Patents

Literature

54results about How to "Meet industrial applications" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for waste mixed plastic separation

ActiveCN104511369AEasy to separateHigh recovery ratePlastic recyclingWet separationLiquid mediumChemistry

The invention discloses a method for waste mixed plastic separation. The method comprises the following steps: crushing waste mixed plastic into mixed plastic particles, adding the obtained mixed plastic particles into a liquid medium I to perform sinking and floating separation, obtaining light-component plastic particles which are smaller than the liquid medium I in density and heavy-component plastic particles which are larger than that of the liquid medium I in density through the sinking and floating separation, adding the heavy-component plastic particles into a liquid medium II to perform surface treatment at a temperature of 70-100 DEG C and performing flotation separation on the heavy-component plastic particles subjected to surface treatment through a floating agent. According to the method, a variety of plastics in waste plastics can be efficiently and selectively separated. The method is simple to operate, is low in cost and meets the industrial application and production.

Owner:CENT SOUTH UNIV

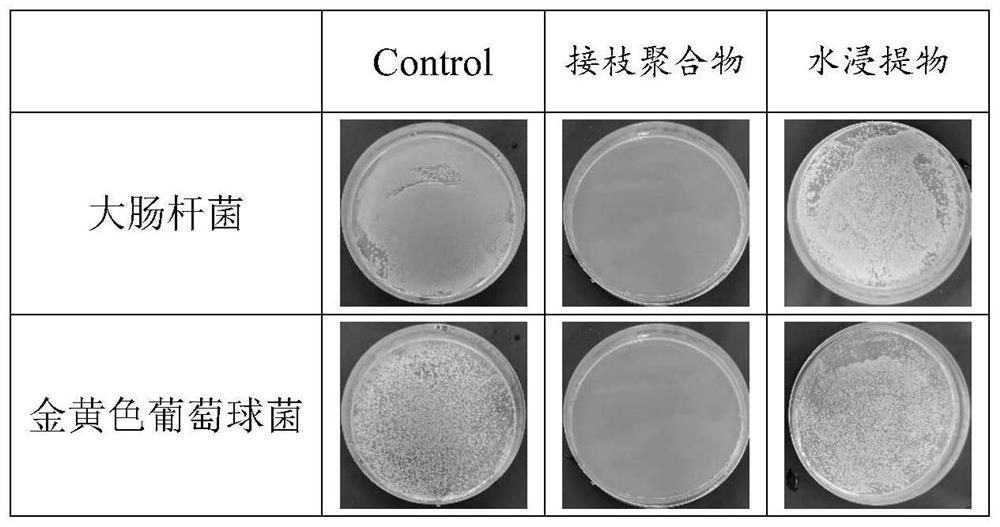

Hydrogel antifouling fiber, preparation method thereof and preparation method of implanted type high-strength hydrogel antiflouling coating layer

InactiveCN103757744AHigh strengthHas superhydrophilic propertiesLiquid surface applicatorsWet spinning methodsFiberPolymer science

The invention discloses a hydrogel antifouling fiber, a preparation method of hydrogel antifouling fiber and a preparation method of an implanted type high-strength hydrogel antiflouling coating layer, and relates to antiflouling materials, preparation methods of the antiflouling materials, and preparation methods of vessel antifouling coating layers, for mainly solving the technical problems that the conventional PVA (Polyvinyl Acetate) fiber implanted type vessel antiflouling coating layer is poor in antifouling effect and short in service life. The hydrogel antifouling fiber disclosed by the invention is a fiber with a core-shell structure, the shell layer of the fiber is made of polyacrylamide, and the core layer is made of carbon nano tube modified polyacrylamide. The preparation method comprises the following steps: 1, preparing polyacrylamide hydrogel, 2, preparing a core layer spinning dope, 3, preparing a shell layer spinning dope, 4, spinning by using a wet method to obtain the hydrogel antifouling fiber. The preparation of the antifouling coating layer comprises the following steps: spraying implantation gel onto a substrate, further implanting the hydrogel antifouling fiber into the substrate through a high-pressure static implantation technique, and drying to obtain the implanted type high-strength hydrogel antifouling coating layer. The coating layer is not changed when being soaked in seawater or industrial water for 6 months, so that the coating layer can be applied to vessel antifouling.

Owner:HARBIN ENG UNIV

Method for synthesizing N-hydroxy phthalimide with solid-phase process

InactiveCN101845012AEfficient green reaction processHigh yieldOrganic chemistryHydroxylamine HydrochlorideNitrogen gas

The invention discloses a method for synthesizing N-hydroxy phthalimide with the solid-phase process by grinding the raw materials of phthalic anhydride and hydroxylamine hydrochloride and the mineralizer of sodium chloride and ferric oxide under the protection of nitrogen. The method for synthesizing N-hydroxy phthalimide with the solid-phase process ensures the thorough reaction, high yield, low energy consumption and less pollution and is suitable for industrial production, thereby being a promising preparation method.

