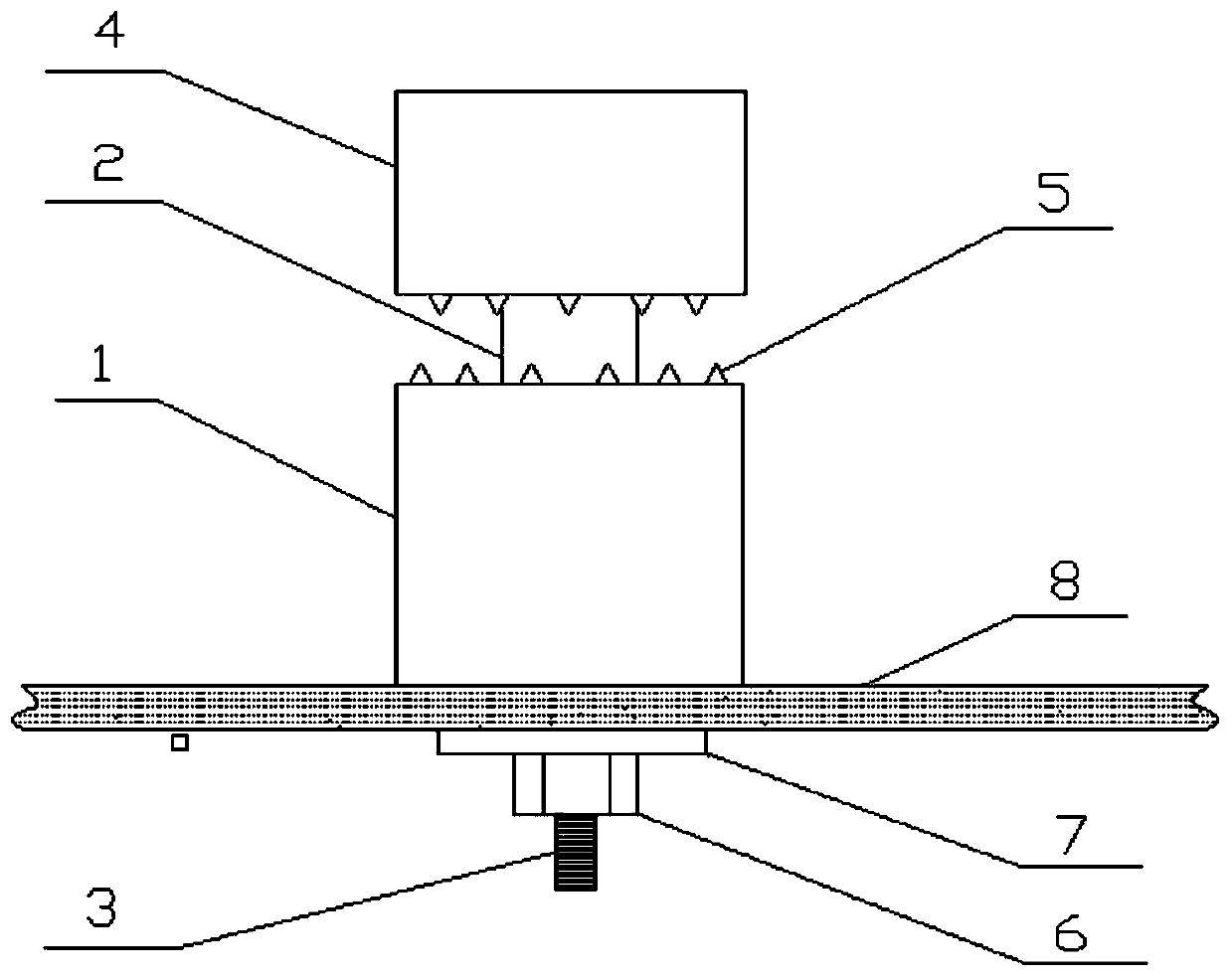

Corrosion coupon clamp for atmospheric exposure environment test

PendingCN111521550AEasy to holdEasy to operateWeather/light/corrosion resistanceWork holdersEngineeringBatten

