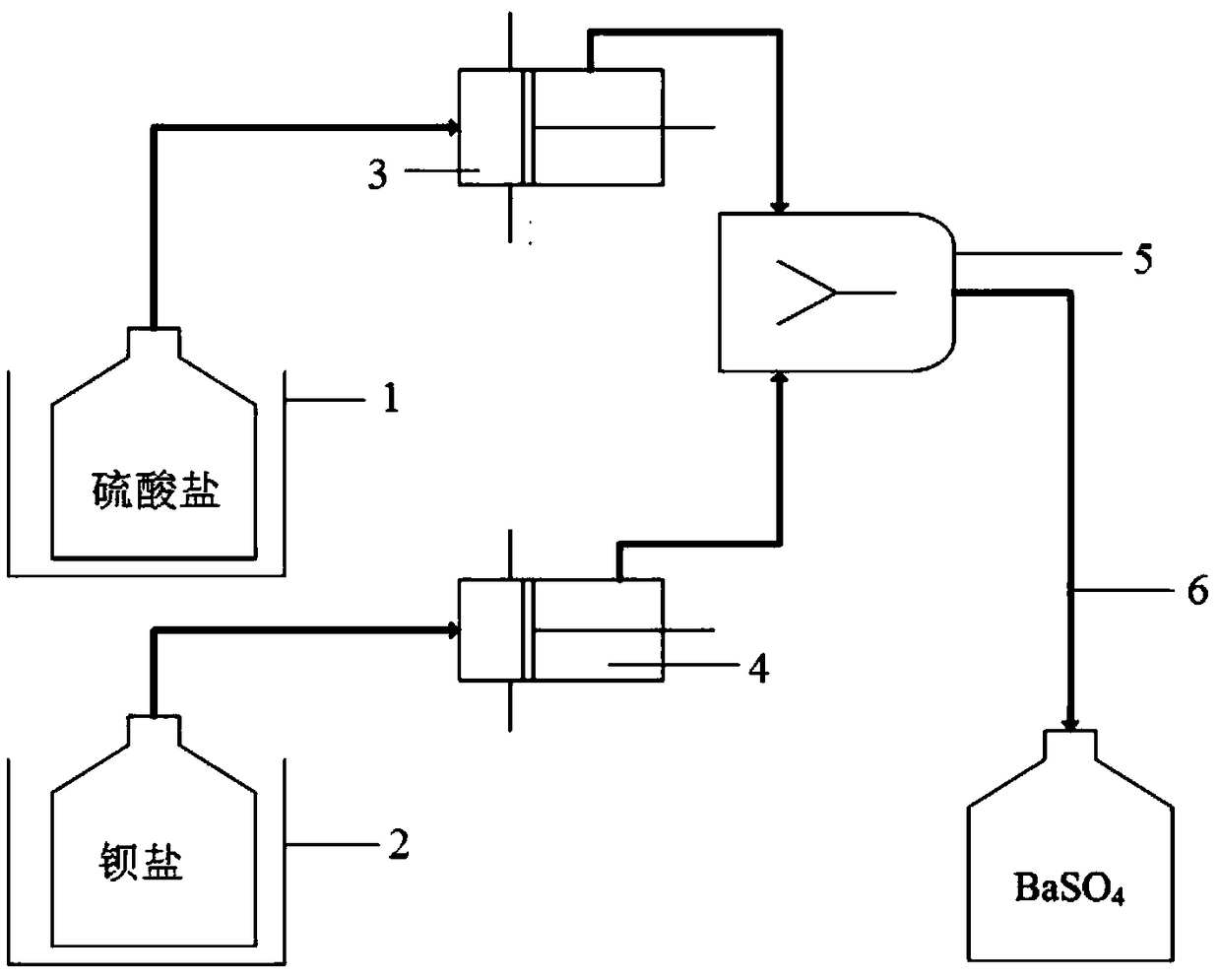

Method for preparing barium sulfate particles through microchannel method

A microchannel and barium sulfate technology, applied in chemical instruments and methods, calcium/strontium/barium sulfate, calcium/strontium/barium compounds, etc., can solve the problems of large amount of surfactant, difficult cleaning of EDTA, expensive equipment, etc. , to achieve the effect of preventing excessive local concentration, small residence time, and small pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh 2.55g of barium acetate and 1.32g of ammonium sulfate in 500mL of distilled water, fully dissolve, and at 25°C, send the reactant solution into the Y-shaped microchannel reactor through the advection pump at a flow rate of 0.6mL / min. The inner diameter of the reactor is 0.2 mm, and the length is 10 cm; after the reaction system is stable, the sample is collected from the outlet of the reactor to obtain the reaction solution; After washing with ethanol several times, the white precipitate was dried in an oven for 12 hours to finally obtain micron-sized, flaky barium sulfate particle powder, and its SEM image is as follows figure 2 shown.

Embodiment 2

[0024] Weigh 5.10g of barium acetate and 4.76g of sodium persulfate in 500mL of distilled water and dissolve them fully. At 35°C, the reactant solution is sent into the Y-shaped microchannel reactor through an advection pump at a flow rate of 1.0mL / min. The inner diameter of the channel reactor is 0.1 mm, and the length is 10 cm; after the reaction system is stable, a sample is taken from the outlet of the reactor to obtain a reaction solution; Wash with water and ethanol for several times, dry the white precipitate in an oven for 12 hours, and finally obtain micron-sized, leaf-shaped barium sulfate particle powder, and its SEM picture is as follows image 3 shown.

Embodiment 3

[0026] Weigh 2.08g of barium chloride and 1.32g of ammonium sulfate in 250mL of distilled water and dissolve them fully. At 45°C, the reactant solution is sent into a T-shaped microchannel reactor at a flow rate of 1.4mL / min through an advection pump. The channel reactor has an inner diameter of 0.1 mm and a length of 10 cm. After the reaction system is stable, take samples from the outlet of the reactor to obtain the reaction solution; centrifuge the obtained reaction solution, wash the obtained white precipitate with ion water and absolute ethanol several times in turn, and put the white precipitate in an oven After drying for 12 hours, irregular cubic barium sulfate particle powder with a particle size of 98-300nm was finally obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com