Engraving and milling machine

A technology of engraving and milling machine and frame, which is applied in the direction of metal processing machinery parts, clamping, supporting, etc. It can solve the problems of high precision and processing of difficult-shaped workpieces, and achieve high processing accuracy, convenient and stable clamping, and lifting clamping The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

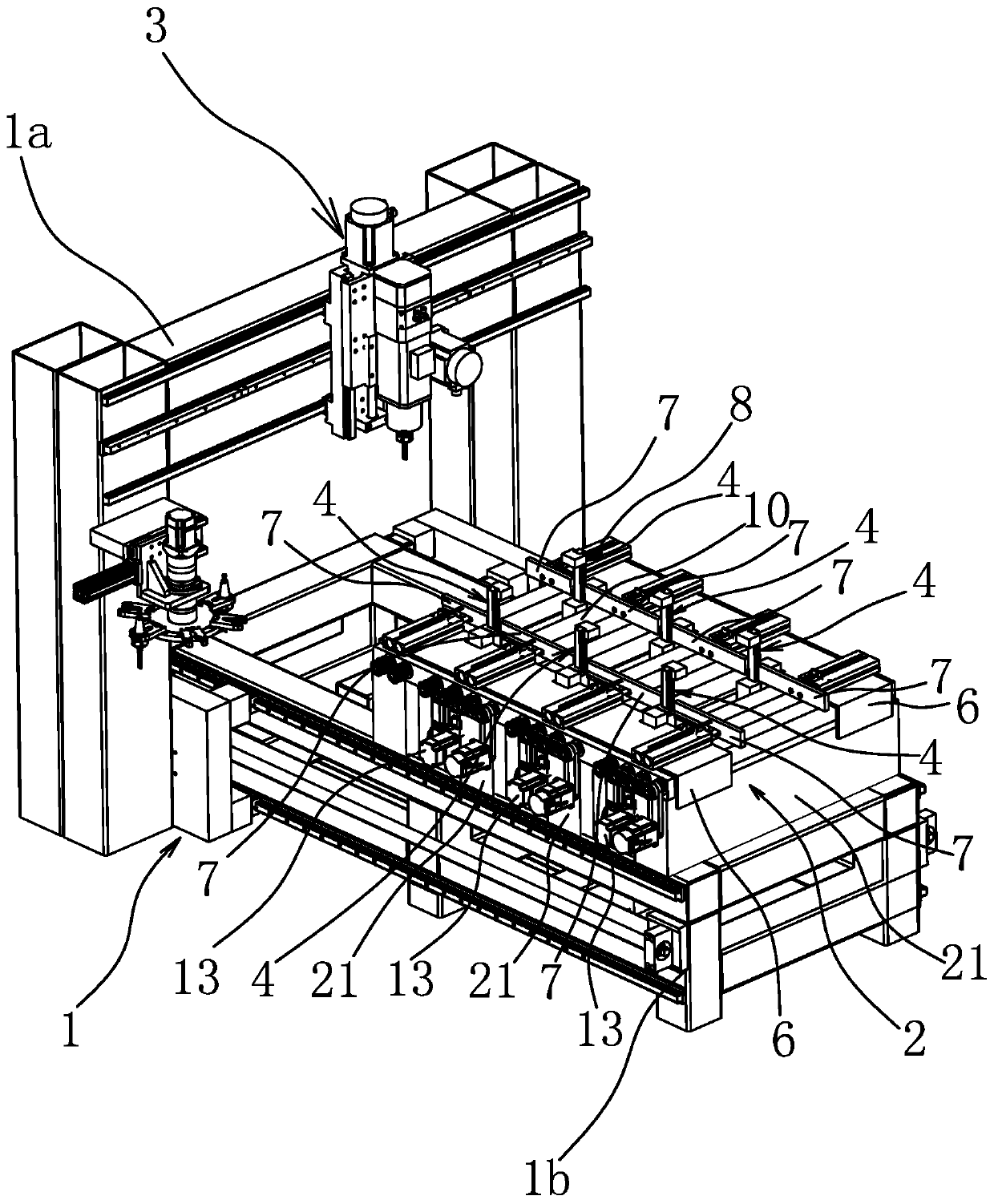

[0040] like figure 1 As shown, the engraving and milling machine includes a frame 1, the frame 1 includes a base 1b, the base 1b is provided with a work platform 2 for placing workpieces, and the base 1b is also provided with a gantry 1a that can slide longitudinally. The engraving assembly 3 is provided on the frame 1a, and the engraving assembly 3 can also move laterally and up and down relative to the gantry 1a, so that the engraving assembly 3 can perform three-dimensional translation relative to the working platform 2. Of course, as another situation, the position of the gantry 1a relative to the base 1b may also be fixed, and the working platform 2 can move longitudinally on the base 1b.

