Equipment and method for preparing crystal of vitamin C by fine crystal removing method

A technology of vitamin and elimination method, applied in the direction of organic chemistry, etc., can solve the problems of ineffective control of product particle size distribution, difficulty in eliminating a large number of fine crystals of products, etc., and achieve the effects of increasing crystallization yield, reducing degradation, and reducing dissolution temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

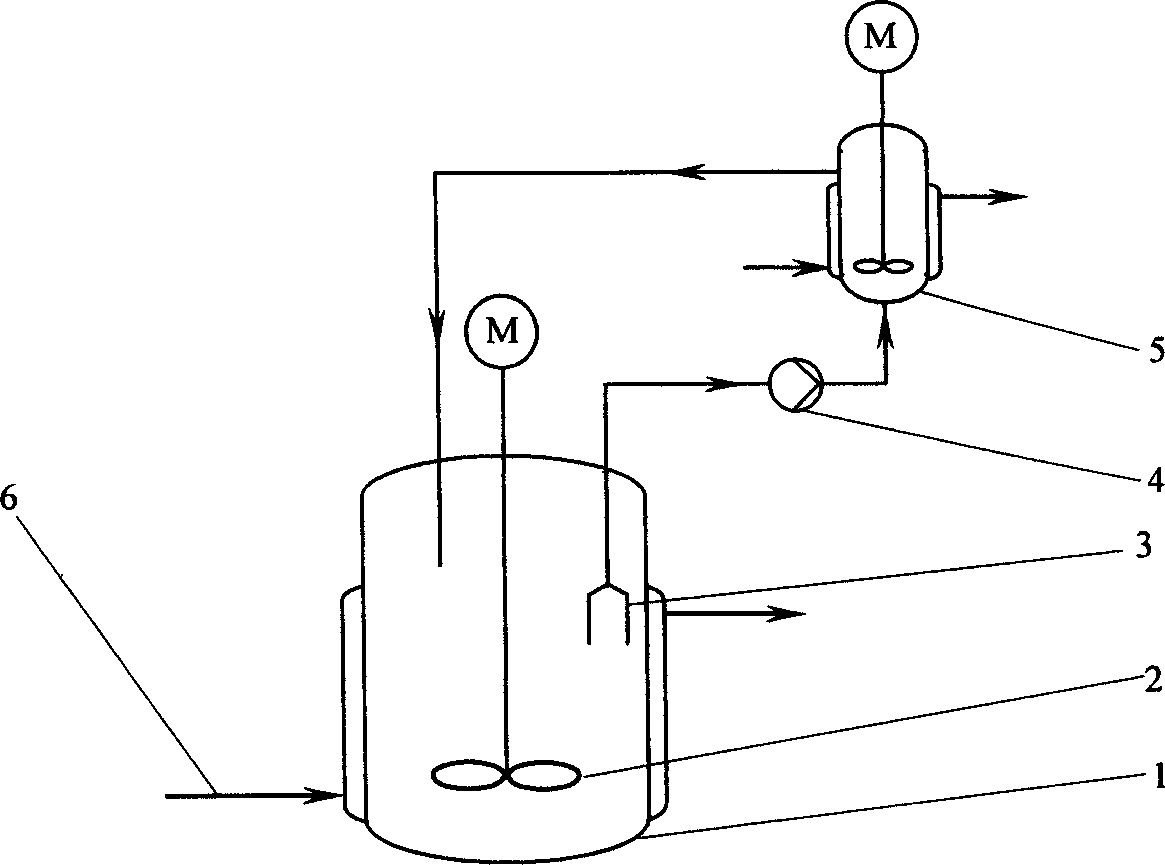

[0023] use as figure 1 device shown. Add 600ml of deionized water into the dissolving tank, preheat to 60°C, add 600g of crude vitamin C with a purity of 98.5%, stir together, heat to 66.5°C to dissolve, add 7.5g of activated carbon to decolorize for 2 minutes, and filter to obtain 950ml of vitamin C solution , which is introduced into crystallizer 1 with a total volume of 1200ml.

[0024] The initial temperature of the solution in the crystallizer 1 is 55°C, and the initial temperature of the cooling medium ethylene glycol aqueous solution 6 is 45°C. By controlling the temperature of the circulating cooling medium 6, the temperature of the solution in the crystallizer is lowered at a rate of 0.15° C. / min under the agitation of the propeller stirrer. When the temperature of the solution reached 41.5° C., 0.24 g of vitamin C crystals passed through a 100-mesh standard sieve were added as seed crystals, and the crystals were grown at a constant temperature for 30 minutes. Con...

Embodiment 2

[0026] use as figure 1 device shown. Add 600ml of deionized water into the dissolving tank, preheat to 60°C, add 610g of crude vitamin C with a purity of 98.5%, stir together, heat to 68°C to dissolve, add 9g of activated carbon for decolorization for 2 minutes, filter to obtain 955ml of vitamin C solution, It was introduced into crystallizer 1 with a total volume of 1200 ml.