The invention provides an atmospheric exposure environment test corrosion coupon clamp and belongs to the technical field of natural environment test devices. The clamp structurally comprises a base,an upright post on the base, a connecting part and a top cover, wherein the base is insulated from the upright post, the upright post is cylindrical and is positioned in the center of an upper surfaceof the base, the top cover is insulated, the bottom of the top cover is hollow corresponding to the upright post, a screw rod is fixedly connected in the base, extends out of the center of a lower surface of the base, and is matched with a nut to be fixed on an exposure rack sample fixing batten, the base and the top cover are connected through an elastic contraction part or are in threaded connection through an outer extension end of the screw rod in the base in the other direction, and protrusions with uniform sizes are distributed on a contact surface of the base and the top cover in a staggered mode. The clamp is advantaged in that the clamp is simple in structure, convenient to operate and capable of stably clamping corrosion hanging pieces with different thicknesses, meanwhile, thedesign of the convex points effectively reduces the contact area of the clamp and the corrosion hanging piece and avoids crevice corrosion.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Automotive body fixture

InactiveCN103449304AImprove work efficiencyHigh strengthLoad-engaging elementsAutomotive engineeringCar manufacturing

Owner:WUXI YICHEN MOLD TECH

A method of testing a tensile property of a single component in a composite fiber

ActiveCN106404530AReduce test errorNot easy to bendMaterial strength using tensile/compressive forcesTest efficiencySingle fibre

A method of testing a tensile property of a single component in a composite fiber is disclosed. The method includes S1) selecting the composite fiber, S2) fixing the composite fiber, S3) adding the fixed composite fiber to a container containing a specific solution, heating, dissolving, and maintaining a fiber to be tested, S4) checking the form of the fiber to be tested, S5) testing the tensile property of the fiber to be tested by a single fibre tensile strength tester, S6) averaging single fibre tensile strength data, and S7) averaging for a second time. The method can achieve dissolution of other fiber components except the fiber to be tested in the composite fiber and tensile property testing of an ultrafine fiber, reduces a tensile property test error of a single component in the composite fiber, and increases the testing efficiency.

Owner:QINGDAO UNIV

I-shaped steel rail calibrating and aligning device for railway construction

ActiveCN110965410AEasy butt weldingSpacing is easy to adjustRailway track constructionGear wheelBevel gear

The invention discloses an I-shaped steel rail calibrating and aligning device for railway construction. The device comprises a mounting frame, a first bevel gear, a second bevel gear and a first adjusting rod, a mounting ring is arranged above the mounting frame, a vertical rod is arranged on the inner side of the mounting ring, grooves are formed in the surface of the vertical rod and the innersurface of the mounting ring, balls are arranged on the inner sides of the grooves, the vertical rod is connected with the mounting ring through the balls, and ground nails are mounted below the mounting frame. According to the I-shaped steel rail calibrating and aligning device for railway construction, a first clamping plate below a first mounting plate is used for clamping the rail; the first clamping plate drives a second clamping plate to synchronously clamp the another rail through the telescopic rod, the first clamping plate and the second clamping plate are located at the same straightline such that the rail clamped by the first clamping plate and the rail clamped by the second clamping plate are located at the same straight line, at the moment, the two rails are aligned, and follow-up butt welding is facilitated.

