Preparation method of stearoylbenzoylmethane and application thereof to molding processing of thermoplastic resin

A technology of stearoyl benzoyl methane and fatty acyl benzoyl methane is applied in the field of preparation of beta-diketones, can solve the problems of toxic crystallization solvent, many by-products, and high raw material cost, and achieves cost reduction and performance improvement Improved, efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

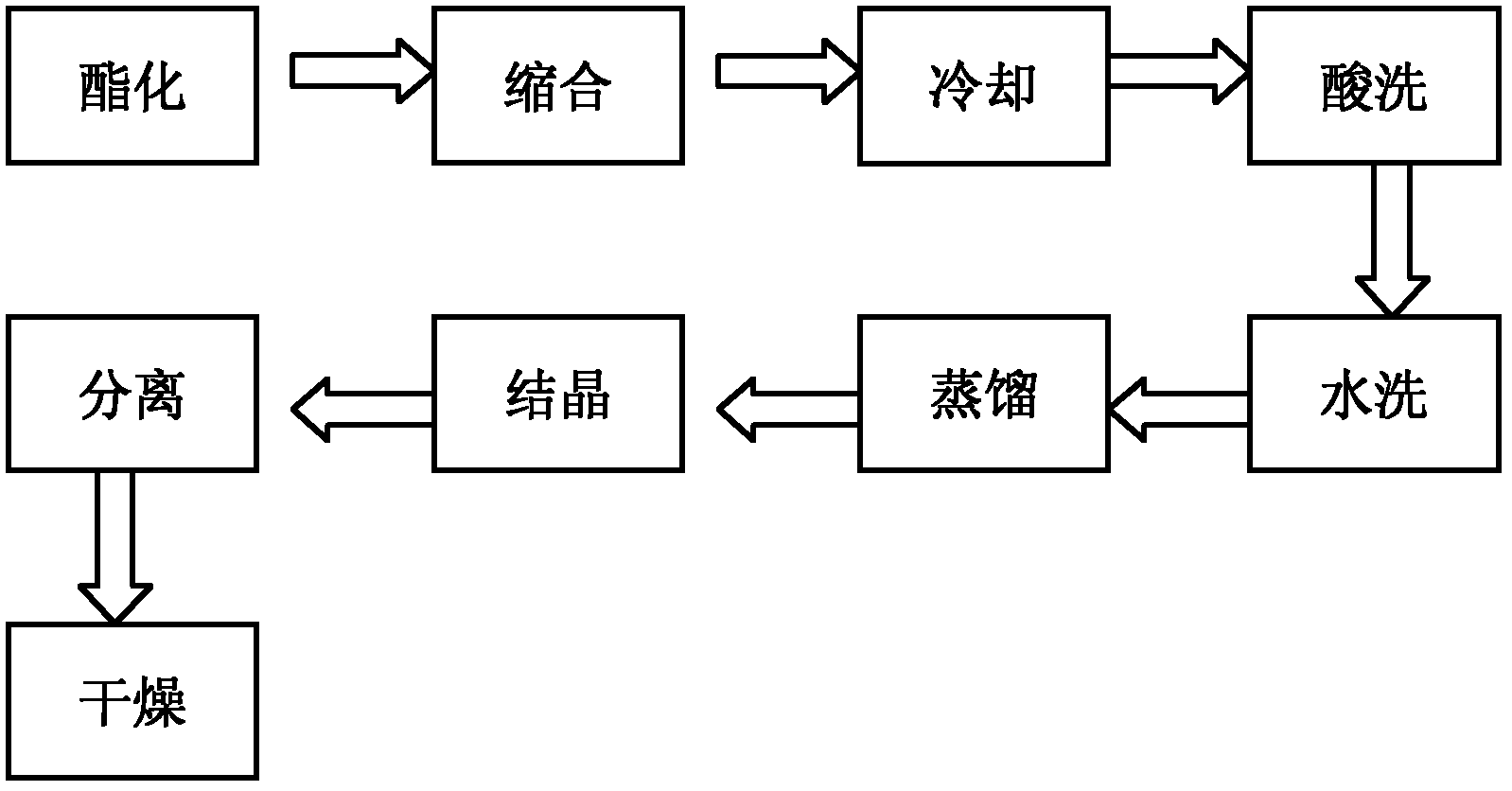

Method used

Image

Examples

Embodiment 1

[0057] Prepare Stearoylbenzoylmethane according to the following steps

[0058] ①. Synthesis of methyl stearate

[0059] Put stearic acid and methanol into a three-necked flask according to the set formula, raise the temperature to 70°C, and after the stearic acid is completely melted, add concentrated sulfuric acid dropwise, and reflux for 2 to 3 hours.

[0060] a. Esterification process conditions

[0061] Stearic acid / methanol molar ratio 1:3~1:4

[0062] Esterification reaction temperature is 65~70°C

[0063] Reaction time hours 2~3

[0064] b.washing

[0065] Put the esterification solution from step a into a separatory funnel, wash with 200ml water 4-5 times until pH=7. Stand to separate the phases, the organic phase is crude methyl stearate, to be distilled;