[0027] The initial temperature of the solution in the crystallizer 1 is 55.3°C, and the initial temperature of the cooling medium ethylene glycol aqueous solution 6 is 45°C. By controlling the temperature of the circulating cooling medium 6, the temperature of the solution in the crystallizer is lowered at a rate of 0.18°C / min under stirring. When the temperature of the solution reaches 40.2°C, nucleation occurs spontaneously, and the crystal is grown at a constant temperature for 30 minutes. Continue cooling. When the crystallization temperature reaches 22.5°C, add 40ml of antifreeze methanol. When ...

Embodiment 3

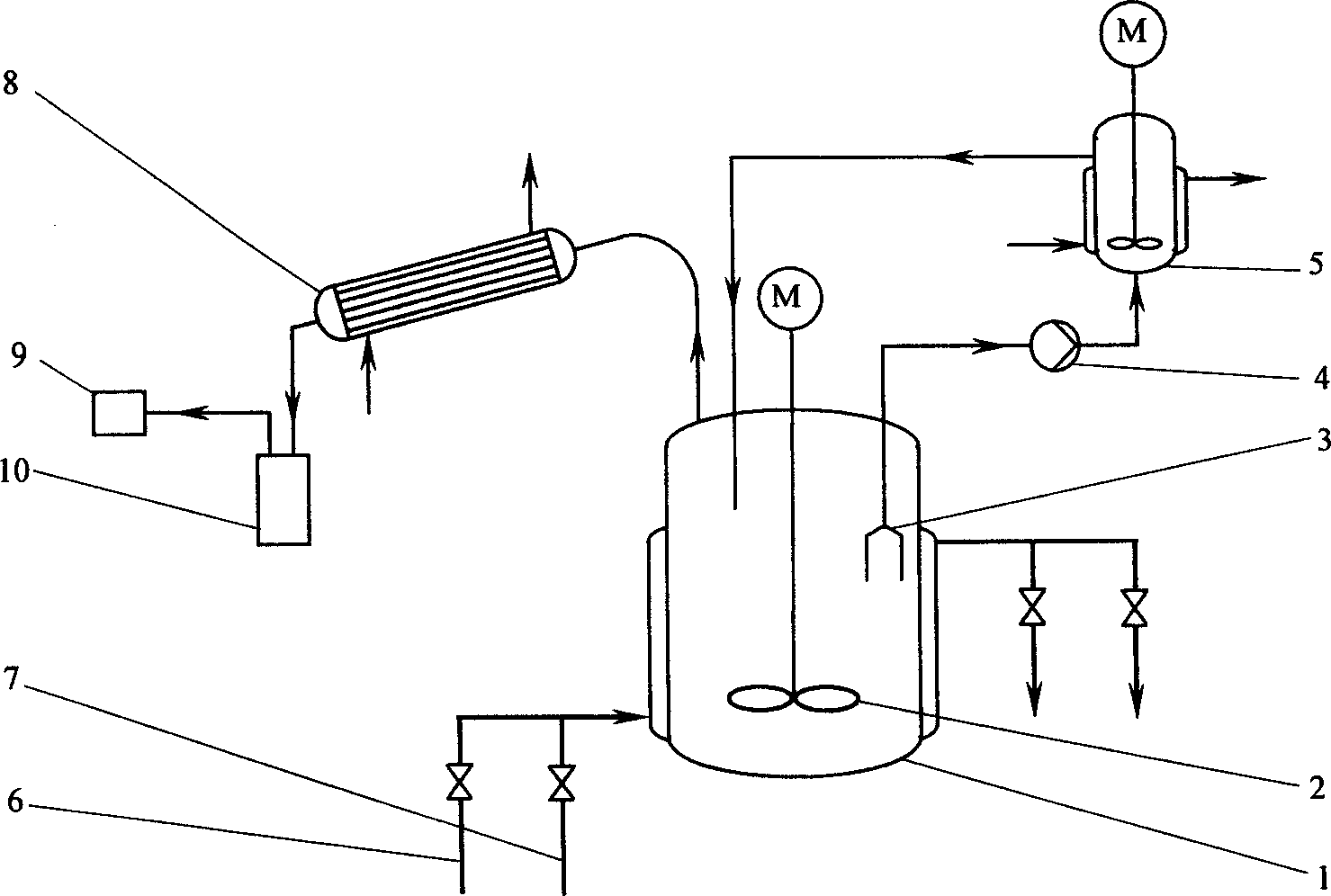

[0029] use as figure 2device shown. Add 1200ml of deionized water into the dissolving tank, preheat to 40°C, add 600g of crude vitamin C with a purity of 98.5%, stir together, heat to 47°C to dissolve, add 9g of activated carbon for decolorization for 2 minutes, and filter to obtain 1530ml of vitamin C solution, It was introduced into crystallizer 1 with a total volume of 2000 ml.

[0030] The initial temperature of the solution in the crystallizer 1 is 45.3°C, and the temperature of the circulating hot water 7 is controlled at 60°C. Turn on the crystallizer stirring and vacuum system 9, and the vacuum degree in the crystallizer 1 is controlled to be about -0.09MPa. When the solution reaches about 47°C, it begins to evaporate. The hot water 7 in the jacket of the crystallizer 1 is switched to the cooling medium ethylene glycol aqueous solution 6, and the vacuum system 9 is closed.

[0031] By controlling the temperature of the circulating cooling medium 6, the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com