Patents

Literature

30results about How to "High rotational positioning accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

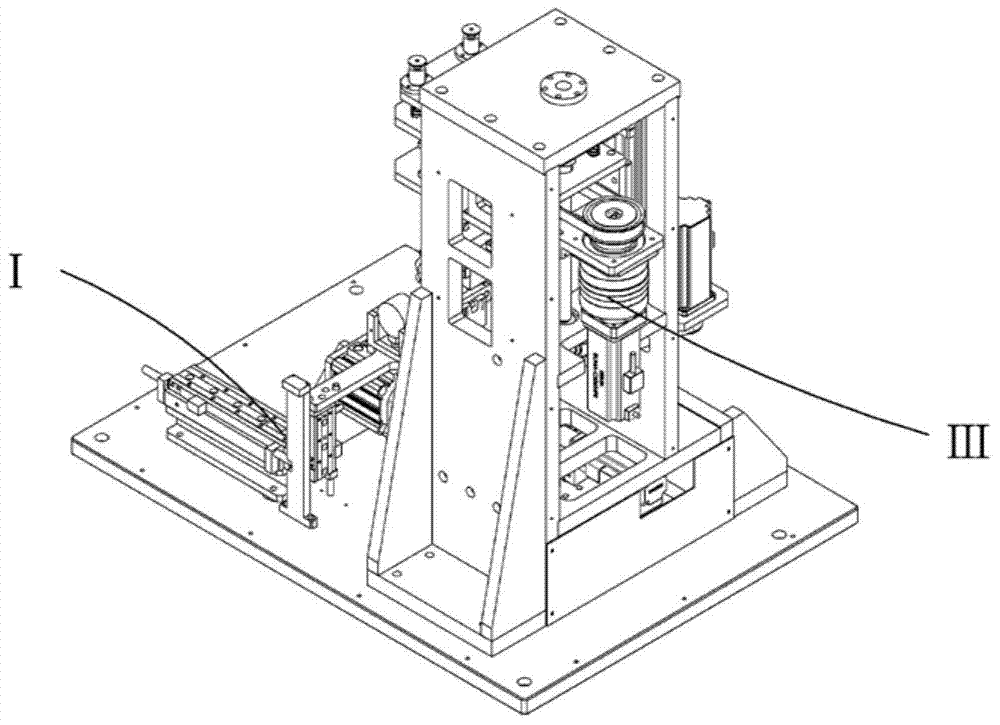

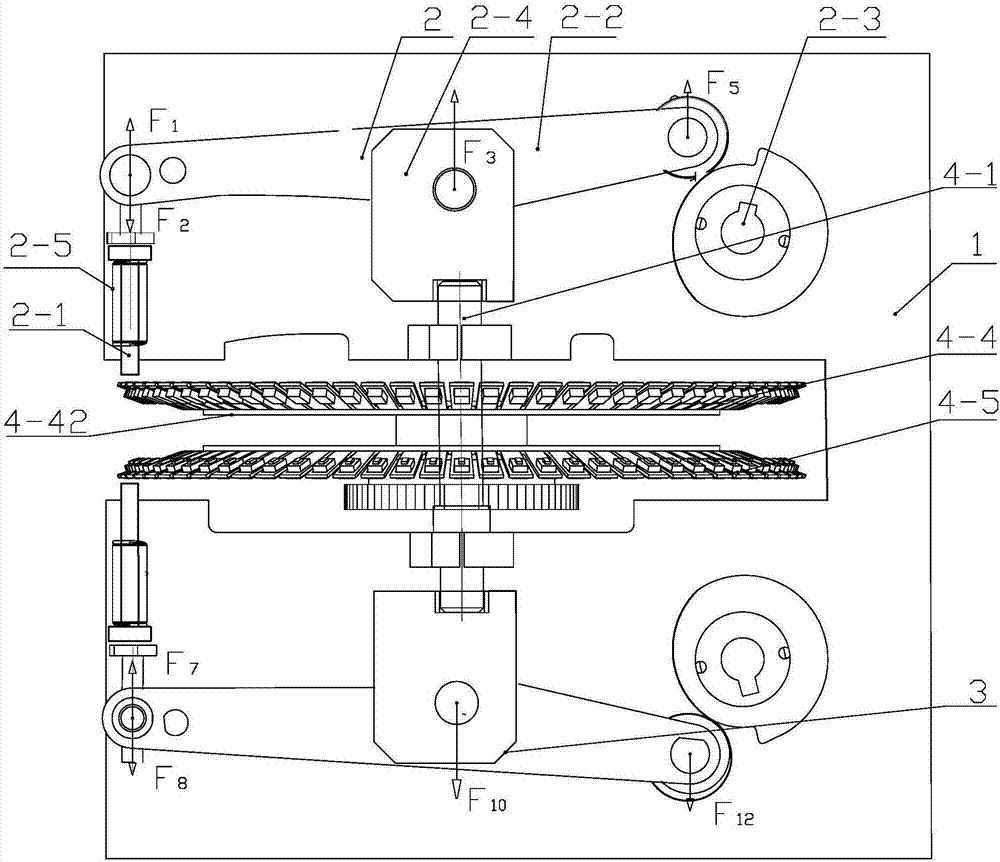

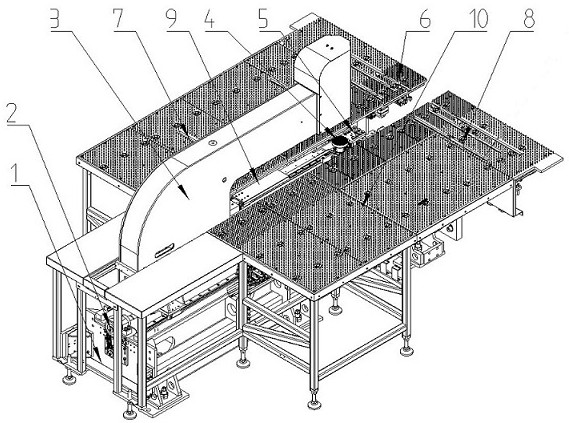

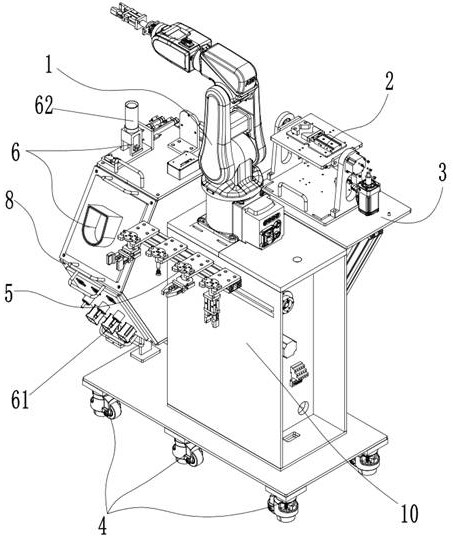

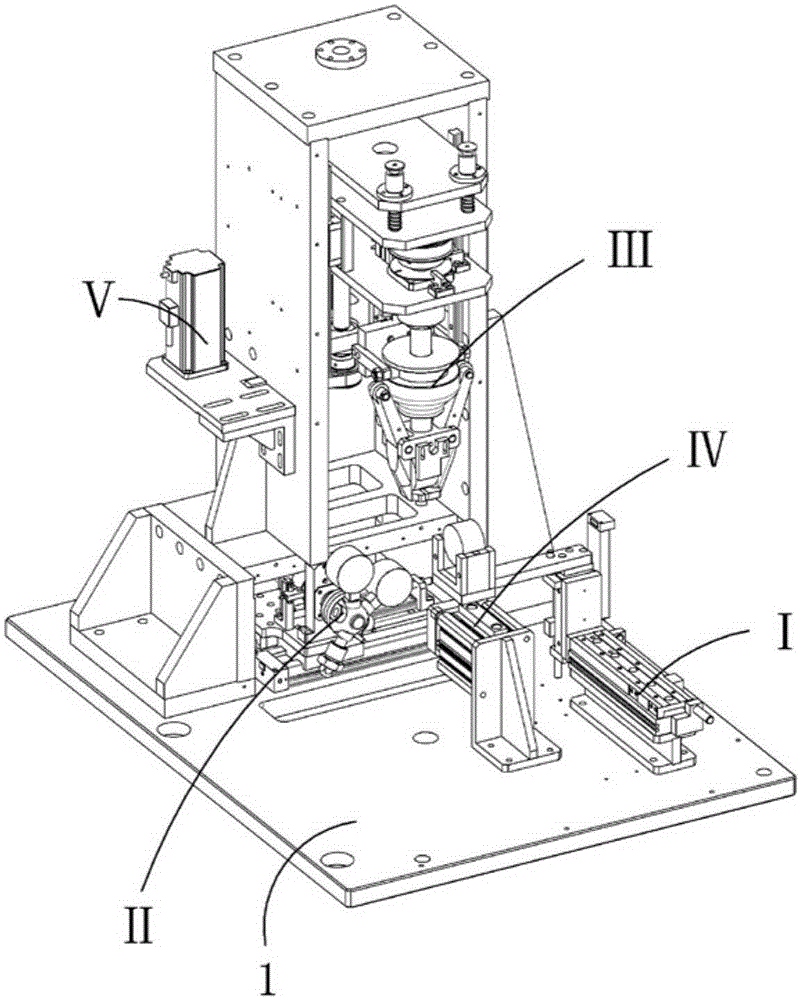

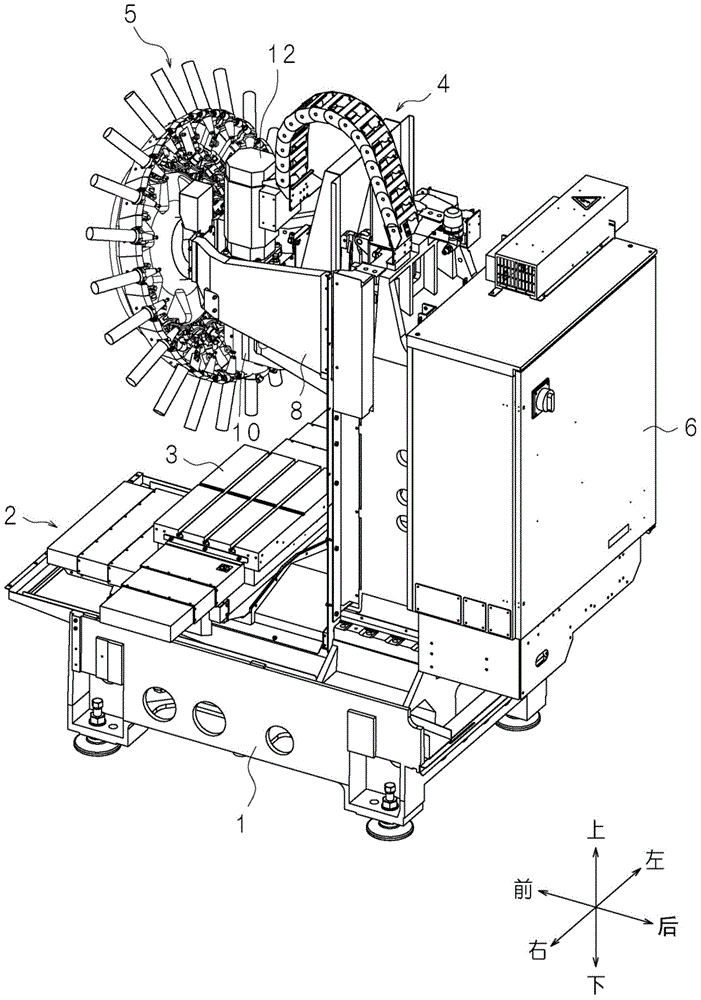

Pressure meter assembling equipment

ActiveCN103692207AGuaranteed not to deviate fromEasy and stable clampingAssembly machinesMetal working apparatusEngineeringCam

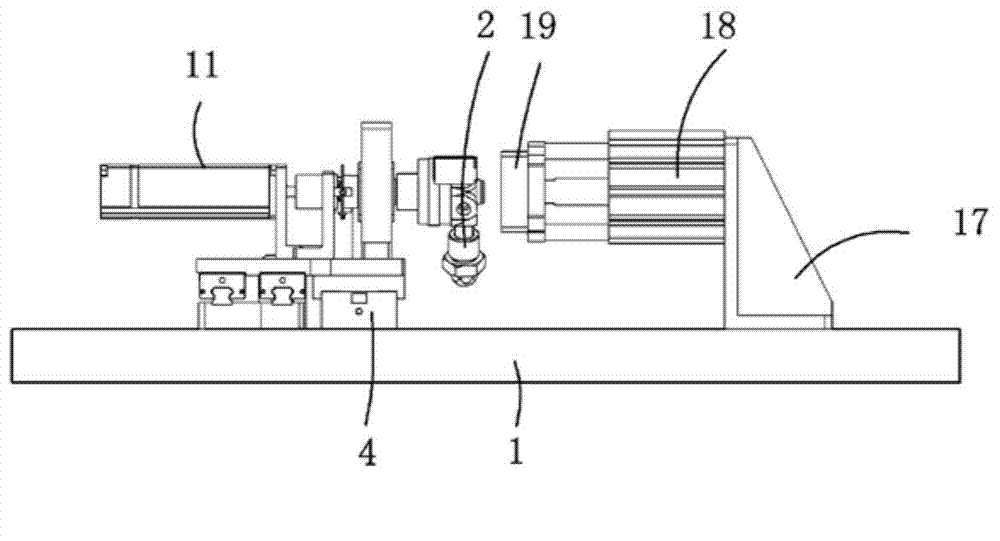

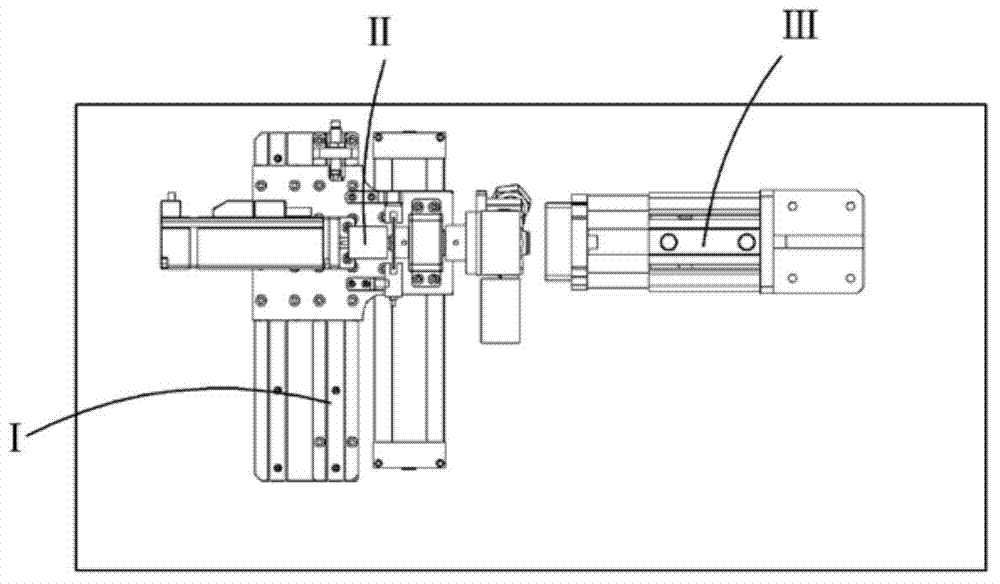

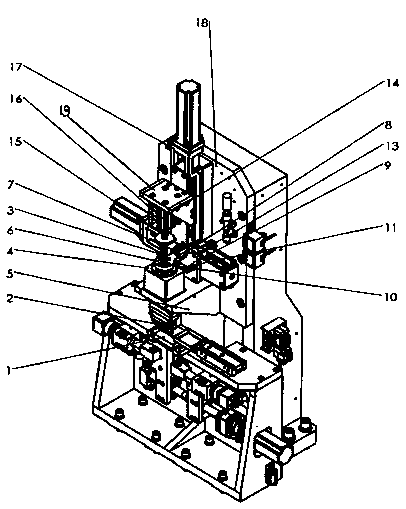

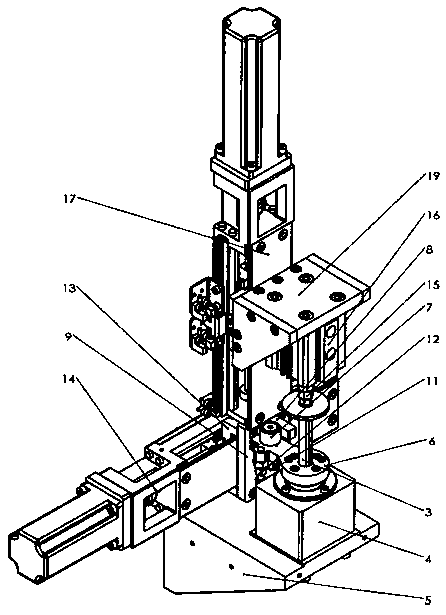

The invention relates to pressure meter assembling equipment. A pressure meter is conveyed below a mounting mechanism by a feeding mechanism; a clamping lifting cylinder of the mounting mechanism drives a lifting connection plate to move up and down on a lifting slide rail, a cam is driven to lift, the cam is descended to drive a meter clamping lever to clamp the pressure meter, the cam is ascended to drive the meter clamping lever to loosen the pressure meter, firstly, the meter clamping lever is loosened, a lifting mechanism drives the mounting mechanism to move downwards to clamp the pressure meter, the feeding mechanism returns back to the initial position, then a rotary mechanism is moved to drive a pressure meter seat to move to a place below the mounting mechanism, a compressing mechanism clamps the pressure meter seat, the mounting mechanism is driven by the lifting mechanism to move downwards, and when the pressure meter reaches a place above the pressure meter seat, the mounting mechanism is driven to drive a rotary spindle to rotate, so the pressure meter is rotated and descended to be screwed into the meter seat, and when the torsion achieves a certain value range, the pressure meter stops rotating. The assembly of the pressure meter is full-automatically performed, the labor intensity of operation staff is reduced, and the production cost is reduced.

