Tilt device

A technology of tilting device and workbench, which is applied in the direction of positioning device, tool changing device, manufacturing tools, etc., can solve the problems of coolant dispersion and reduction of machining accuracy, so as to improve machining accuracy, reduce time and labor, and improve rotation positioning accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

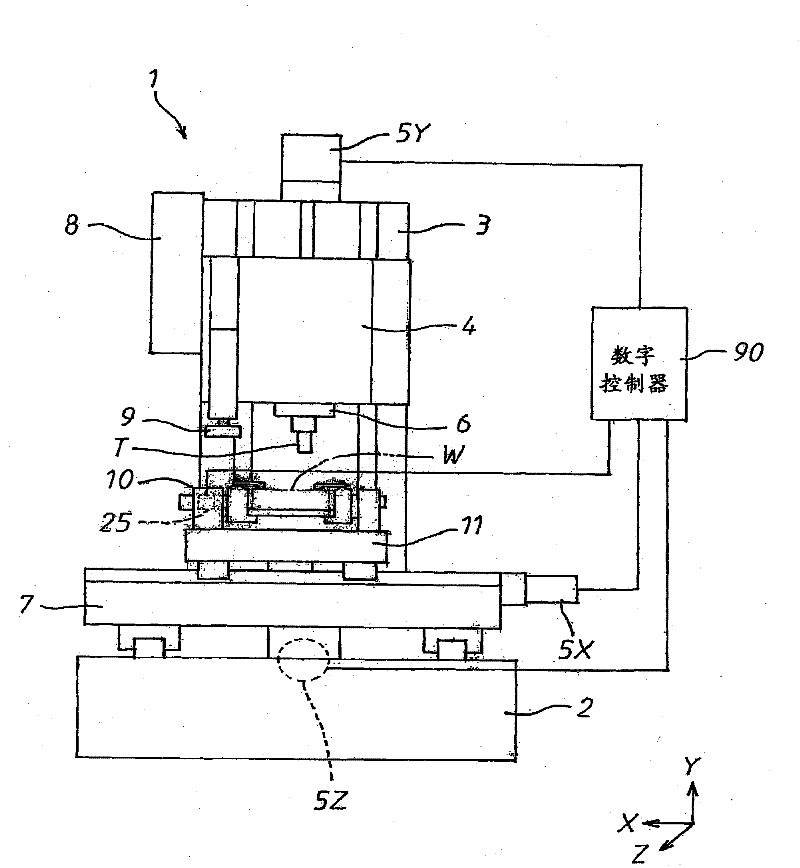

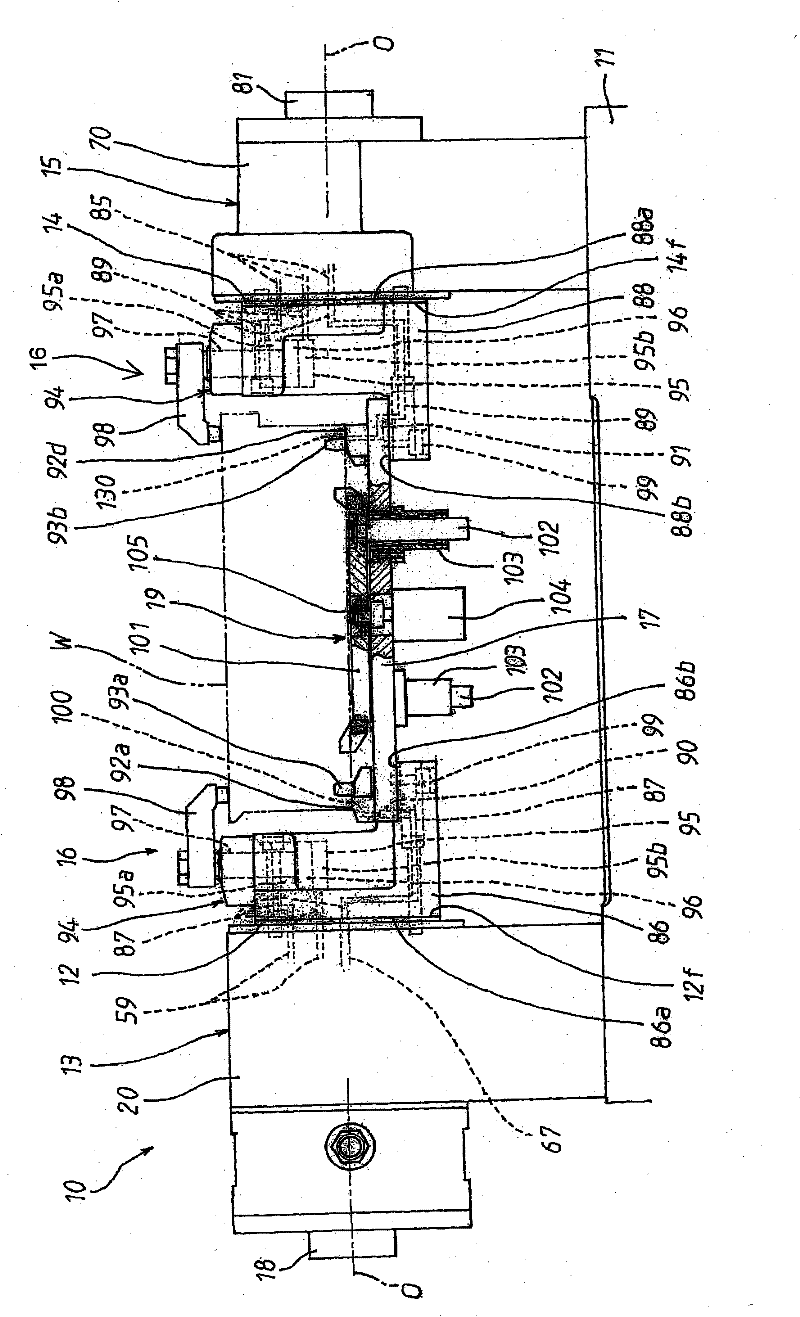

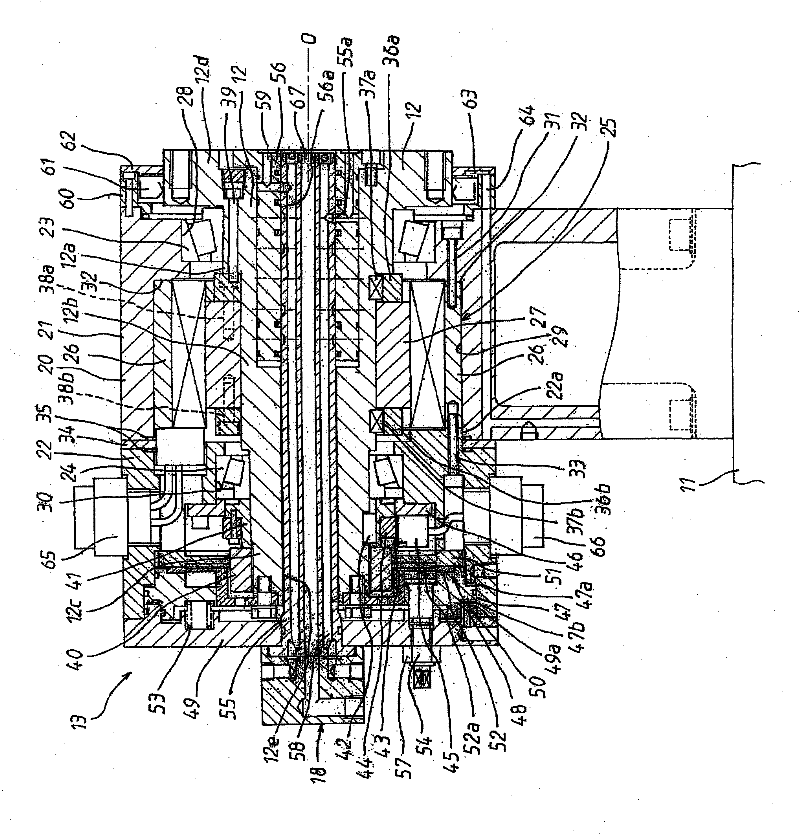

[0030] A tilting device in an embodiment of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 As shown, the tilting device 10 is fixed on a table 11 of a machine tool such as a vertical machining center 1 . In the machining center 1, a column 3 is vertically provided on a bed 2, and a spindle head 4 is mounted on the column 3 so as to be movable in the vertical direction, and is moved by a ball screw rotationally driven by a servo motor 5Y. A tool spindle 6 is supported in the spindle head 4 so as to be rotatable about a vertical axis, and is rotationally driven by a built-in motor (not shown). The tool spindle 6 is provided with a tool attachment device that detachably holds a tool T inserted into a tool attachment hole formed at the lower end of the tool spindle 6 . On the bed 2, a slide plate 7 is mounted movable in the horizontal front-rear direction, and moved in the Z-axis direction by a ball screw rotationally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com