Novel method for extracting sodium gluconate

A kind of technology of sodium gluconate and new method, applied in the field of sodium gluconate extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

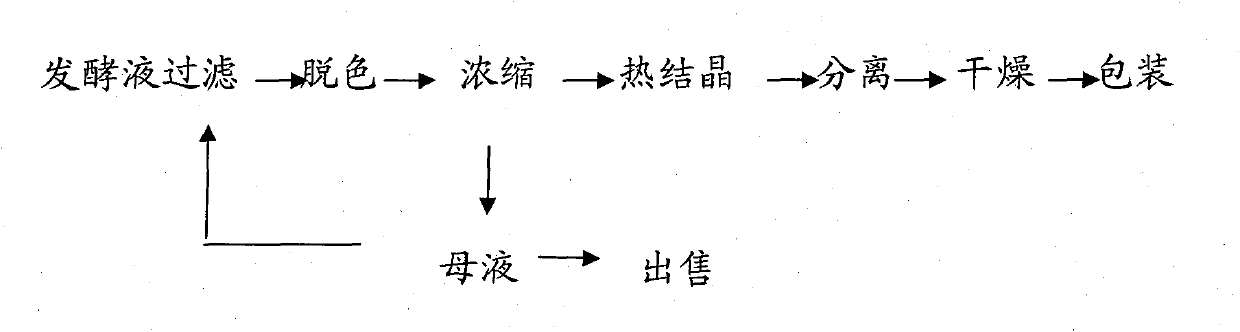

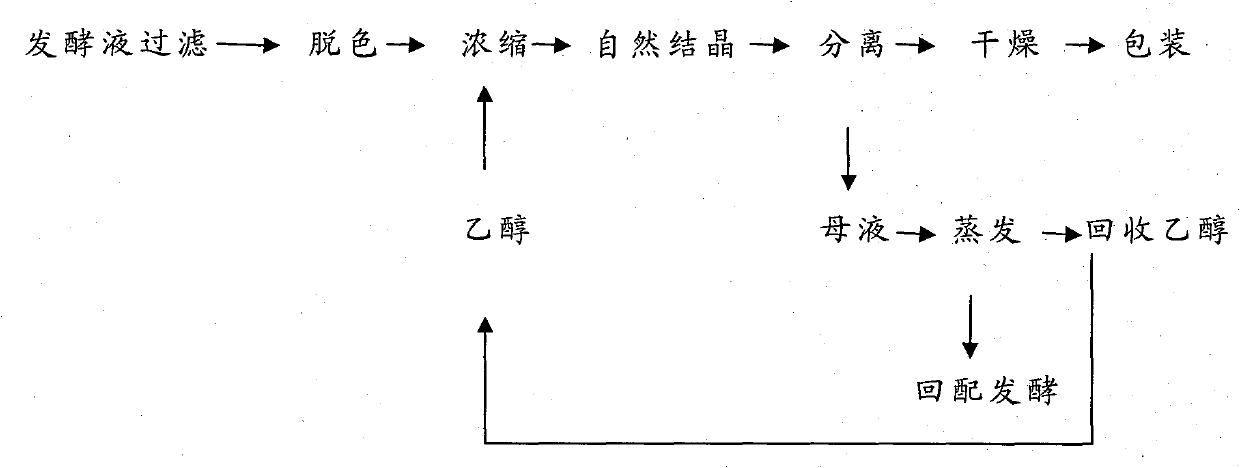

Method used

Image

Examples

Embodiment

[0019] 1. Take 5000ml of the feed solution after filtration and decolorization of the sodium gluconate fermentation broth. Under the condition of 25°C, the specific gravity of the aqueous solution of sodium gluconate is 1.13, and the content of sodium gluconate is 31.2g / dl.

[0020] 2. Concentrate the feed solution to 55%-60% of the original concentration at 65°C.

[0021] 3. Slowly add 80%-95% ethanol solution at 30°C, stir evenly, and stop adding ethanol solution when crystals are precipitated.

[0022] 4. At 30°C, crystallize for 8 hours to separate sodium gluconate crystals

[0023] 5. The separated supernatant is evaporated to recover ethanol, and the raffinate is mixed back into the fermentation medium, and the crystals can be de-dried, wherein the water content in the crystals is determined to be 2%, and the mass is 1560 g.

[0024] The following is the calculation of the method sodium gluconate extraction yield:

[0025] The quality of sodium gluconate in the ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com