Precise rotating, aligning and pre-pressing execution mechanism of bonder

A technology of rotary alignment and actuators, applied in nonlinear optics, instruments, optics, etc., can solve problems such as low alignment accuracy and poor stability, and achieve improved rotation positioning accuracy, low cost, and strong pressure-bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

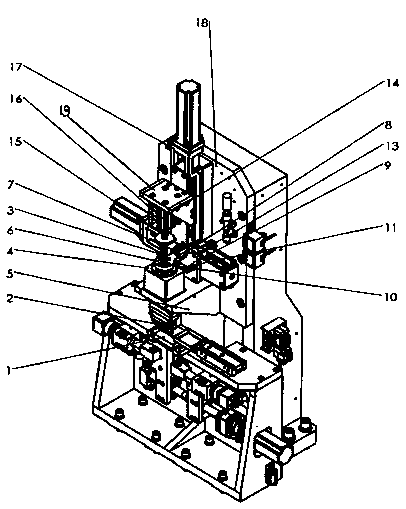

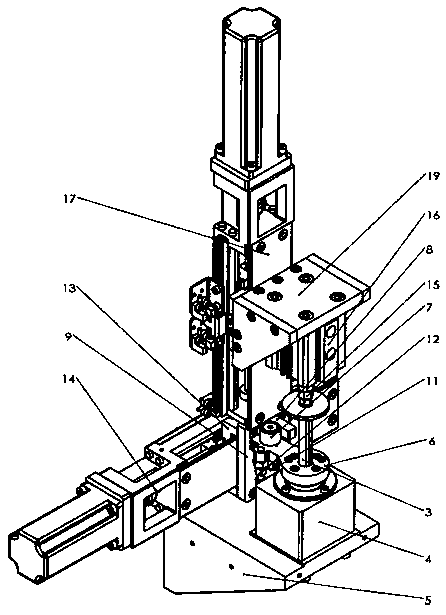

[0011] The present invention is described in detail below in conjunction with accompanying drawing:

[0012] A precise rotary alignment preloading actuator for a bonding machine, comprising a bonding preloading workbench 1, on the rear side of the bonding preloading workbench 1 a frame stand 18 is fixed, A bonded liquid crystal display is placed on the workbench 1, and a rotating bearing installation bracket 5 is arranged directly above the bonded liquid crystal display. On the 18, the rotary bearing 4 is arranged on the rotary bearing mounting bracket 5, and the lifting screw module 17 is arranged on the frame vertical plate 18 above the rotary bearing mounting bracket 5, and the lifting slide of the lifting screw module 17 An inverted L-shaped mounting plate 19 is fixedly arranged on the block, and a downward-pressing rotary spline shaft 3 moves through the rotary bearing 4, and a suction head mechanism 2 is arranged at the lower end of the downward-pressing rotary spline sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com