[0066] c. Distillation

[0067] Put the crude methyl stearate from step b into a three-necked flask, raise the temperature to 100° C., and distill under reduced pressure to remove low-boiling fractions to obt...

Embodiment 2~ Embodiment 5

[0087] According to the method and step of Example 1, the stearoylbenzoylmethane product of the present invention is prepared according to the formula of Table 1

[0088] Table 1

[0089] Raw material and yield

Embodiment 6

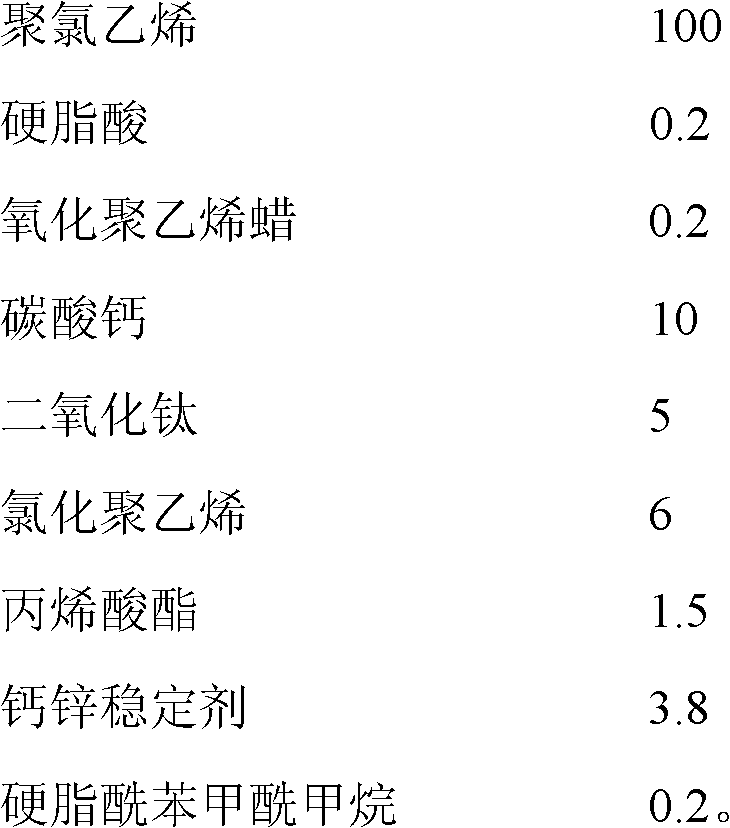

[0091] Stearoylbenzoylmethane of the present invention is as follows according to the application formula of mass fraction agent in PVC resin molding process:

[0092]

[0093] Weigh 120g of the test materials mixed according to the above formula, and masticate them on a double-roll plasticizer with a roller distance of 1mm. Sampling at 90 seconds, 120 seconds, 240 seconds, 360 seconds, and 510 seconds for comparison is the dynamic thermal stabilization time. Record the color change time from light yellow, light red, red, deep red, brown black, black, and compare.

[0094] Test Results:

[0095] 90 seconds

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com