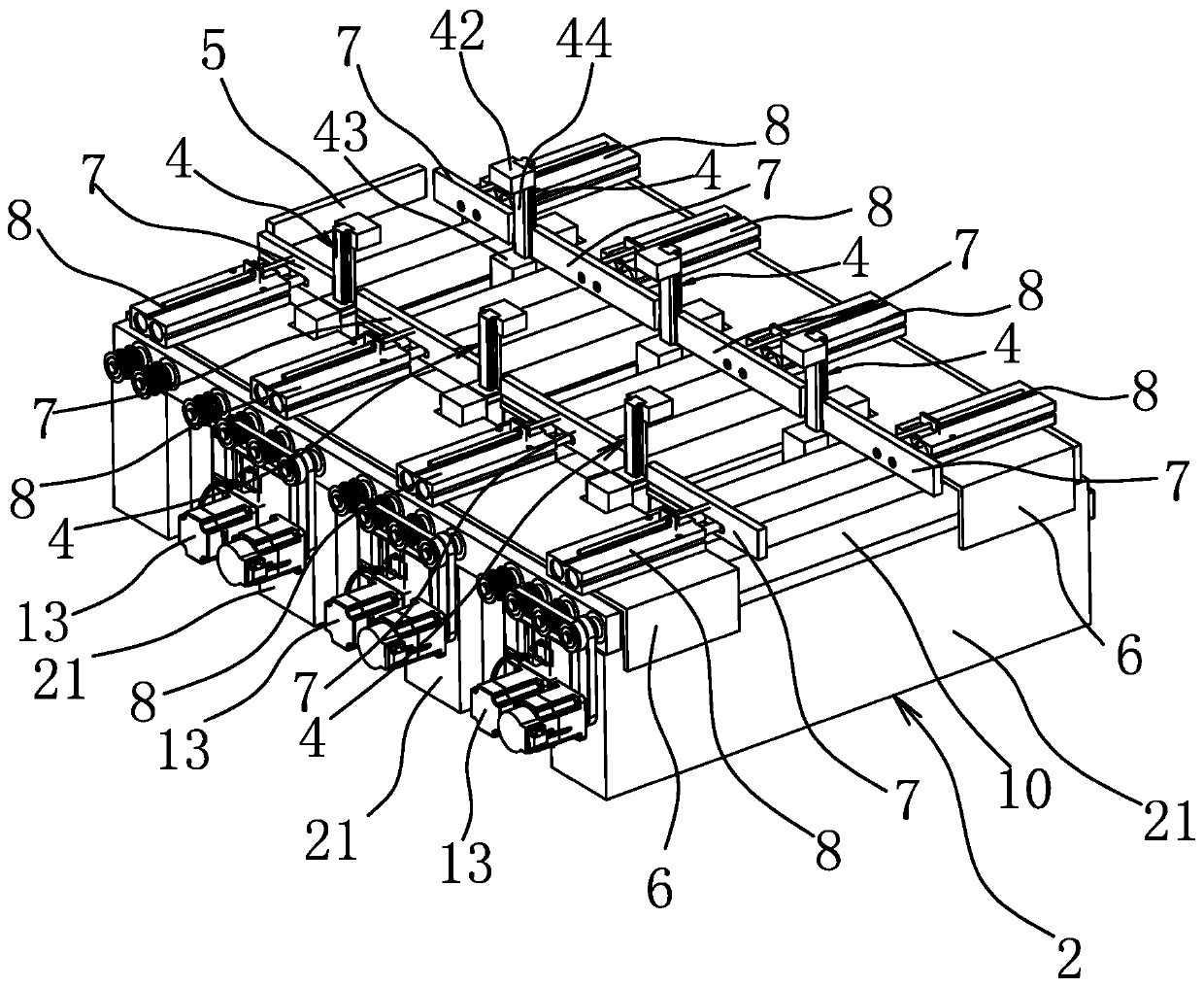

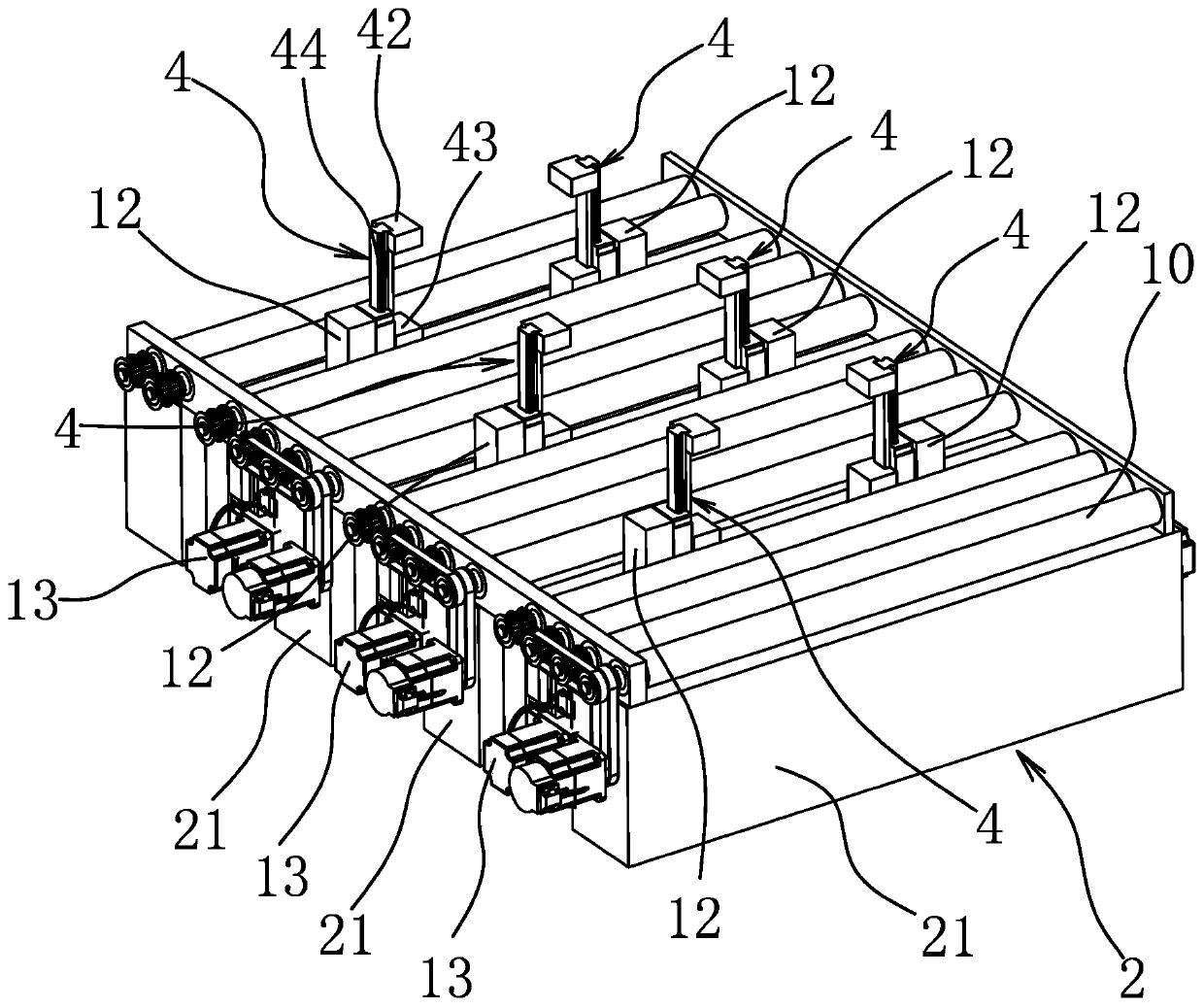

[0041] like figure 2 As shown, two rows of clamping parts 4 that can clamp the workpiece from the side of the workpiece are arranged at intervals along the transverse direction on the working platform 2, and the number of clamping parts 4 in each row is three and arranged at interval...

Embodiment 2

[0051] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference lies in: the quantity and arrangement of clamping parts 4 are different, such as Figure 15 As shown, the number of clamping parts 4 on the working platform 2 is three, and the three clamping parts 4 are arranged at intervals along the longitudinal direction of the working platform. Each clamping part 4 can move horizontally and horizontally relative to the working platform 2 independently move. This structure is mainly used for processing special-shaped workpieces with small width. During processing, the workpiece relies on the side backing 7 and the front backing 5 on the working platform 2, so that the workpiece is positioned at a preset position, and then depends on the movement of the three clamping parts 4 to clamp the workpiece first. During the processing, by retracting one clamping part 4 away from the workpiece each time, and relying on the other two ...

Embodiment 3

[0053] The structure and principle of this embodiment are basically the same as that of the first embodiment, except that four clamping parts 4 are arranged on the engraving platform, and the four clamping parts 4 are arranged in two rows along the horizontal direction of the working platform 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com