Flexible fixture device and method for processing long stringers of aircraft composite materials

A technology of flexible fixtures and composite materials, applied to metal processing machinery parts, positioning devices, manufacturing tools, etc., can solve problems such as single form, poor reliability, and high cost, and achieve the effects of convenient operation, low cost, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In the following detailed description of the preferred embodiment, reference is made to the accompanying drawings which form a part hereof. The accompanying drawings show, by way of example, specific embodiments in which the invention can be practiced. The illustrated embodiments are not intended to be exhaustive of all embodiments in accordance with the invention. It is to be understood that other embodiments may be utilized and structural or logical changes may be made without departing from the scope of the present invention.

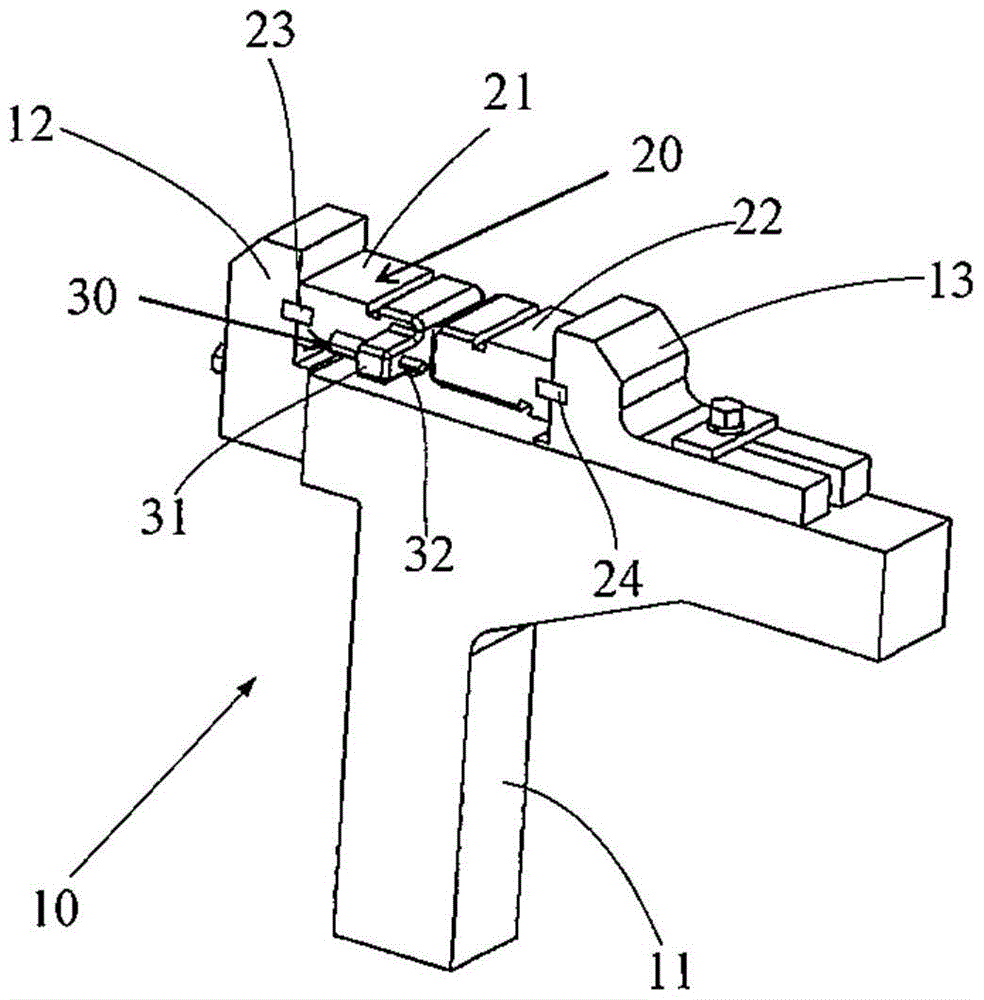

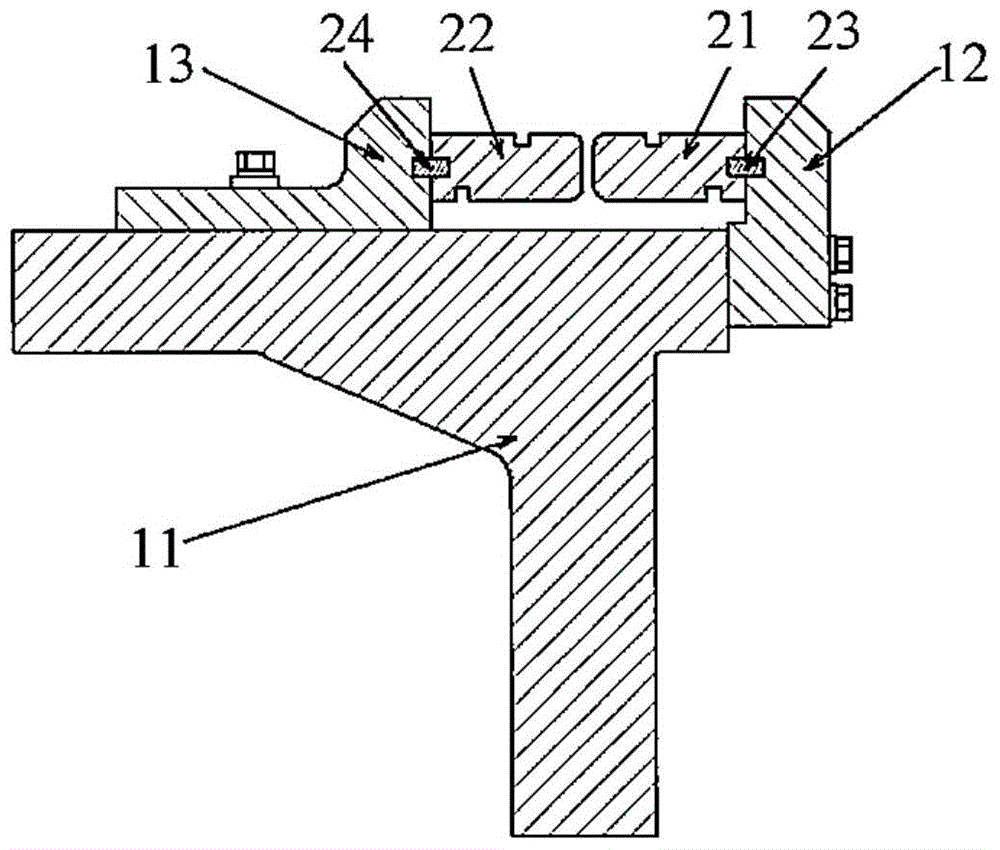

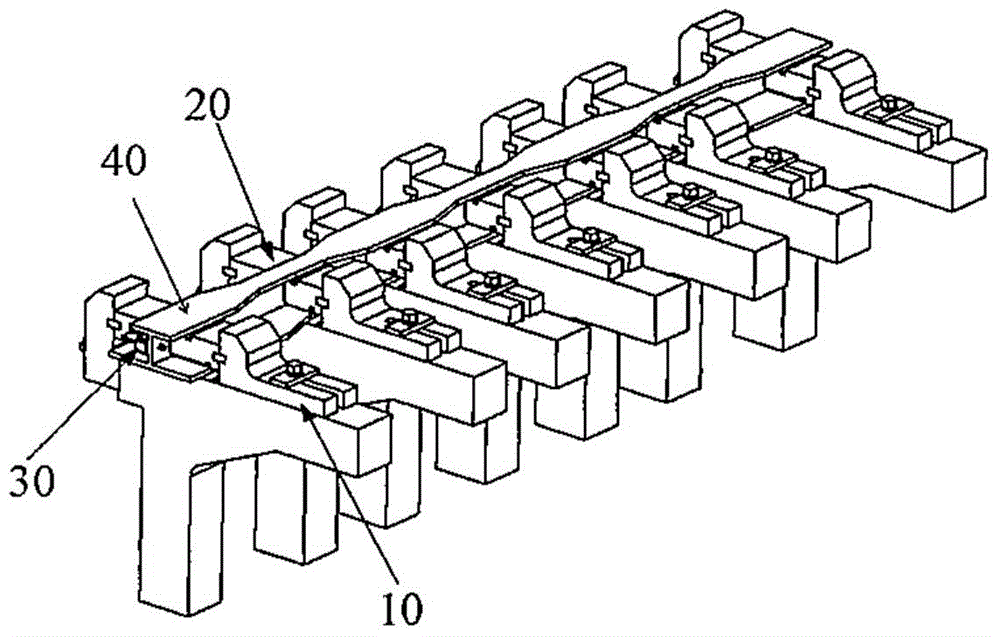

[0031] Such as Figure 1 to Figure 2 As shown in , the flexible clamp device of the present invention mainly includes a movable chuck assembly 10 , a positioning block assembly 20 and an end positioning assembly 30 . Wherein the movable chuck assembly 10 is installed on the CNC machining machine tool, the movable chuck assembly 10 includes a base 11, a fixed chuck 12 and a movable chuck 13, the fixed chuck 12 is fixedly connected with the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com