Assembly head and automatic assembling machine

A technology of assembly heads and assembly machines, applied in the direction of electrical components, electrical components, etc., can solve problems such as adverse effects on positioning accuracy, and achieve the effects of small torque, small axial force, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

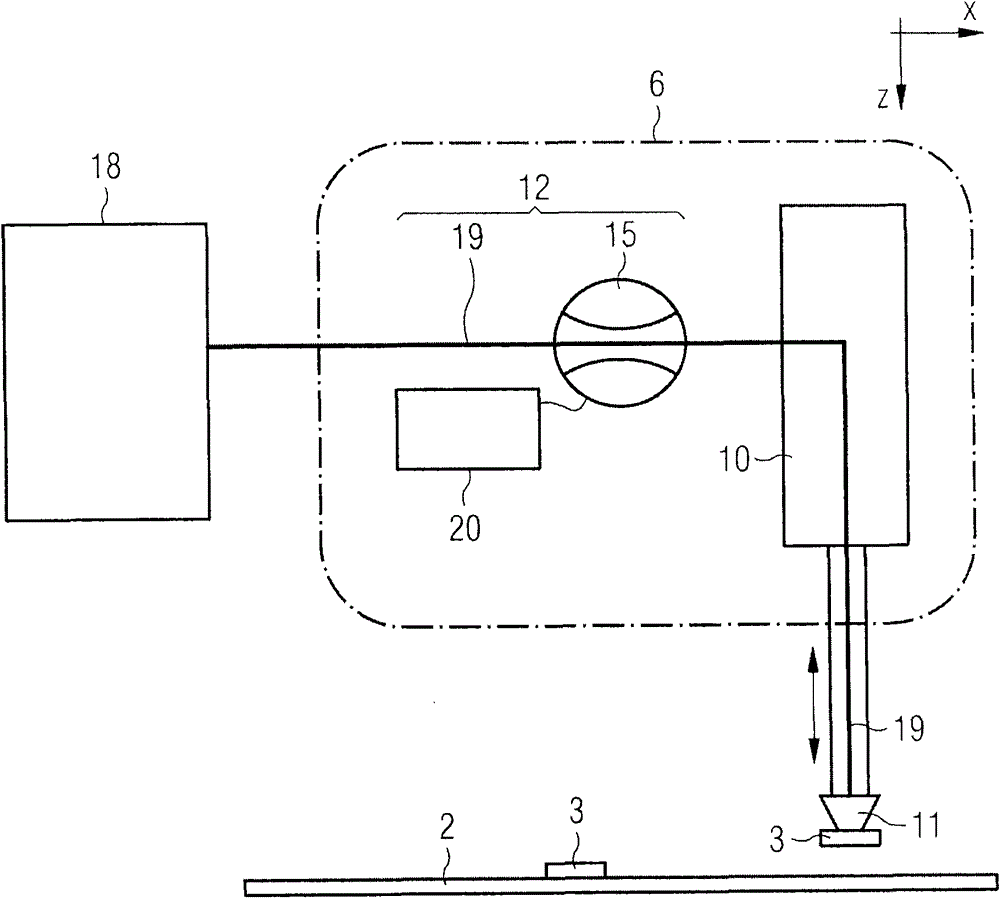

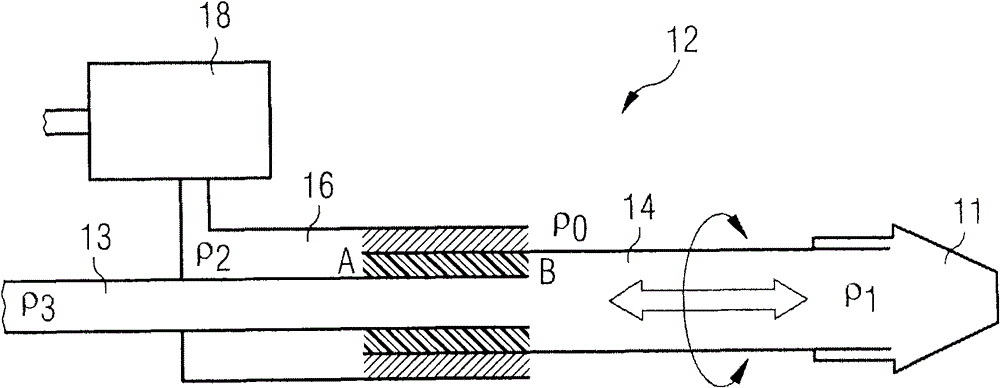

[0030] In the different representations of the figures, the same components always bear the same reference numerals. This description applies to all figures in which corresponding parts can likewise be identified.

