Card code printing mechanism with light elastic piece

A shrapnel and card technology, which is applied in the field of card coding mechanism, can solve the problems of difficulty in controlling the rotation accuracy of the dial, high production cost of the dial, and high quality of the dial mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

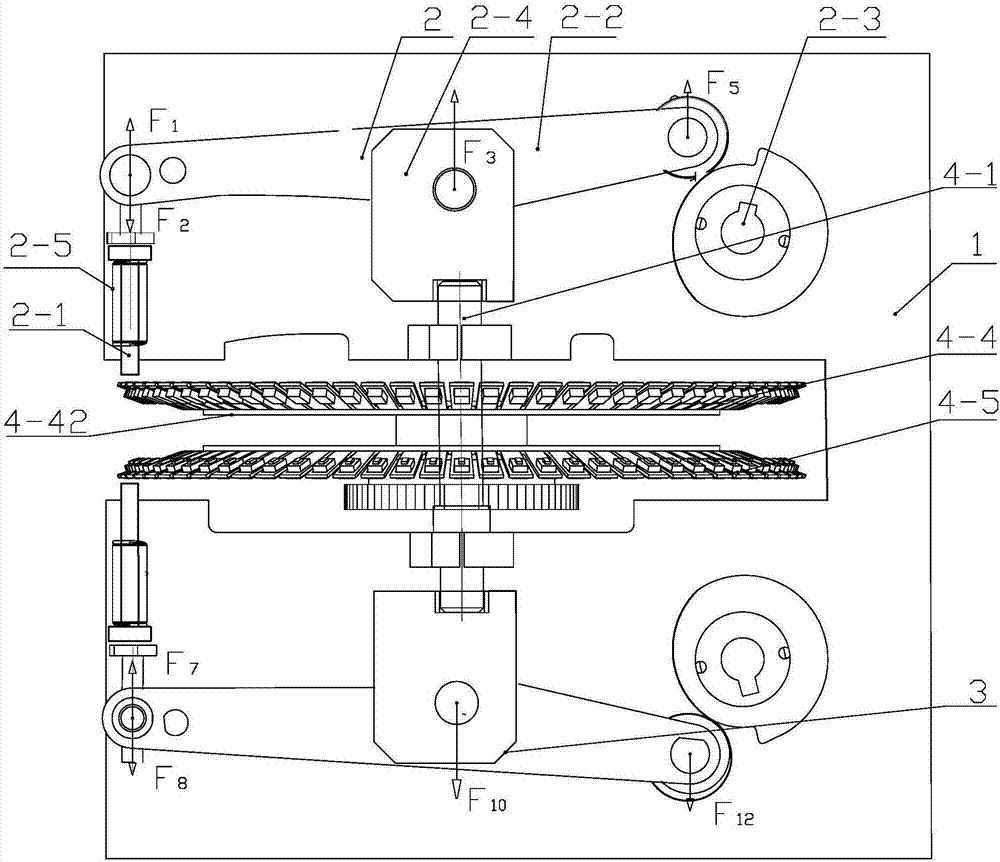

[0019] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this embodiment, a card coding mechanism with light-duty shrapnel, which includes a vertical plate bracket 1, a dial assembly, a first hammer assembly 2 and a second hammer assembly 3, the dial assembly, the second hammer assembly Both the hammer assembly 2 and the second hammer assembly 3 are fixed on the vertical plate bracket 1, and the first hammer assembly 2 and the second hammer assembly 3 are symmetrically arranged on the upper and lower sides of the dial assembly both ends,