Owner:BOZHON PRECISION IND TECH CO LTD

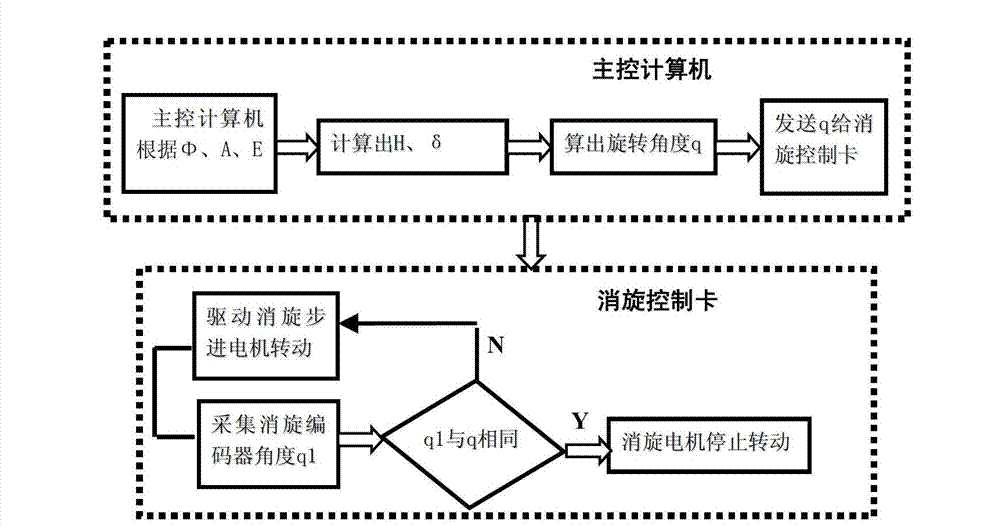

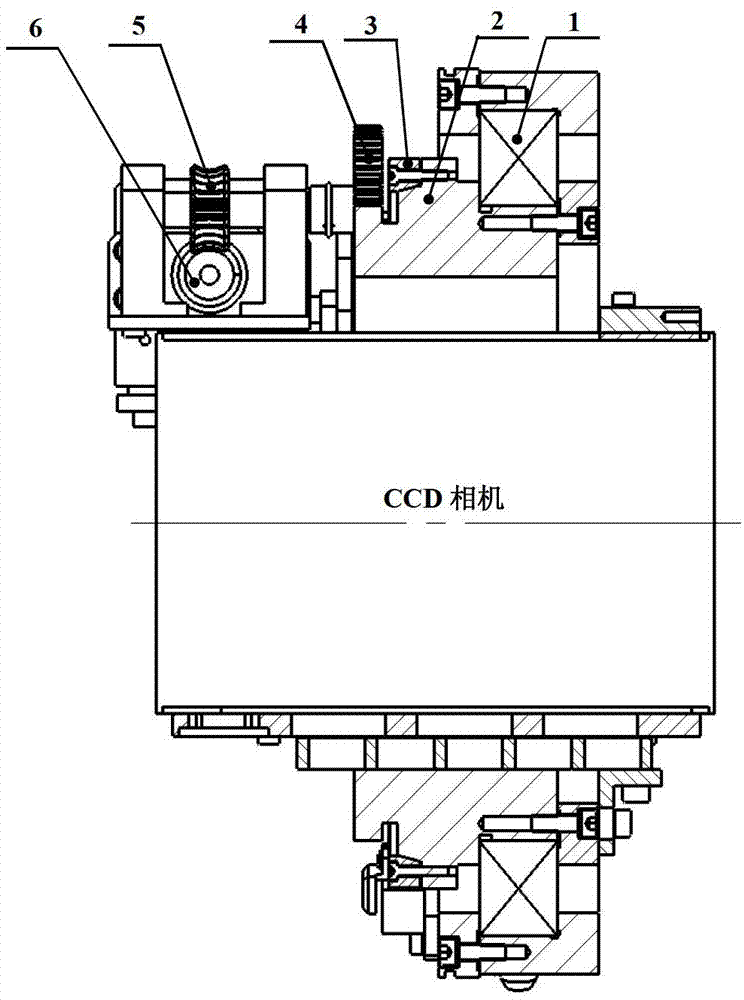

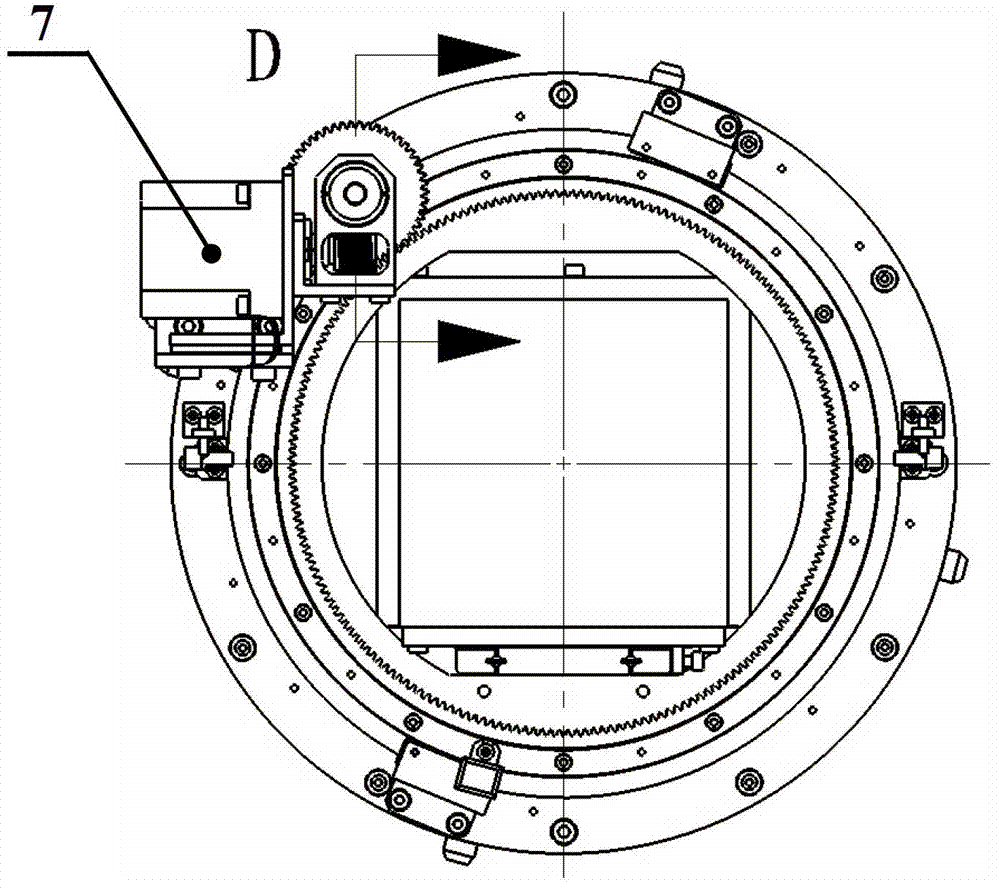

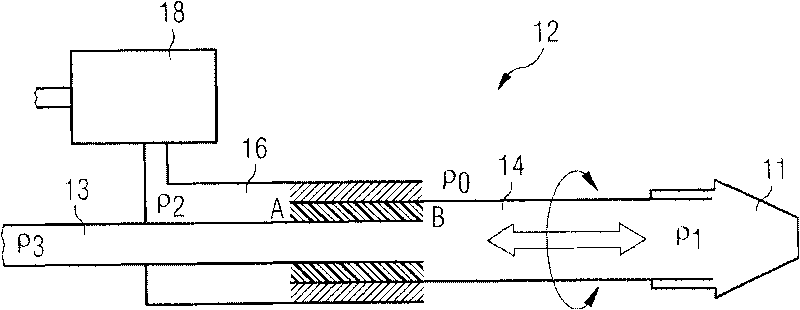

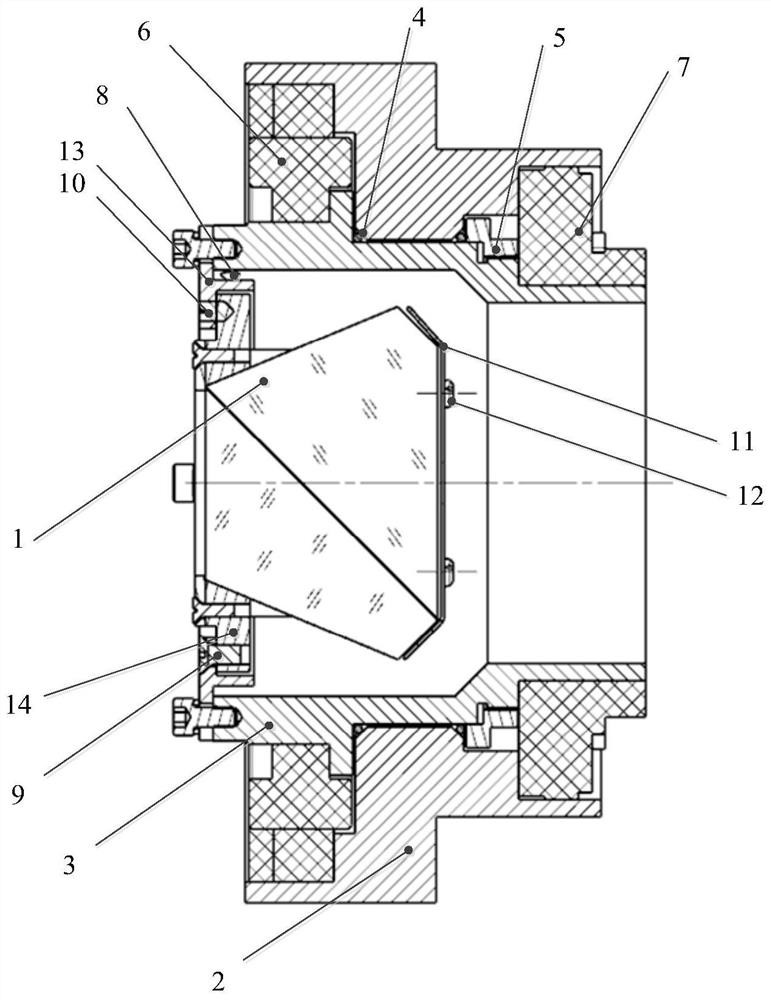

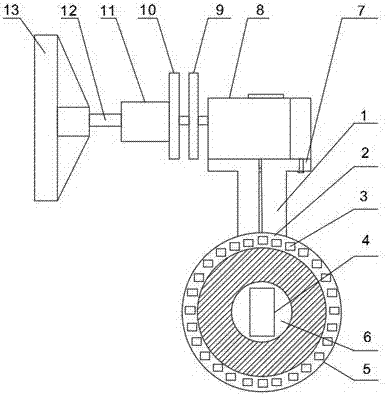

Visual field eliminating rotation mechanism of horizontal telescope

InactiveCN102879897AHigh rotational positioning accuracyHigh rotation accuracyTelescopesFixed starsGrating

The invention provides a visual field eliminating rotation mechanism of a horizontal telescope. The visual field eliminating rotation mechanism comprises a cross roller bearing (1), straight toothed spur gears (2 and 4), a metal reflection type circular grating encoder (3), a worm wheel (5), a worm rod (6), a step motor (7) and a CCD (Charge Coupled Device) camera, wherein the encoder and the bearing are coaxially mounted; and the photosensitive surface of the CCD camera is perpendicular to a rotating shaft. When the telescope is in the process of tracking a fixed star, a rotation angle is calculated by a theoretical model of visual field rotation according to the real-time pointing positions of the telescope: an azimuth angle A and an angular altitude E, the mechanism is driven in real time to drive a CCD to rotate so as to eliminate the visual field rotation phenomenon in the process of tracking the fixed star by the horizontal telescope, the formed images of all the fixed stars on the CCD camera are clear point images all the time in integral time, and the star images are kept to be fixed all the time on a CCD detector. According to the visual field eliminating rotation mechanism, the bearing adopts the cross roller bearing, the metal circular grating is adopted to measure the angle in real time and perform position feedback in the rotation process, and higher rotation positioning precision can be obtained.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

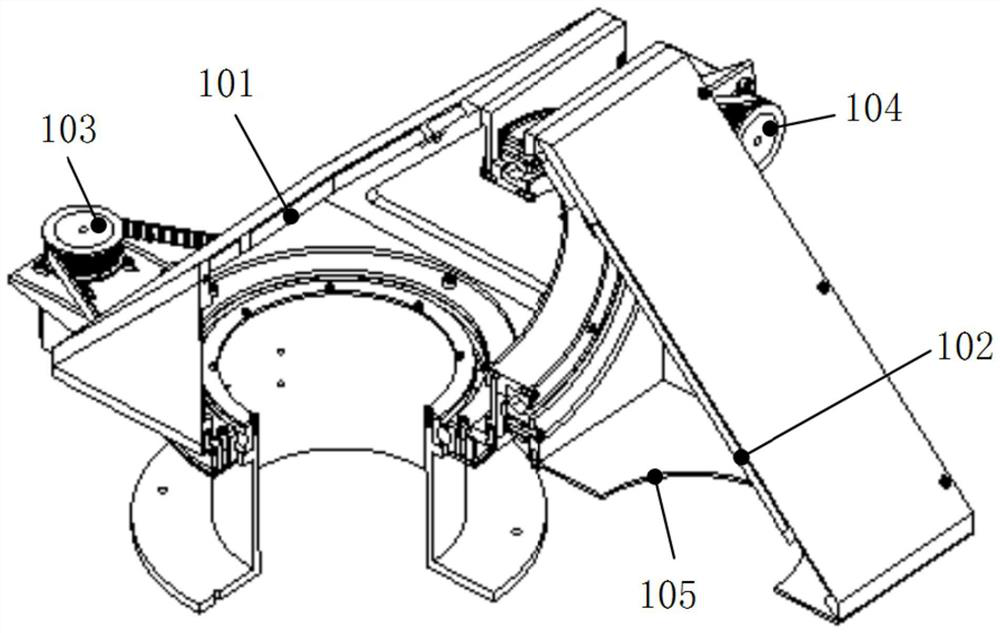

Horizontal rotating mechanism of photovoltaic tracker

InactiveCN103138629ASimple structureReasonable designPhotovoltaic supportsPhotovoltaic energy generationEngineeringLower half

The invention discloses a horizontal rotating mechanism of a photovoltaic tracker. The horizontal rotating mechanism comprises a support base, a servo motor fixedly connected at the top end of the support base, a worm and worm gear reducing mechanism connected with an output shaft of the servo motor, a harmonic gear reducing mechanism connected with the worm and worm gear reducing mechanism, a vertical shaft connected with the harmonic gear reducing mechanism and a horizontal rotating platform connected at the top end of the vertical shaft. The worm and worm gear reducing mechanism and the harmonic wave gear reducing mechanism are both installed in the reducing box which comprises a lower box body fixedly connected at the top end of the support base and an upper box body movably connected at the top end of the lower box body, a vertical bearing is installed in the upper box body, the lower half part of the vertical shaft is installed in the vertical shaft, and the top end of the upper box body is connected with a vertical bearing cover. The horizontal rotating mechanism is simple in structure, reasonable in design, convenient to achieve, high in intelligence degree, convenient to use and operate, high in rotating and positioning accuracy, low in cost, strong in practical applicability, good in using effect and convenient to popularize and use.