Owner:JIANGSU CHENPAI PHARM GRP CO LTD

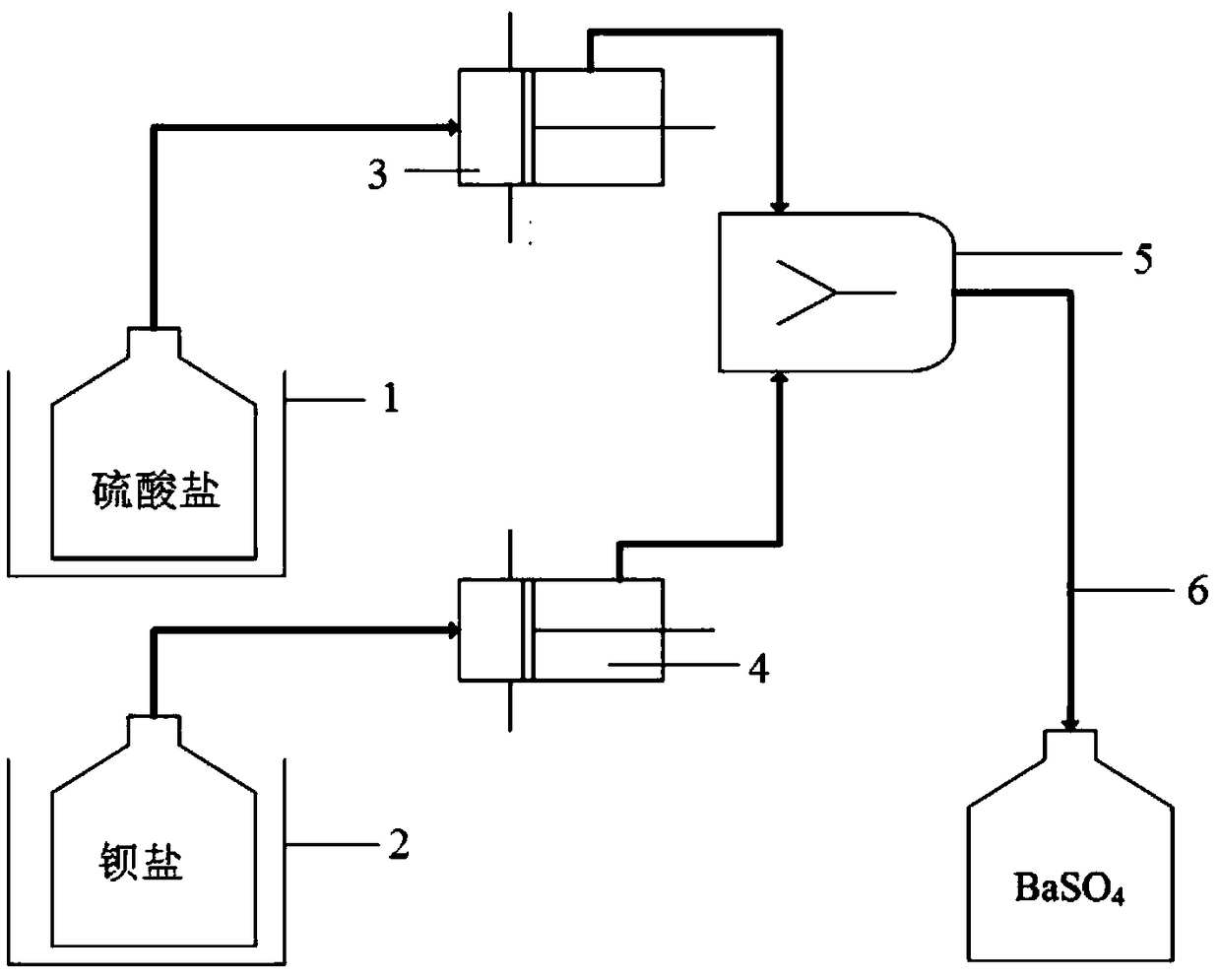

Method for preparing barium sulfate particles through microchannel method

ActiveCN108862355ALarge specific surface areaShort stayMaterial nanotechnologyCalcium/strontium/barium sulfatesBarium dichlorideBarium salt

The invention belongs to a method for preparing barium sulfate particles through a microchannel method in the technical field of nanomaterial preparation. The method comprises the following steps: introducing a sulfate water solution and a barium salt water solution into a microchannel reactor for reacting and ageing, and centrifuging, washing and drying an obtained reaction solution, thus obtaining the barium sulfate particles, wherein selected sulfate is sodium sulfate, ammonium sulfate or sodium persulfate, and barium salt is barium chloride, barium acetate or barium nitrate. The morphologyand the particle size distribution of the obtained barium sulfate particles are controllable, and industrial application of medical dry films can be met to a larger extent.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

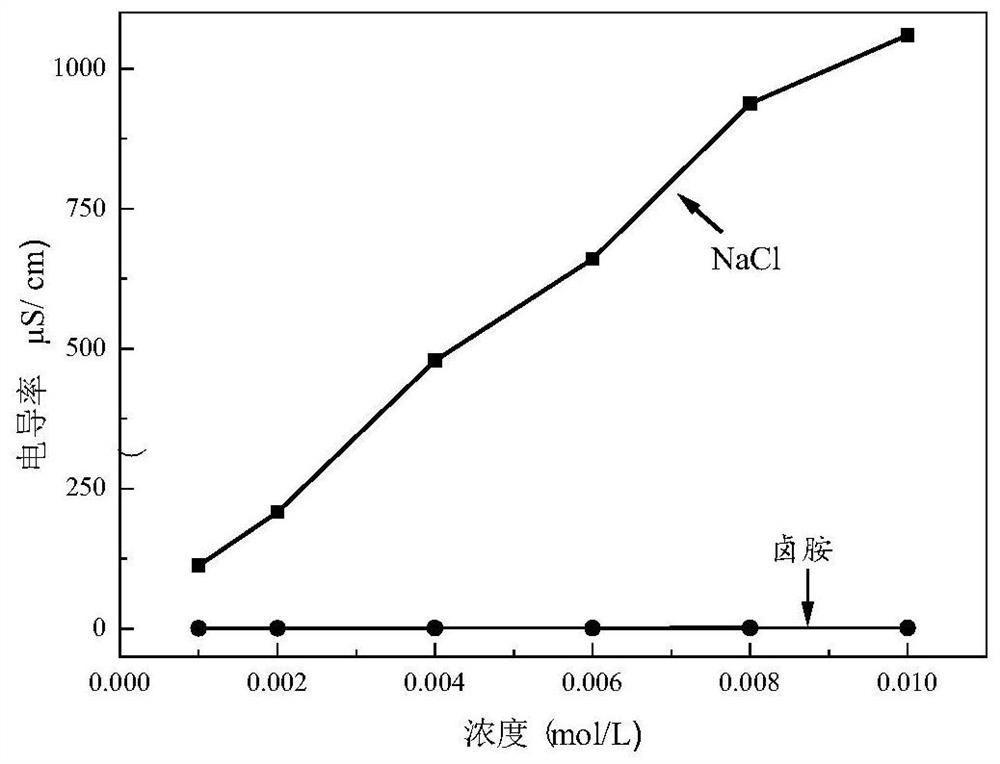

Method of separating chlorine-containing plastics from waste mixed plastics

ActiveCN104589545AEfficient recyclingLow costPlastic recyclingFlotationVolumetric Mass DensityOxidative treatment

The invention discloses a method of separating chlorine-containing plastics from waste mixed plastics. The method comprises the following steps: crushing at least one kind of chlorine-containing plastics and at least one kind of plastic without containing chlorine into mixed plastic particles, carrying out oxidation treatment on the mixed plastic particles by virtue of an oxidant, and carrying out flotation separation on the mixed plastic particles after oxidation treatment by virtue of a flotation agent to obtain the chlorine-containing plastics and the plastics without containing the chlorine, wherein the densities of the plastics are close. The method is capable of efficiently and selectively separating out the chlorine-containing plastics from waste plastics and meeting industrial application and production and is simple in operation and low in cost.

Owner:CENT SOUTH UNIV

A separating method of mixed plastics

ActiveCN105399983AEasy to separateEfficient separationPlastic recyclingAqueous solutionNuclear chemistry

The invention relates to a separating method of mixed plastics and belongs to the technical field of waste plastic recovery. The method includes subjecting mixed plastic particles to surface modification by dipping the mixed plastic particles into an aqueous solution containing a wetting agent until an adsorption amount of the wetting agent on surfaces of the mixed plastic particles is not less than 5 g / t, performing solid liquid separation, adding the obtained solid into an eluant, eluting for not more than 20 min, performing solid liquid separation to obtain solid that is eluted mixed plastic particles, and subjecting the eluted mixed plastic particles to floatation to obtain a single plastic with high purity. The method is high in separation efficiency, simple in operation, easily controllable and low in cost and facilitates large-scale industrial application.

