Multi-axis linkage type numerical control drilling and milling machine tool

A drilling and milling machine tool, multi-axis linkage technology, applied to the parts of the boring machine/drilling machine, boring/drilling, large fixed members, etc., can solve the problems of incomplete processing, low processing efficiency, clamping and positioning, etc., to achieve reduction The number of clamping times, convenient and firm clamping, and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

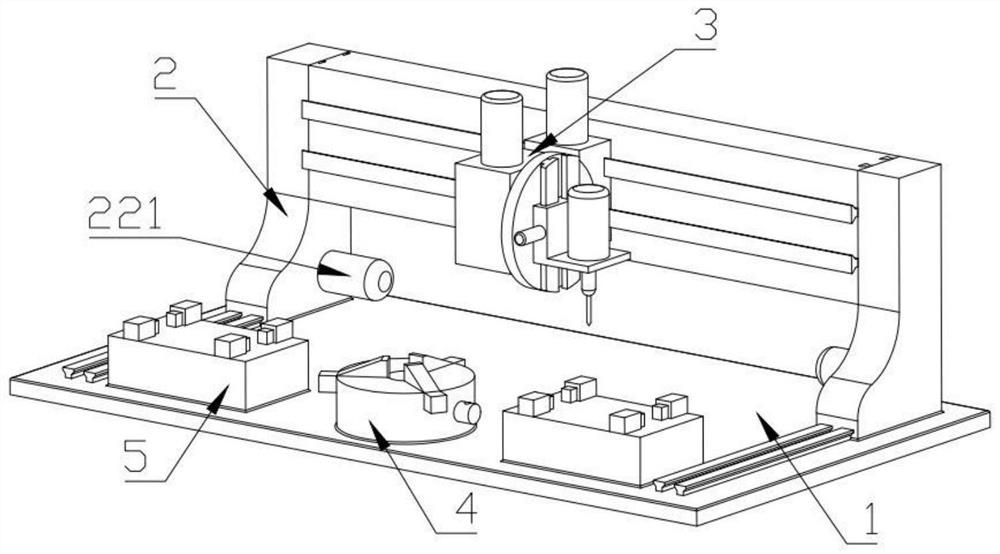

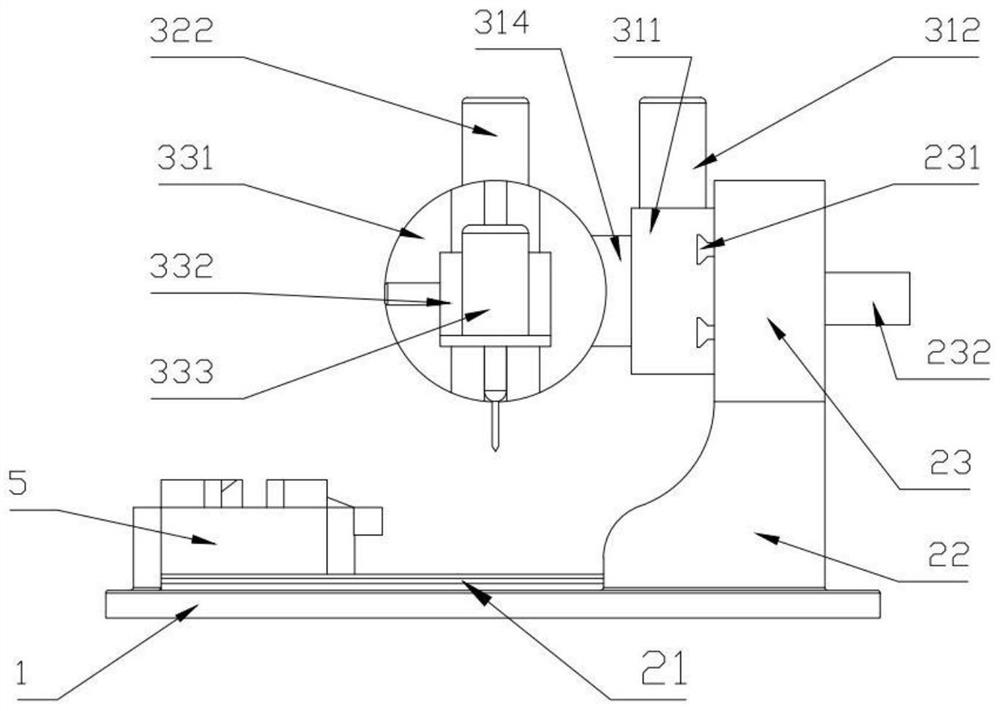

[0035] This embodiment provides a multi-axis linkage CNC drilling and milling machine tool, see figure 1 , including a base 1, a gantry 2 and a clamping device, the base 1 is arranged horizontally, a gantry 2 is arranged on it, and a drilling and milling system 3 is also provided on the gantry 2, which is used for drilling and milling of parts to be processed For processing work, the clamping device is located at the upper front end of the base 1 and is used for clamping and fixing the workpiece to be processed.

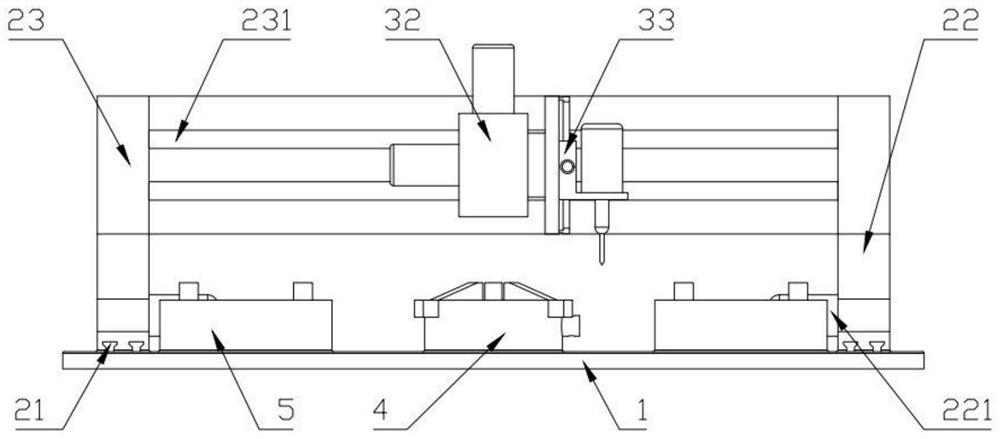

[0036] In this example, combined with figure 2 , the base 1 is a rectangular plate structure, which is arranged horizontally, and the gantry 2 includes two columns 22 at both ends thereof and a cross column 23 between the two columns 22 .

[0037] Further, first guide rails 21 are provided on both sides of the upper part of the base 1 along the width direction of the base 1 , and the bottom end of the column 22 is provided with a first slide groove matched with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com