Owner:嘉兴尚坤科技有限公司

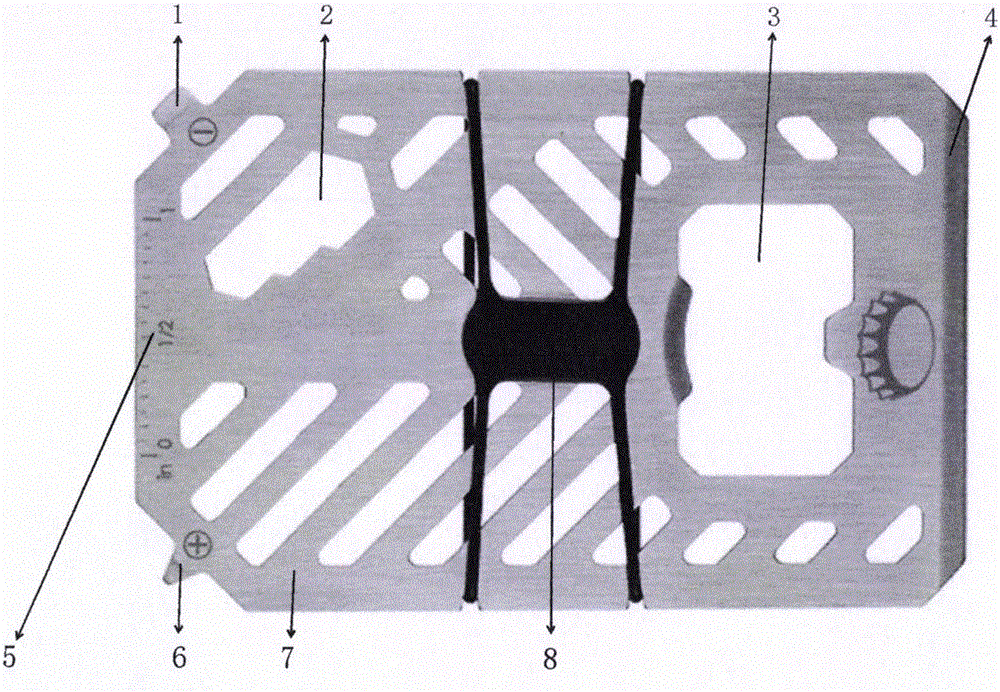

Billfold multipurpose tool

The technical problem to be solved by the invention is to provide a billfold multipurpose tool. The billfold multipurpose tool has a function of a simple and portable wallet and integrates the functions of a wrench, a large screwdriver, a small screwdriver doubling as an unpacking knife, a bottle opener, a ruler, a billfold and the like. The technical problem to be solved by the invention is solved by the technical scheme of the billfold multipurpose tool comprising a billfold main body and a billfold belt.