Owner:CENT SOUTH UNIV

The producing method of the rare earth based flat plate denitrification catalyst

ActiveCN106268769AGood synergyImprove high temperature stabilityHeterogenous catalyst chemical elementsDispersed particle separationRare earthCobalt

The invention discloses a producing method of the rare earth based flat plate denitrification catalyst which applies the anatase titanium dioxide powder as the first carrier, the titanium silicon molybdenum compound oxides as the active components, one or more of the nanometer oxides of tungsten, cobalt, nickel, zirconium iron as the assistant catalyst. What's more, add the binder and lubricant and then form the pastes of the denitrification catalyst. The pastes of the catalyst needs to be decayed, coated, dried, cut and calcined to make the flat plate denitrification catalyst. The rare earth denitrification catalyst produced in this method has a good stability of high temperature and frame. The anti-wear and anti-seismic functions are quite excellent. it also has features like wider temperature windows, higher denitrification efficiency and simple recycling and processing of waste catalyst. The processing is simple and low-cost so it can meet the requirements of the industrial application and will be adapted to the denitrification of all the fixed and moving sources.

Owner:DATANG NANJING ENVIRONMENTAL PROTECTION TECH

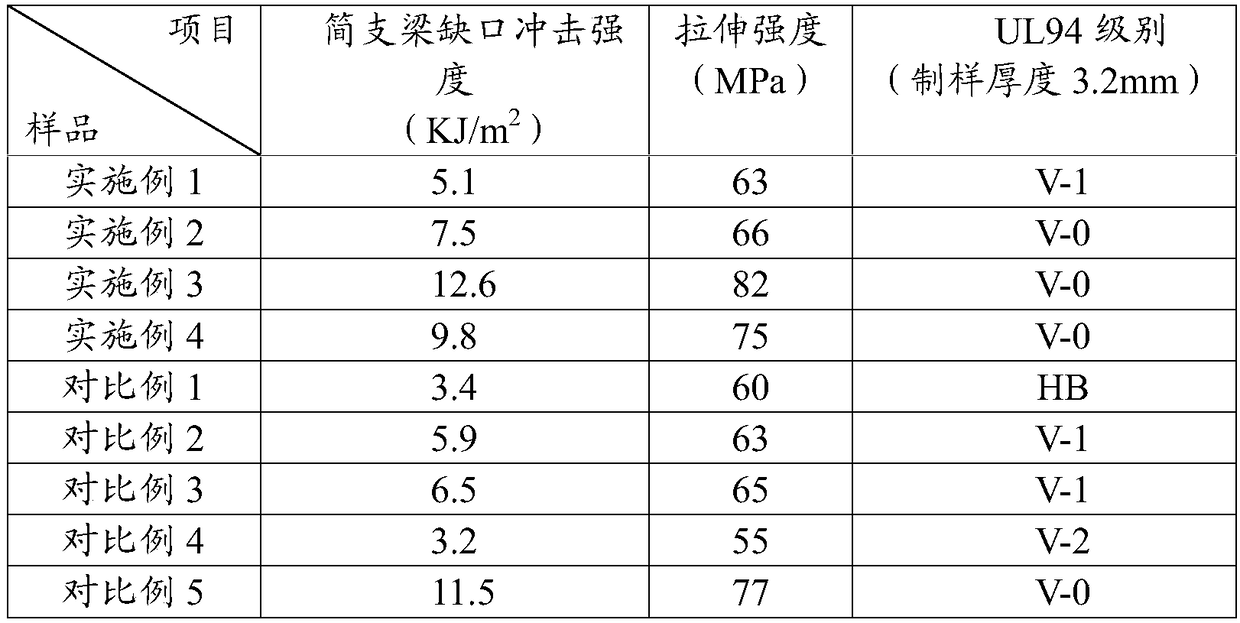

White graphene modified polybutylene terephthalate composite material and preparation method thereof

InactiveCN108570222ASimple and fast operationMeet industrial applicationsPolytetramethylene terephthalatePolyethylene terephthalate

The invention discloses a white graphene modified polybutylene terephthalate composite material and a preparation method thereof. The modified composite material is mainly prepared from, by weight, 0.5-6 parts of high polymer modified white graphene, 75-88.5 parts of polybutylene terephthalate, 10-15 parts of a phosphorus-nitrogen flame retardant, 0.5-2 parts of an antioxidant and 0.5-2 parts of adispersing agent. The white graphene modified polybutylene terephthalate composite material has advantages of environmental friendliness and high flame resistance.