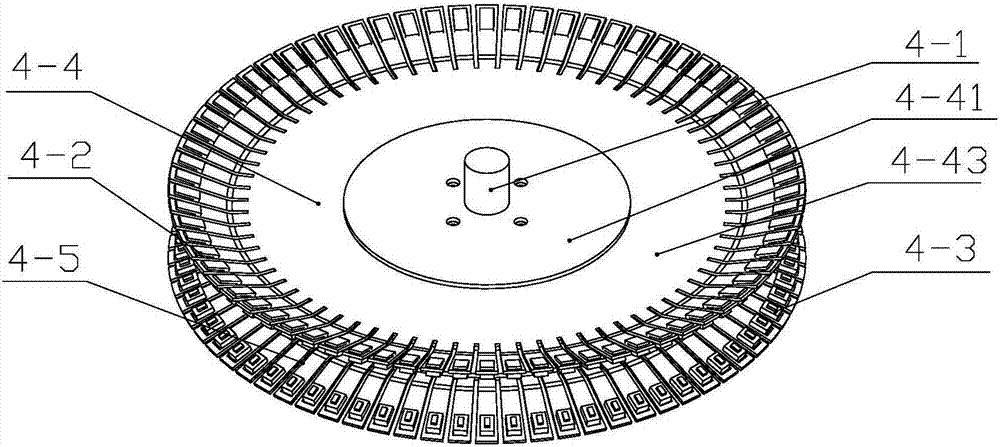

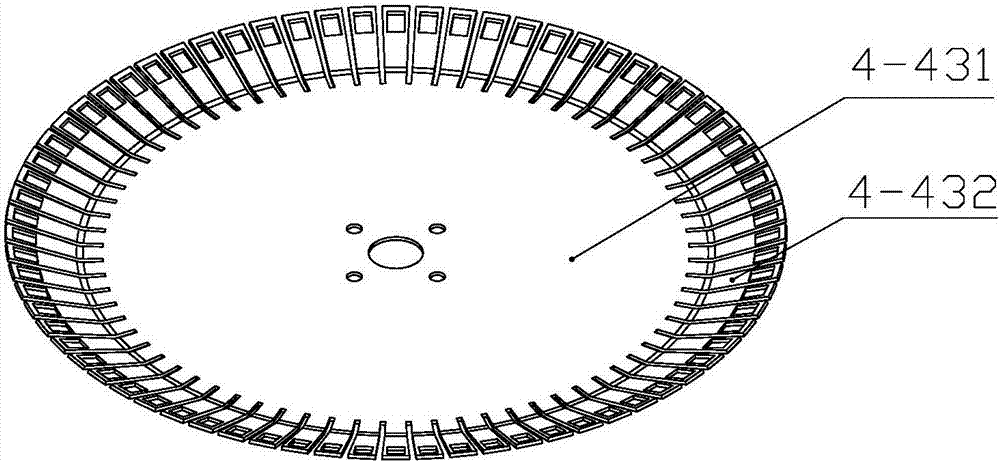

[0020] The dial assembly includes a dial shaft 4-1, several first fonts 4-2, several second fonts 4-3, symmetrically arranged first circular dials 4-4 and second circular dials 4- 5. Both the first round dial 4-4 and the second round dial 4-5 are rotatably fixed on the dial shaft 4-1 through bearings, and the first round dial 4-4 includes the second round dial 4-5. An inner disc 4-41, a first outer disc 4-42 and a fir...

specific Embodiment approach 2

[0022] Specific implementation mode two: combination Figure 1 ~ Figure 3 To illustrate this embodiment, the first elastic strip 4-432 and the second elastic strip are in the shape of bent strips. In such a design, the bending angle of the bending part of the elastic strip is related to the length of the elastic strip and the distance between the first elastic strip and the second elastic strip, so that when the first font 4-2 and the second font 4-3 are pressed together , the two fonts fit together horizontally. Other compositions and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0023] Specific implementation mode three: combination Figure 1~3 To illustrate this embodiment, the first hammer assembly 2 and the second hammer assembly 3 are symmetrically arranged at both ends of the dial shaft 4-1, and the first hammer assembly 2 includes the first hammer 2- 1. The first character arm 2-2 and the first cam component 2-3, the first cam component 2-3 is fixed on the vertical plate bracket 1, and one end of the first character arm 2-2 is vertically fixed with the first character hammer 2-1, and the first word hammer 2-1 is located between the first word arm 2-2 and the dial assembly, and the other end of the first word arm 2-2 always abuts against the first cam assembly 2-3 On the surface of the cam, the axial center of the first character arm 2-2 is hingedly installed on the top of the dial shaft 4-1 through the first fixed block 2-4, and the dial shaft 4-1 is simultaneously located on the first circular dial 4-4 The center position of and the center pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com