Owner:乔逸凡

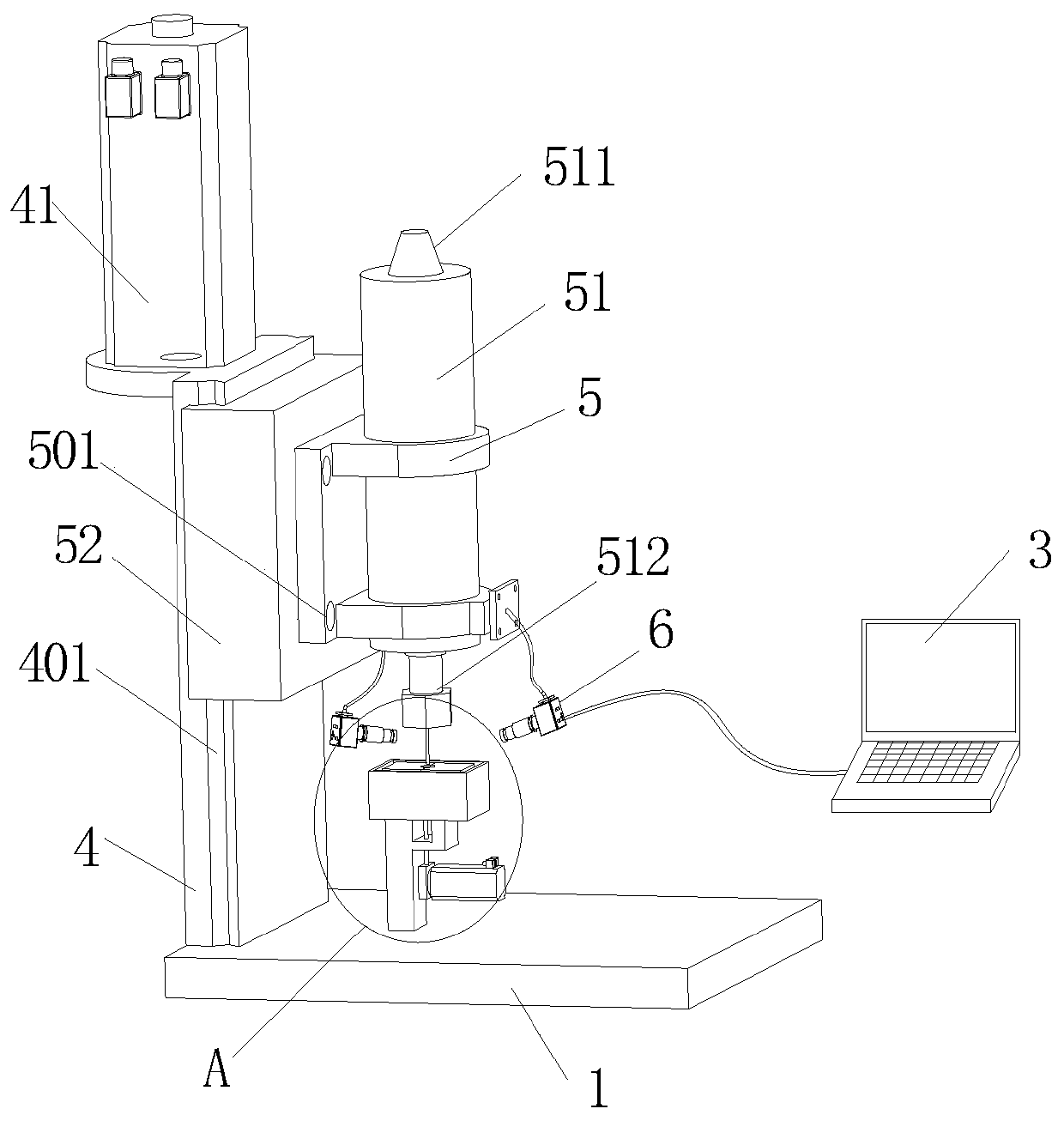

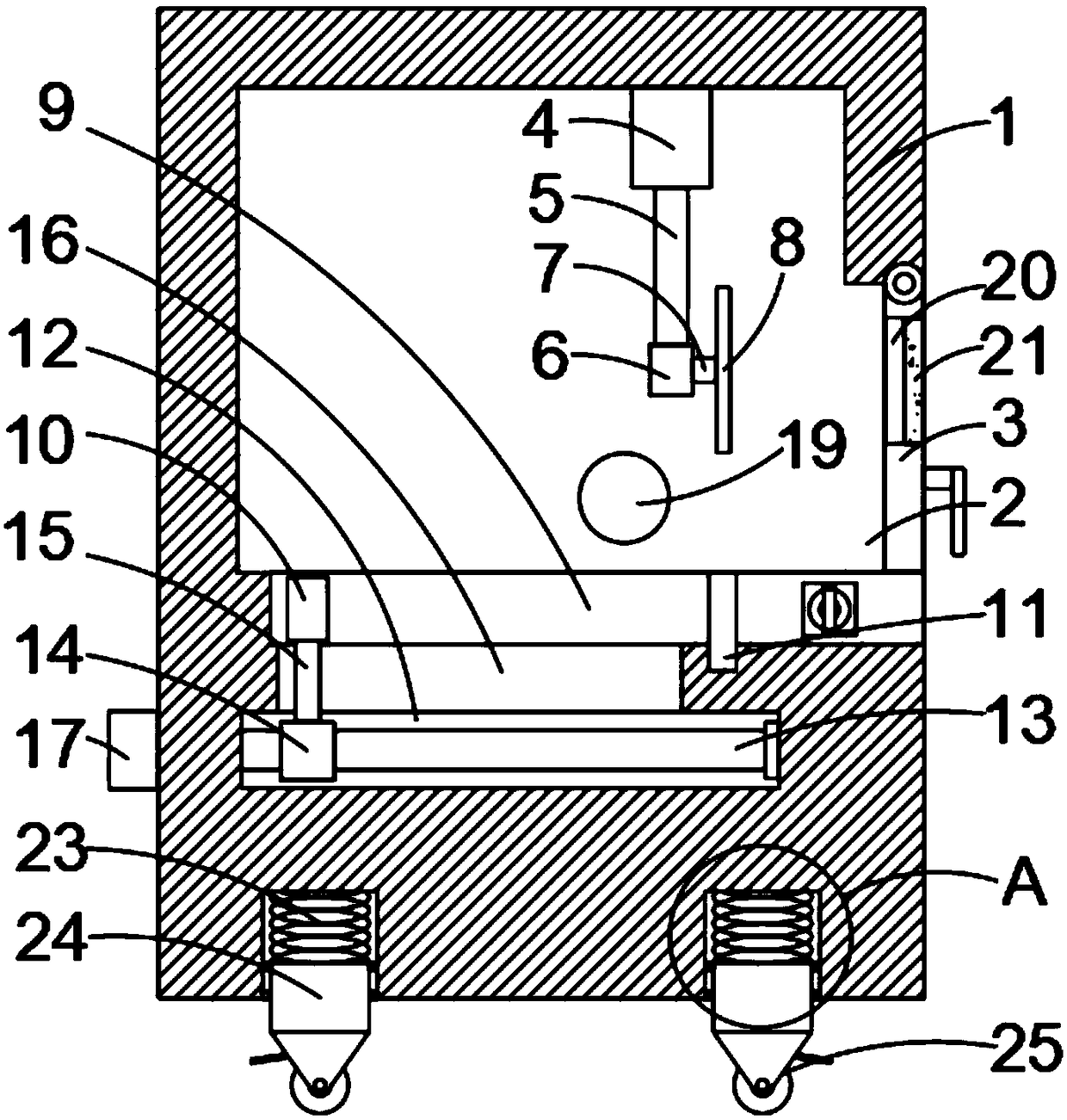

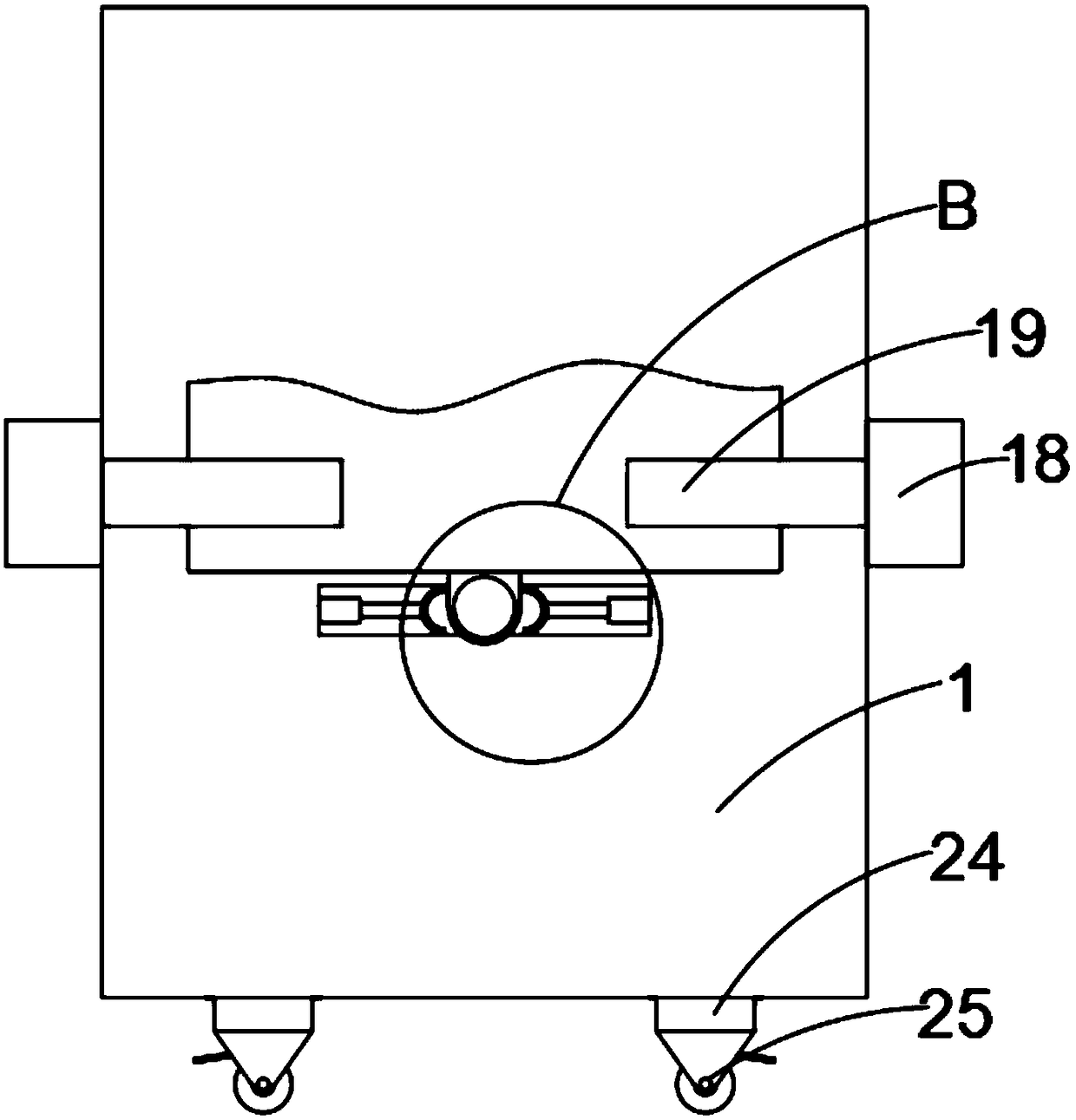

Combined machining testing device of spark electrolysis discharging, applied to semicircle orifice