Owner:XIAN DAYU PHOTOELECTRIC TECH

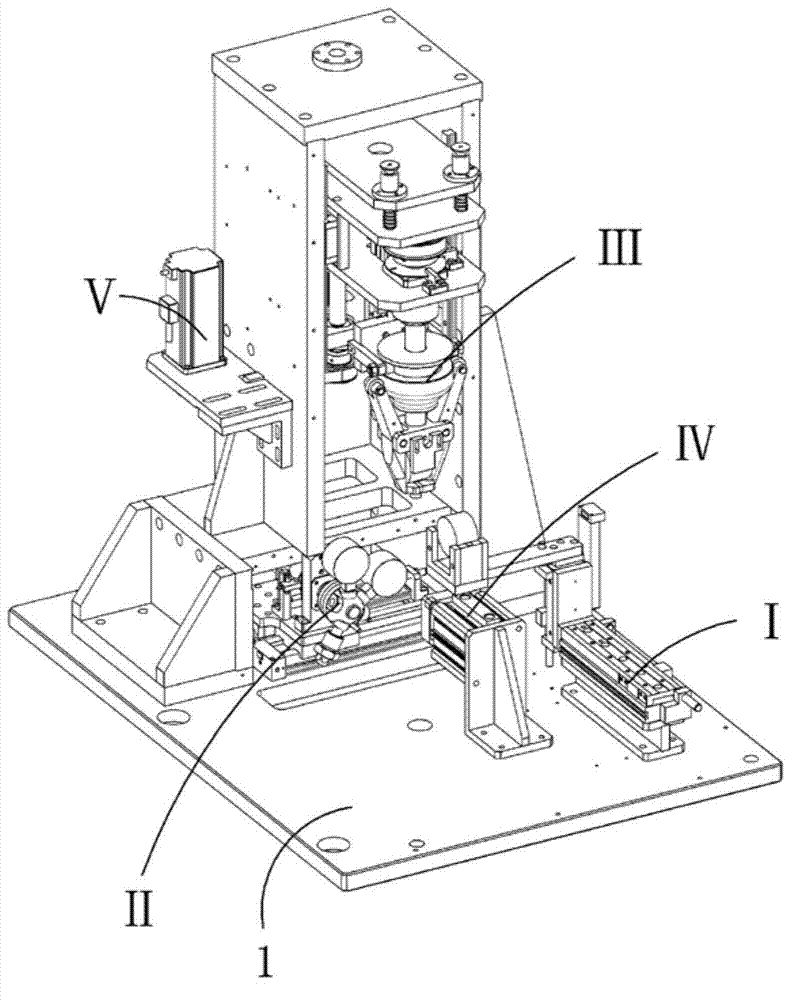

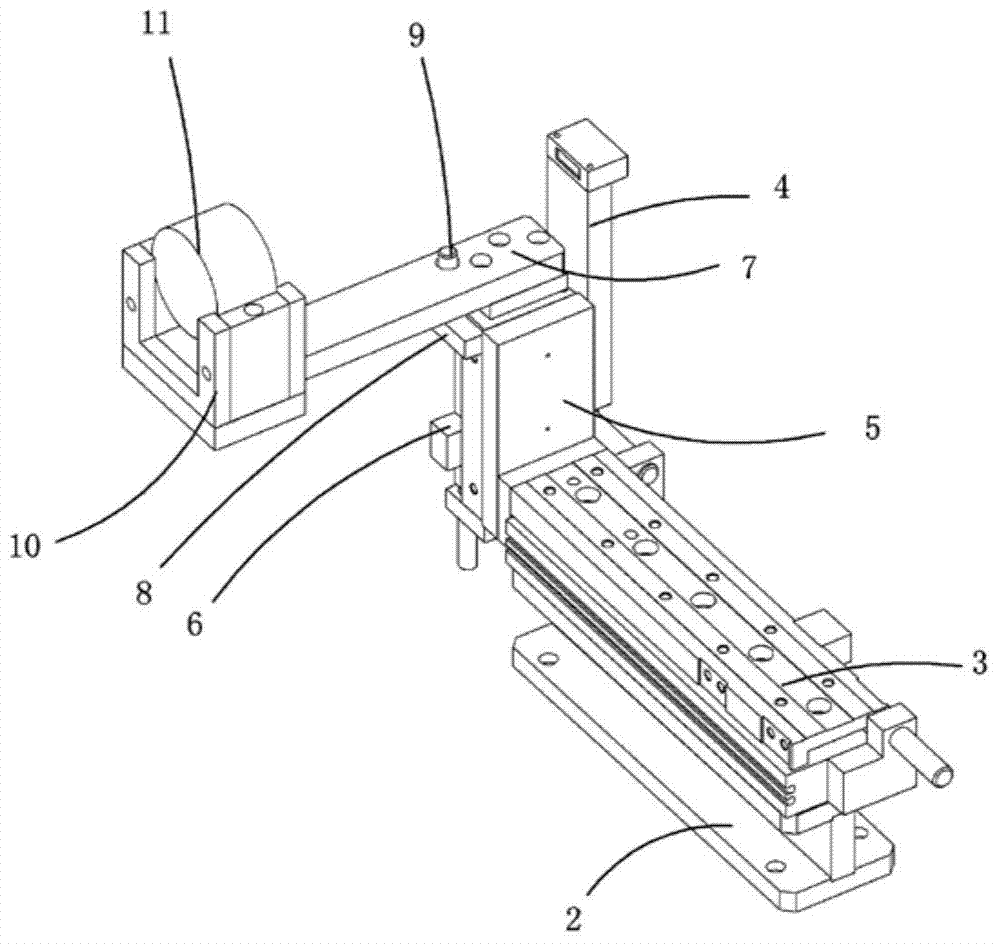

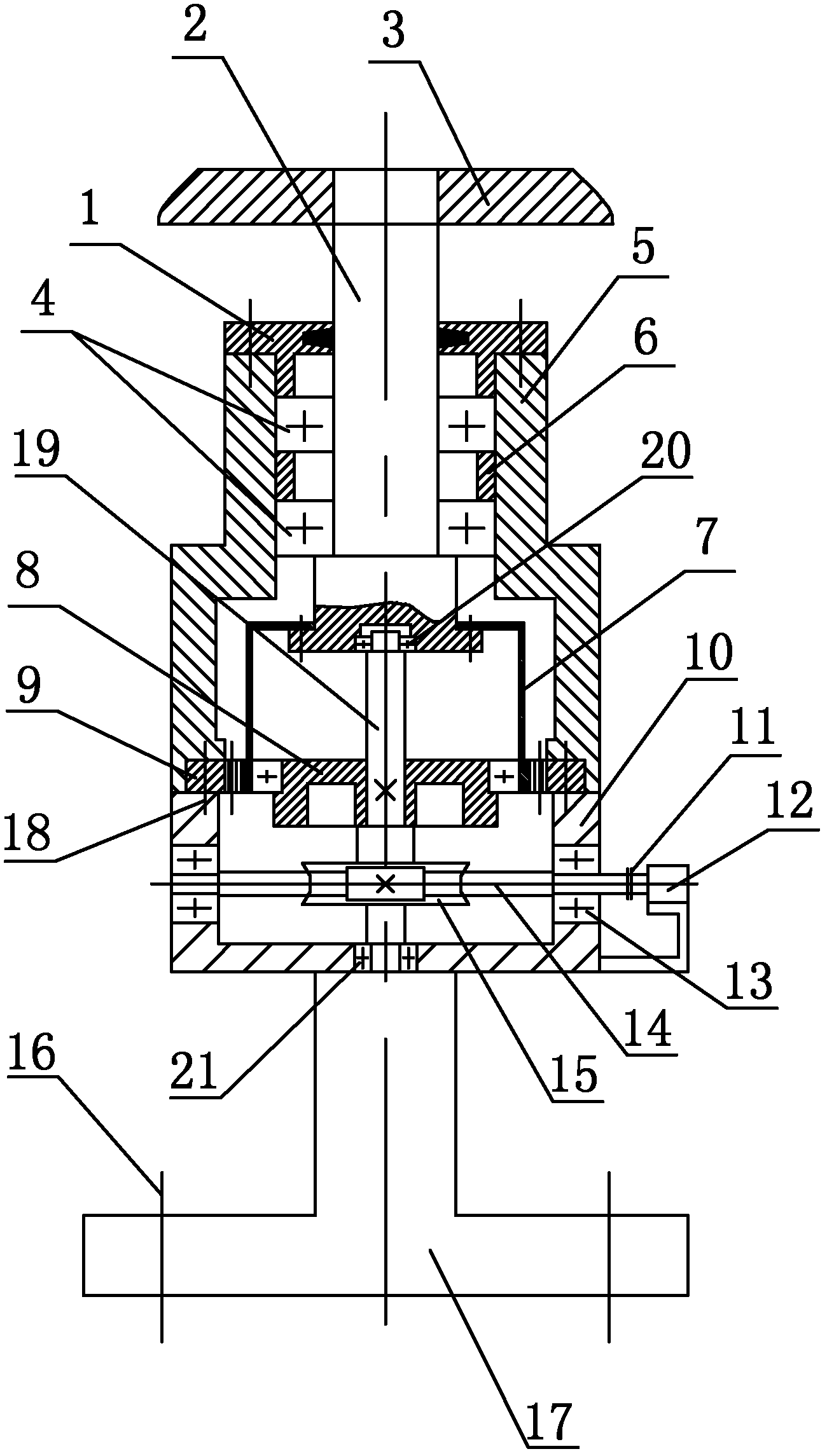

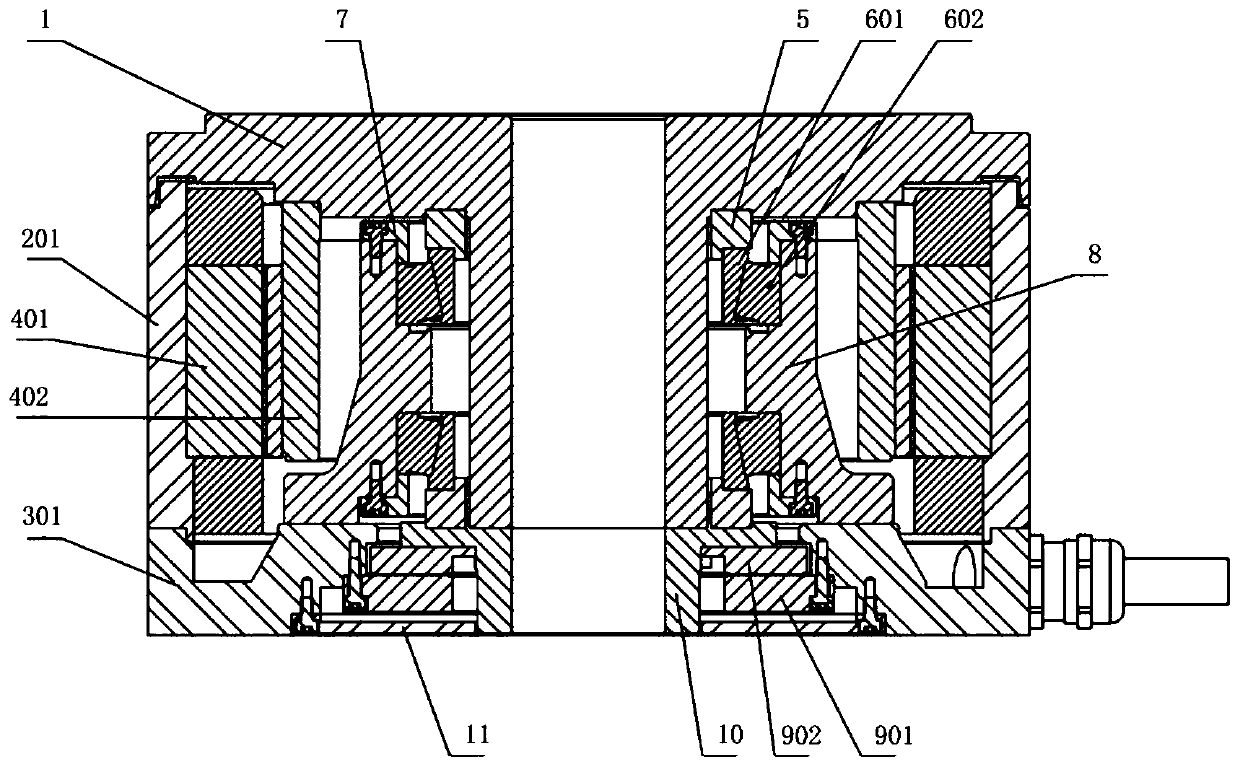

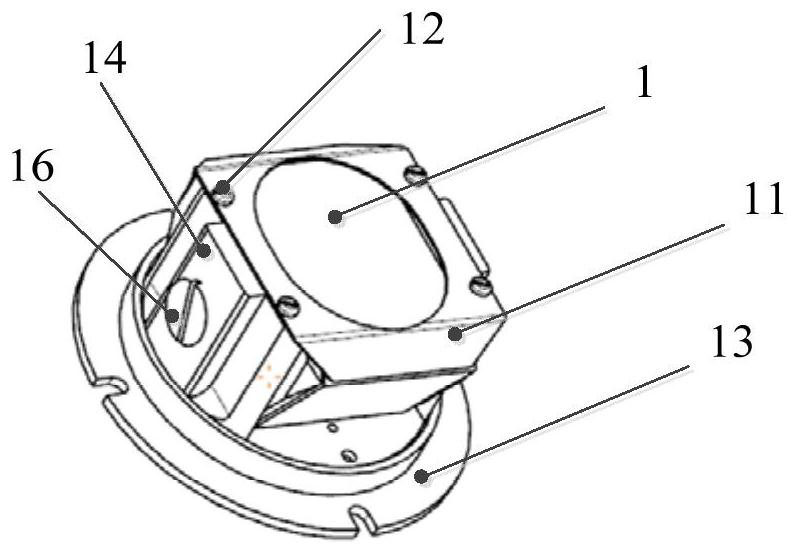

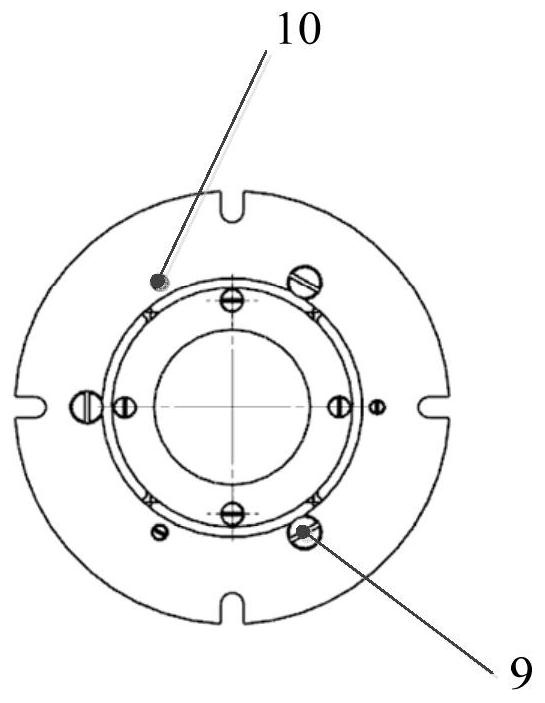

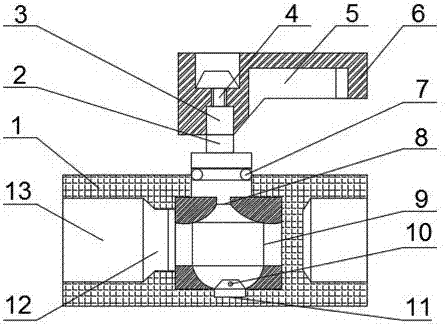

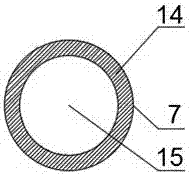

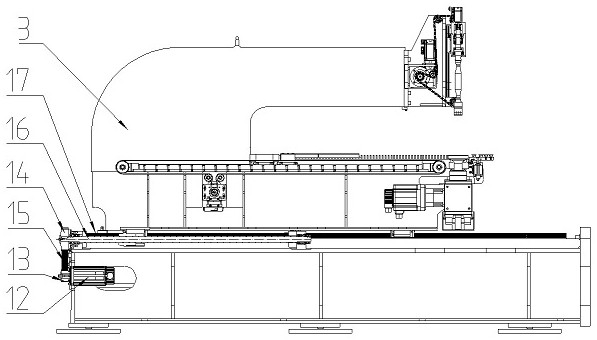

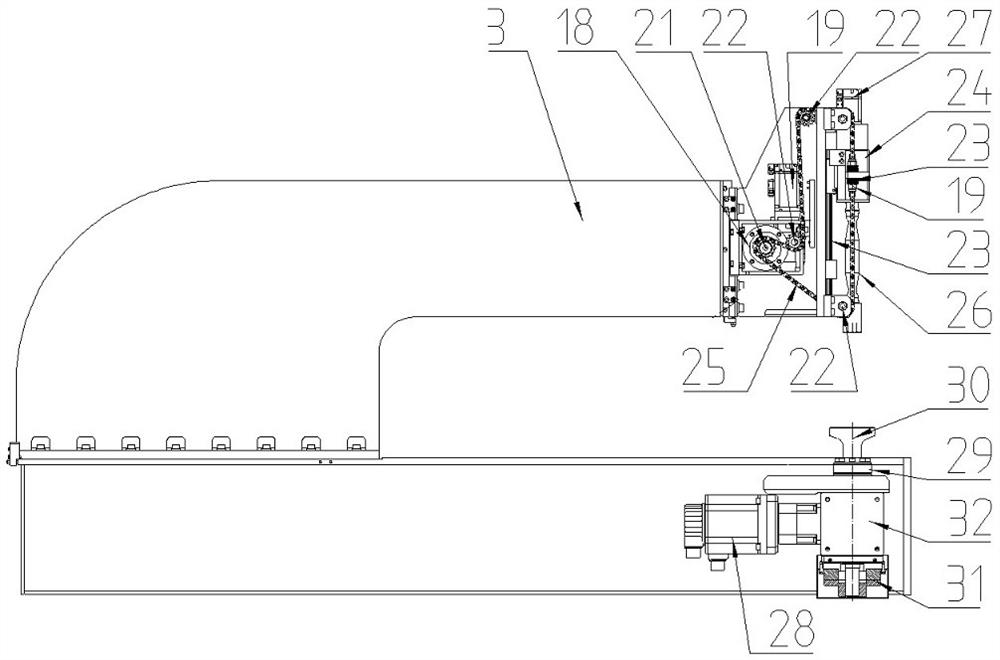

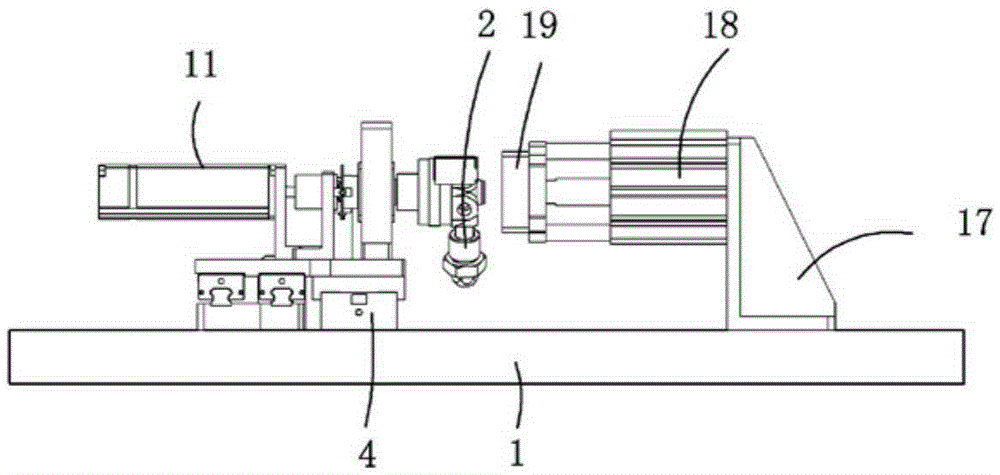

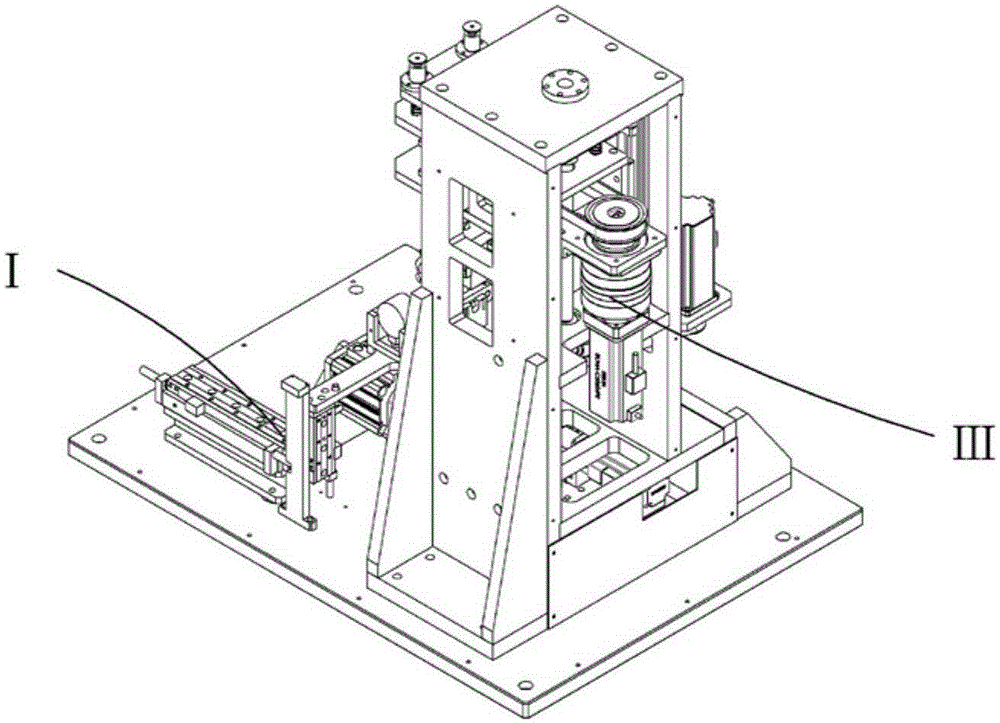

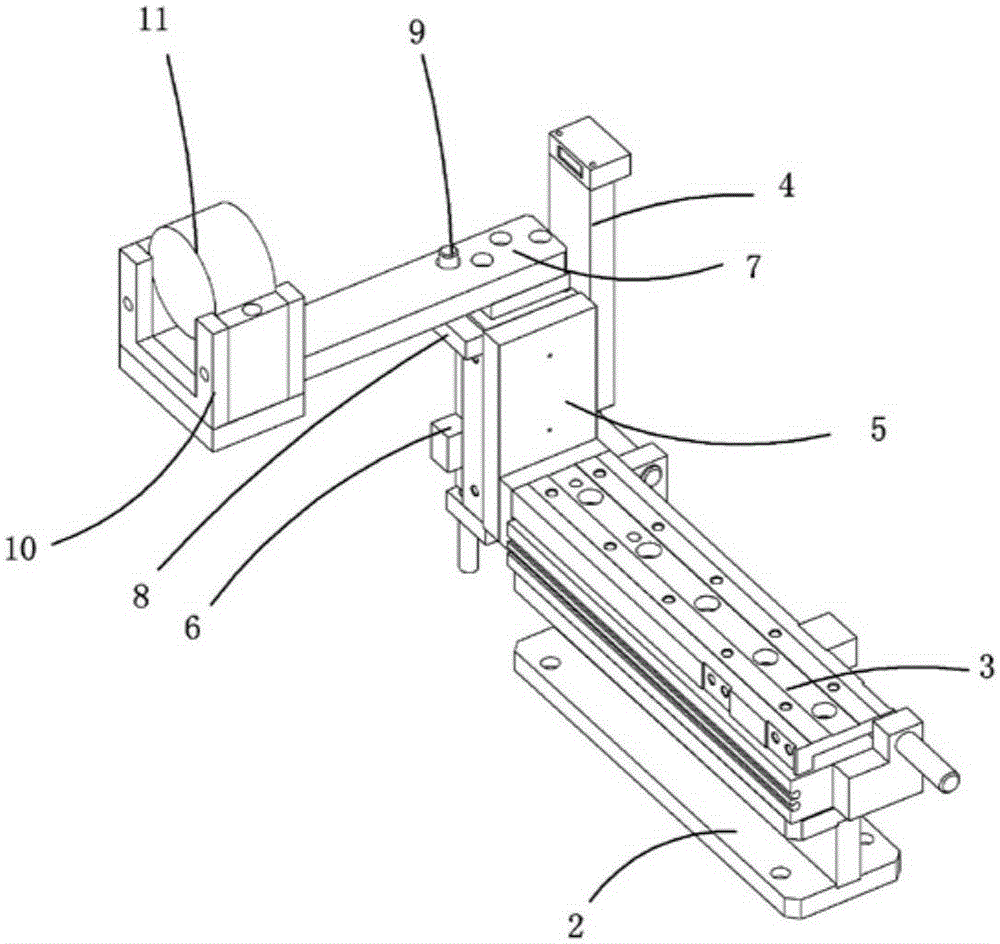

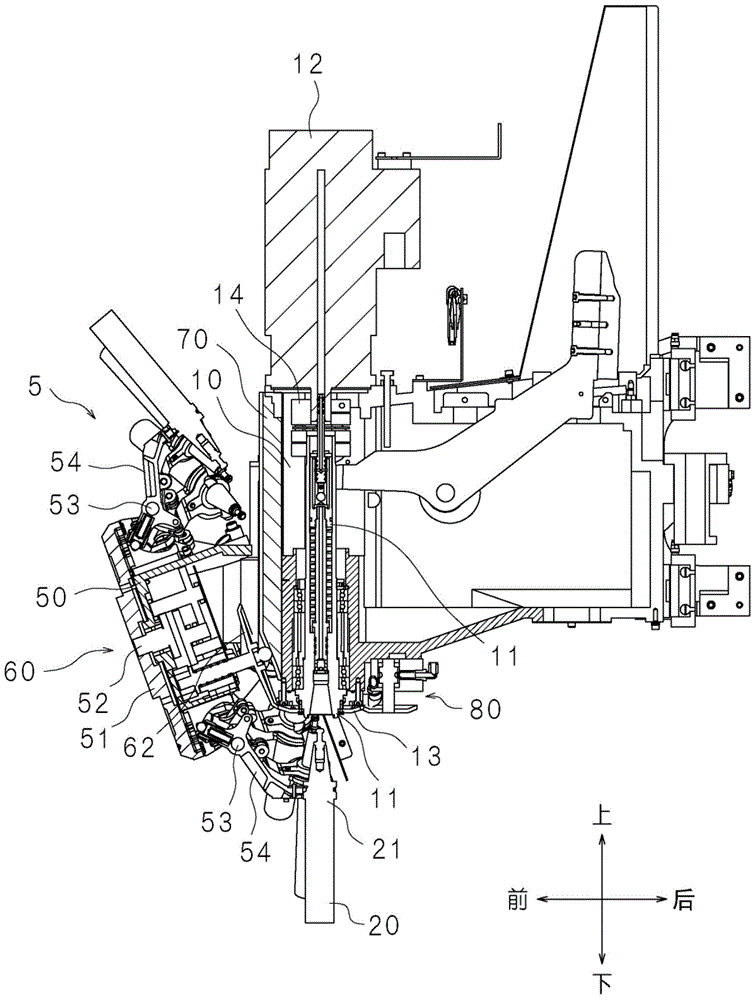

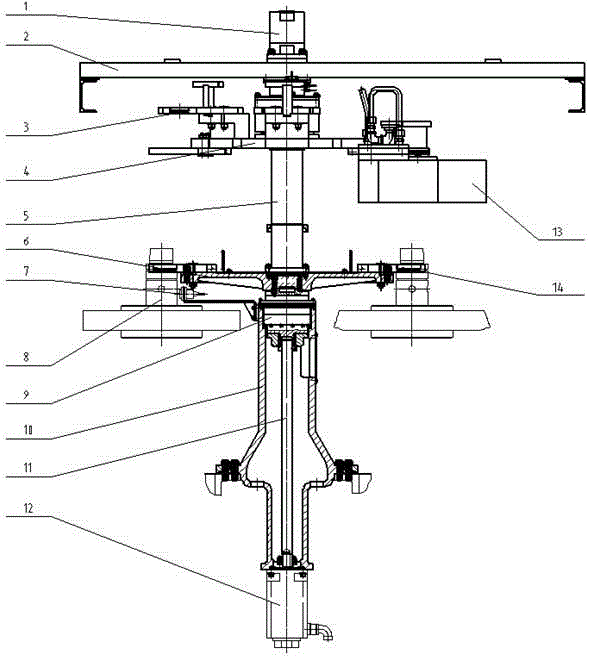

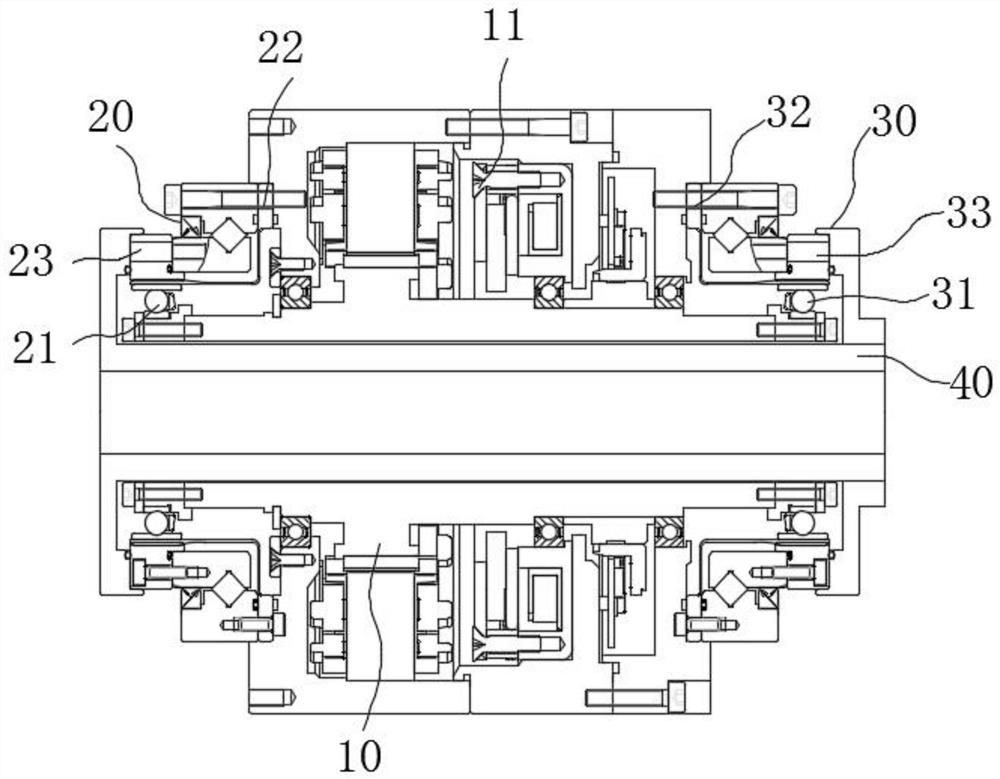

Pressure meter seat moving mechanism

ActiveCN103692181AHigh rotational positioning accuracyEasy and stable clampingMetal working apparatusEngineeringFree rotation

The invention relates to a pressure meter seat moving mechanism, comprising a bottom plate, a mobile module, a rotary module, a clamping module, a pressure meter seat and a pressure meter; the mobile module and the clamping module are arranged on the bottom plate respectively; the rotary module is arranged on the mobile module; the pressure meter seat is positioned on the rotary module by a clamp; the pressure meter is mounted on the pressure meter seat; a mobile cylinder of the mobile module drives the pressure meter seat to a machining position; the direction of the pressure meter seat is rotated to a designated position by the rotary module, then a clamping cylinder clamps the pressure meter seat and ensures that the pressure meter seat is not loosened in the use process, and the pressure meter seat can freely rotate in the rotation process. The pressure meter seat moving mechanism can perform rotation motion while clamping, the rotating positioning precision is high, and a work position is not deviated as a rotary motor of the rotary module can be braked. The labor intensity of operation staff is reduced, and the production cost is reduced.

Owner:BOZHON PRECISION IND TECH CO LTD

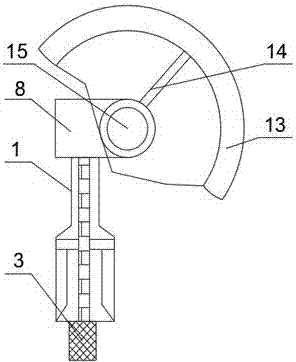

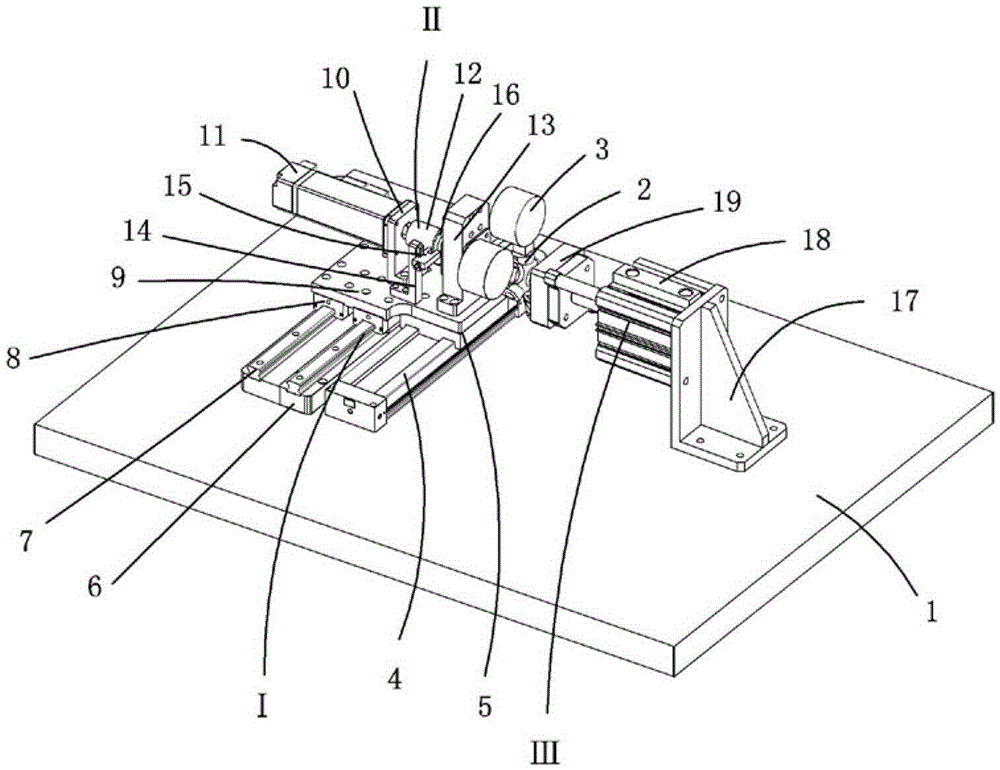

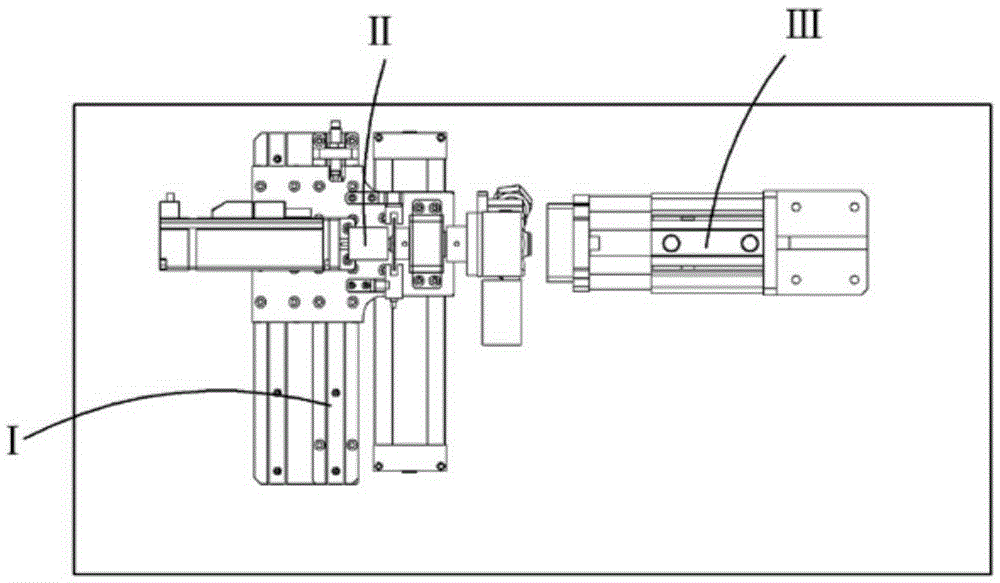

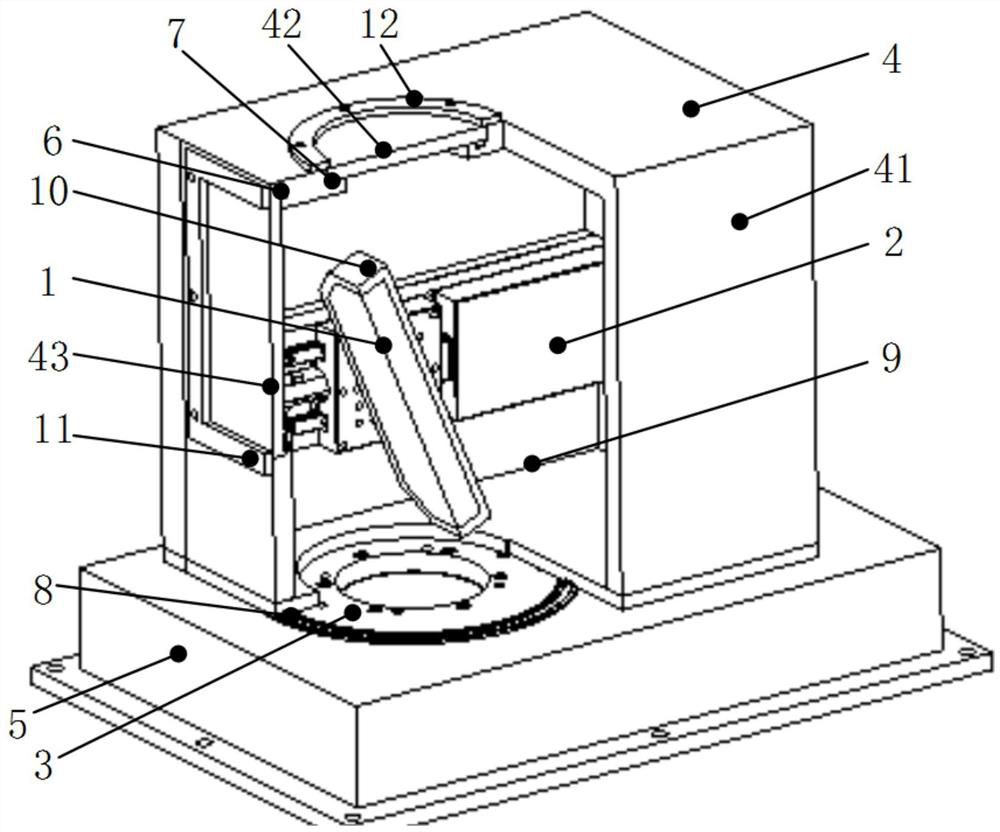

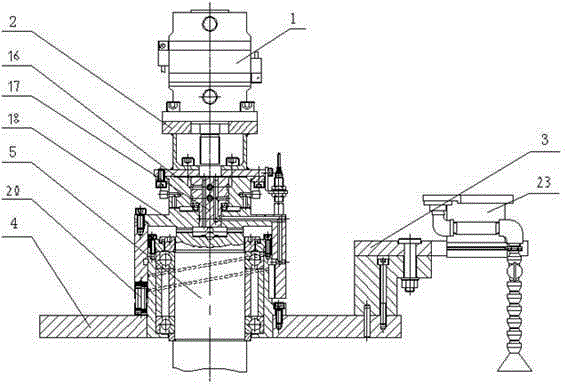

Precise rotating, aligning and pre-pressing execution mechanism of bonder

PendingCN108710231AImprove decomposition abilityHigh rotational positioning accuracyNon-linear opticsCamEngineering

The invention discloses a precise rotating, aligning and pre-pressing execution mechanism of a bonder and solves the problem that existing bonding rotating positioning mechanisms are low in stabilityand aligning accuracy. A pressing-down rotating spline shaft (3) is movably arranged in a rotating bearing (4), an adsorption head mechanism (2) is arranged at the lower end of the pressing-down rotating spline shaft (3) below the rotating bearing (4), the upper end of the pressing-down rotating spline shaft (3) above the rotating bearing (4) is connected with a rotatable output shaft of a rotatable pre-pressing cylinder (16), a screw module (14) moving horizontally is fixedly arranged on the vertical face of an inverted-L-shaped mounting plate (19), a rotating cantilever swing rod (6) is fixedly connected on the pressing-down rotating spline shaft (3) above the rotating bearing (4), a pin shaft and a cam driven bearing (7) are fixedly arranged on the upper end face of the outer side of the rotating cantilever swing rod (6), and the cam driven bearing (7) and a push rod (8) are in movable leaning-against connection. Rotating positioning accuracy is improved.

