Environment-friendly nickel stripper and preparation method and using method thereof

An environment-friendly, nickel stripping agent technology, applied in the field of environment-friendly nickel stripping agent and its preparation, can solve the problems of uneven distribution of power lines, low stripping rate, easy-to-corrosion abutment, etc., to improve the use stability and Effect of shelf life, inhibition of self-decomposition, and guaranteed pH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

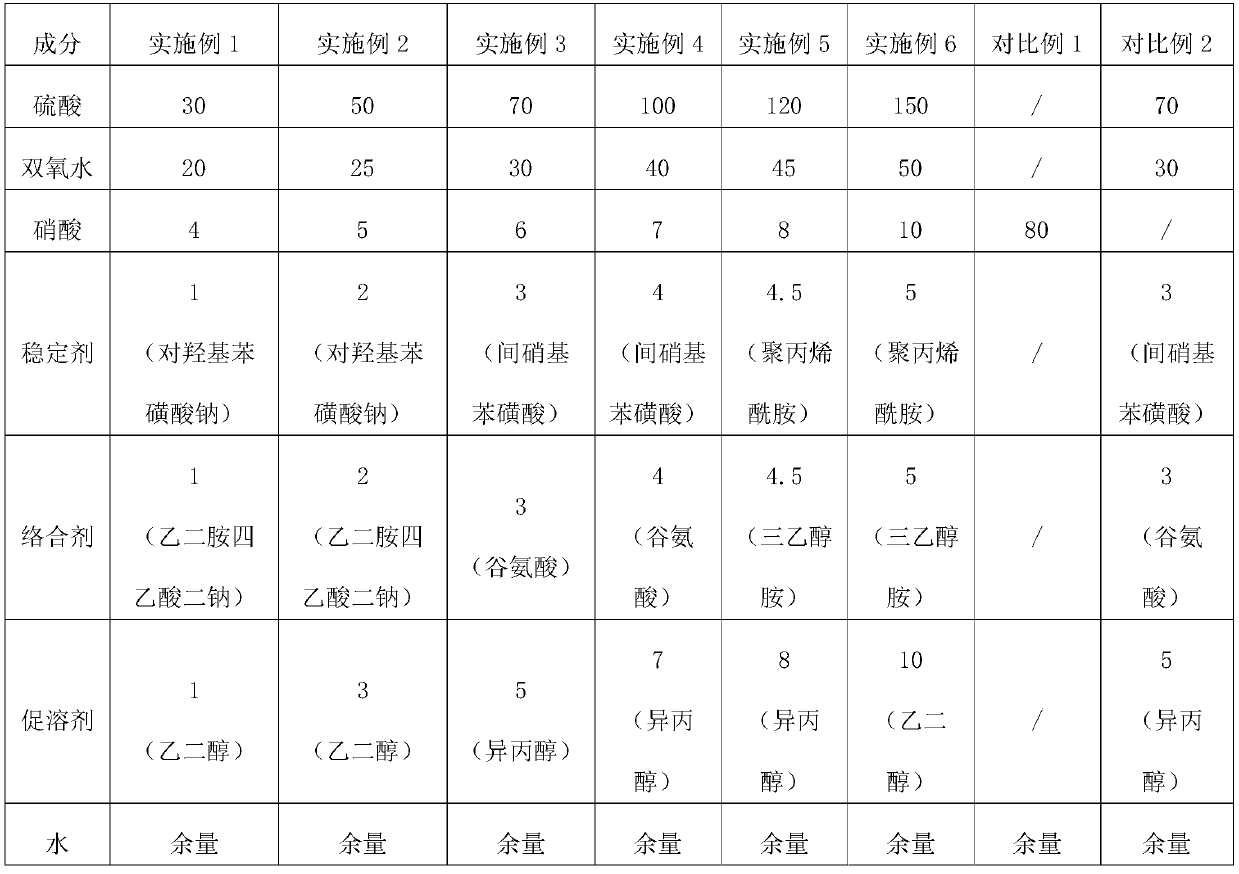

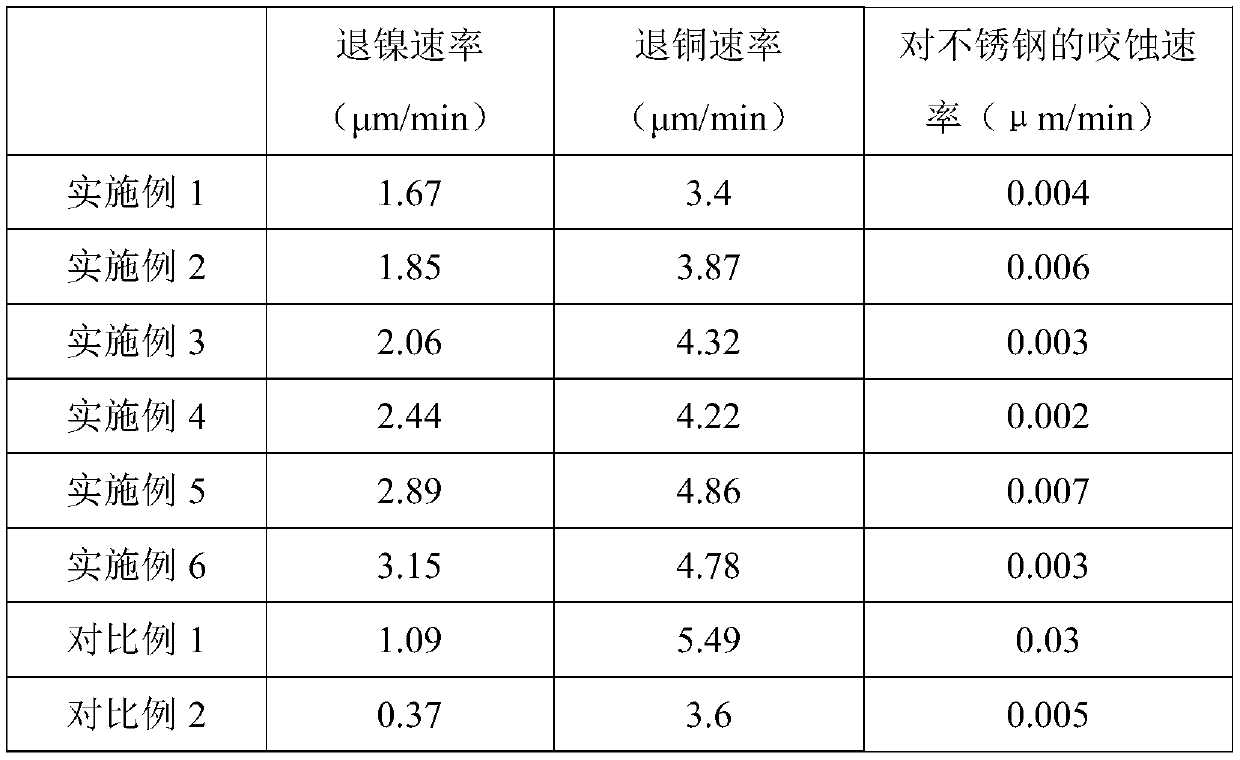

[0027] Embodiment: take each component in table 1 and prepare nickel stripper according to the following method, the preparation method of embodiment 1-6 is as follows:

[0028] S1: Measure half of the total volume of the nickel stripping agent in water, weigh the sulfuric acid solution of the formulated amount, slowly add it into the water, and keep stirring, and cool down to obtain the diluted sulfuric acid solution;

[0029] S2: Weigh the hydrogen peroxide solution and nitric acid solution in the formula amount, add them into the diluted sulfuric acid solution, and stir evenly to obtain a mixed solution;

[0030] S3: add the solubilizer, stabilizer and complexing agent in the prescribed amount in sequence, and after stirring evenly, add the remaining pure water, stir evenly to obtain the nickel stripper, and set aside;

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com