SMA mixture, and preparation method and application thereof

A mixture and aggregate technology, which is applied in climate change adaptation, roads, construction, etc., can solve the problems of less repair cost and full utilization of resources, unsatisfactory research, lower temperature control during mixing, etc., to ensure skeleton performance, Effect of reducing dosage and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

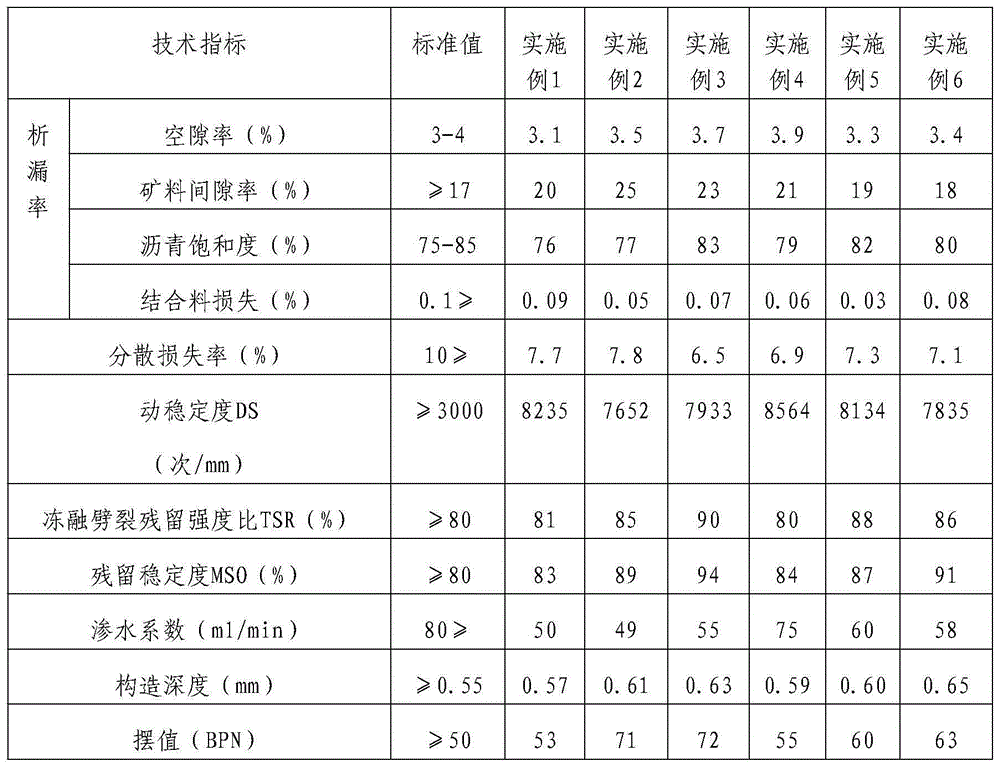

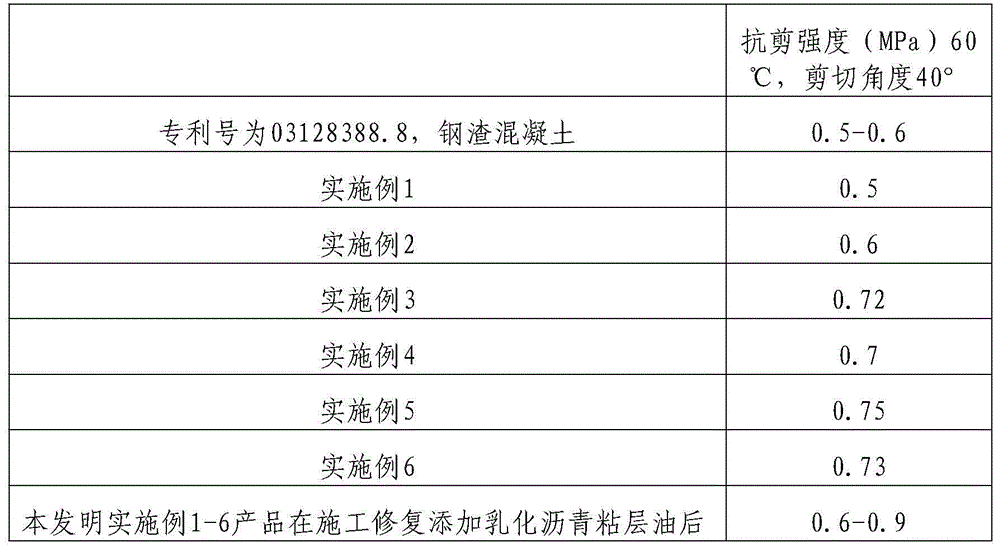

Embodiment 1

[0037] A kind of SMA mixture, the formula is 7kg of aggregate, 2kg of mineral powder, 0.35kg of fiber, 2kg of additives composed of resin, modified asphalt, heavy traffic asphalt, asphalt rejuvenator, milling material, and modified asphalt, heavy traffic The weight percentage of asphalt produced by asphalt and asphalt regenerant is 0.64kg of the total weight of all raw materials combined; wherein the aggregate is divided into coarse aggregate and fine aggregate, and the coarse aggregate is 3mm diabase, and the maximum particle size is 8mm, The soil content is less than 0.5%, the polishing value is greater than 42, and the needle flake content is less than 10%. The fine aggregate is fine sand rolled from 3mm limestone; the mineral powder is ground from 0-8mm limestone. The apparent relative density is 2.720; the fibers are wood fibers and are loose flocculent fibers with a water content of ≤1%; the weight ratio of milling material and resin in the additive is 1:3.

[0038] Its ...

Embodiment 2

[0044] A kind of SMA mixture, its formula is aggregate 8kg, mineral powder 4kg, fiber 0.45kg, is made up of additive 3kg by resin, modified asphalt, heavy traffic asphalt, asphalt regeneration agent, milling material, inorganic aluminosilicate, wherein Aggregate is divided into coarse aggregate and fine aggregate. The coarse aggregate adopts 10mm steel slag, and the maximum particle size is 10mm, the soil content is less than 0.5%, the polishing value is greater than 42, and the needle flake content is less than 10%. Fine sand rolled from 1mm limestone; the mineral powder is ground from 1mm limestone, and its apparent relative density is 2.720; the fiber is chemical fiber, and it is loose flocculent fiber, with a water content ≤ 1%; additives The weight ratio of the milling material to the resin is 1:3; the weight of the inorganic aluminosilicate is 300g.

[0045] Its preparation method comprises the following steps:

[0046] (1) Preparation of additives: According to the tec...

Embodiment 3

[0051] A kind of SMA mixture, its formula is 7.5kg of aggregate, 3kg of mineral powder, 0.4kg of fiber, made of resin, modified asphalt, heavy traffic asphalt, asphalt regenerant, milling material, inorganic aluminosilicate, fly ash The composition of additives is 2.5kg, and the aggregate is divided into coarse aggregate and fine aggregate. The coarse aggregate is a mixture of 6mm diabase and steel slag, and the maximum particle size is 9mm, the soil content is less than 0.5%, and the polishing value is greater than 42. Needle flake content is less than 10%; fine aggregate is fine sand rolled from 2mm limestone; mineral powder is ground from 7mm limestone, and its apparent relative density is 2.720; the fiber is mineral fiber and is loose Flock fiber, water content ≤ 1%; the weight ratio of milling material and resin in the additive is 1:3, and the weight of inorganic aluminosilicate and fly ash accounts for 250g of the additive, of which fly ash and inorganic silicon aluminum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com