Method for combined production of mannitol and D-lactic acid by virtue of microorganism anaerobic fermentation

An anaerobic fermentation and mannitol technology, applied in the biological field, can solve problems such as difficulty in utilization, waste residue pollution, etc., and achieve the effects of significant economic and social benefits, improving crystallization yield, and improving product quality and yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

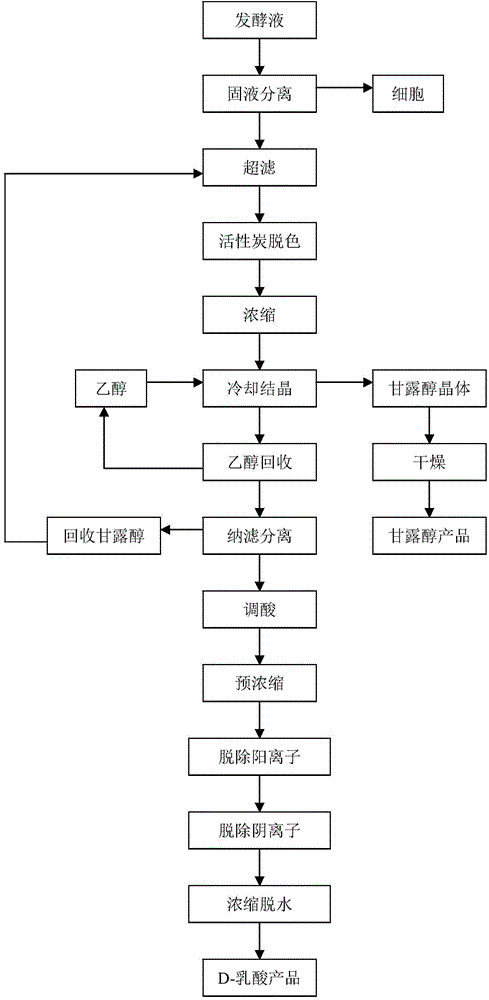

Image

Examples

Embodiment 1

[0042] (1) Seed liquid culture:

[0043] Using fructose syrup as the carbon source, the total sugar is 20g / L (the mass ratio of fructose to glucose is 3:1).

[0044] Primary seed culture: Inoculate the Leuconostoc pseudoenterolis G123 bacterial solution stored at -80°C at 1% v / v in the primary seed medium, and cultivate aerobically at 30°C and 200rpm for 12 hours.

[0045] The formula of the primary seed medium is: peptone 10g / L, beef extract 10g / L, yeast powder 5g / L, sodium acetate 5g / L, triammonium citrate 2g / L, dipotassium hydrogen phosphate trihydrate 2g / L L, magnesium sulfate heptahydrate 0.2g / L, manganese sulfate monohydrate 0.05g / L, Tween-801mL / L, with fructose syrup as carbon source (wherein the mass ratio of fructose to glucose is 3:1), total sugar 20g / L, the medium was sterilized at 121°C for 20min.

[0046] Secondary seed culture: transfer from the primary seed solution to the secondary seed medium with an inoculum of 5% v / v, 30°C, 200rpm, sterile air ventilation ...

Embodiment 2

[0054] (1) Seed liquid culture:

[0055] Using fructose syrup as the carbon source, the total sugar is 20g / L (the mass ratio of fructose to glucose is 1:1).

[0056] Primary seed culture: Inoculate the Leuconostoc pseudoenterolis G123 bacterial solution stored at -80°C at 1% v / v in the primary seed medium, and cultivate aerobically at 30°C and 200rpm for 12 hours.

[0057] The formula of the primary seed medium is: peptone 10g / L, beef extract 10g / L, yeast powder 5g / L, sodium acetate 5g / L, triammonium citrate 2g / L, dipotassium hydrogen phosphate trihydrate 2g / L L, magnesium sulfate heptahydrate 0.2g / L, manganese sulfate monohydrate 0.05g / L, Tween-801mL / L, with fructose syrup as carbon source (the mass ratio of fructose and glucose is 1:1), total sugar 20g / L, the medium was sterilized at 121°C for 20min.

[0058] Secondary seed culture: transfer from the primary seed solution to the secondary seed medium with an inoculum of 5% v / v, 30°C, 200rpm, sterile air ventilation of 0.1v...

Embodiment 3

[0064] (1) Seed liquid culture:

[0065] Using fructose syrup as the carbon source, the total sugar is 20g / L (the mass ratio of fructose to glucose is 2:1).

[0066] Primary seed culture: Inoculate the Leuconostoc pseudoenterolis G123 bacterial solution stored at -80°C at 1% v / v in the primary seed medium, and cultivate aerobically at 30°C and 200rpm for 12 hours.

[0067] The formula of the primary seed medium is: peptone 10g / L, beef extract 10g / L, yeast powder 5g / L, sodium acetate 5g / L, triammonium citrate 2g / L, dipotassium hydrogen phosphate trihydrate 2g / L L, magnesium sulfate heptahydrate 0.2g / L, manganese sulfate monohydrate 0.05g / L, Tween-801mL / L, with fructose syrup as carbon source (wherein the mass ratio of fructose and glucose is 2:1), total sugar 20g / L, the medium was sterilized at 121°C for 20min.

[0068] Secondary seed culture: transfer from the primary seed solution to the secondary seed medium with an inoculum of 5% v / v, 30°C, 200rpm, sterile air ventilation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com