Owner:GUANGDONG NANOLUTION SCI & TECH CO LTD

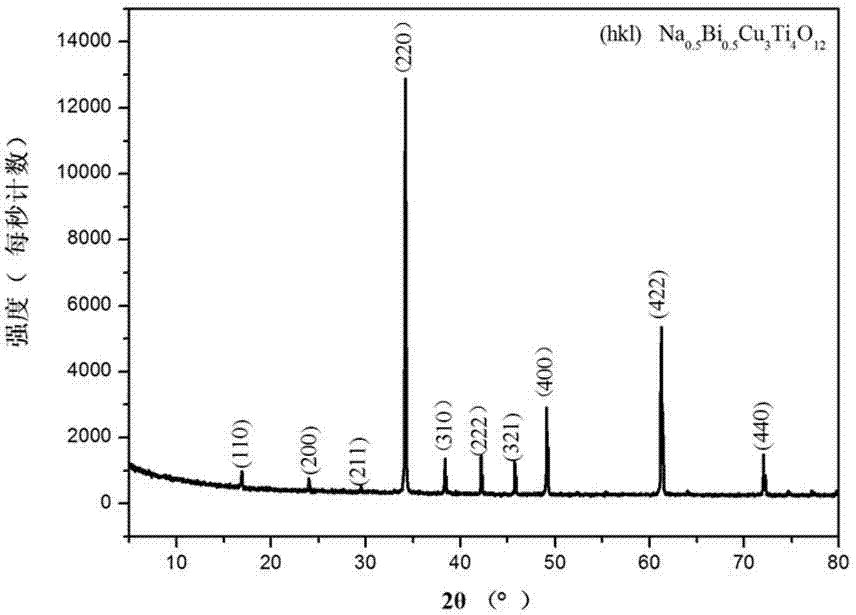

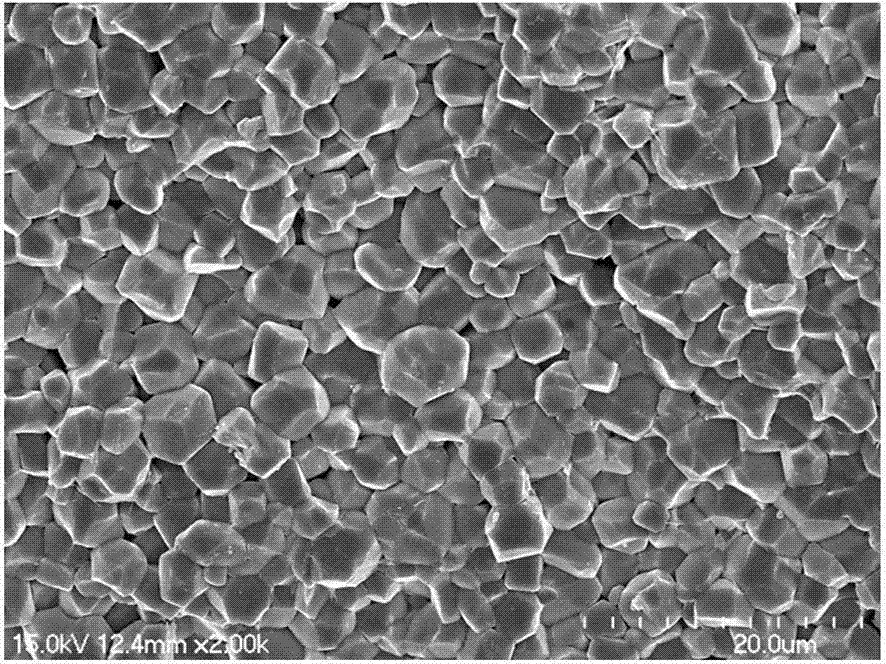

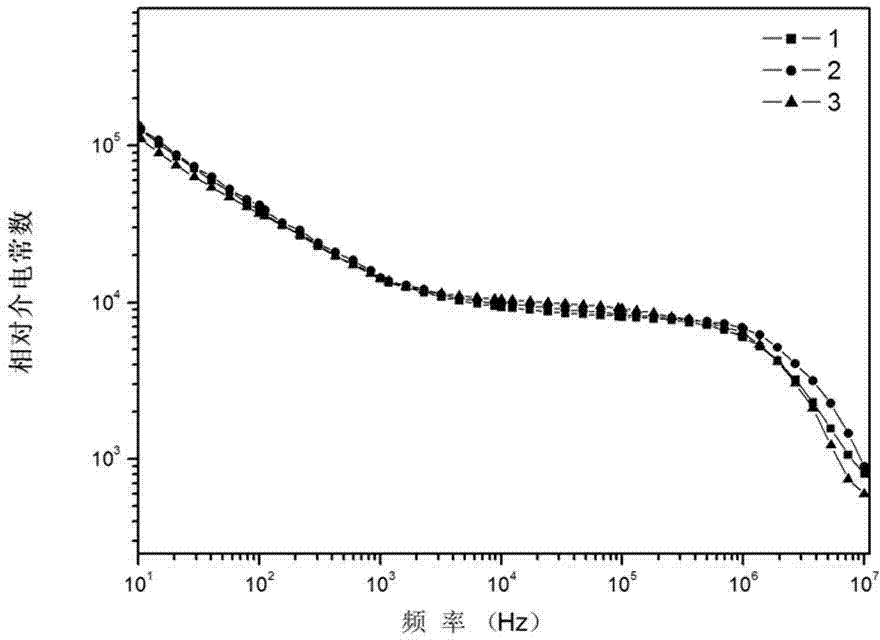

Method for preparing copper titanate bismuth sodium ceramic

The invention relates to a method for preparing a Na0.5Bi0.5Cu3Ti4O12 ceramic. Na2CO3, Bi2O3, CuO and TiO2 serve as raw materials, NaCl and KCl are added into the raw materials, and the raw materials are ball-milled, pre-burned, formed and sintered to form a product. By the method, the raw materials can react at low temperature, a synthetic product is high in purity and small in grain size and has a great value in the field of high dielectric constant materials, the microscopic structure of the copper titanate bismuth sodium ceramic can be obviously improved, and further dielectric property is improved.

Owner:SUZHOU UNIV

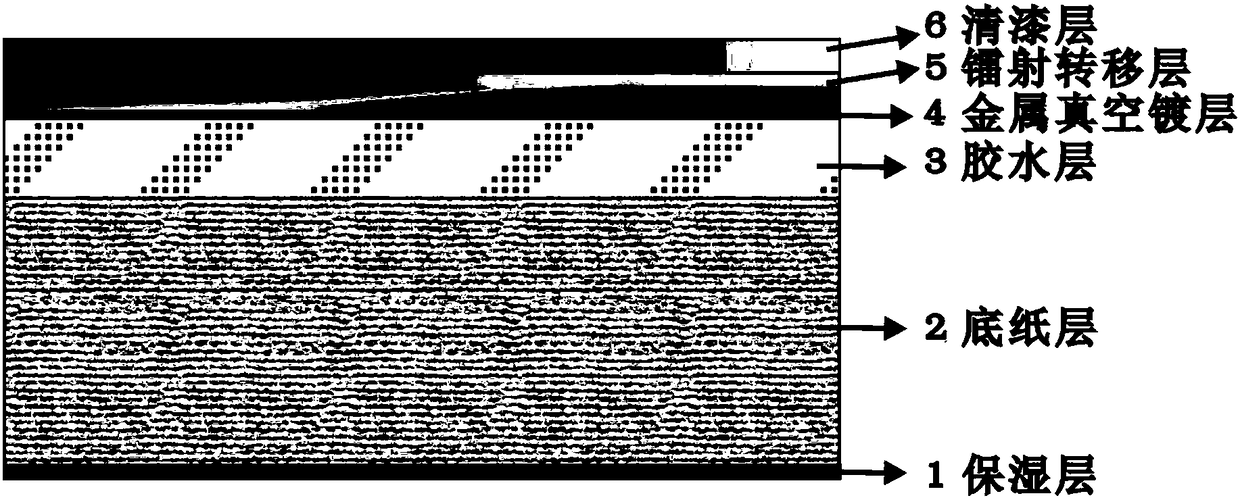

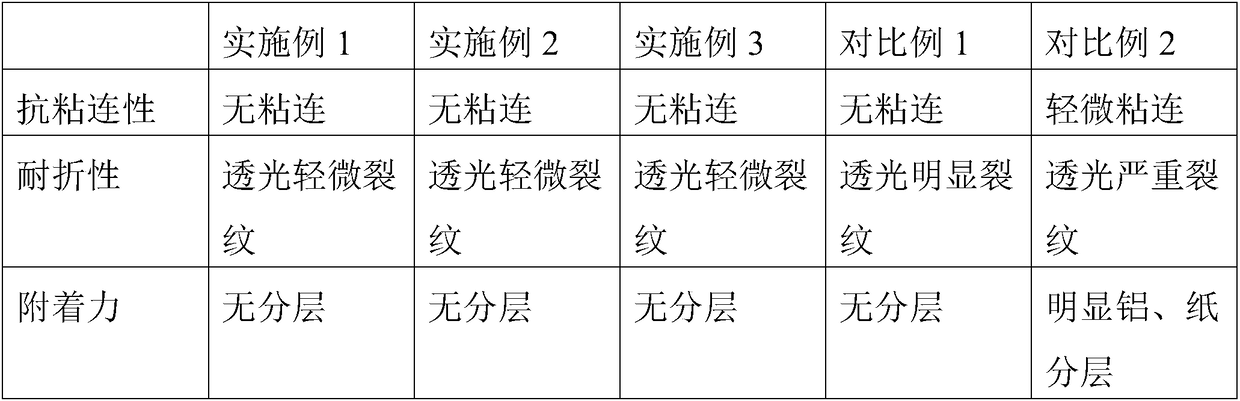

Laser transfer paper based on combination of water-based materials and preparation method of laser transfer paper

