Corrosion coupon clamp for atmospheric exposure environment test

A technology for corrosion coupons and environmental tests, which is applied in the fields of weather resistance/light resistance/corrosion resistance, manufacturing tools, workpiece clamping devices, etc., and can solve the problem of affecting the reliability of atmospheric exposure environmental test results, large contact area between corrosion coupons and fixtures , crevice corrosion and other problems, to avoid crevice and galvanic corrosion, to facilitate fixed clamping and disassembly operations, and to reduce the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

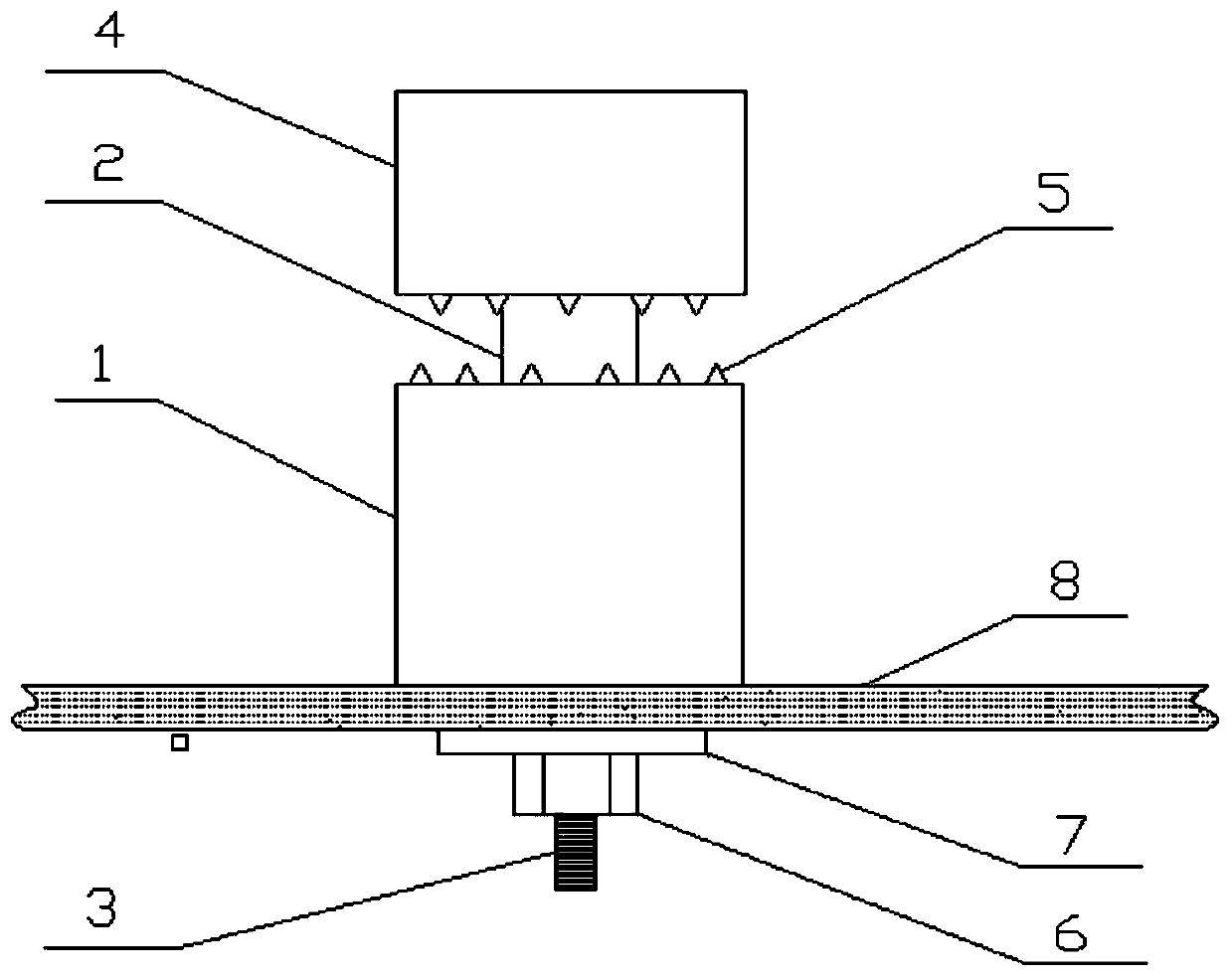

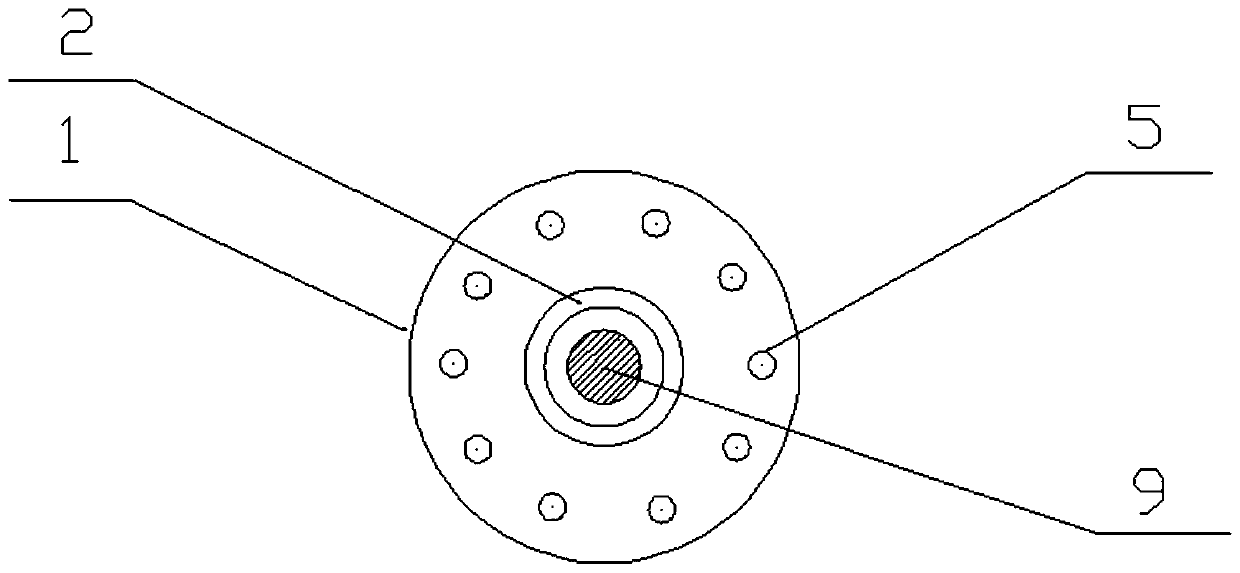

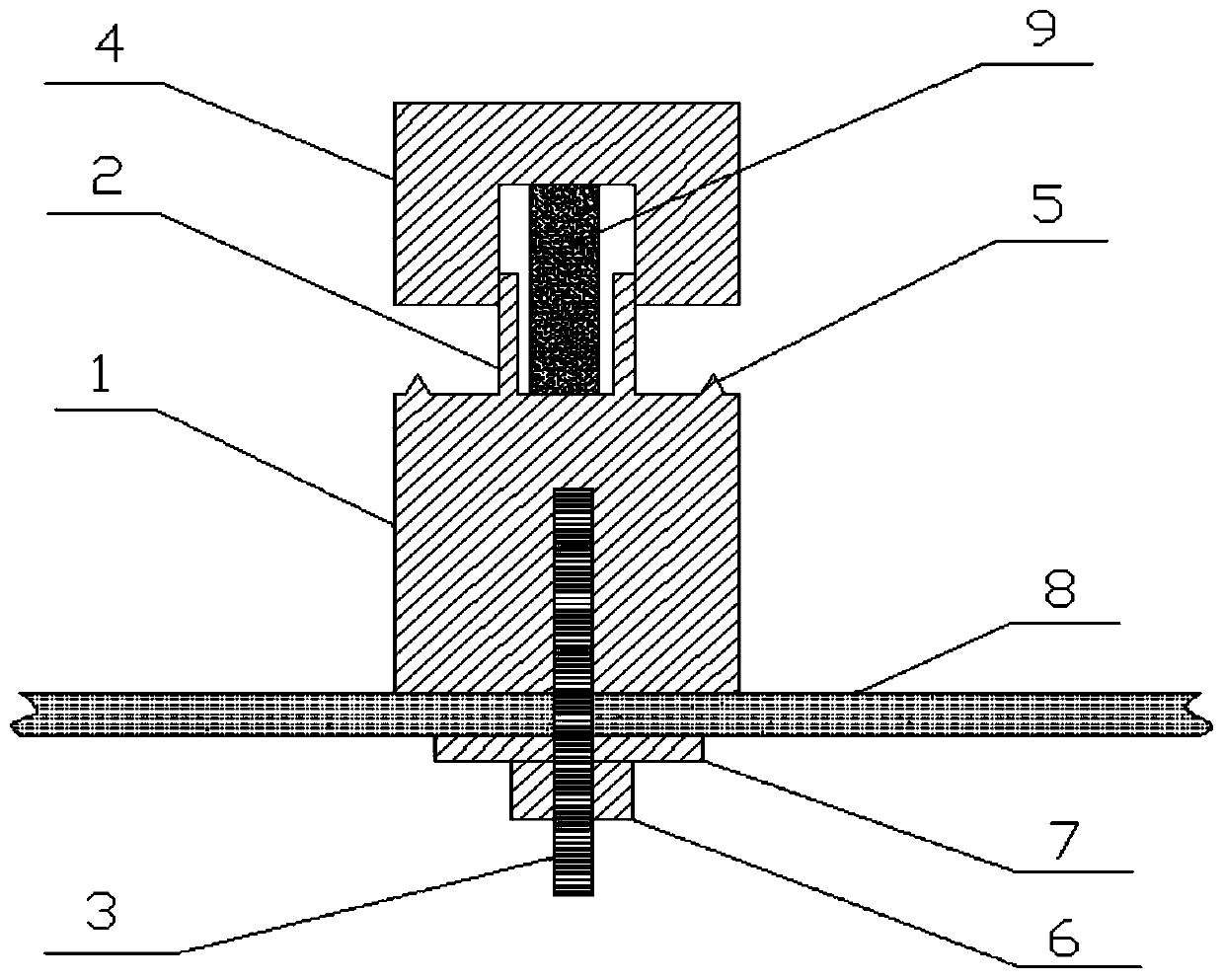

[0031] For the second specific implementation of the corrosion coupon fixture for an atmospheric exposure environment test of the present invention, in combination with the attached Figure 4 for further clarification.

[0032] The clamp is mainly composed of a base 1, a column 2 on the base, a screw rod 3, a nut 6, a gasket 7 and a top cover 4. The second embodiment of the clamp is the same as the first embodiment and will not be repeated. Compared with the first embodiment, the main difference of the clamp is that the elastic contraction device 9 is replaced by the fixed screw rod 3 in the base 1. The extension of one end makes the cover rotate up and down around the screw rod 3 through the internal thread of the top cover 4, which is similar to the bolt fixing method to achieve stable clamping of corrosion coupons of different thicknesses. like Figure 4 As shown, the upper end of the screw rod 3 fixed in the base 1 runs through the base 1 and the column 2, and protrudes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com