Owner:TAIYUAN FENGHUA INFORMATION EQUIP

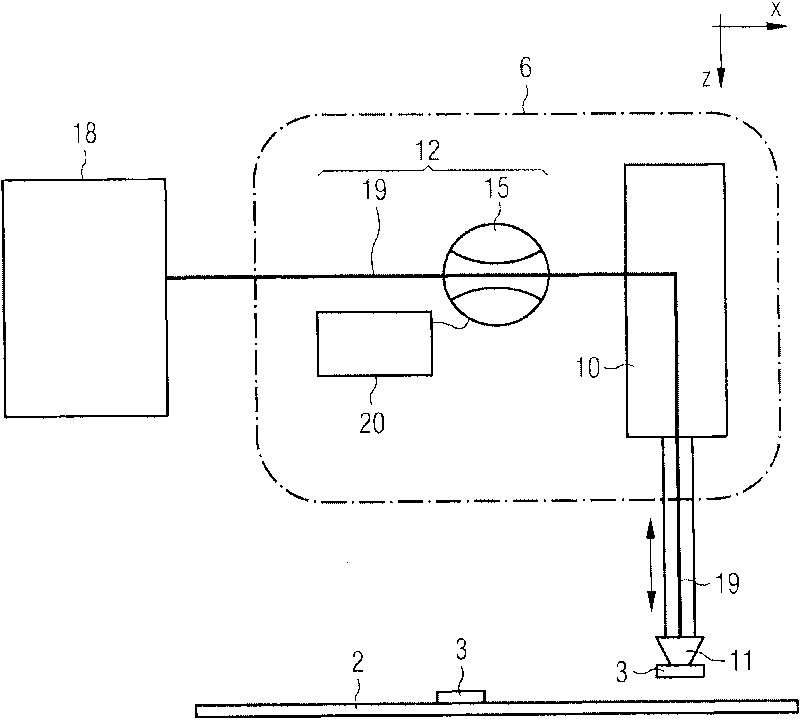

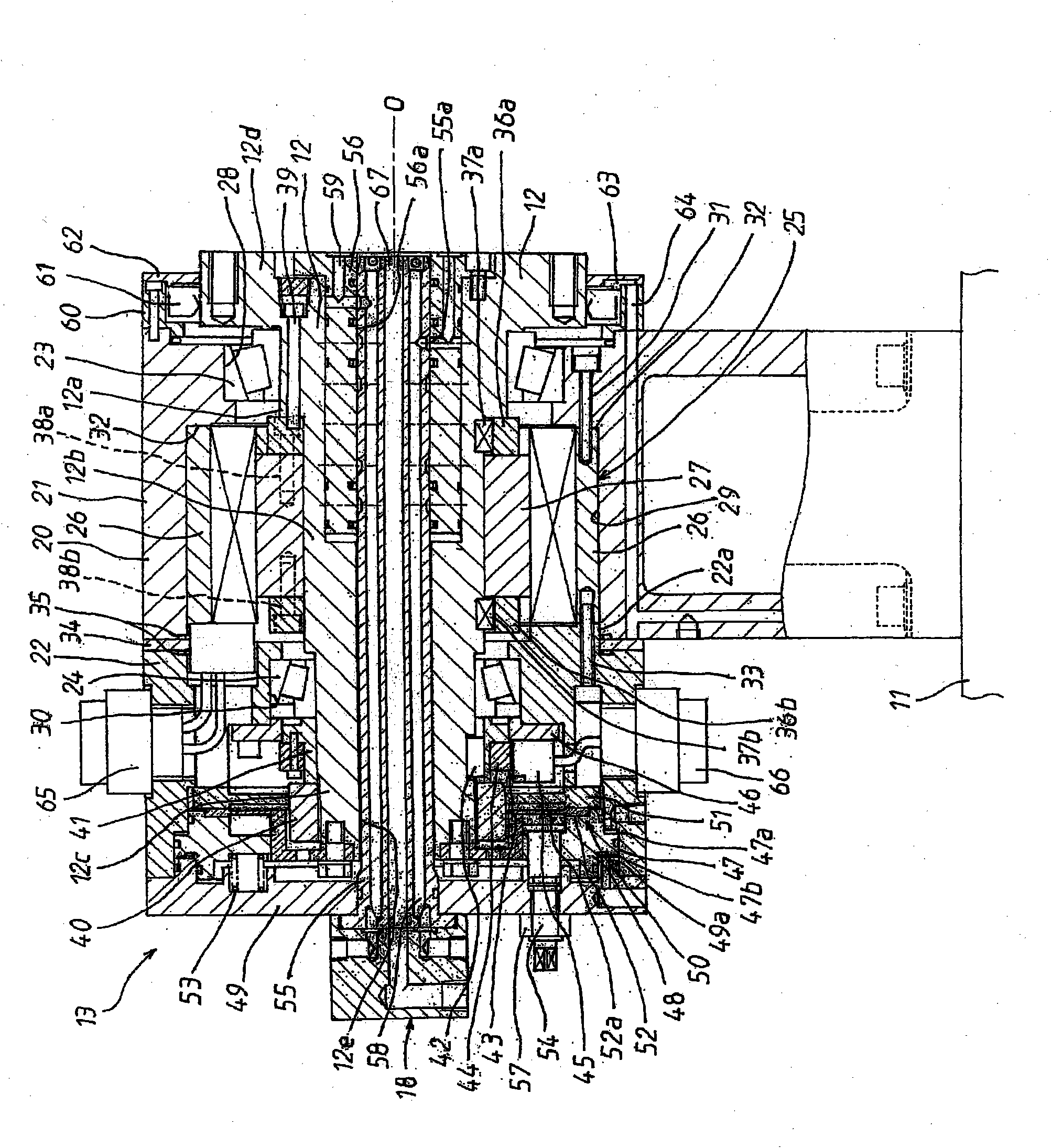

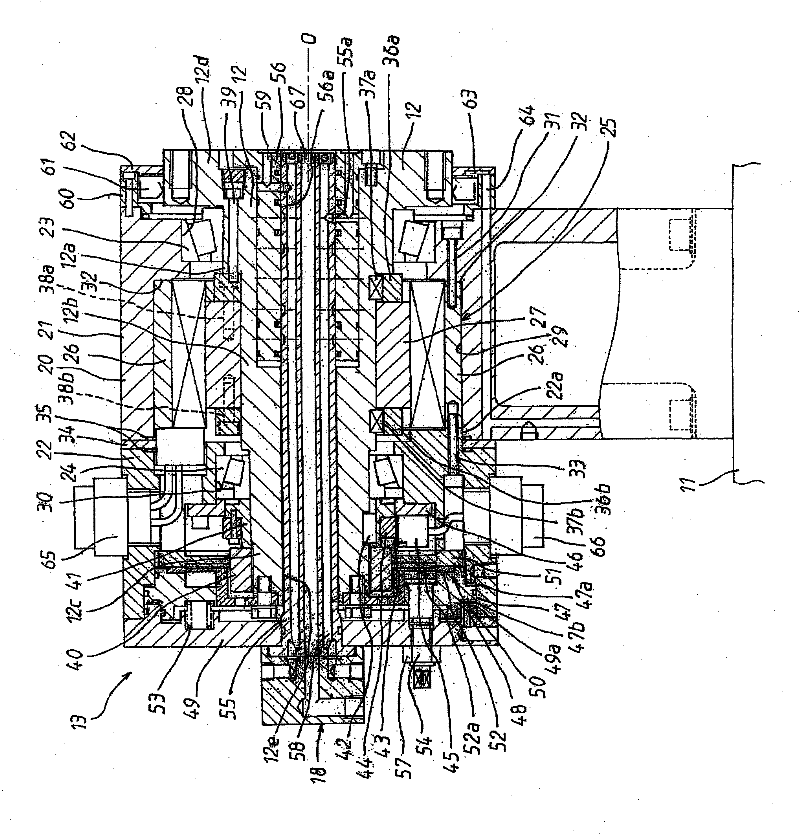

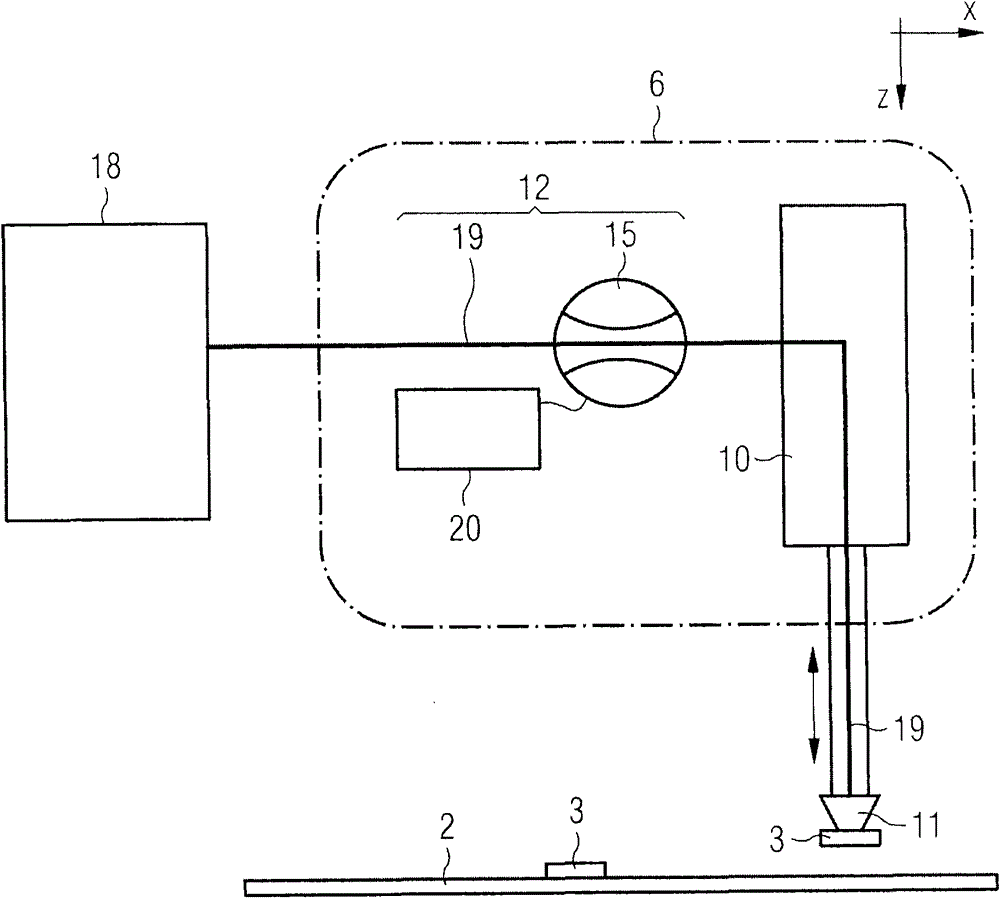

Assembly head and automatic assembling machine

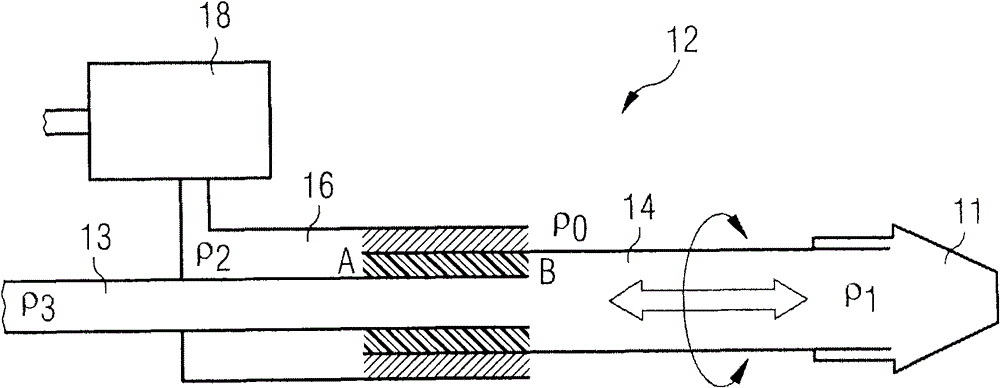

ActiveCN101754672AHigh rotational positioning accuracyReduce torqueElectrical componentsEngineeringManipulator

The present invention relates to an assembly head (6) which comprises the following components: a manipulator (11) which is designed for picking and holding a component (3); and a pneumatic unit (12) which is designed for loading a preset first pressure (p1) for the manipulator (11). Hereon, the pneumatic unit comprises the following components: a pneumatic first pipe (13) which is provided on the assembly head (6); and a pneumatic second pipe (14) which at least partially guides in the manipulator (11) and can be connected with the pneumatic first pipe (13). The pneumatic first pipe (13) and the pneumatic second pipe (14) are particularly designed to rigid connecting pipes. The two connecting pipes are inserted with each other for connecting, therefore the first pneumatic first pipe and the second pneumatic second pipe (13,14) can advance and rotate relatively with each other, thereby realizing axial and / or rotating movement of the manipulator (11) relatively to the assembly head (6).

Owner:ASM ASSEMBLY SYST GMBH & CO

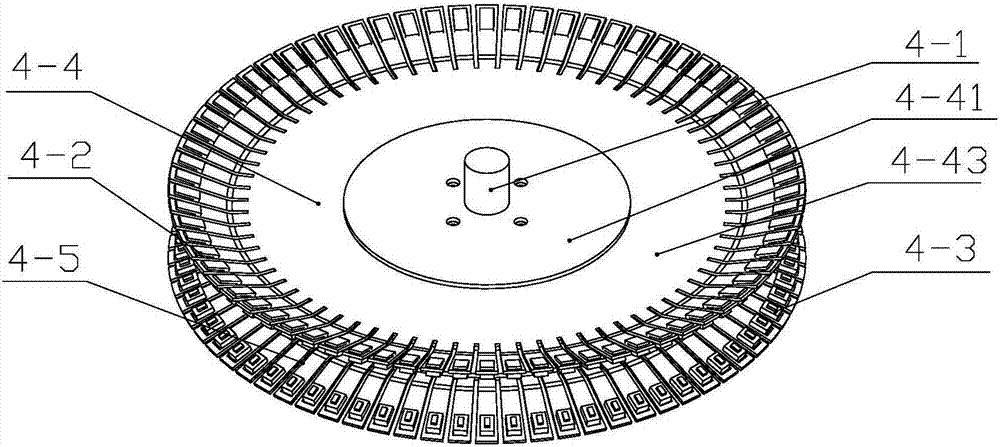

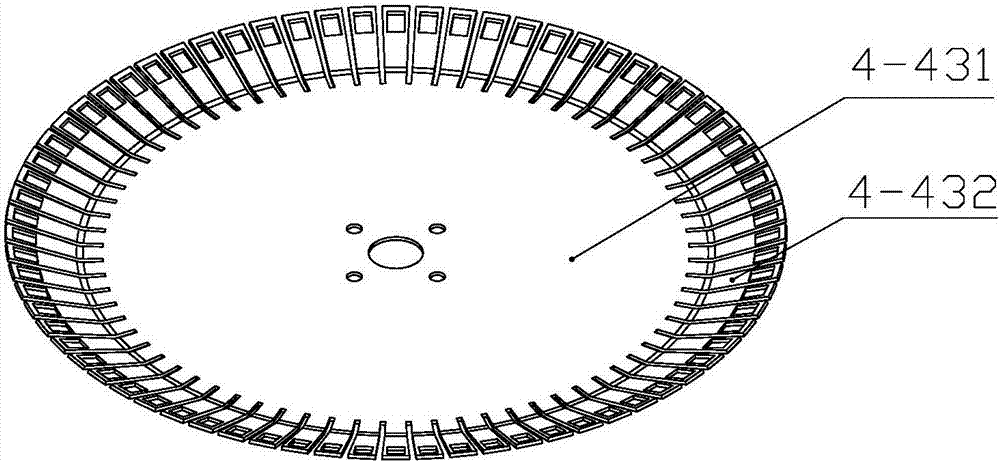

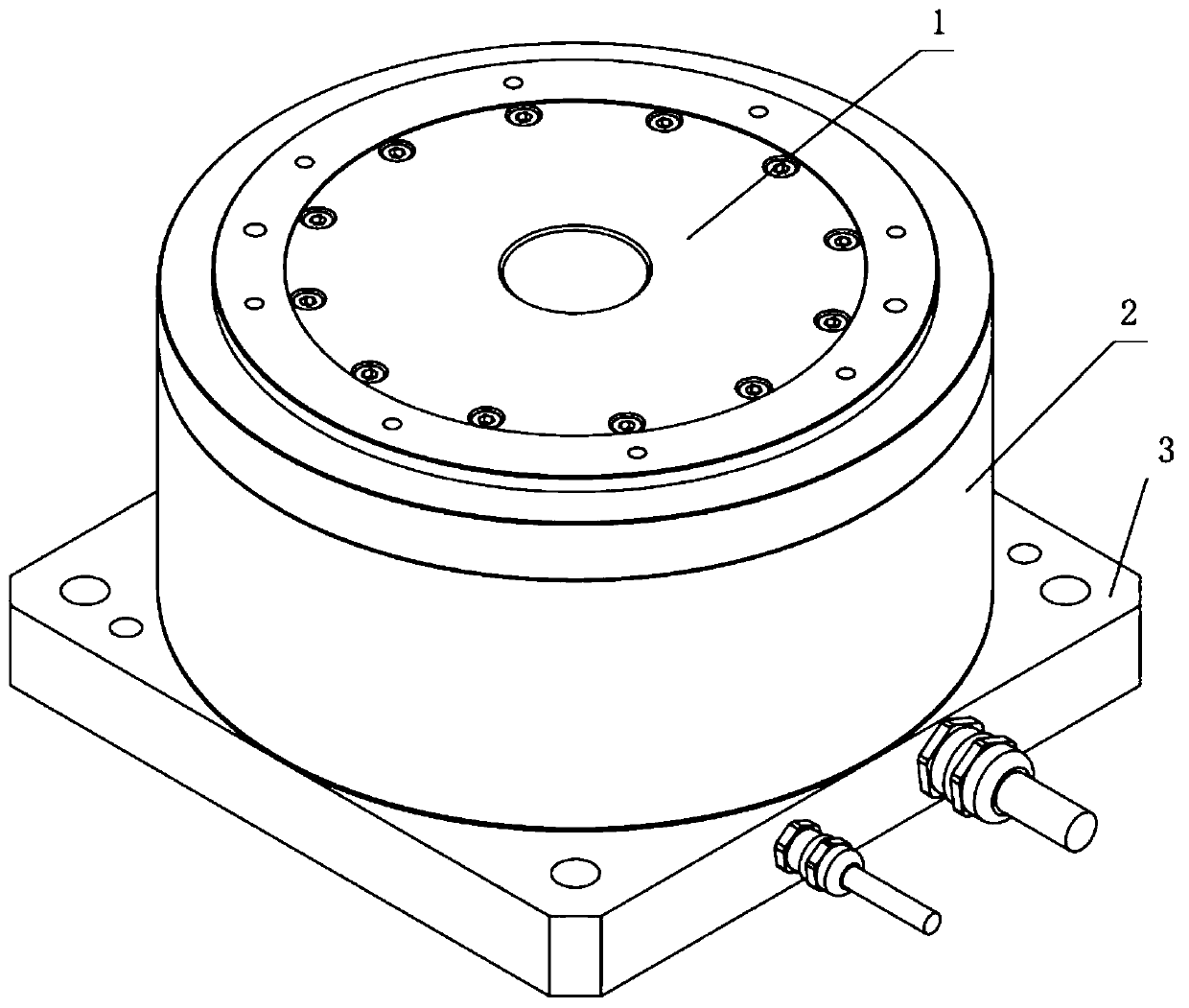

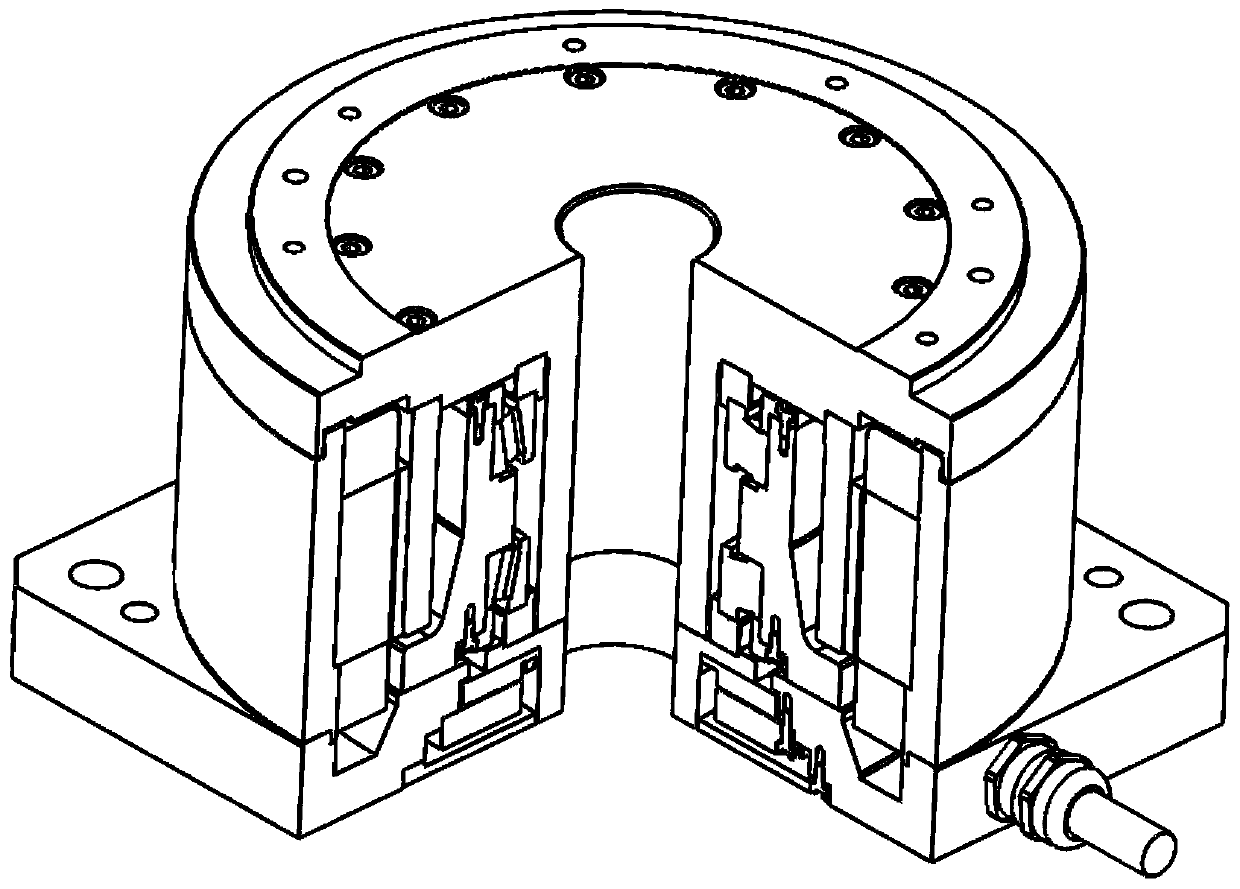

Card code printing mechanism with light elastic piece

The invention provides a card code printing mechanism with a light elastic piece and belongs to the technical field of identification card printing. The card code printing mechanism solves the problems that an existing case mechanism is large in mass, the case rotating precision is difficult to control, and the production cost of cases is high. A first circular case and a second circular case are both rotationally and fixedly connected to a case shaft through bearings. The first circular case comprises a first inner disc, a first outer disc and the first disc-shaped elastic piece. The first disc-shaped elastic piece comprises a first base plate and multiple first elastic piece strips evenly arranged in the circumferential direction of the first base plate. The first base plate is fixedly connected between the first inner disc and the first outer disc. The end, fixedly connected with the first base plate, of each first elastic piece strip is the fixed end, and the other end of each first elastic piece is the movable end. Multiple first matrixes are arranged at the movable ends of the first elastic piece strips in a one-to-one manner. Multiple second matrixes are arranged at the movable ends of the second elastic strips in the second circular case in a one-to-one manner. The card code printing mechanism is used for printing of identification cards.

Owner:SHENZHEN SILONE TONGHUI TECH

Rigid-flexible coupling rotating platform

InactiveCN110941241ASimplified Compensation Control MethodSimple structural designProgramme controlComputer controlCouplingKinematic pair

The invention discloses a rigid-flexible coupling rotating platform. The rigid-flexible coupling rotating platform comprises a machine base, a rigid bearing, a bearing sleeve, a core rotating platform, a rotating driver and a composite rotating flexible hinge ring. The bearing sleeve is fixed to the machine base. The rigid bearing is connected with the core rotating platform through the compositerotating flexible hinge ring kinematic pair. The rigid bearing is connected with the machine base through the bearing sleeve. The rotary driver is used for driving the core rotary platform to rotate.When the rotary driver applies driving force to the core rotary platform to enable the core rotary platform to rotate, the driving force can enable the composite rotary flexible hinge ring to generateelastic deformation. According to the rigid-flexible coupling rotating platform, the friction dead zone is overcome and the rotation is compensated by utilizing the elastic deformation of the composite flexible hinge ring, a highly accurate friction force model does not need to be utilized, and a compensation control method is simplified.