InactiveCN108215556AImprove bindingImprove flatnessNon-fibrous pulp additionPaper coatingWater basedPaper based

The invention discloses laser transfer paper based on combination of water-based materials and a preparation method of the laser transfer paper. The laser transfer paper based on combination of the water-based materials comprises a moisture preserving layer, a backing paper layer, a glue layer, a metal vacuum plating layer, a laser transfer layer and a varnish layer which are stacked sequentially,wherein the glue layer is a self-crosslinking modified acrylate layer; the laser transfer layer is a modified polyurethane layer; the moisture preserving layer, the glue layer, the laser transfer layer and the varnish layer are all prepared from water-based resin; film-forming resin of the modified polyurethane layer is Xinrui DFW-09. Materials used by the laser transfer paper based on combination of the water-based materials are all water-based environment-friendly materials, the environmental performance is good, the laser transfer paper based on combination of the water-based materials isgood in continuous mold pressing performance, better in brightness, good in folding resistance and excellent in gloss loss resistance, plate blocking in mold pressing is avoided, and continuous stripping can be realized.

Owner:GUANGDONG XINRUI NEW MATERIAL TECH

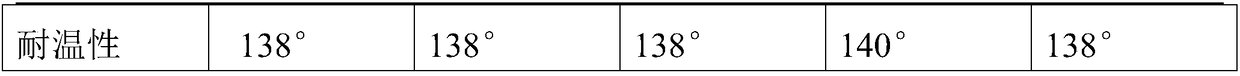

Dual solvent step-by-step phase conversion preparation method of polymethyl methacrylate gel electrolyte microporous membrane

ActiveCN107394265AHigh mechanical strengthUniform sizeSecondary cells servicing/maintenanceElectrolyte immobilisation/gelificationCooking & bakingDischarge efficiency

The invention discloses a dual solvent step-by-step phase conversion preparation method of a polymethyl methacrylate gel electrolyte microporous membrane. The preparation method comprises the following steps: mixing a pore forming agent and a volatile solvent, dissolving polymethyl methacrylate polymer, after complete dissolution, uniformly painting the solution on a flat plate by using a scraper; allowing the flat plate to stand still for a while, after the volatile solvent is completely volatized, soaking the flat plate in deionized water, after the pore forming agent in the polymer membrane is dissolved in water, taking out the flat plate, drying the flat plate through baking, and after drying, soaking the polymer membrane into lithium salt electrolyte to obtain the PMMA gel electrolyte microporous membrane. A solvent, which can be easily dissolved in water and has a boiling point greater than 100 DEG C, is taken as the pore forming agent, the uniformity of the gel electrolyte microporous membrane is improved; compared with a conventional diaphragm, the electrochemical stability window and charge / discharge efficiency are higher; a better liquid absorbing effect is achieved, no leakage happens, the mechanical strength of the membrane is enhanced; the safety problem of liquid lithium ion batteries is solved, the problem that the conductivity of solid batteries is low is solved; and the method can be applied to industrial production easily.

Owner:中科(淮安)新能源技术开发有限公司

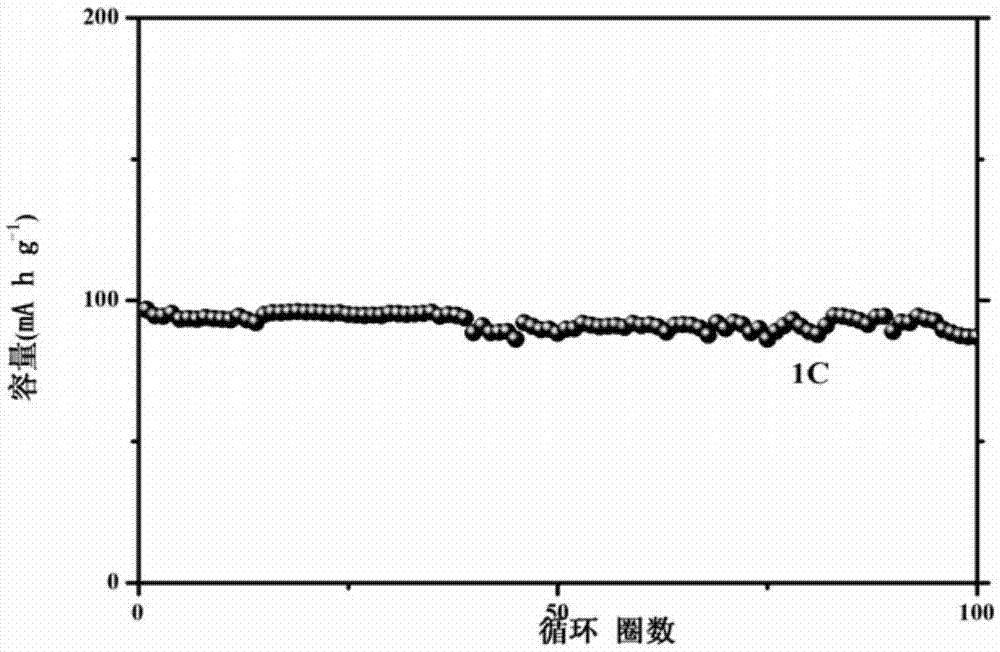

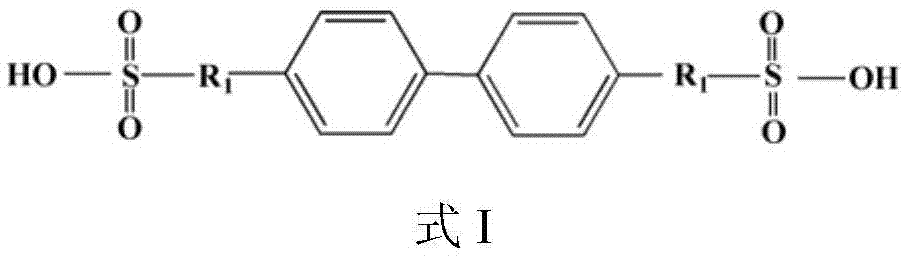

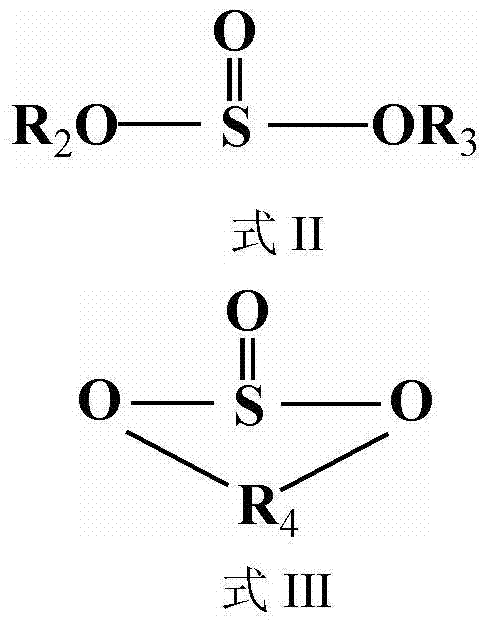

High-voltage stable electrolyte for lithium-ion battery

ActiveCN105449277AImprove electrochemical stabilityAvoid destructionSecondary cellsOrganic electrolytesOrganic solventDecomposition

The invention discloses a high-voltage stable electrolyte for a lithium-ion battery. The electrolyte comprises an organic solvent, a lithium salt and an additive, wherein the additive comprises a symmetrical biphenyl compound containing double sulfonic groups and a fluoro-sulfite compound. According to the electrolyte, high-voltage stable and compact interfacial films are simultaneously formed on the surfaces of a positive electrode and a graphite negative electrode, so that oxidative decomposition of the electrolyte is suppressed; recycling of the lithium-ion battery in a high-voltage condition can be met; and the service lifetime of the electrolyte is prolonged.