PendingCN110293272ANo intermittent feed defectsHigh transmission precisionMaterial analysis by optical meansElectricityMotor drive

The invention discloses a combined machining testing device of spark electrolysis discharging, applied to a semicircle orifice. The device comprises a testable base, wherein a guide rail platform is disposed on the testable base; an electric main shaft clamp is in slide connection to a side edge of the guide rail platform; a high-speed electric main shaft is installed in the electric main shaft clamp; an electric main shaft clamping head is installed on the bottom of the high-speed electric main shaft; a tool electrode is clamped by the electric main shaft clamping head; a to-be-processed workpiece and a prefabricated mold which are adhered mutually are clamped inside a box body structure of an electrolytic bath; a micro lead screw vertically passes through a channel in which a semicircleguide hole of the prefabricated mold is located; a semicircle servo plate is disposed on the top of the micro lead screw; and the semicircle servo plate is in clearance fitting inside the semicirclecolumnar guide hole. In the device, the micro lead screw which is driven by a second servo motor drives the semicircle servo plate to make axial feeding; synchronous and homodromous constant-speed feeding is realized between the micro lead screw and the high-speed electric main shaft; and intermittent feeding defects are not generated during transmission of the micro lead screw, so actual transmission accuracy is increased.

Owner:ANHUI UNIV OF SCI & TECH

Automatic cutting device for steel pipe

InactiveCN108705152AAdjustable lengthEasy to operateWork clamping meansLarge fixed membersEngineeringMechanical engineering

The invention discloses an automatic cutting device for a steel pipe. The automatic cutting device comprises a casing, wherein the casing is hollow, a side wall of one side of the casing opens a feeding port communicating with the interior thereof, and the opening of the feeding port is rotatably connected with a cover plate. A handle is fixedly connected to the side wall of the cover plate a first cylinder is fixedly connected to the upper inner wall of the casing, and a first piston rod is connected to the output end of the first cylinder in a sliding mode. A first driving motor is fixedly connected to one end, away from the first cylinder, of the first piston rod, a first rotating shaft is fixedly connected to the output end of the first driving motor, and a cutting wheel is fixedly arranged on one end, away from the first driving motor, of the first rotating shaft in a sleeving mode. A sliding groove is formed in the casing, and the opening of the sliding groove is disposed towardthe feeding port. The automatic cutting device for the steel pipe has the advantages that operation is simple, use is convenient, adjustment of the cutting length of steel pipe materials is convenient, application range of the device is improved, and safety performance is high.

Owner:湖州恒奥成套电气设备有限公司

Test tube heating bracket for traditional Chinese medicine and pharmacy tests

InactiveCN108554476AEasy to useLabor savingHeating or cooling apparatusTest tube stands/holdersPharmacyEngineering

The invention discloses a test tube heating bracket for traditional Chinese medicine and pharmacy tests. The test tube heating bracket comprises a bottom plate, wherein a plurality of support rods areuniformly fixedly connected with the upper end of the bottom plate; the walls of the support rods are moveably sleeved by sleeves; a plurality of screw holes are formed in the sleeves and walls of the support rods correspondingly; the sleeves are in fastened connection with the support rods through bolts; two connecting rods are fixedly connected with the outer wall of each sleeve symmetrically;positioning cylinders are fixedly connected with ends far away from the sleeves, of the connecting rods; through holes are formed in the walls of the positioning cylinders; T-shaped pull rods are sleeved by the through holes through guide bearings; arc-shaped clamping plates are fixedly connected with ends inside the positioning cylinders, of the pull rods; a plurality of return springs are fixedly connected between the outer side walls of the arc-shaped clamping plates and the inner walls of the positioning cylinders; a plurality of alcohol burners for heating test tubes are fixedly arrangedat the upper end of the bottom plate; a protection cover is connected with one side of the upper end of the bottom plate through hinges. The test tube heating bracket facilitates stably clamping of test tubes of different diameter sizes and is wide in application range, and the labor can be saved.