Owner:GUANGDONG UNIV OF TECH

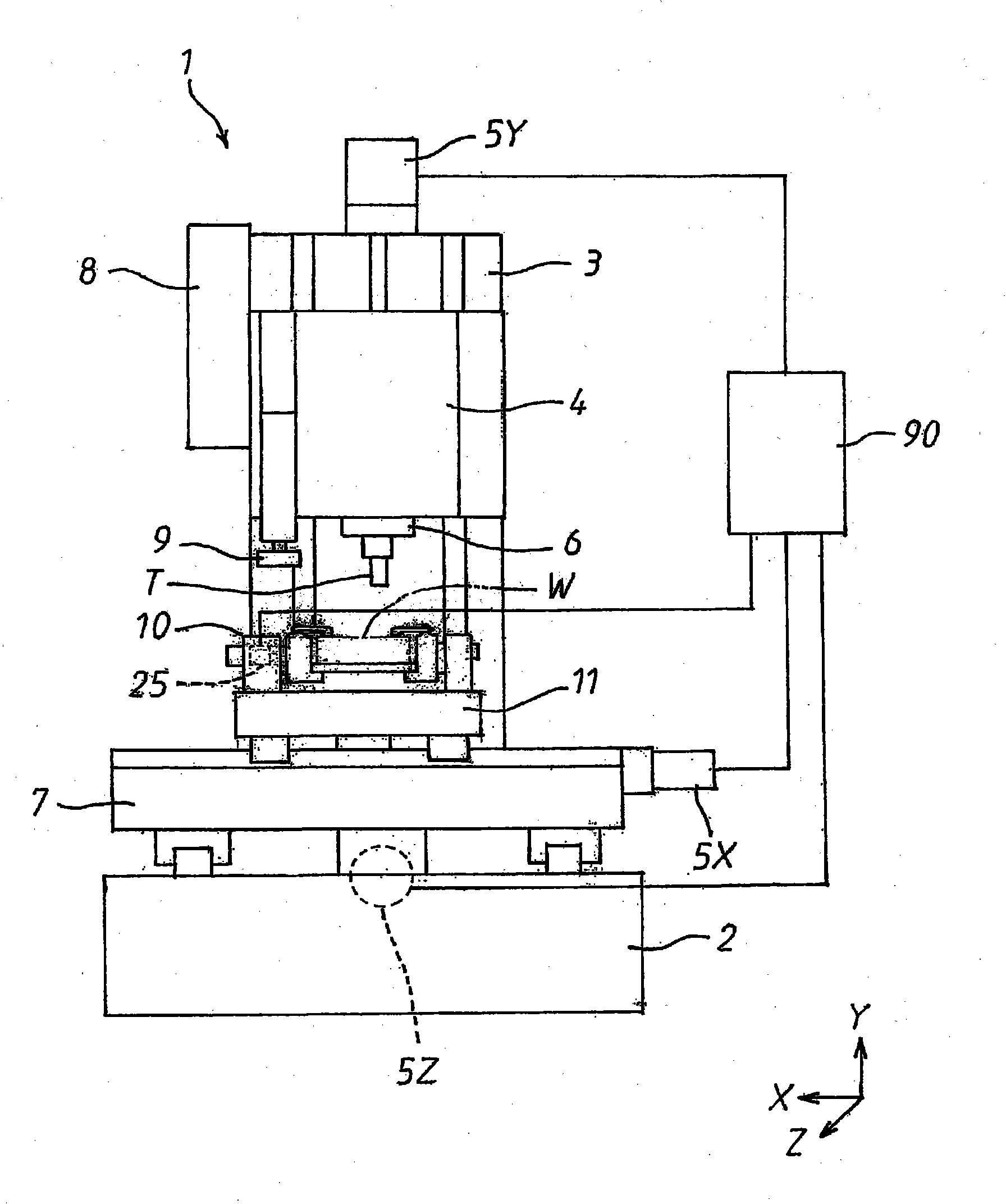

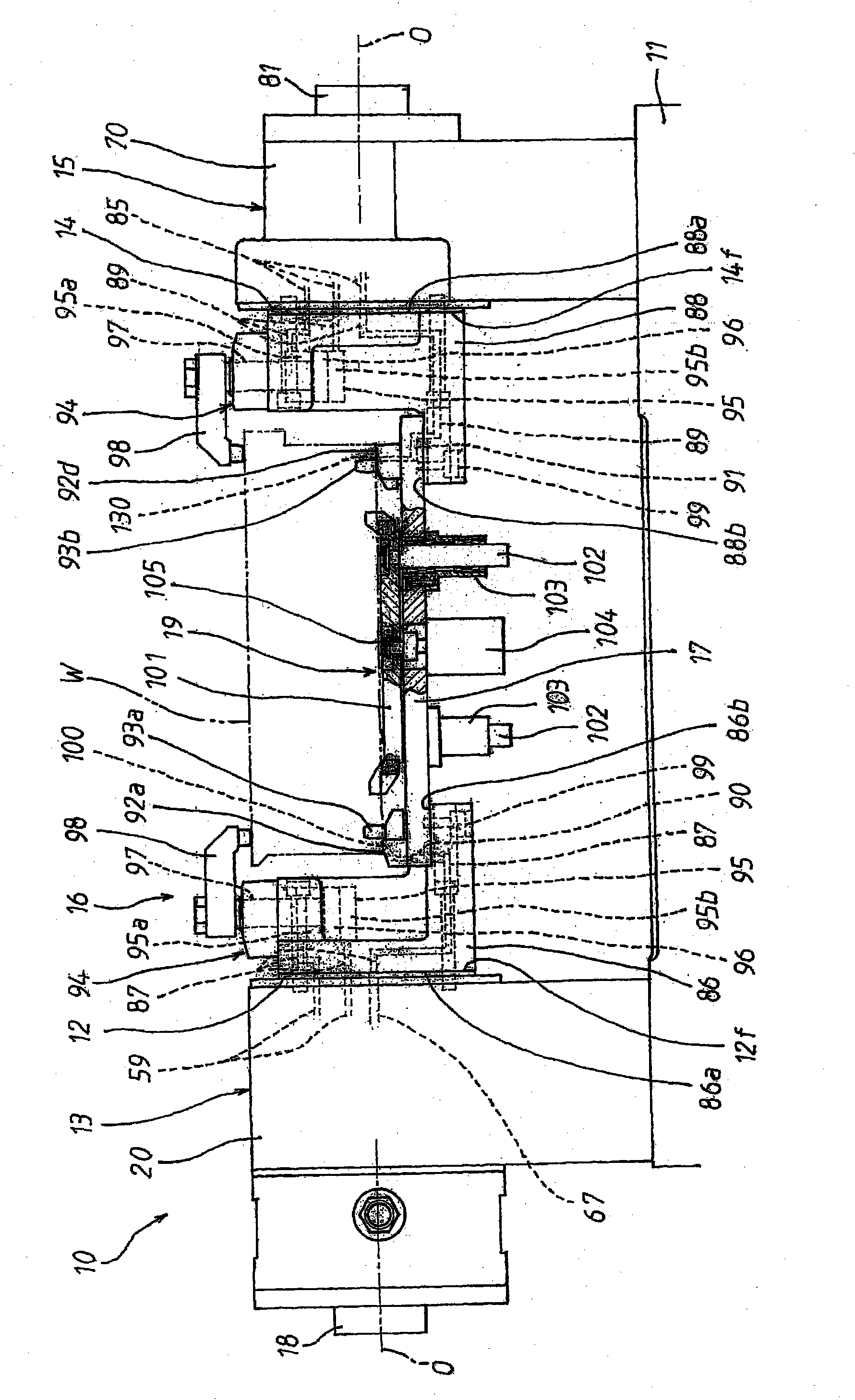

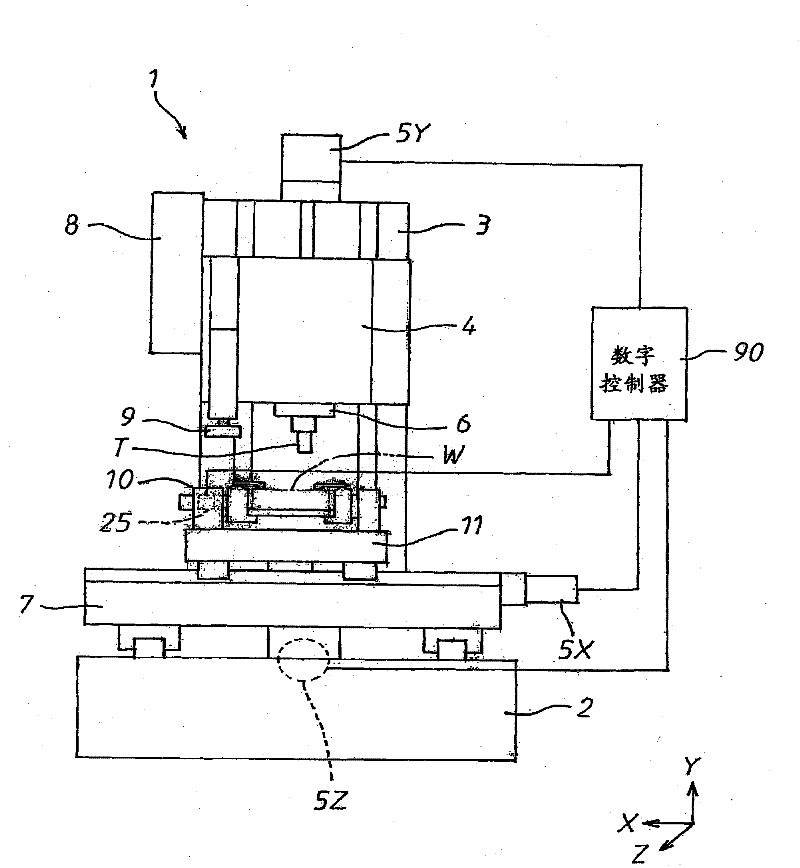

Tilt device

ActiveCN101918173AHigh rotational positioning accuracyHigh-speed smooth rotationTool changing apparatusLarge fixed membersDrive shaftDrive motor

A tilt device, wherein a tilt table is rotated by a direct drive motor to control the relative angular positions of a tool and a workpiece and wherein the tilt table is rotated at a high speed in order to spin off cut debris from the workpies in a predetermined time period. While a workpiece (W) is being worked by a tool (T), a drive shaft (12) is rotated by a direct drive motor (25) to control the relative angular positions of the tool (T) and the workpiece (W). Also, the direct drive motor (25) is rotated at a high speed for a predetermined time period with a headstock (4) and a work table (11) separated from each other, and this rotates the drive shaft (12) and in turn rotates a tilt table (17) at a high speed to spin off cut debris from the workpiece.

Owner:三惠C&C株式会社 +3

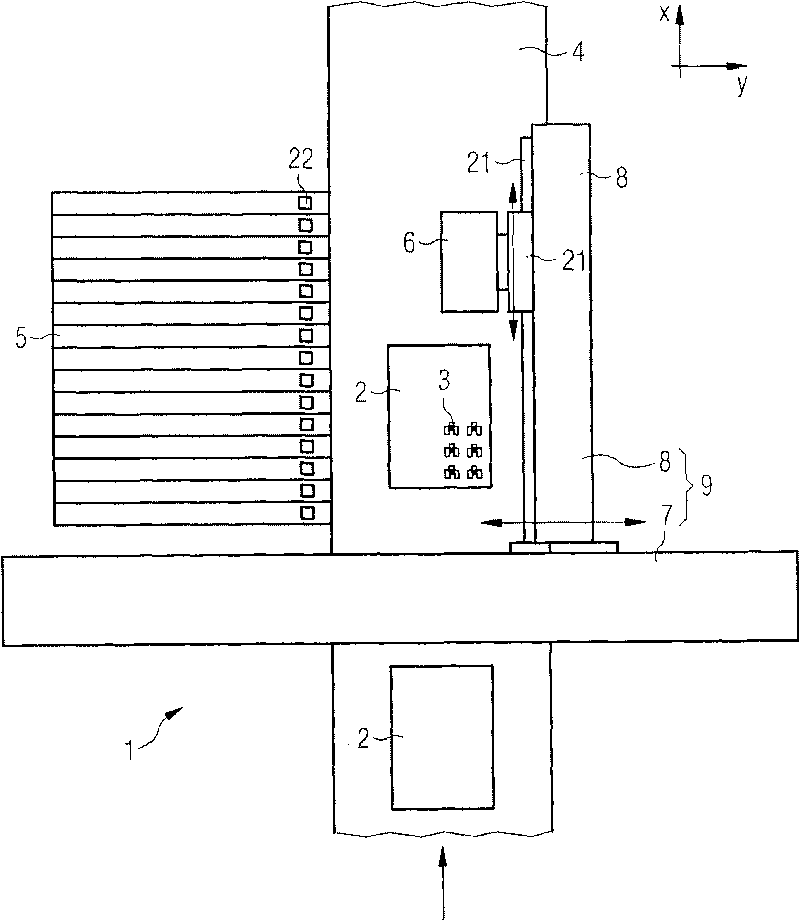

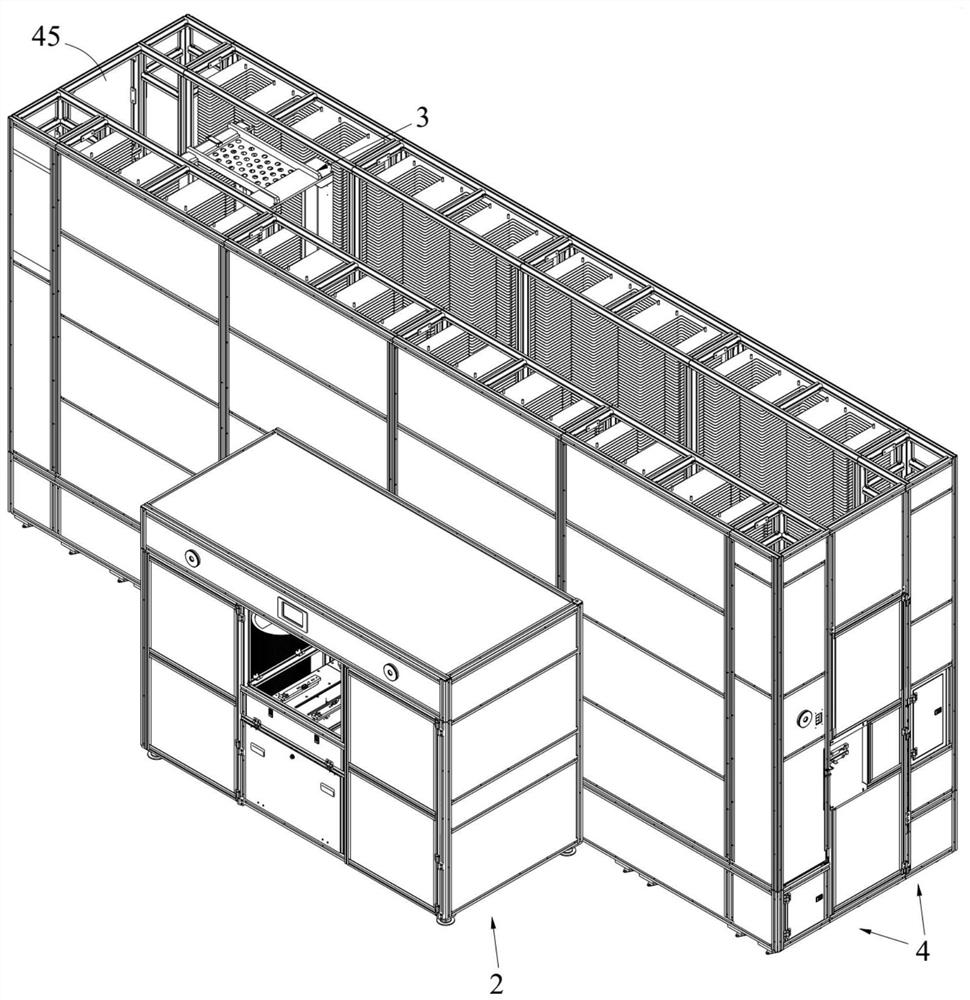

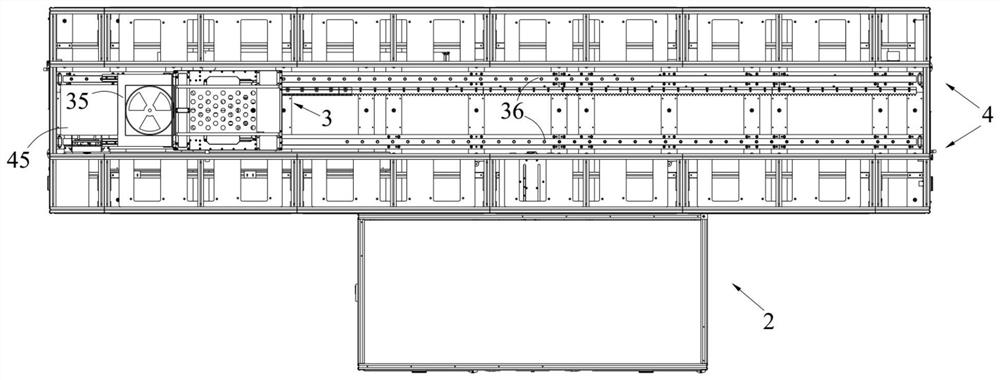

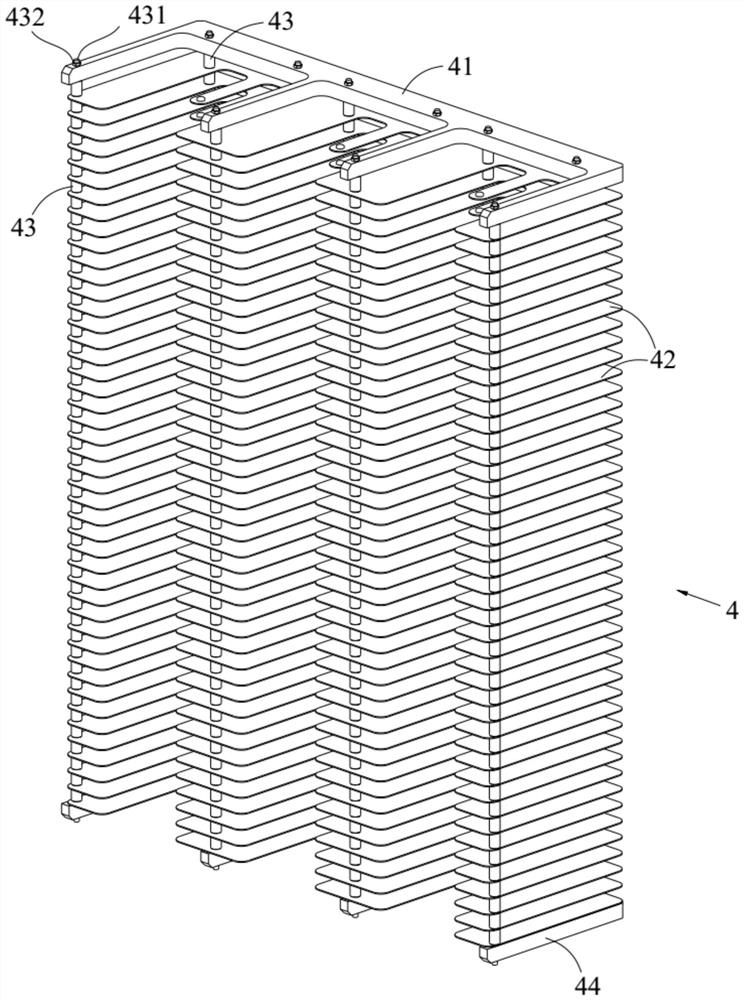

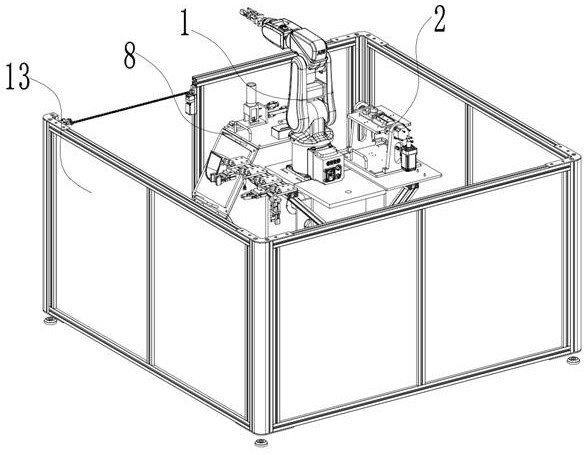

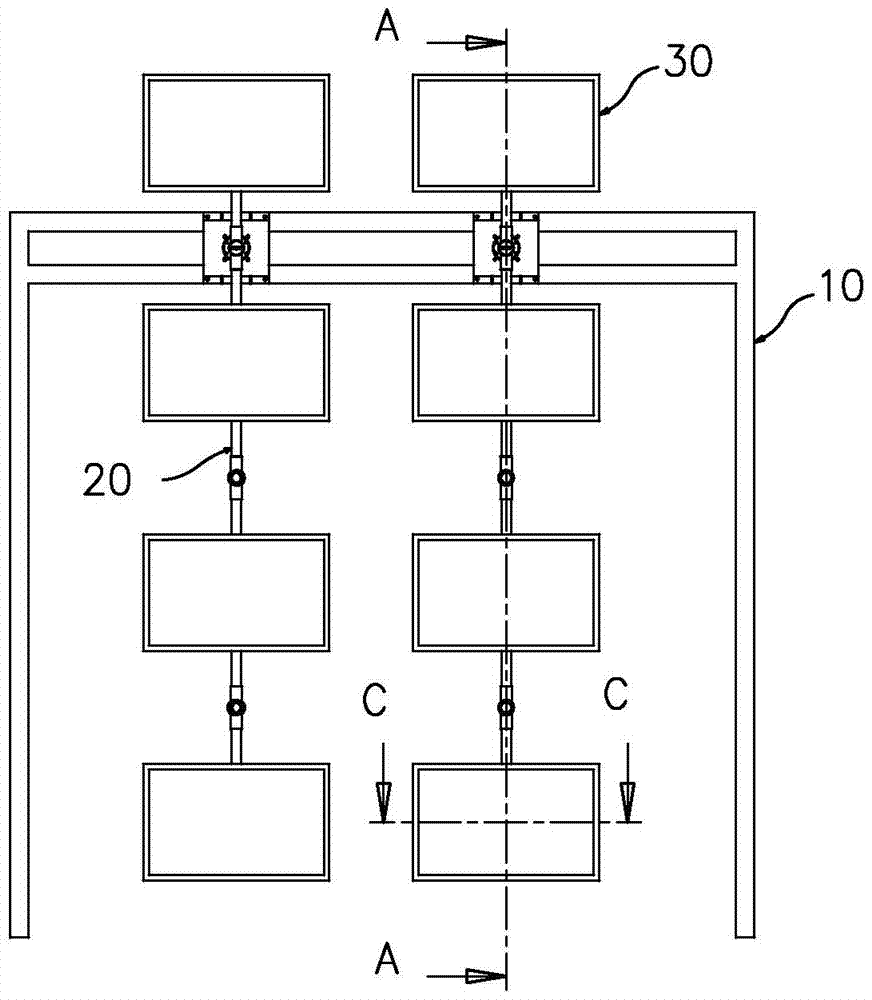

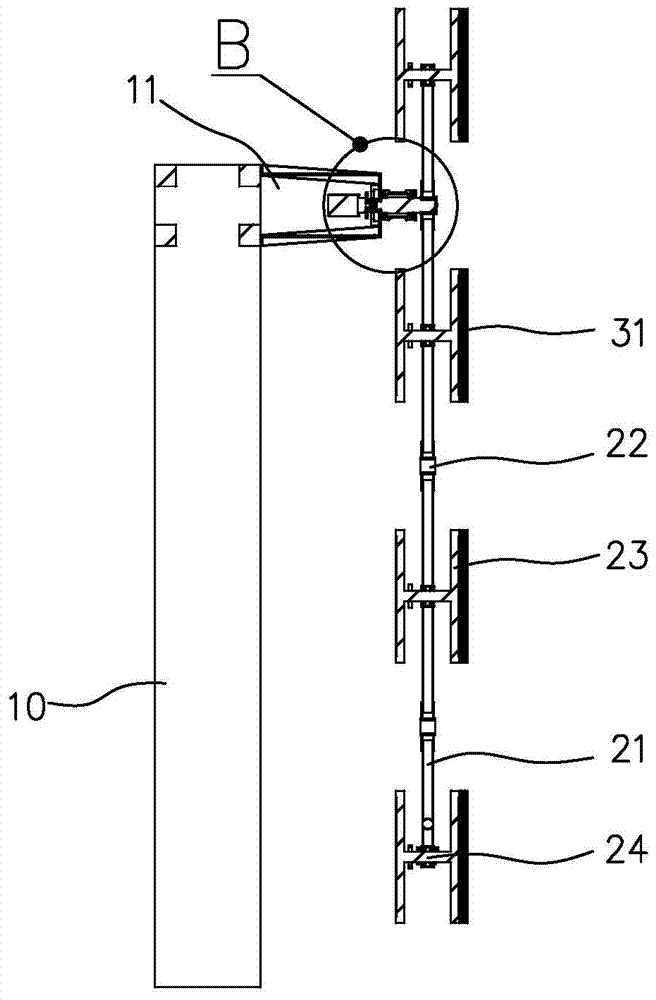

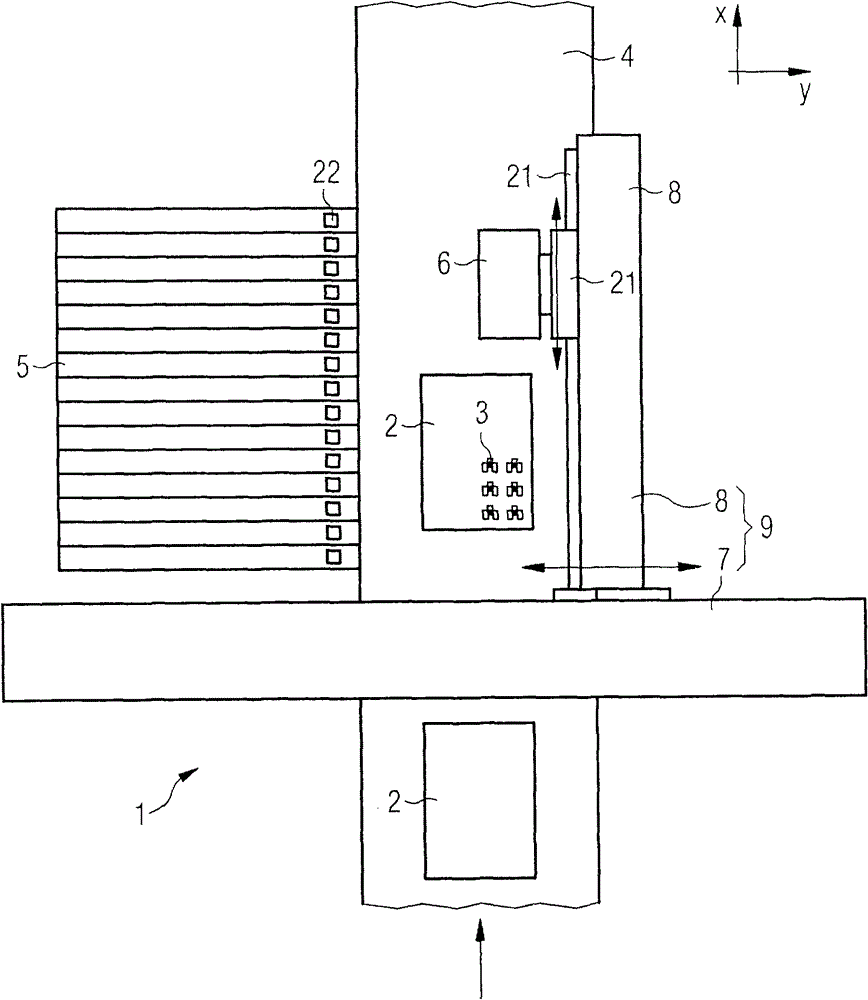

Automatic stereoscopic warehouse used for buffering and storing semiconductor components

