Automatic changing device of grinding wheel and grinding wheel cover of vertical internal and external grinding machine

An internal and external cylindrical grinding machine, automatic replacement technology, applied in grinding/polishing safety devices, grinding/polishing equipment, metal processing equipment, etc. Grinding auxiliary time is long and other problems, to achieve the effect of reducing auxiliary time, reducing labor intensity, and high rotation positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

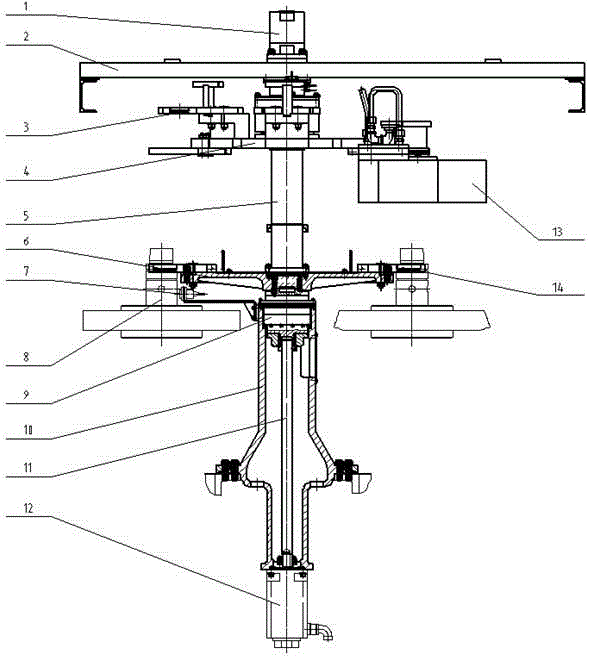

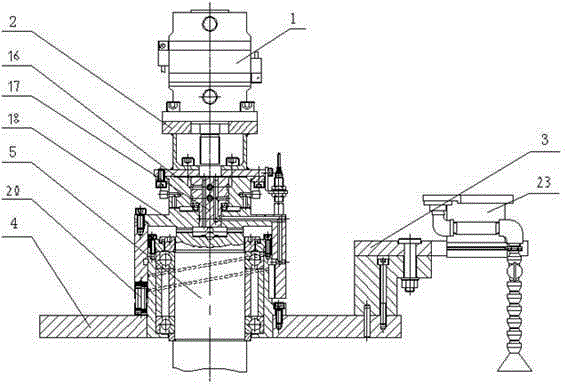

[0016] Such as figure 1 , as shown in 2, the vertical inner and outer cylindrical grinder grinding wheel and the grinding wheel cover automatic replacement device of the present invention include a cylinder 1, a cylinder seat 2, a grinding wheel cover claw 3, a grinding wheel cover mounting disc 4, a rotating shaft 5, and a grinding wheel mounting disc 6. Positioning sensor 7, inner grinding wheel, outer grinding wheel 8, reducer 9, body shell 10, transmission shaft 11, servo motor 12, outer grinding wheel cover 13, grinding wheel claw 14, guide sleeve 16, guide shaft 17 , Clutch 18, spring 20, inner wheel cover 23, etc.

[0017] The body shell 10 is fixed on the bed, and a servo motor 12 is installed under the body shell 10. The output shaft of the servo motor 12 is connected to the input shaft of the reducer 9 through the transmission shaft 11 locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com