Tap chuck for mechanical processing

A tap chuck and mechanical processing technology, applied in the direction of the chuck, etc., can solve the problems of troublesome clamping, few clamping positions of the tap, and difficult to take out, etc., and achieve the effects of protection against breakage, wide range of taps, and convenient clamping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below the utility model is further described in conjunction with the embodiments in the accompanying drawings:

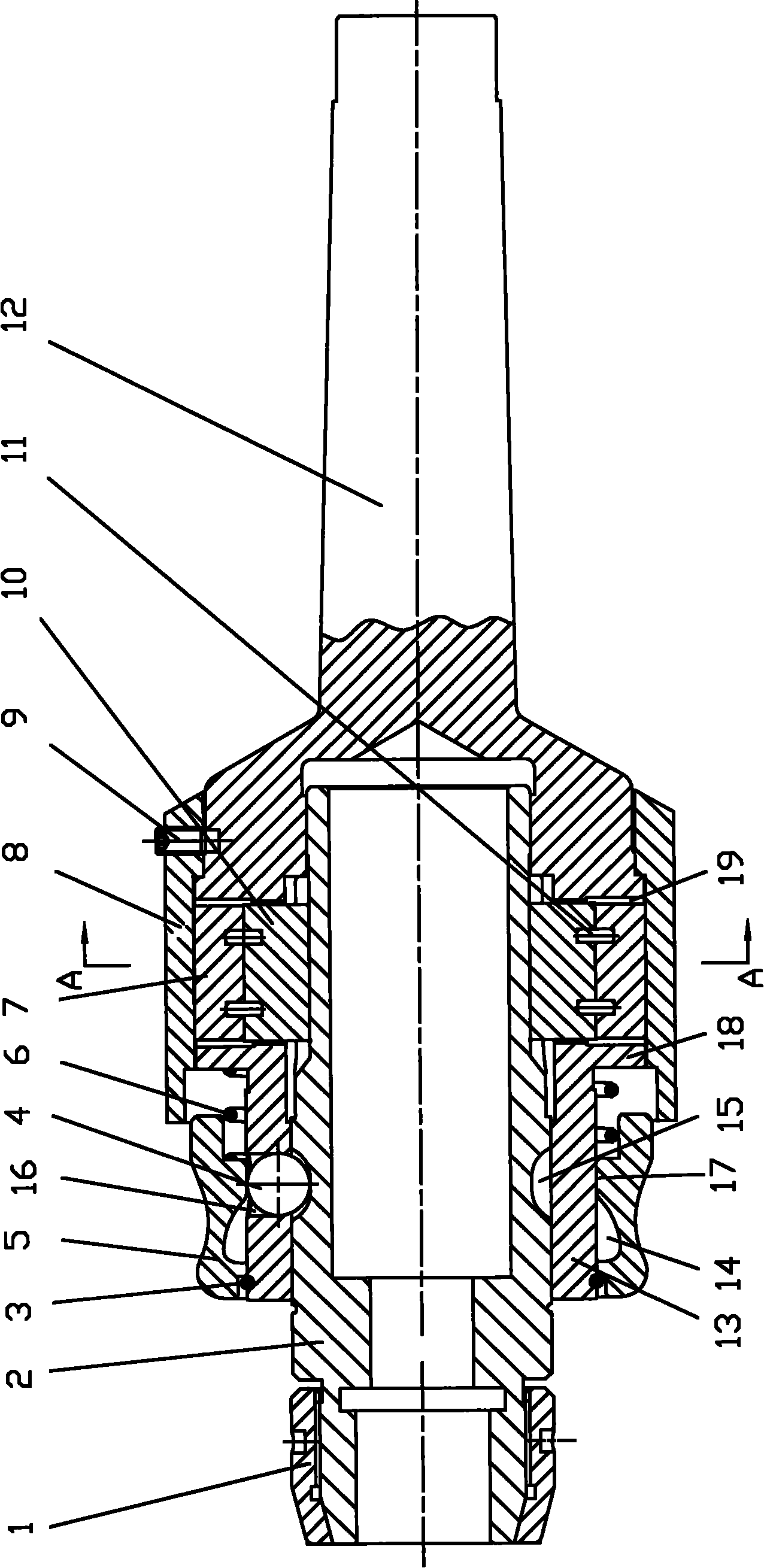

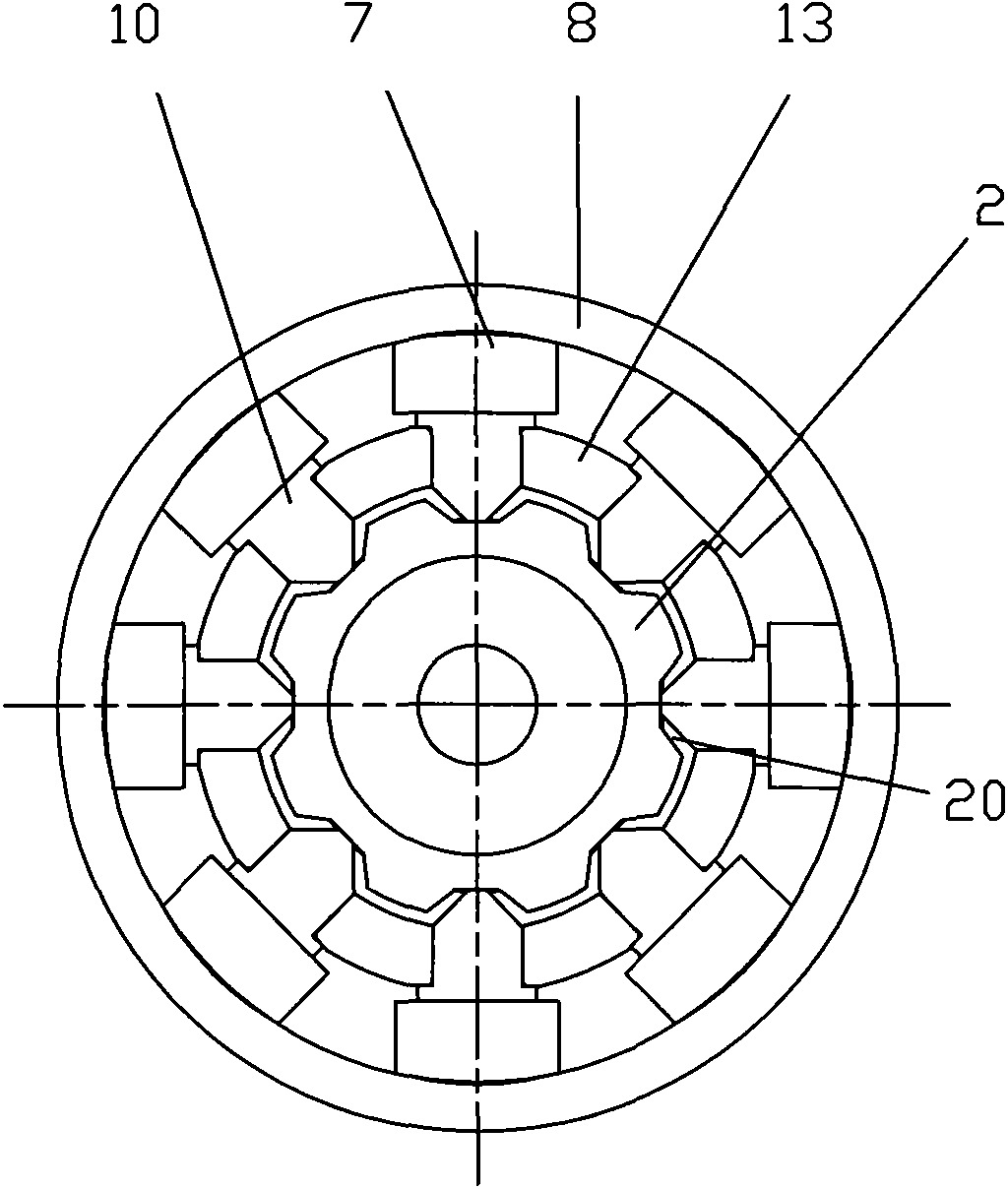

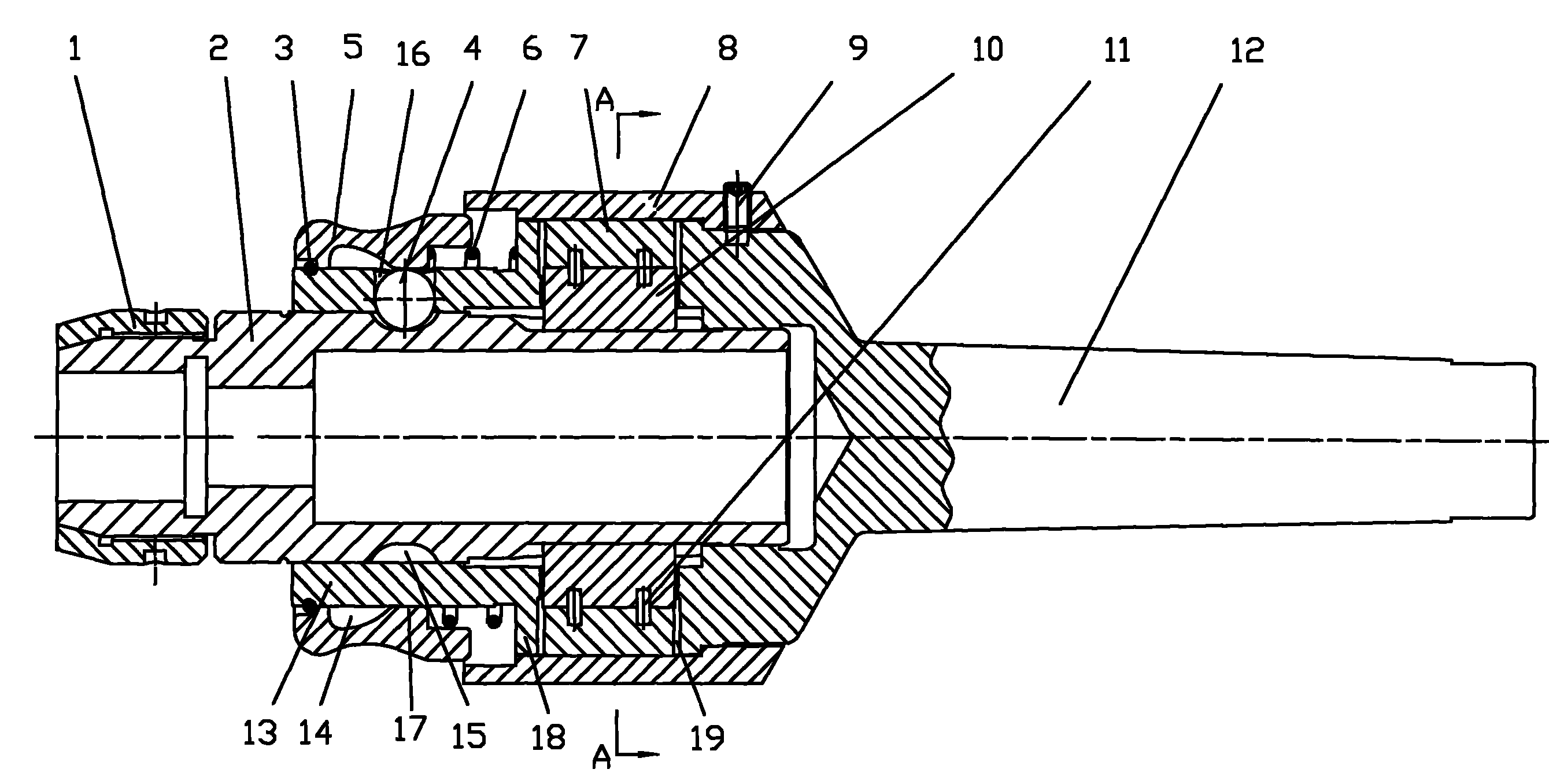

[0011] Such as figure 1 As shown: the tap chuck for machining includes a main handle 12 and a tap jacket 2, one end of the main handle 12 is a cylindrical body 13, and one end of the tap jacket 2 is detachably located in the cylinder In the body 13; on the wall near the left end of the cylindrical body 13, a plurality of through holes 16 are arranged, and the balls 4 are placed in the through holes 16; The toggle sleeve 5 that can move axially relative to the cylindrical body 13 is provided with a space 14 for accommodating the ball 4 and a space for pushing the ball 4 to move radially in the through hole 16 on the toggle sleeve 5 . Protrusion 17; a step 18 is set in the middle of the cylindrical body 13, and a spring 6 is set outside the cylindrical body 13, between the end face of the toggle sleeve 5 and the step 18; the outer wall of the tap jacket 2 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com