InactiveCN113023193AShorten the path of movementImprove storage effectStorage devicesMechanical conveyorsEngineeringTransfer mechanism

The invention discloses an automatic stereoscopic warehouse used for buffering and storing semiconductor components. The automatic stereoscopic warehouse comprises two sets of goods shelves arranged in parallel, a buffer-storing and feeding mechanism, a feeding and discharging transfer mechanism and a material taking and placement mechanism. The two sets of goods shelves are arranged in a spaced manner so as to form a transfer channel located between the two sets of goods shelves, and a butt joint channel communicating the inside and the outside of the goods shelves is formed in one set of goods shelves. The buffer-storing and feeding mechanism comprises a rack and a buffer-storing and carrying assembly arranged in the rack. The feeding and discharging transfer mechanism is arranged in the rack and located under the buffer-storing and carrying assembly. The material taking and placement mechanism comprises a horizontal guide rail arranged in the transfer channel, a lifting frame connected with the horizontal guide rail in a sliding manner and a taking and placement assembly connected with the lifting frame in a sliding manner. According to the automatic stereoscopic warehouse, the moving path for storing and taking materials is reduced, meanwhile, the materials can be stored and taken in two directions, and the storage and taking efficiency is improved while the storage capacity of the stereoscopic warehouse is improved.

Owner:成川科技(苏州)有限公司

Optical image rotation eliminating mechanism of periscopic panoramic sighting telescope

PendingCN112882221AHigh rotational positioning accuracyReduce derotation errorTelescopesMountingsRotational axisTorque motor

The invention discloses an optical image rotation eliminating mechanism of a periscopic panoramic sighting telescope. The optical image rotation eliminating mechanism comprises a prism rotating shaft system, a Pechan prism assembly, a direct-current torque motor and a photoelectric encoder. The prism rotating shaft system comprises a base and a rotating shaft coaxially mounted in the base, and the Pechan prism assembly is mounted on the rotating shaft; the direct-current torque motor and the photoelectric encoder are arranged at the two ends of the shafting respectively, the direct-current torque motor is located at the front end of the shafting, the photoelectric encoder is located at the rear end of the shafting, stators of the direct-current torque motor and the photoelectric encoder are fixedly installed on the base respectively, rotors and the rotating shaft are coaxially installed, the direct-current torque motor is used for driving the Pechan prism assembly rotating shaft system to rotate, the photoelectric encoder is used for real-time angle measurement and position feedback, and the image rotation eliminating function is achieved. The mechanism is simple in structure, low in manufacturing cost, convenient to install and adjust and high in imaging precision, and the problem of image rotation in the 360-degree panoramic sighting process of the periscopic panoramic sighting telescope is solved.

Owner:西安应用光学研究所

Internal positioning utility-type valve for pipeline

The invention discloses an internal positioning utility-type valve for a pipeline. The internal positioning utility-type valve comprises a main valve body, a valve rod and a handle. The main valve body is internally provided with a ball valve core, a flat shaft is arranged above the ball valve core, and a circular ring is arranged above the flat shaft; the circular ring is internally provided with an inner ring, the inner ring is embedded in an outer ring, a positioning hole is formed in the lower portion of the ball valve core, and a positioning column is installed below the positioning hole; the left side of the ball valve core is connected with a valve cap, the left side of the valve cap is connected with a valve chamber, and the valve rod is installed above the circular ring; the handle is installed above the valve rod, a column connecting device and the handle are connected to the upper portion of the valve rod, and the column connecting device is arranged in the handle; and the handle is provided with a hand-holding part, bolts are arranged on the upper portion of the column connecting device, are arranged in the handle and are lower than the hand-holding part, and the positioning hole and the positioning column are integrally connected. The internal positioning utility-type valve has the advantages that the improved ball valve is further low in production cost, convenient to manufacture, high in rotary positioning precision and the like.

Owner:JIANGSU SUNDIDE INTELLIGENT TECH CO LTD

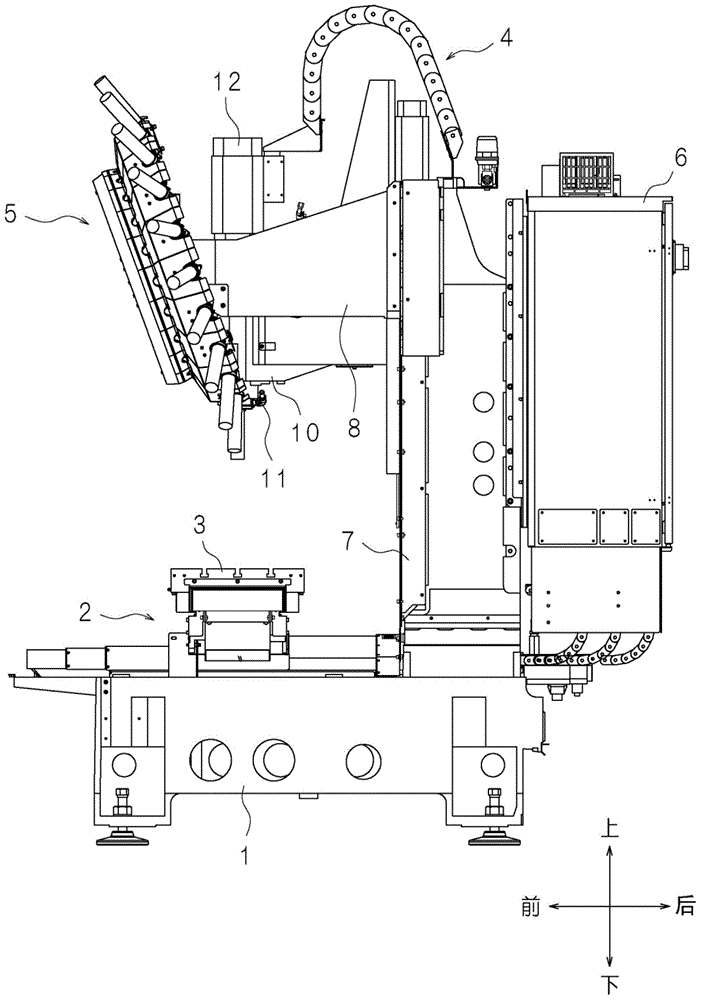

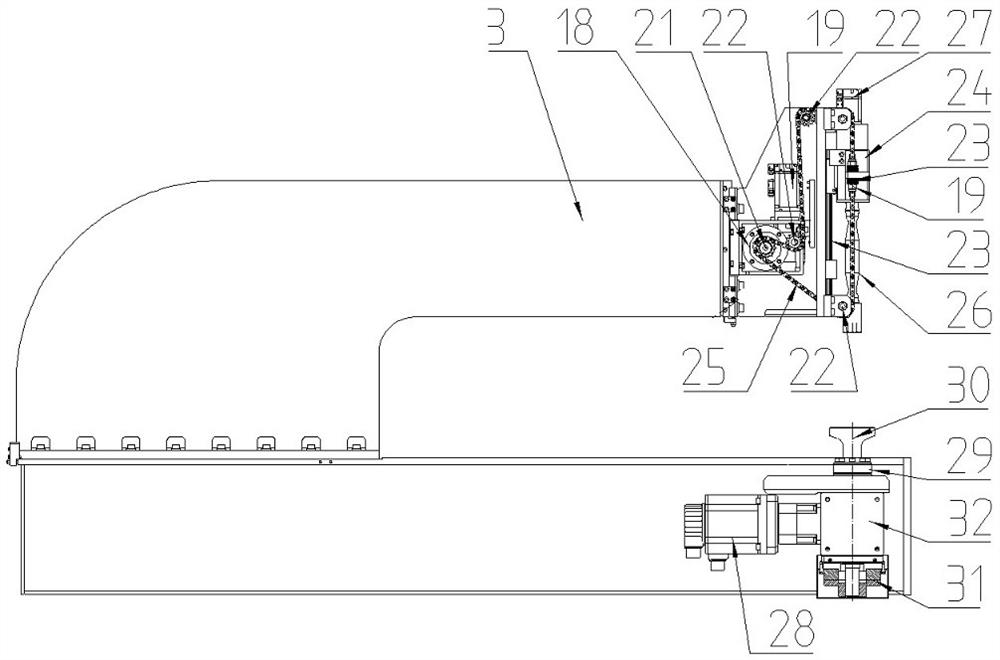

Bending center front feeding equipment

ActiveCN114160691APrecise positioningExpand the scope of processingMetal-working feeding devicesMetal working apparatusRobot handMechanical engineering

The invention discloses bending center front feeding equipment which comprises a fixed base, a C-shaped pressing arm driving device, a C-shaped pressing arm, a rotary positioning mechanism, an auxiliary feeding mechanical arm, a plate front end positioning assembly, a plate left side positioning assembly, a plate right side auxiliary pushing assembly, a plate rear side auxiliary pushing assembly and a feeding and discharging platform. According to the bending center front feeding equipment, by means of a comprehensive plate positioning mode, positioning stop blocks are arranged at the front end and the left end of a plate, auxiliary pushing mechanisms are arranged at the right end and the rear end of the plate, workpiece positioning is more accurate, and deviation caused by manual feeding is avoided. And meanwhile, for some special-shaped workpieces, secondary positioning of the workpieces can be automatically achieved through mutual cooperation of the positioning mechanisms, the machining range of the workpieces is enlarged, and therefore the utilization rate of the equipment is increased.

Owner:DERATECH MASCH TOOL (SUZHOU) CORP LTD

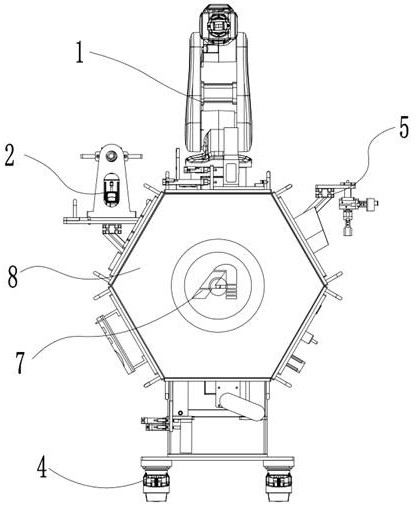

Intelligent rotatable practical teaching platform

PendingCN114495620AEasy to mix and matchConvenient electricity and gas supplyCosmonautic condition simulationsSimulatorsRotational axisRotary stage

The invention discloses an intelligent rotatable practical training teaching platform, which comprises a seat frame, a rotatable polyhedral rotating table is arranged on the seat frame, the rotating table performs intermittent rotary motion under the action of a rotation driving mechanism, a plurality of surfaces of the rotating table are respectively provided with a practical training unit, each practical training unit can be provided with a son plug, a mother plug is arranged in the rotating table, and the mother plug is connected with the son plug. The rotation driving mechanism comprises a rotating shaft, the rotating shaft comprises a threading pipe and a rotating shaft sleeve, the rotating shaft sleeve is rotatably mounted on the seat frame, the rotating table is fixedly connected with the rotating shaft sleeve, the threading pipe is mounted in the rotating shaft sleeve, and the threading pipe is fixedly connected with the rotating shaft sleeve. The outer end of the threading pipe penetrates out of the seat frame and is fixedly connected with the seat frame, the inner end of the threading pipe is located in the rotating table, and an electrical cable can be arranged in the threading pipe in a penetrating mode. According to the invention, different practical training units can be freely and conveniently switched, the rotation positioning precision is high, and electricity and gas sources can be conveniently provided for each practical training unit.

Owner:YALONG INTELLIGENT EQUIP GRP CO LTD

Pipe position locking mechanical valve

InactiveCN107152556ASolve the structural defect of automatic closingGuaranteed reliabilityOperating means/releasing devices for valvesPreventing unauthorised/accidental actuationNeck partsEngineering

The invention discloses a pipe position locking mechanical valve. The pipe position locking mechanical valve comprises a valve body neck part, a valve body, a valve part and a hand wheel; the right side of the hand wheel is connected with a fixed pipe sleeve; the hand wheel is connected with the fixed pipe sleeve through a hand wheel shaft; a movable disc is mounted on the right side of the fixed pipe sleeve; the right side of the movable disc is connected with a fixed disc; a fixed ring is arranged on the right side of the fixed disc; a flange is mounted on the lower side of the fixed ring; the valve body neck part is arranged below the flange; the valve body is connected below the valve body neck part; a valve ring is embedded in the valve body, and is provided with a plug column; the valve part is embedded in the valve ring; a valve element is mounted in the valve part; the inner side of the hand wheel is connected with a hand wheel support rod; and the tail end of the hand wheel support rod is connected with a hand wheel rotating core. The movable disc is higher than the fixed pipe sleeve; the flange and the valve body neck part are connected integrally; the movable disc and the fixed disc are produced by stainless steel metal; and the hand wheel support rod and the hand wheel are fixedly connected. The pipe position locking mechanical valve has the following advantages: the improved valve body is low in production cost, convenient in production, high in rotary positioning precision and the like.

Owner:JIANGSU SUNDIDE INTELLIGENT TECH CO LTD

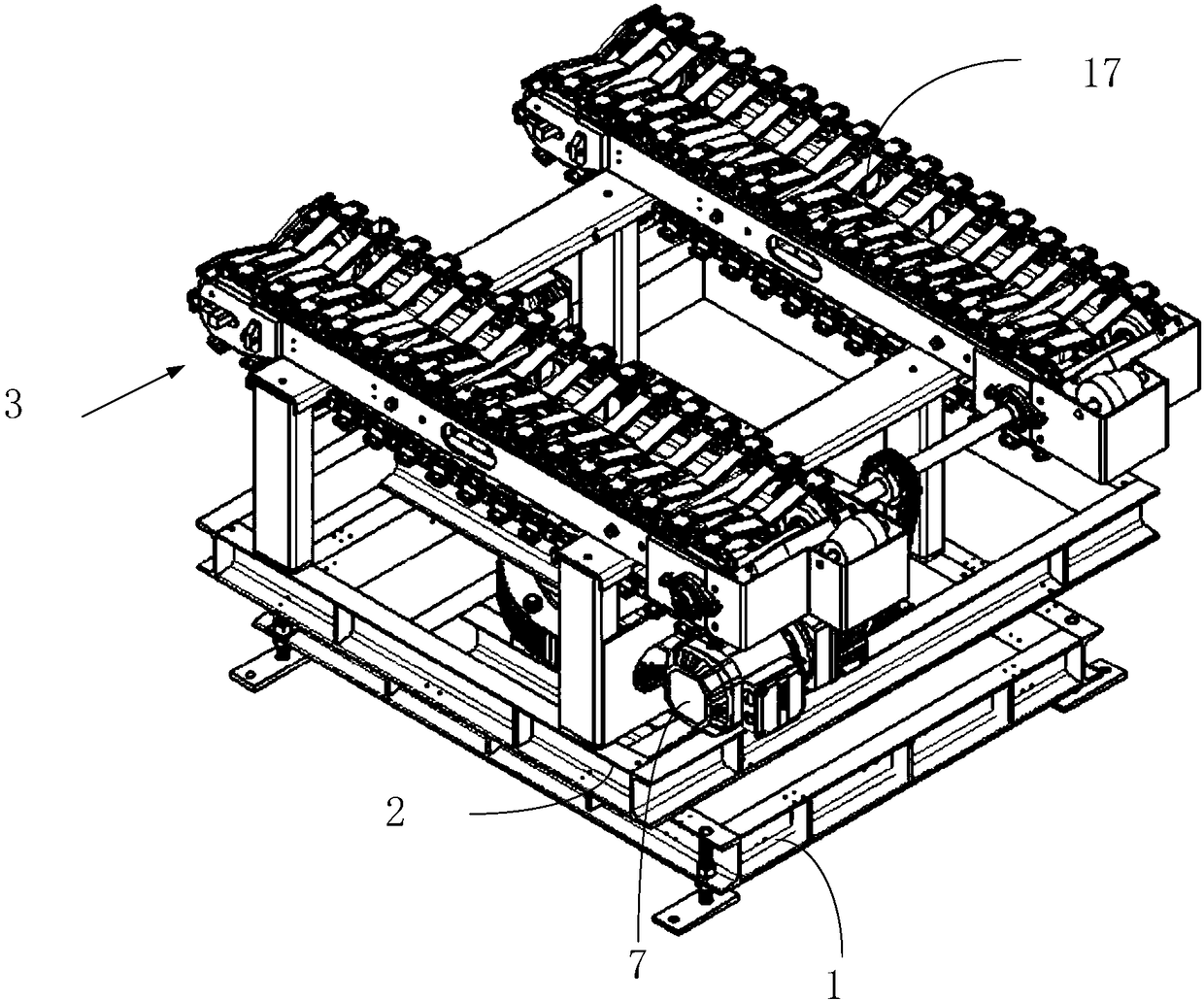

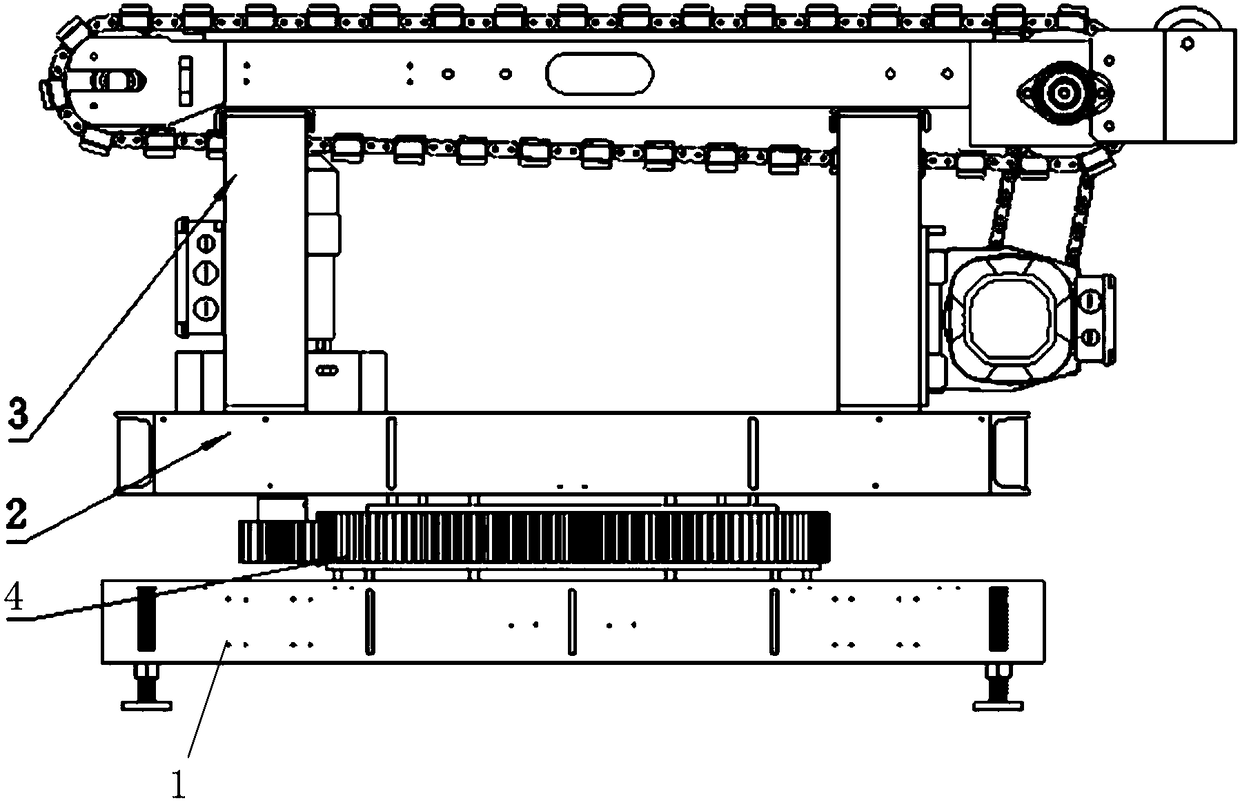

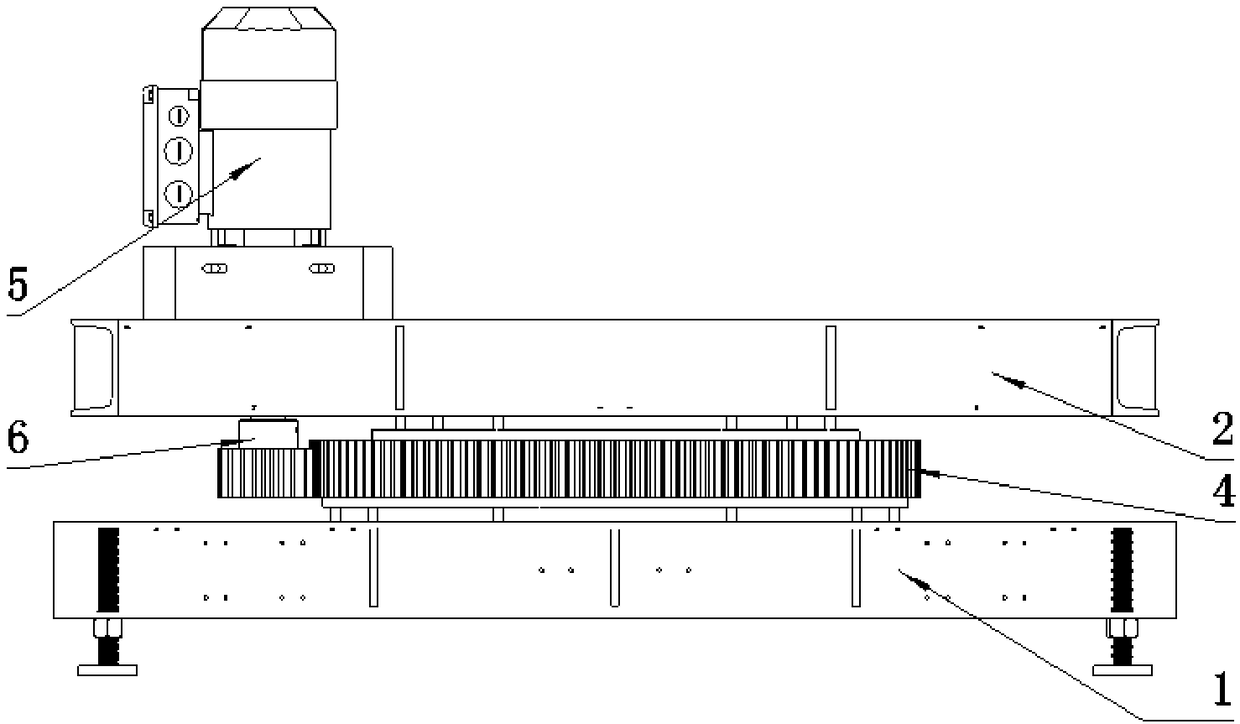

Rotary conveying platform and logistics conveying equipment

PendingCN108584346AAchieve rotationRealize the function of reversing conveyingConveyorsSupporting framesLogistics managementMechanical engineering

Owner:BOZHON PRECISION IND TECH CO LTD

A pressure gauge seat moving mechanism

ActiveCN103692181BHigh rotational positioning accuracyEasy and stable clampingMetal working apparatusEngineeringUltimate tensile strength

The invention relates to a pressure meter seat moving mechanism, comprising a bottom plate, a mobile module, a rotary module, a clamping module, a pressure meter seat and a pressure meter; the mobile module and the clamping module are arranged on the bottom plate respectively; the rotary module is arranged on the mobile module; the pressure meter seat is positioned on the rotary module by a clamp; the pressure meter is mounted on the pressure meter seat; a mobile cylinder of the mobile module drives the pressure meter seat to a machining position; the direction of the pressure meter seat is rotated to a designated position by the rotary module, then a clamping cylinder clamps the pressure meter seat and ensures that the pressure meter seat is not loosened in the use process, and the pressure meter seat can freely rotate in the rotation process. The pressure meter seat moving mechanism can perform rotation motion while clamping, the rotating positioning precision is high, and a work position is not deviated as a rotary motor of the rotary module can be braked. The labor intensity of operation staff is reduced, and the production cost is reduced.