Owner:广西奕琦科技有限公司

Easy-to-install bracket for inspection of auto parts

InactiveCN108663207AEasy to moveEasy to detectVehicle testingMachine part testingMotor vehicle partArchitectural engineering

Owner:苏州傲达通信设备有限公司

Spraying device with quick drying function for production of steel sheets of windscreen wipers

InactiveCN112191431APrevent leakageEvenly distributedLiquid spraying apparatusSpray boothsMotor vehicle partStructural engineering

The invention discloses a spraying device with a quick drying function for production of steel sheets of windscreen wipers, and relates to the technical field of production of automobile parts. The spraying device specifically comprises a base, a screw rod chuck mechanism, a wedge clamping mechanism, a spraying mechanism and a quick drying mechanism, wherein a supporting column is arranged at oneend of the top end of the base; and the screw rod chuck mechanism is arranged at the bottom end of a lifting ring. According to the spraying device with the quick drying function for production of thesteel sheets of the windscreen wipers, the quick drying mechanism is arranged, a circulating mechanism is arranged, so that uniform distribution of the temperature in a cavity of a rack is guaranteed; a sliding groove which is shaped like a Chinese character 'jing (well)' is formed in the surface of a drying layer, so that a magnetic base can freely move on the surface of the sliding groove conveniently, and the adaptability to to-be-dried materials of different types and specifications is high; the magnetic base guarantees effective adsorption, and meanwhile, the contact between the magneticbase and the to-be-processed materials is reduced, so that the drying effect is guaranteed; and the drying layer and a heating layer can run at different rates due to the arrangement of a differential mechanism, so that the to-be-dried materials are uniformly heated, the drying rates of different parts are consistent, and the applicability is higher.