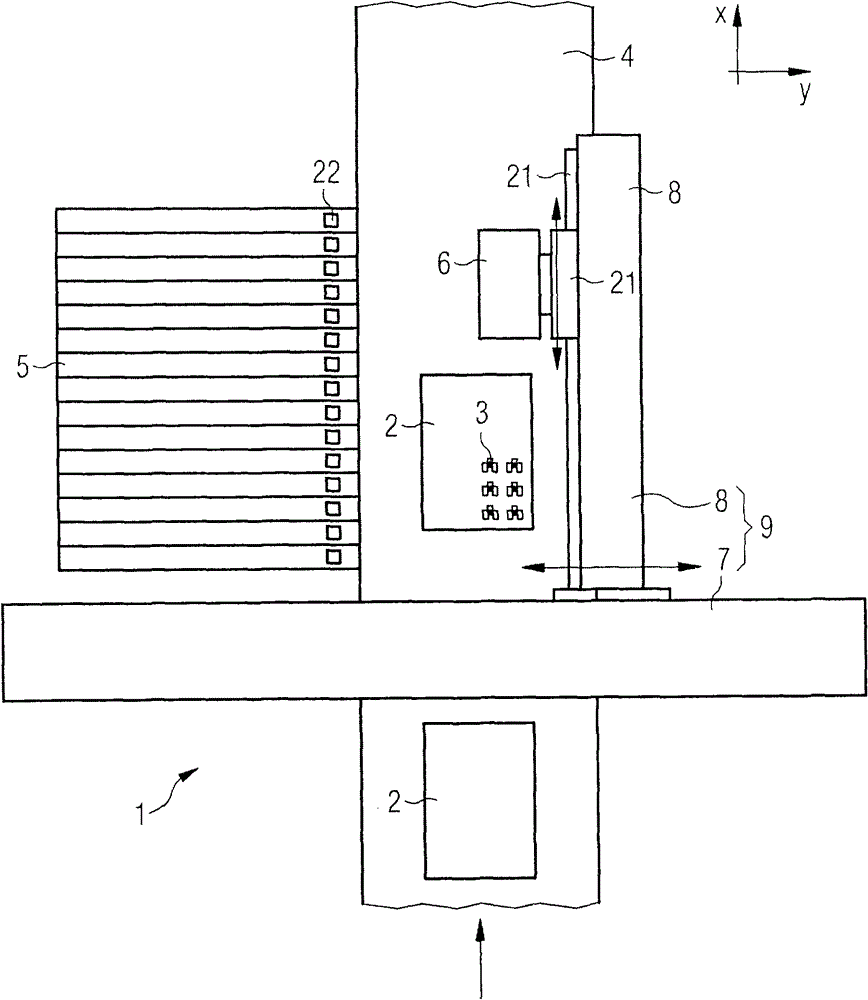

[0031] figure 1 The general structure of an automatic assembly machine 1 for assembling components 3 for substrates 2 is schematically shown, which is adapted to accommodate a mounting head 6 according to the invention. The automatic assembly machine 1 has a cross member 7 which extends in the y-direction and which is fixedly connected to a frame (not shown). Mounted on the crossbeam 7 is a mast arm 8 which extends in the x-direction and is fastened on the crossbeam 7 so that it can move in the y-direction. The crossbeam 7 and the mast arm 8 together form a positioning system 9 , wherein a Cartesian coordinate system is formed by the x-axis and the y-axis. Arranged on the mast arm 8 is a mounting head 6 which can be moved in the x-direction along the mast arm 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com