Owner:BOZHON PRECISION IND TECH CO LTD

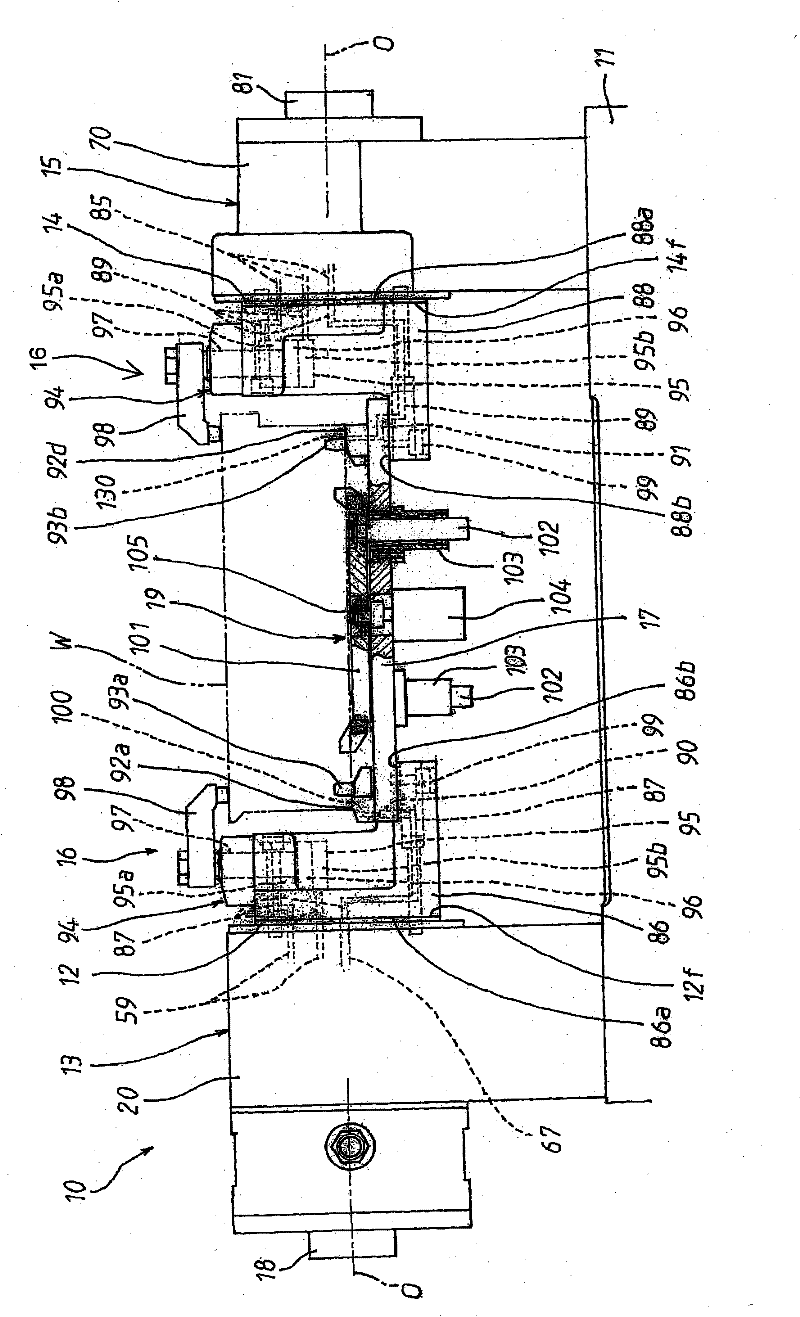

Tilt device

ActiveCN101918173BHigh rotational positioning accuracyHigh-speed smooth rotationTool changing apparatusLarge fixed membersDrive motorEngineering

In the course of a machining of a workpiece with a tool, a drive spindle with a tilt table secured thereto of a tilt device provided on a work table of a machining center is rotated by a direct drive motor to control the relative angular position between the tool and the workpiece, and within a predetermined period of time in the course of a machining, the direct drive motor is rotated at a high speed with a spindle head and the work table of the machining center kept away to rotate the drive spindle and hence, the tilt table at a high speed, so that chips and cutting lubricant can be shaken from the workpiece and the tilt table.

Owner:三惠C&C株式会社 +3

A kind of pressure gauge assembly equipment

ActiveCN103692207BGuaranteed not to deviate fromEasy and stable clampingAssembly machinesMetal working apparatusCamMechanical engineering

Owner:BOZHON PRECISION IND TECH CO LTD

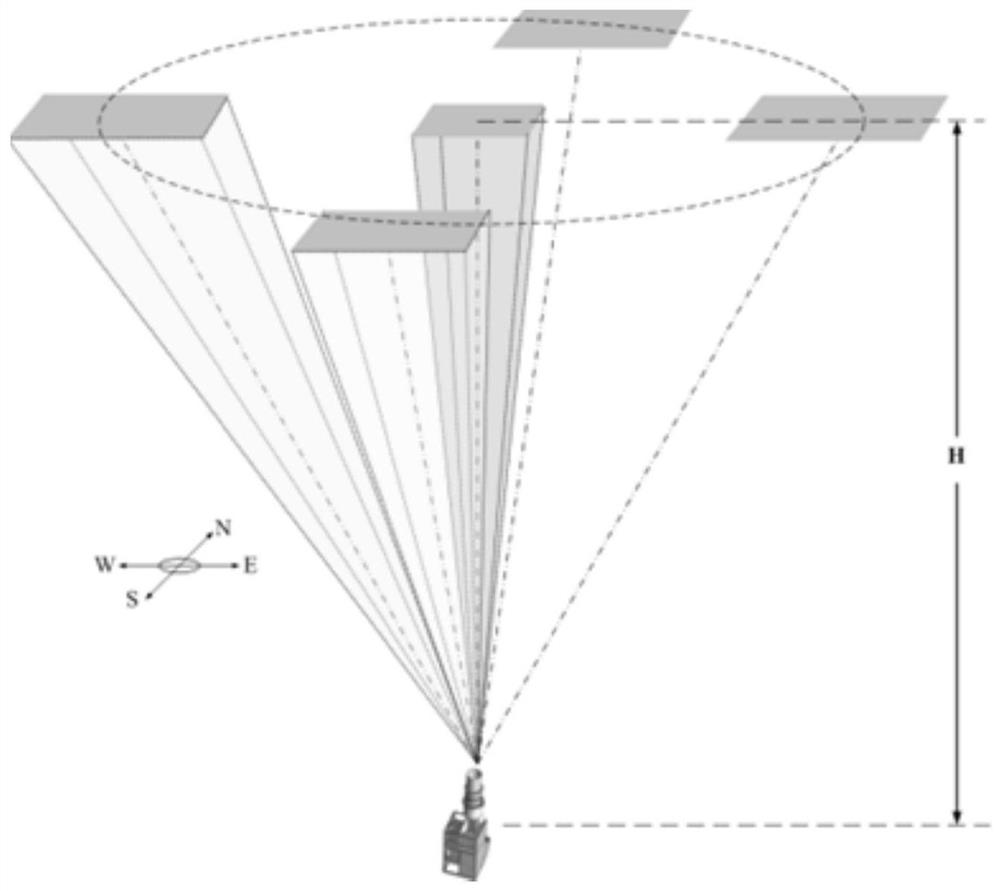

Front scanning mirror system for measuring atmospheric wind field of upper layer of foundation

ActiveCN113552716ASimplify structural complexityDifficulty of SimplificationICT adaptationOptical elementsWind fieldAtmospheric sciences

The invention provides a front scanning mirror system for measuring an atmospheric wind field of a foundation upper layer. The front scanning mirror system mainly aims at overcoming the defects that an existing front scanning mirror for measuring the atmospheric wind field of the foundation upper layer is complex in structure, large in scanning motion range, large in weight, difficult to be subjected to waterproof sealing to adapt to outdoor measurement and the like. The front scanning mirror system comprises a reflecting mirror, a one-dimensional linear displacement platform, a rotary platform, a rotary protective cover and a rotary protective cover, the rotary platform drives the reflector to rotate in the axial direction of the main light path through the one-dimensional linear displacement platform, and the rotary protection cover is used for protecting the rotary platform and the environment of the main light path from being polluted by the external environment. The rotary protection cover comprises a protection cover body, a zenith protection window and a side protection window, the protection cover body is arranged on the rotating platform, the side protection window is arranged on a reflection light path of the reflecting mirror, light signals collected by the side protection window are reflected to the main light path through the reflecting mirror, and the main light path transmits the collected light signals to the foundation upper layer atmosphere wind field measuring system.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

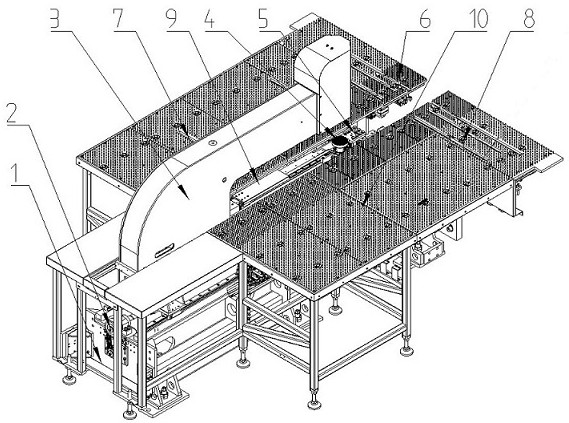

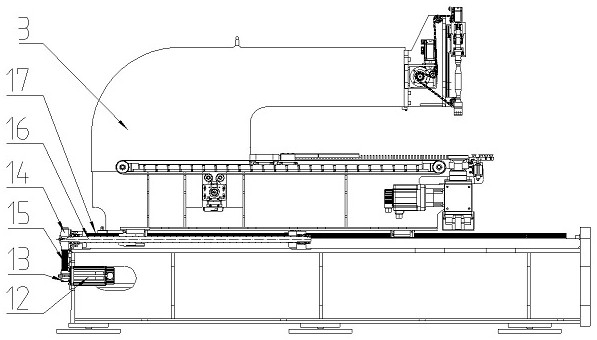

Machine tool

ActiveCN104625824AReliable engagementHigh rotational positioning accuracyLarge fixed membersPositioning apparatusEngineeringMachine tool

The invention relates to a machine tool capable of using turning cutter by maintaining universality of a cutter handle. The machine tool comprises a main spindle nose used for maintaining a main spindle, a driving source used to drive the main spindle to rotate around the axis, a cutter warehouse used for accommodating the cutter, a main spindle gear disposed on the main spindle, and a transmission gear disposed on the cutter warehouse. The transmission gear is used to transmit the rotation of the main spindle to the cutter warehouse by being engaged with the main spindle gear. The main spindle nose is provided with a limiting part, which is used to limit the rotation of the main spindle by being clamped with the main spindle gear, and the limiting part is provided with a clamping gear clamped with the main spindle gear and a limiting mechanism used to limit the rotation of the clamping gear. The limiting mechanism is used to limit the rotation of the clamping gear, and then the main spindle cannot rotate, and therefore the machine tool can use the turning cutter by using the common cutter handle for the processing.

Owner:BROTHER KOGYO KK

a demonstration device that can swing or rotate

ActiveCN104181935BRealize an interactive presentationAvoid boringControl using feedbackIdentification meansDisplay deviceEngineering

The invention discloses a demonstration device capable of swinging or rotating, which includes a bracket, a plurality of display groups, a connector, a revolution mechanism and an autorotation mechanism, the connector connects the bracket and the display group, and the revolution mechanism drives the The display group rotates or swings, and the self-rotating mechanism is used to drive each display in the display group to swing or rotate. It is used to solve the problem that the multimedia display in the prior art can only be played in a static state, and provides a structural basis for satisfying different viewing angles and performing dynamic demonstrations with multimedia images. The revolution mechanism drives the display group to rotate or swing, and the autorotation mechanism drives each display to swing or rotate. The display group rotates or swings and the swing or rotation of the display can cooperate with the content of the display for dynamic demonstration, realizing the multi-media screen of multiple displays. The interaction between screen and media screen and between media screen and machinery.

Owner:HEFEI GENERAL MACHINERY RES INST

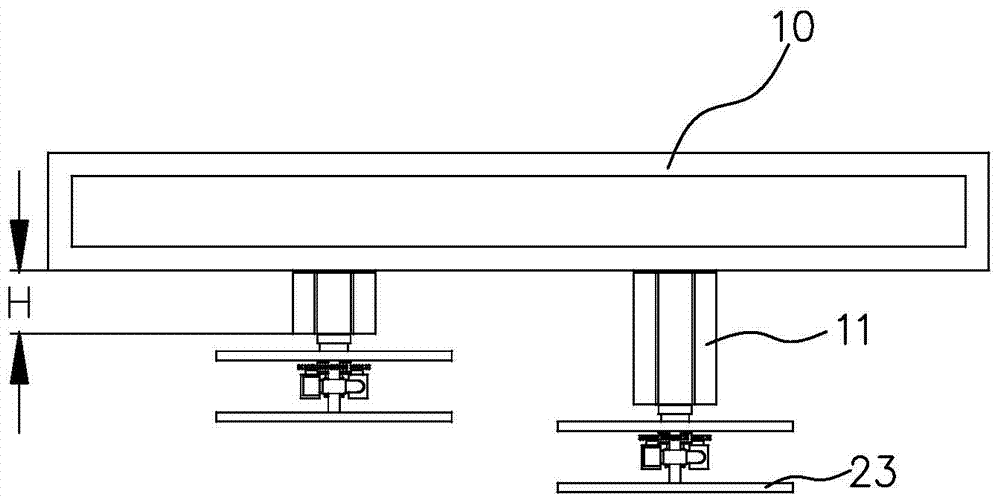

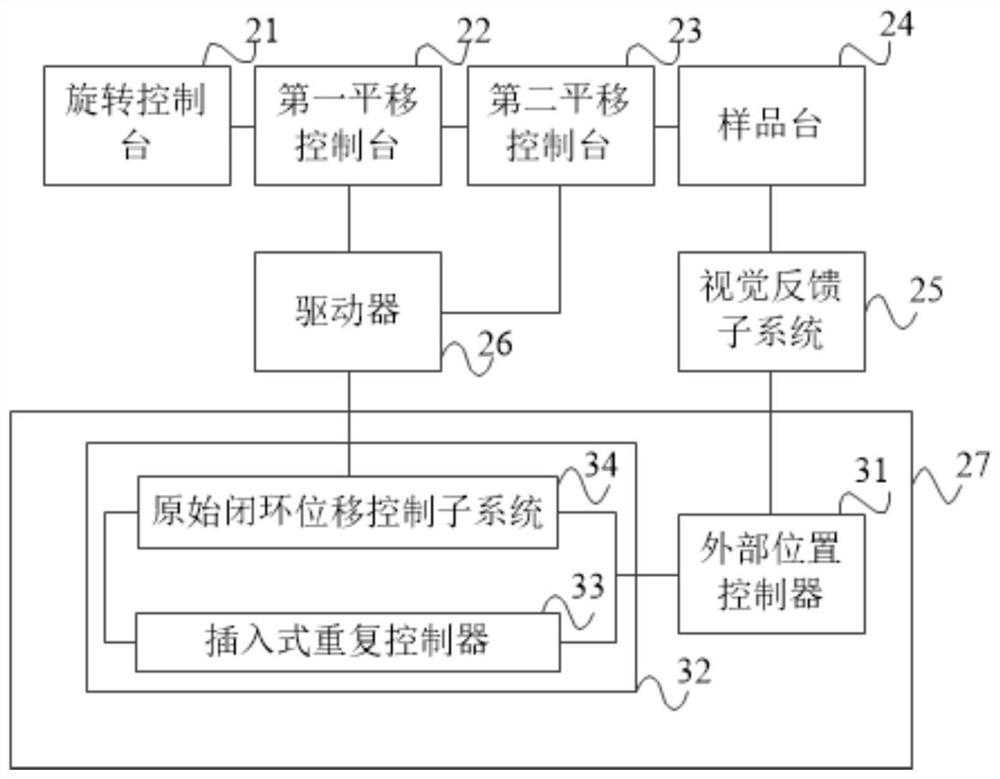

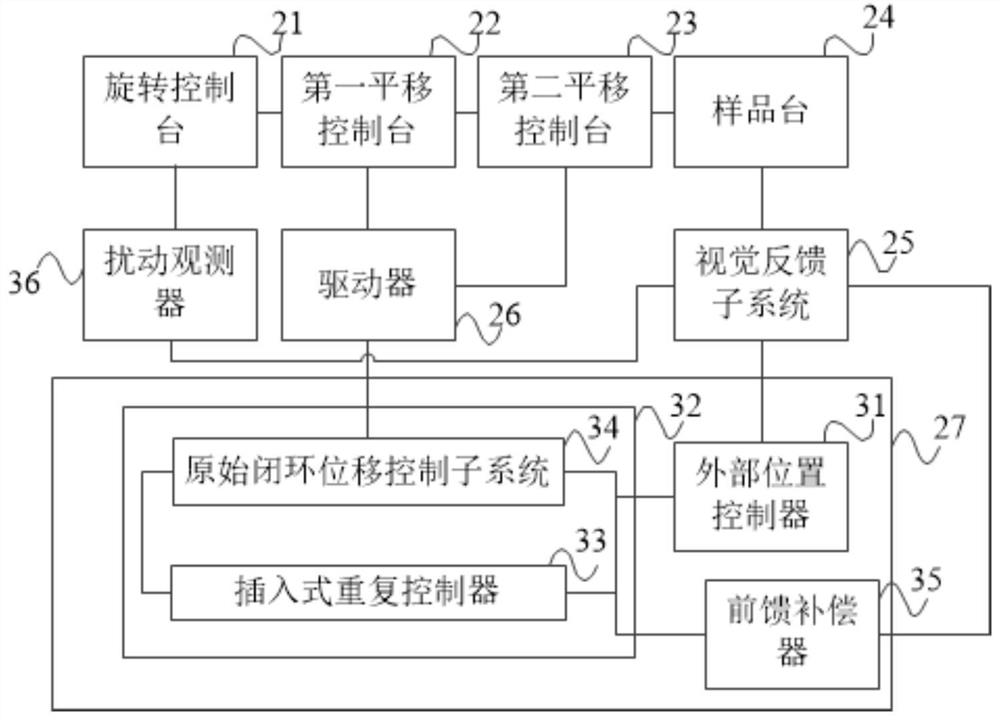

Control system and control method for rotary positioning platform under microscope

ActiveCN108563246BImprove Microscopic ImagingHigh rotational positioning accuracyMicroscopesControl using feedbackRotational axisLoop control

Owner:GUANGDONG MINGKAI MEDICAL ROBOTS CO LTD

Automatic changing device of grinding wheel and grinding wheel cover of vertical internal and external grinding machine

ActiveCN102886741BAutomatic replacementAccurate rotation positioningGrinding/polishing safety devicesNumerical controlDrive shaft

The invention relates to an automatic changing device of a grinding wheel and a grinding wheel cover of a vertical internal and external grinding machine, wherein a body shell is fixed on a machine body, a servo motor is installed below the body shell, an output shaft of the servo motor is connected with an input shaft of a speed reducer through a transmission shaft located in the body shell, and the output shaft of the speed reducer is connected with a grinding wheel mounting disk; a rotating shaft is installed in the grinding wheel mounting disk; the upper end of the rotating shaft is connected with a grinding wheel cover mounting disk through a clutch, the clutch is connected with a cylinder piston rod through a guide sleeve and a guide shaft, a cylinder is fixedly connected with a clutch shell through a cylinder seat, and a spring is installed between the clutch shell and the grinding wheel cover mounting disk. According to the automatic changing device provided by the invention, the grinding wheel and the grinding wheel cover of the vertical internal and external grinding machine can be changed automatically; the operation of changing a grinding wheel turntable and a grinding wheel cover turntable is switched by the clutch, and the operations can not interfere each other during the changing process; the clutch is controlled by the cylinder and the spring; and the mechanism is driven by a numerical control servo motor, and the rotating and locating precision of the grinding wheel and the grinding wheel cover are high.

Owner:SHANGHAI MACHINE TOOL WORK

Assembly head and automatic assembling machine

ActiveCN101754672BHigh rotational positioning accuracyReduce torqueElectrical componentsEngineeringPneumatic tube

The head has a mechanical arm (11) for picking and holding a member (3), and a pneumatic unit (12) for loading preset pressure (p1) to the mechanical arm. A pneumatic tube (13) is mounted on an assembly head. Another pneumatic tube (14) is partially guided in an interior of the mechanical arm and connected with the former pneumatic tube. The pneumatic tubes are used as rigid connecting tubes and mutually plugged on connecting positions (A-B) to be connected. A flow rate sensor determines a volume flow in the former pneumatic tube.

Owner:ASM ASSEMBLY SYST GMBH & CO

Hollow parallel harmonic reduction device and driving method thereof

InactiveCN113074233AHigh rotational positioning accuracyIncreased torsional rigidityGearingGearing detailsReduction driveEngineering

The invention relates to a hollow parallel harmonic reduction device and a driving method thereof. The harmonic reduction device comprises a hollow shaft, a harmonic reduction assembly and an output shaft, wherein the hollow shaft can rotate around the central axis thereof, and a first hollow hole is formed in the hollow shaft; the harmonic reduction assembly is arranged on the outer side wall of the hollow shaft and comprises a first harmonic reducer and a second harmonic reducer which are distributed in the axial direction of the hollow shaft; the output shaft is located in the first hollow hole and is connected with the harmonic reduction assembly to achieve power output of the harmonic reduction assembly; and the hollow shaft drives the first harmonic reducer and the second harmonic reducer to work synchronously, the first harmonic reducer and the second harmonic reducer transmit power to the output shaft, and the output shaft outputs the power. The harmonic reduction device can obtain higher rotary positioning precision and higher torsional rigidity, and is good in synchronism, compact in structure and good in stability.