Owner:东莞市龙飞数控科技有限公司

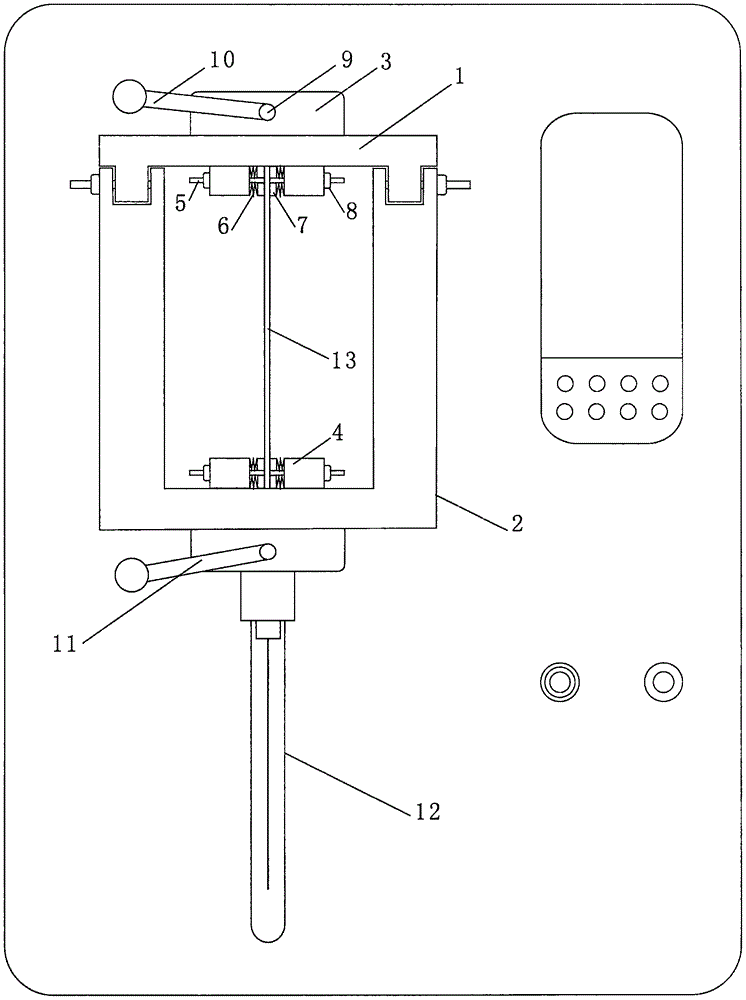

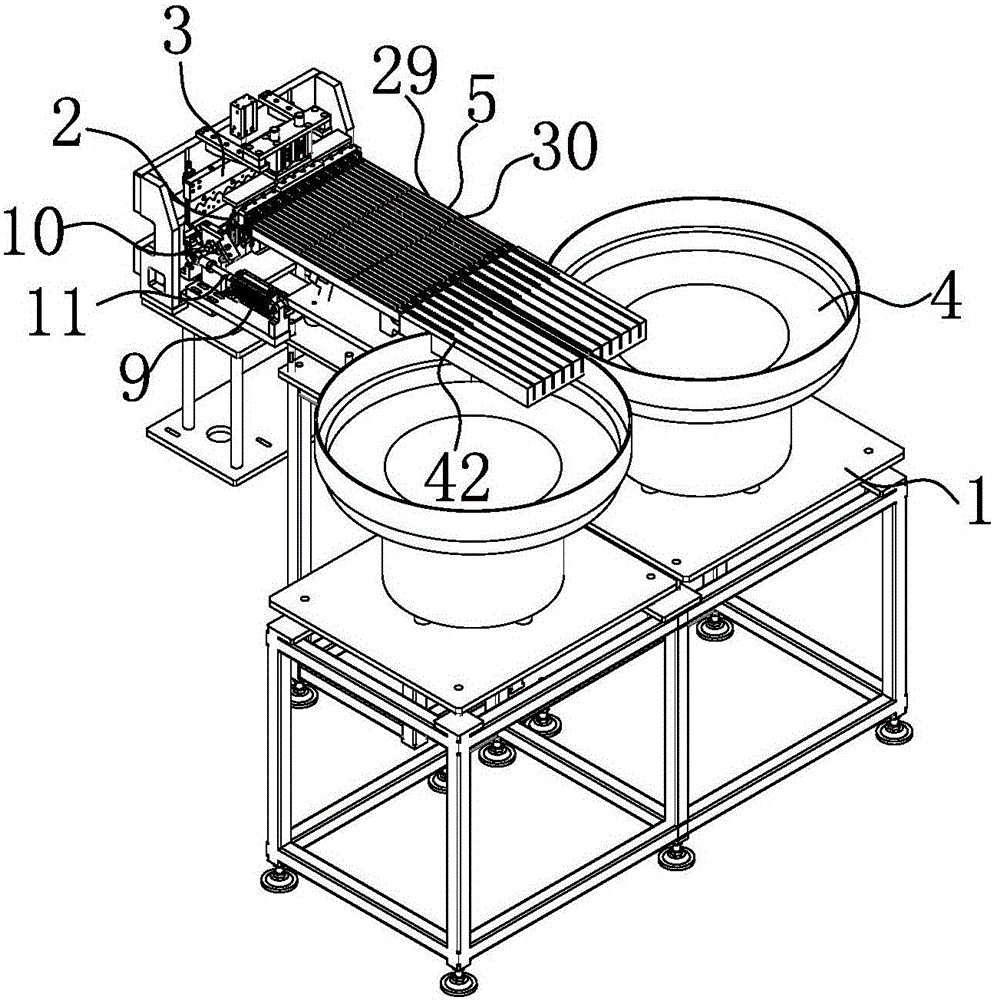

Two-way tube and catheter assembling device

PendingCN106064298ARealize the assemblyImprove accuracyMetal working apparatusMedical equipmentEngineering

The invention belongs to the technical field of medical equipment, and particularly relates to a two-way tube and catheter assembling device which comprises a rack. The two-way tube and catheter assembling device is characterized in that a two-way tube fixture and a catheter fixture are arranged in the rack; a vibrator bowl is arranged on one side of the two-way fixture; a two-way tube conveying mechanism capable of conveying a two-way tube on the vibrator bowl to the end where the two-way fixture is positioned is arranged between the vibrator bowl and the two-way fixture; the two-way fixture is connected with a rotary driving mechanism capable of driving the two-way fixture to be turned over, and further connected with a transverse driving mechanism capable of driving the two-way fixture to move horizontally; and after the two-way fixture is turned over in place, the two-way tube on the two-way fixture is positioned on the same axis with a catheter on the catheter fixture. The two-way tube and catheter assembling device has the advantages that the assembling accuracy between the two-way tube and the catheter is high, and the overall design is reasonable.

Owner:梁启明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com