Owner:南宁翌思达新能源科技有限公司

Method for utilizing mixed waste acids in acetic acid production device

ActiveCN104387256AAchieve recyclingReduce contentCarboxylic acid salt preparationCarboxylic compound separation/purificationFluidized bed dryingPropionate

The invention discloses a method for utilizing mixed waste acids in an acetic acid production device, which comprises the following steps: (1) pumping waste acid materials into a falling film evaporator, evaporating to obtain acetic acid and propionic acid vapor, condensing the acetic acid propionic acid vapor, and sending the condensate into a receiver tank; (2) pumping the acetic acid and propionic acid condensate into a reactor from the receiver tank, adding calcium carbonate into the reactor, reacting until the pH value of the reaction solution is 8-9, and taking out the solution; (3) filtering the reaction solution, sending part of the filtrate into a fluidized bed dryer, drying to obtain a calcium acetate and calcium propionate salt mixture, sending the calcium acetate and calcium propionate salt mixture into the other part of filtrate to form a calcium acetate and calcium propionate saturated solution; and (4) sending the saturated solution into a crystallizer, heating to precipitate calcium acetate crystals, and lowering the temperature to precipitate calcium propionate crystals. The method implements recovery of propionic acid and acetic acid in the waste acids.

Owner:TIANJIN BOHUA YONGLI CHEM IND

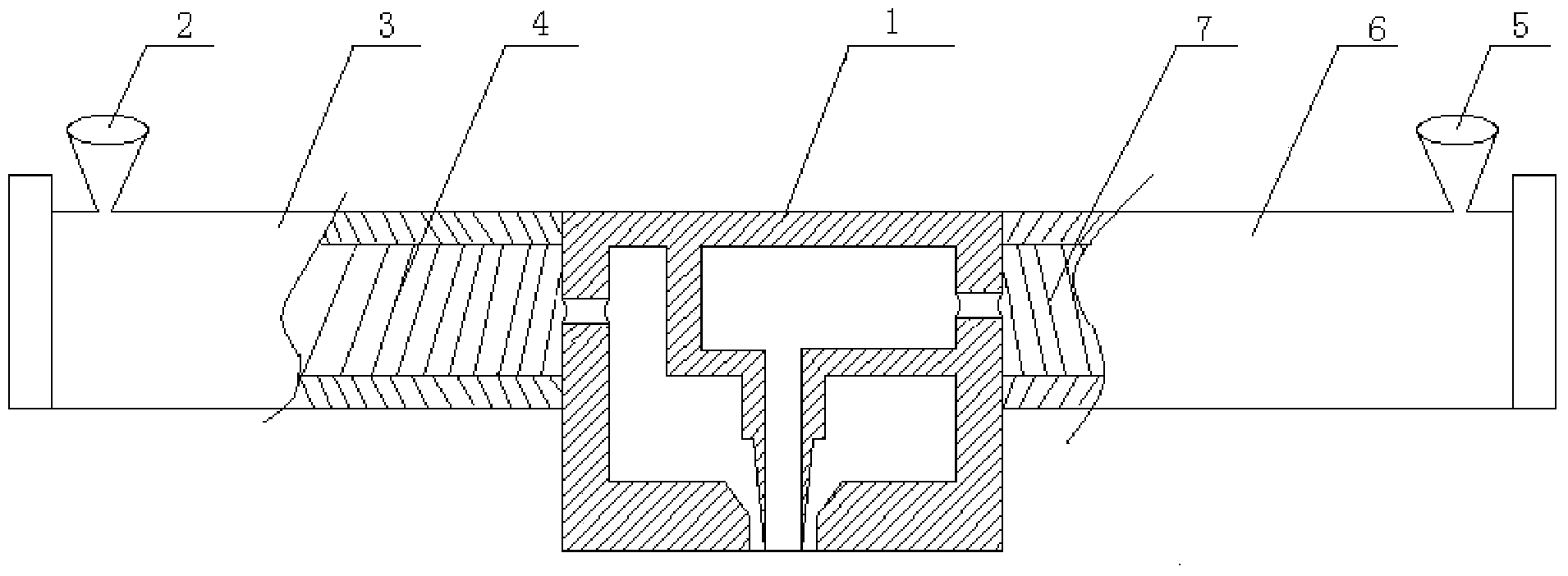

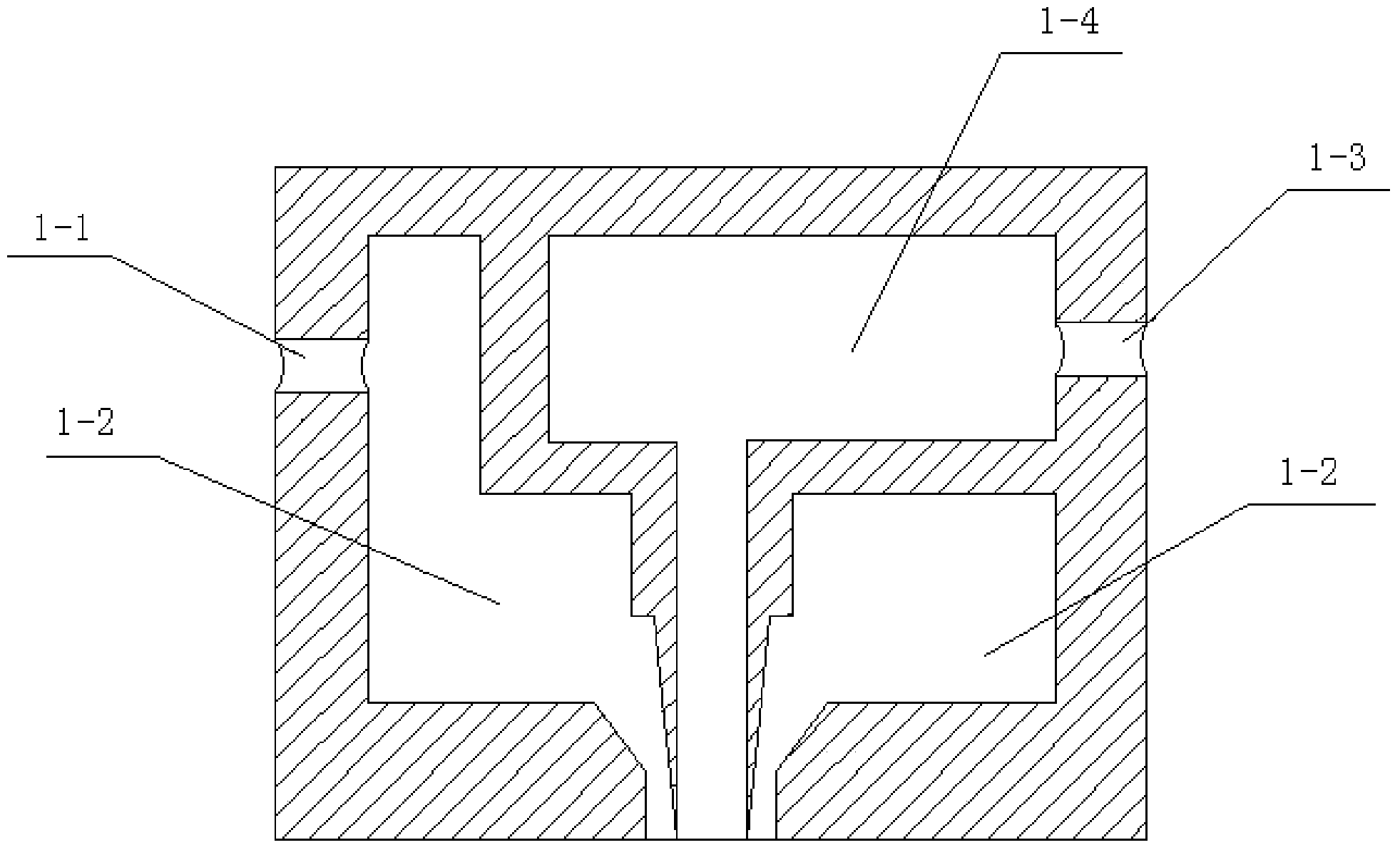

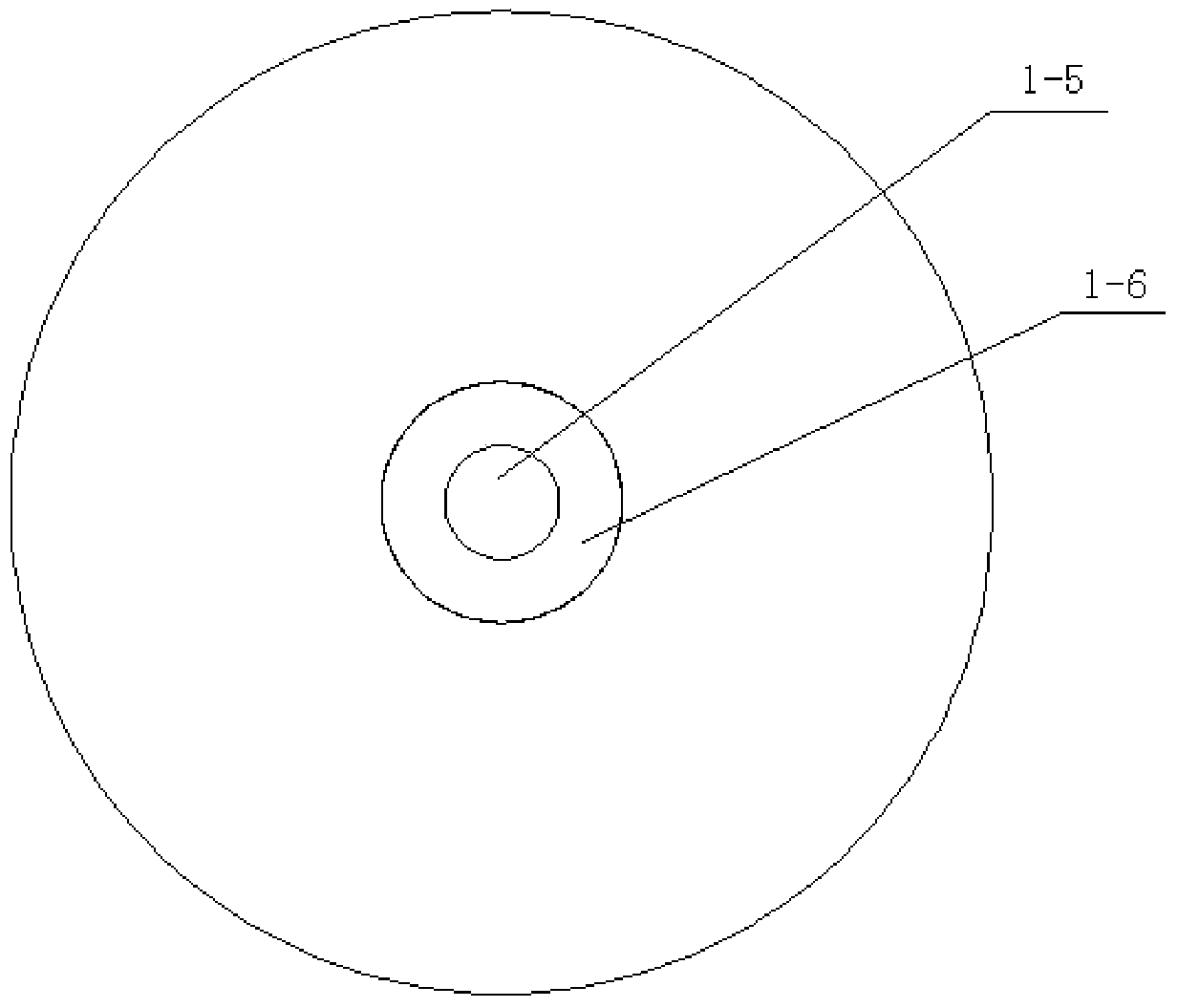

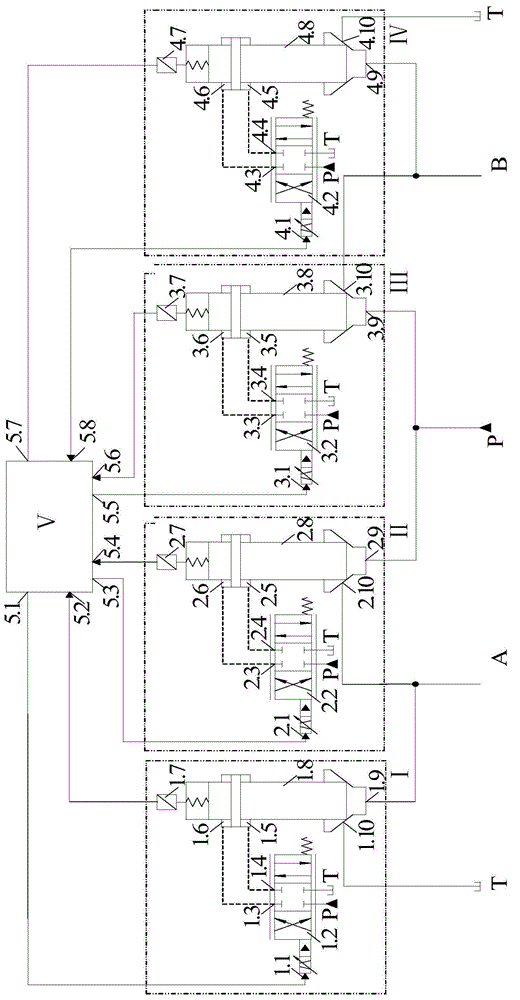

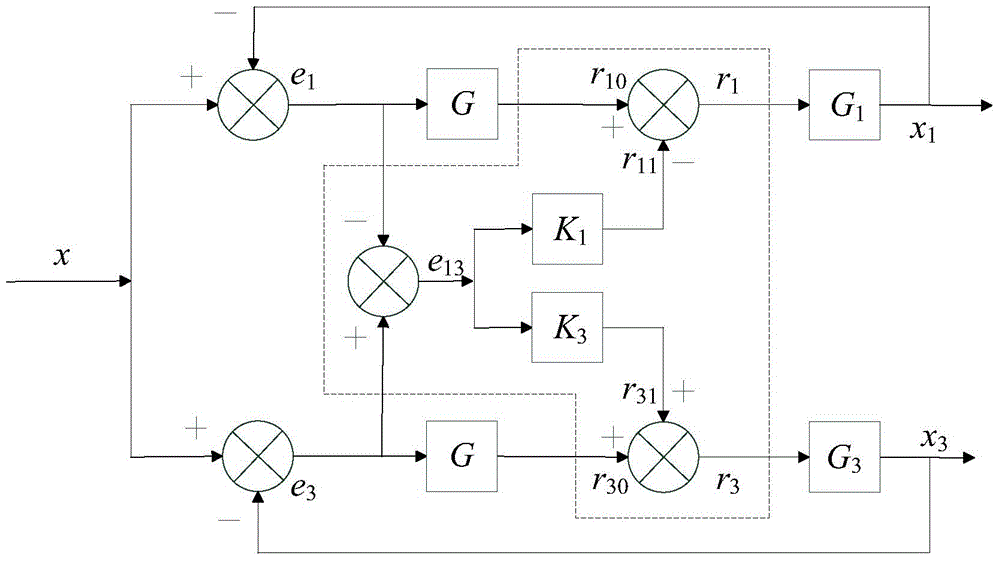

High-flow plug-in mounting type three-position four-way electro-hydraulic servo valve and control method thereof

ActiveCN105003479AImprove performanceHigh frequency responseServomotor componentsBridge typeControl signal

Disclosed is a high-flow plug-in mounting type three-position four-way electro-hydraulic servo valve. The high-flow plug-in mounting type three-position four-way electro-hydraulic servo valve comprises a control unit and four plug-in mounting type two-way servo valves. Four signal output ports of the control unit are connected with control signal input ports of the plug-in mounting type two-way servo valves respectively, and four signal input ports of the control unit are connected with valve plug displacement signal output ports of the plug-in mounting type two-way servo valves respectively. Every two plug-in mounting type two-way servo valves are