Owner:江苏镌极特种设备有限公司

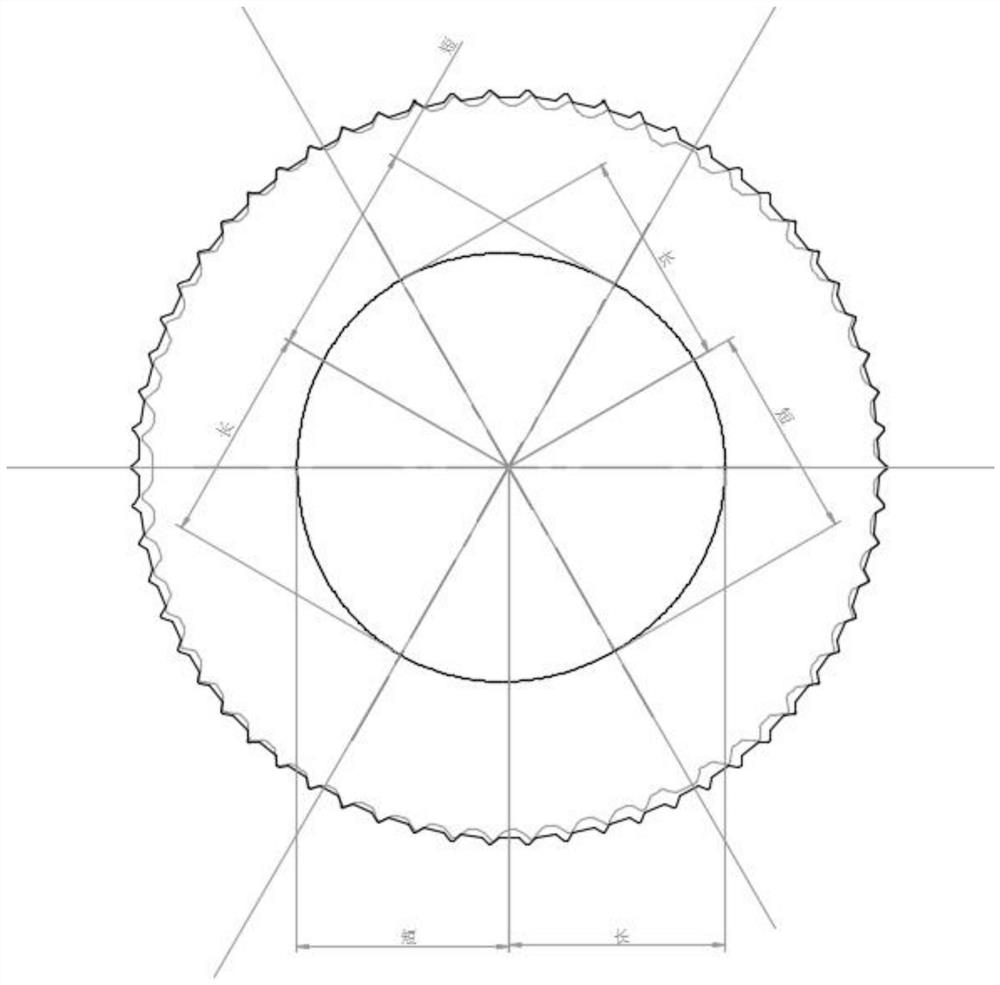

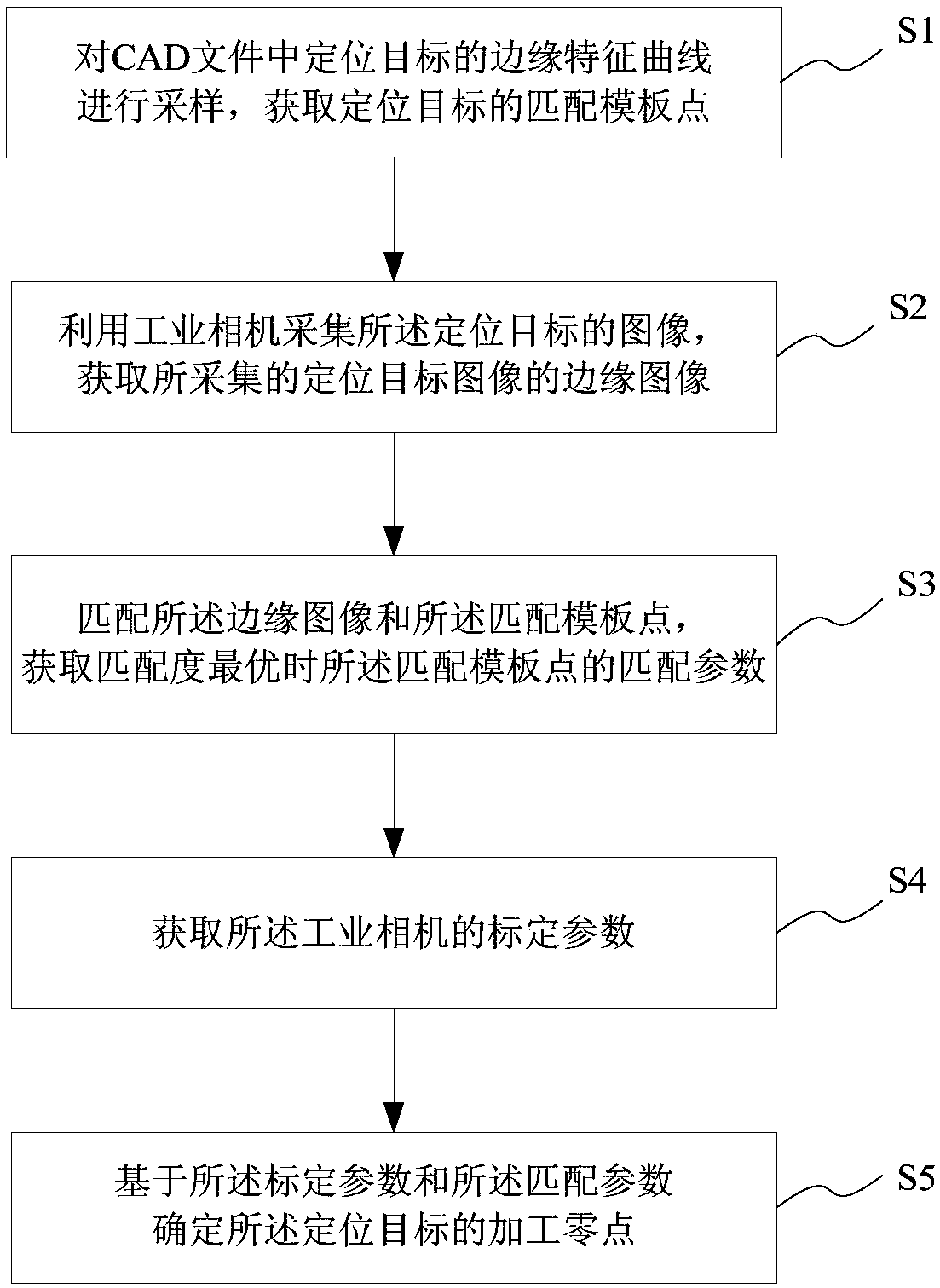

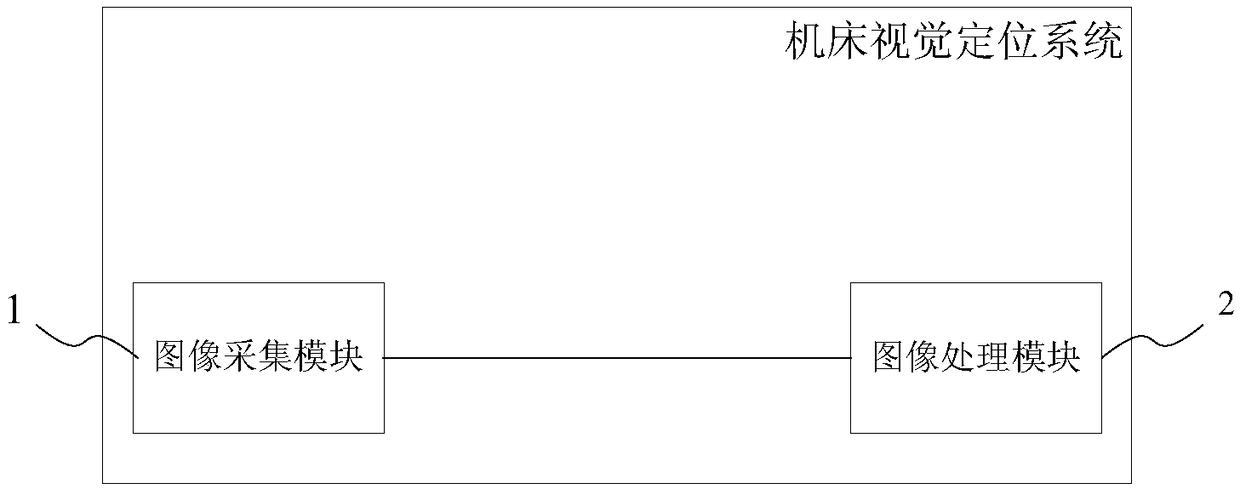

A machine tool visual positioning method and system, and machine tool

ActiveCN107942949BRealize automatic positioningWide applicabilityProgramme controlComputer controlVisual positioningVisual perception

The invention provides a machine tool vision positioning method and system and a machine tool. The method includes the following steps: sampling the edge characteristic curve of a positioning target in a CAD file, and obtaining a matching template point of the positioning target; collecting an image of the positioning target by using an industrial camera, and obtaining an edge image of the collected positioning target image; matching the edge image with the matching template point, and obtaining the matching parameters of the matching template point when the matching degree is optimal; obtaining the calibration parameters of the industrial camera; and determining the machining zero of the positioning target based on the calibration parameters and the matching parameters. According to the machine tool vision positioning method and system and the machine tool, the shaped drawn by CAD is used as the characteristic of edge positioning, automatic positioning of a work piece positioned in anon-tooling way can be realized, the machining zero can be obtained and the actual size of the positioning target can be measured, and therefore, the positioning efficiency and machining efficiency ofwork pieces can be improved.

Owner:SYMG SHANGHAI INTELLIGENCE SYST CO LTD

A bending center front feeding equipment

ActiveCN114160691BPrecise positioningExpand the scope of processingMetal-working feeding devicesMetal working apparatusEngineeringManipulator

The invention discloses a feeding device at the front of a bending center, which comprises a fixed base, a C-shaped pressing arm driving device, a C-shaped pressing arm, a rotating positioning mechanism, an auxiliary feeding manipulator, a front-end positioning assembly of a sheet material, and a left-side positioning assembly of the sheet material , the auxiliary pushing assembly on the right side of the sheet, the auxiliary pushing assembly on the rear side of the sheet, and the loading and unloading platform, a feeding device at the front of the bending center of the present invention, through a comprehensive sheet positioning method, the front and left ends of the sheet There are positioning stops, and the right and rear ends of the sheet are equipped with auxiliary pushing mechanisms, so that the positioning of the workpiece is more accurate, and the deviation caused by manual feeding is avoided. At the same time, for some special-shaped workpieces, the secondary positioning of the automatic workpiece can be realized through the mutual cooperation between the positioning mechanisms, which expands the processing range of the workpiece, thereby improving the utilization rate of the equipment.

Owner:DERATECH MASCH TOOL (SUZHOU) CORP LTD

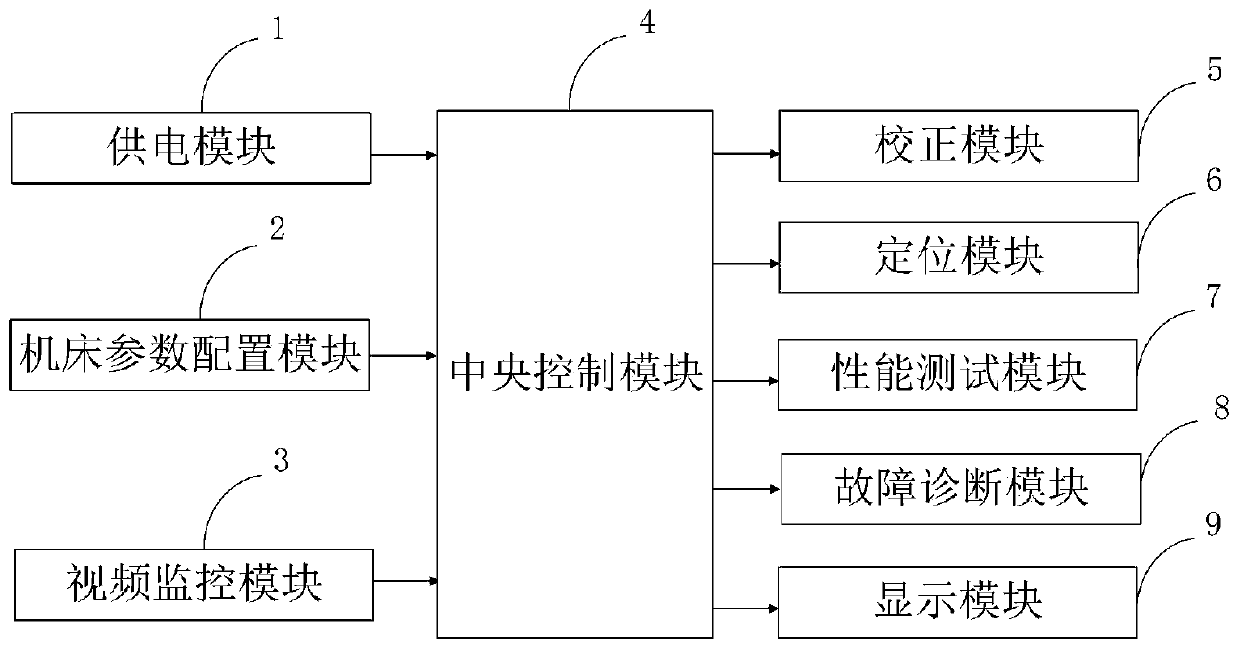

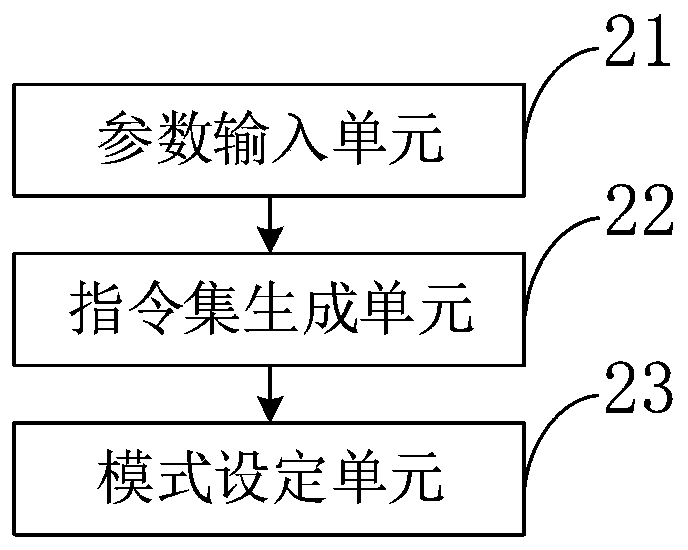

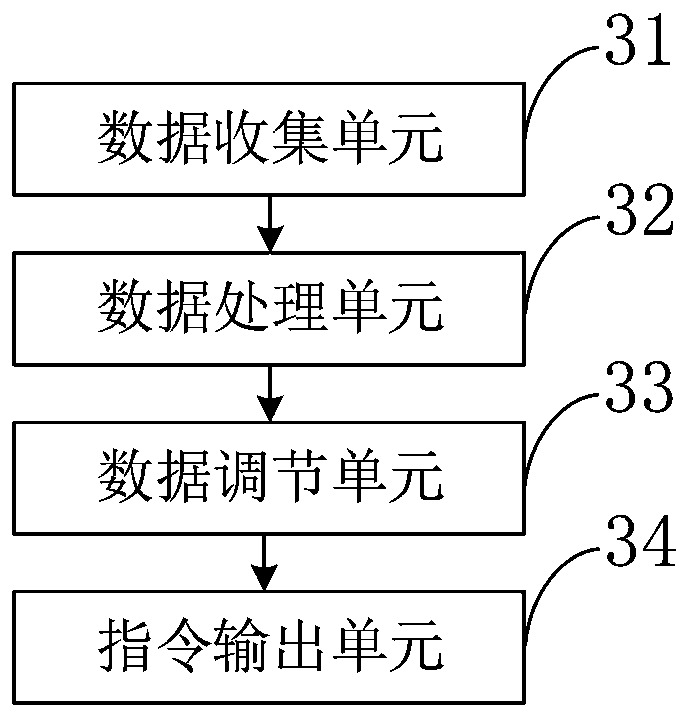

Parallel multi-channel numerical control machine tool

InactiveCN111562768AEasy to findScientific Performance IndicatorsProgramme controlComputer controlNumerical controlVideo monitoring

The invention belongs to the technical field of numerical control machine tools, and discloses a parallel multi-channel numerical control machine tool, which comprises a power supply module, a machinetool parameter configuration module, a video monitoring module, a central control module, a correction module, a positioning module, a performance test module, a fault diagnosis module and a displaymodule. According to the invention, the positioning module is used for positioning by taking a shape drawn by CAD as an edge positioning characteristic, so that a machining zero point can be found conveniently and quickly, and the positioning efficiency and the machining efficiency are improved; high translation positioning precision, high rotation positioning precision and high repeated positioning precision can be realized, and the practicability is high; meanwhile, the performance of each part of the machine tool can be judged more specifically and specifically through the performance testmodule, the state of the machine tool can be reflected, and more scientific performance indexes of the machine tool can be obtained through proper weight allocation when the performance indexes of themachine tool are obtained.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

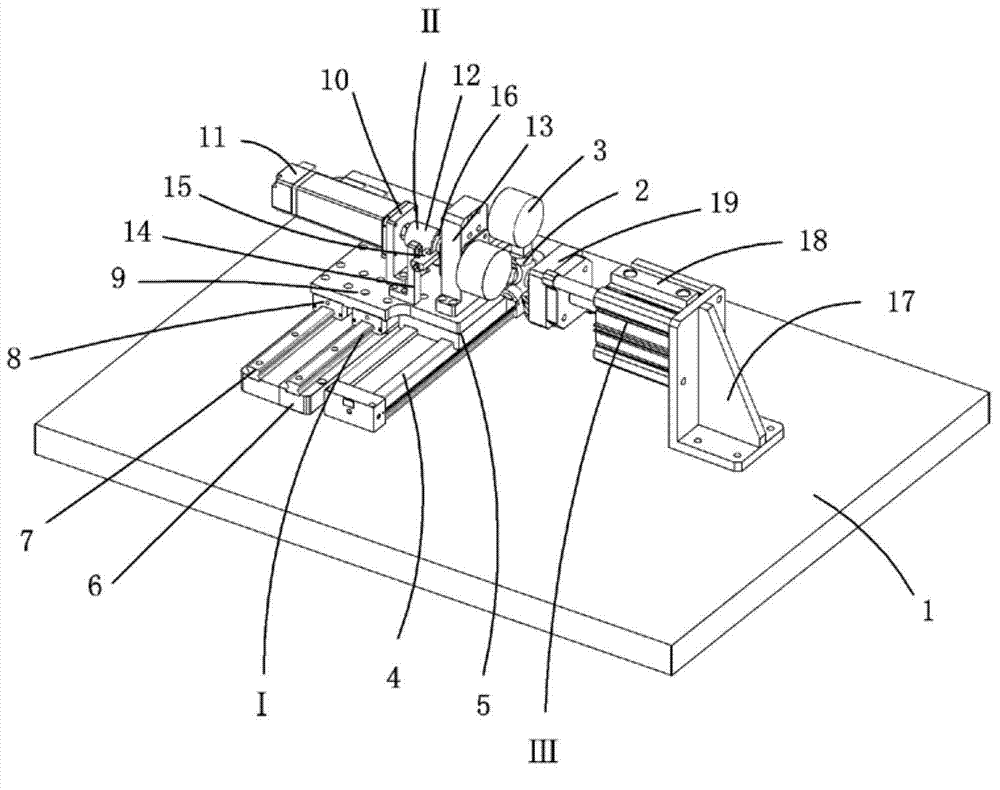

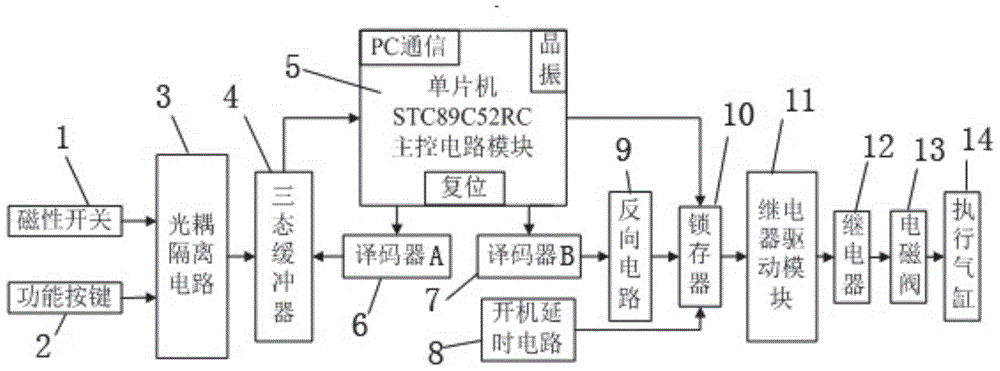

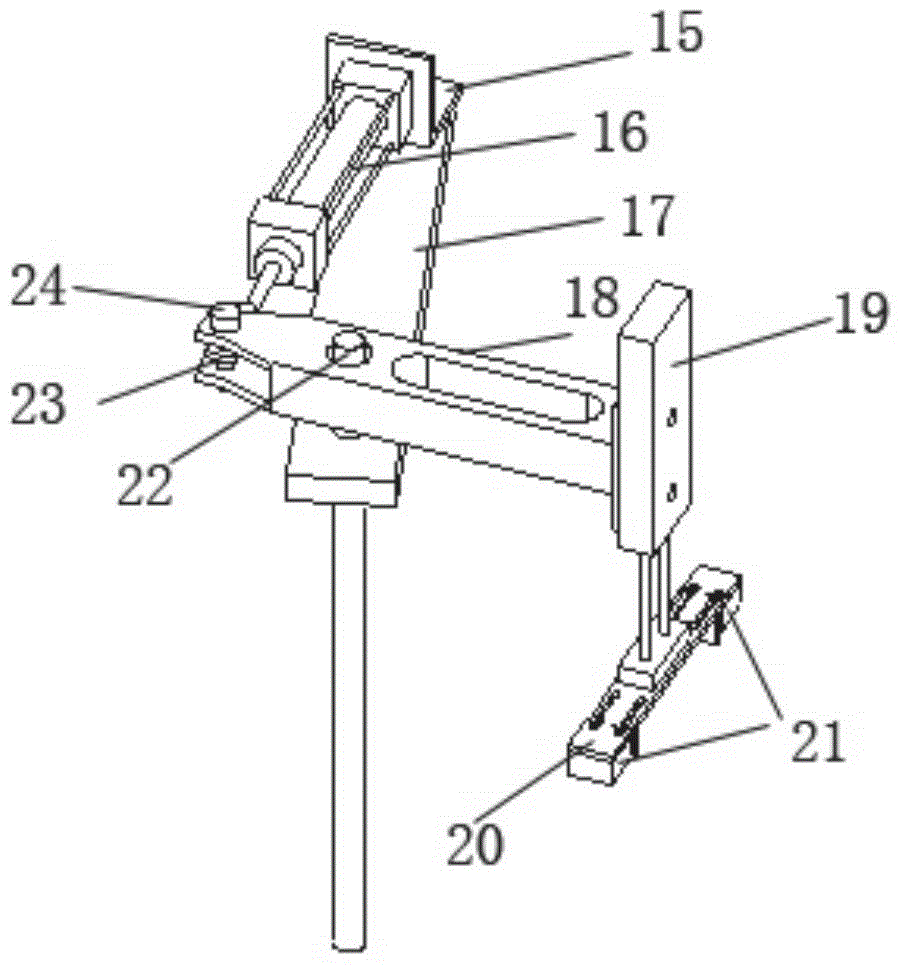

A mechanical mechanism and control system of a pneumatic handling manipulator

InactiveCN104924304BHigh rotational positioning accuracyLow costProgramme-controlled manipulatorControl systemEngineering

The invention relates to a mechanical mechanism and control system of a pneumatic handling mechanical hand, and belongs to the field of pneumatic handling mechanical hands. The mechanical mechanism of the pneumatic handling mechanical hand comprises the relevant connection relation of a horizontal telescopic air cylinder fixing seat, a horizontal telescopic air cylinder, a horizontal supporting seat, a rotary arm, a vertical lifting air cylinder, a clawing claw fixing seat, clamping claws, a rotary shaft and a connector I. The control system comprises a magnetic switch, a function key, an opto-isolator circuit, a three-state buffer, a single-chip microcomputer STC89C52RC master control circuit module, a decoder, a starting delay circuit, a reverse circuit, a latch, a relay drive module, a relay, an electromagnetic valve and an execution air cylinder. The designed pneumatic handling mechanical hand is easy to achieve, accurate in locating and high in economic efficiency, can be switched between two work stations, and is especially suitable for point location handling of injection molding blades in air conditioners.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com