Vertical mechanical vibrating hydraulic extruder

A mechanical vibration and extruder technology, applied in the field of vertical mechanical vibrating hydraulic extruders, can solve the problems of the influence of the axial feed speed of the hydraulic cylinder on the vibration control, and the vibration cannot be controlled independently, so as to shorten the length of the fuselage. , The effect of compact structure and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

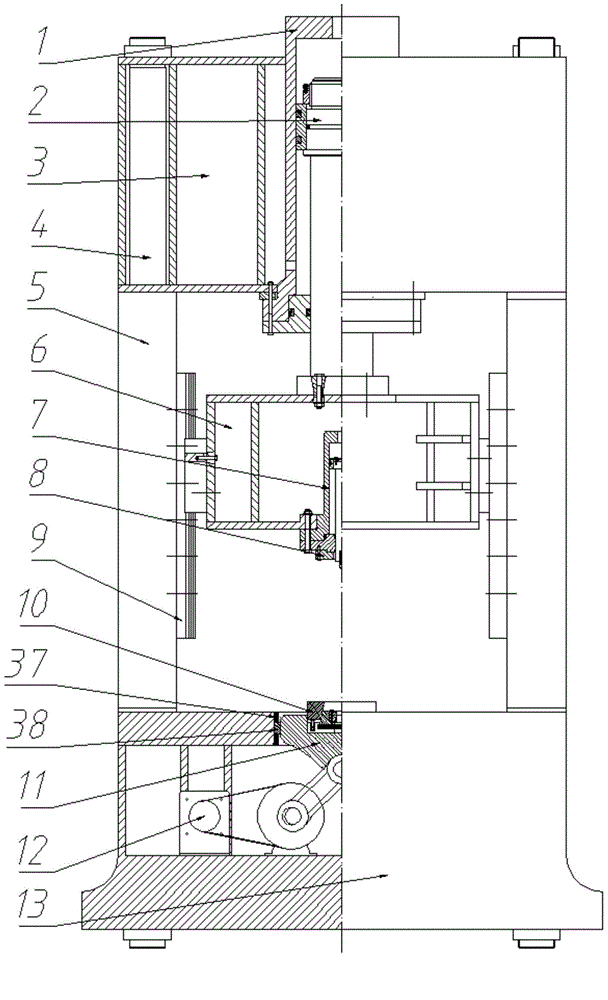

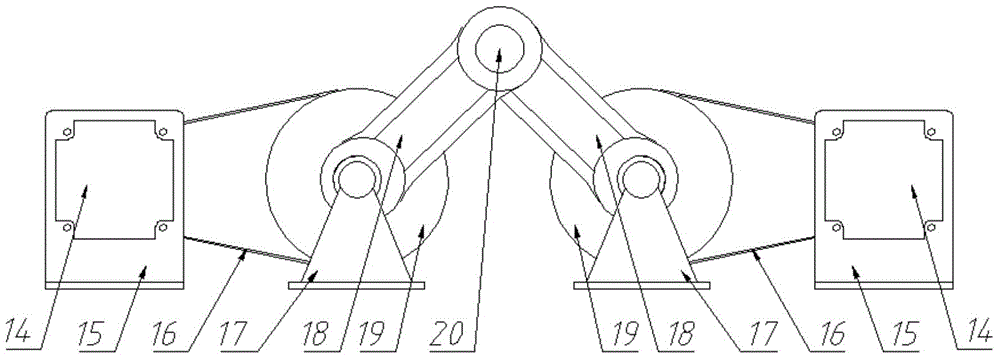

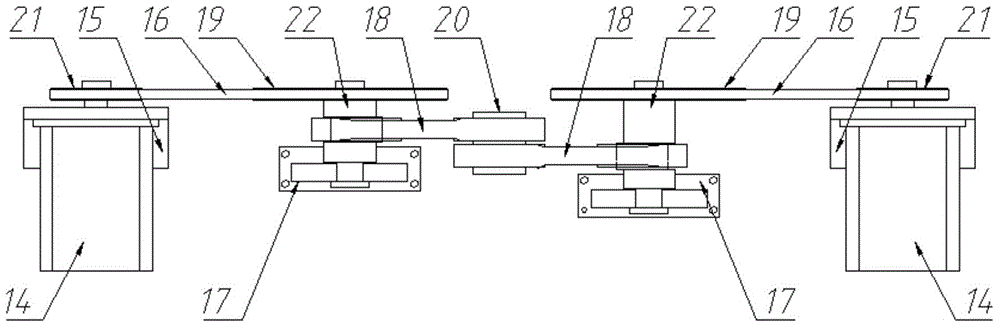

[0025] refer to figure 1 , a vertical mechanical vibration hydraulic extrusion machine, including four columns 4, the two ends of the four columns 4 are respectively connected with the upper beam 3 and the base 13, the first hydraulic cylinder 1 is fixed on the upper beam 3 by bolts, the first The end of the first piston rod 2 of the hydraulic cylinder 1 is connected to the upper part of the first slider 6, and the side of the first slider 6 cooperates with the first slide rail 9, and the first slide rail 9 is fixed on the column fixing sleeve 5, and the column 4 is installed in the column fixing sleeve 5, the second hydraulic cylinder 7 is fixed on the lower part of the first slider 6, the mold 8 is connected to the lower part of the second hydraulic cylinder 7, the vibration mechanism 12 is fixed inside the base 13, and is connected with the workbench 11 The botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com