connected in series, an oil outlet of one of every two connected plug-in mounting type two-way servo valves is connected with an oil inlet of the other plug-in mounting type two-way servo valve, so that two series-connected dual-valves are formed. Oil outlets of the series-connected dual-valves are used for being connected with an oil tank, oil inlets of the series-connected dual-valves are used for being connected with a hydraulic oil source, equivalently, the series-connected dual-valves are connected in parallel, so that a bridge type loop is formed, and the high-flow plug-in mounting type electro-hydraulic servo valve with a three-position four-way function is formed. The plug-in mounting type two-way servo valves are controlled by the control unit to change the opening degrees of valve ports so that changes of the flow direction and the flow quantity of oil can be achieved. The contradiction between the high flow and the high frequency response of an existing electro-hydraulic servo valve is effectively overcome, and the high-flow plug-in mounting type three-position four-way electro-hydraulic servo valve has the technical characteristics of the high flow and the high frequency response.

Owner:HUAZHONG UNIV OF SCI & TECH

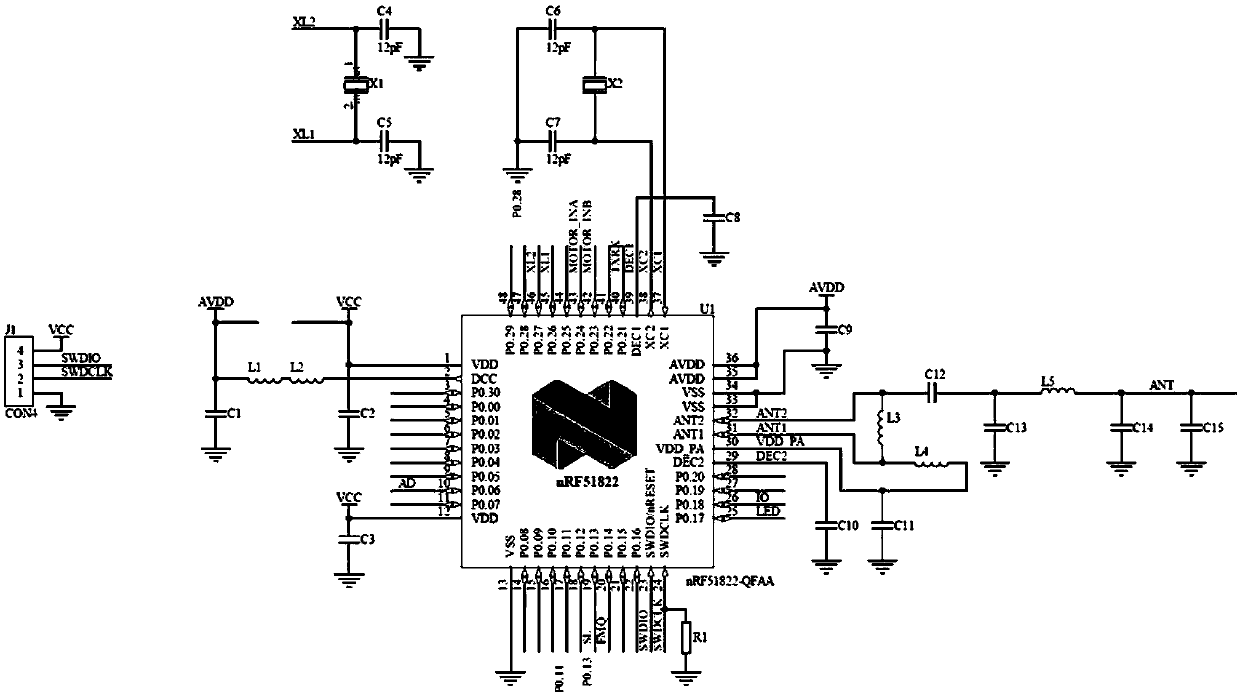

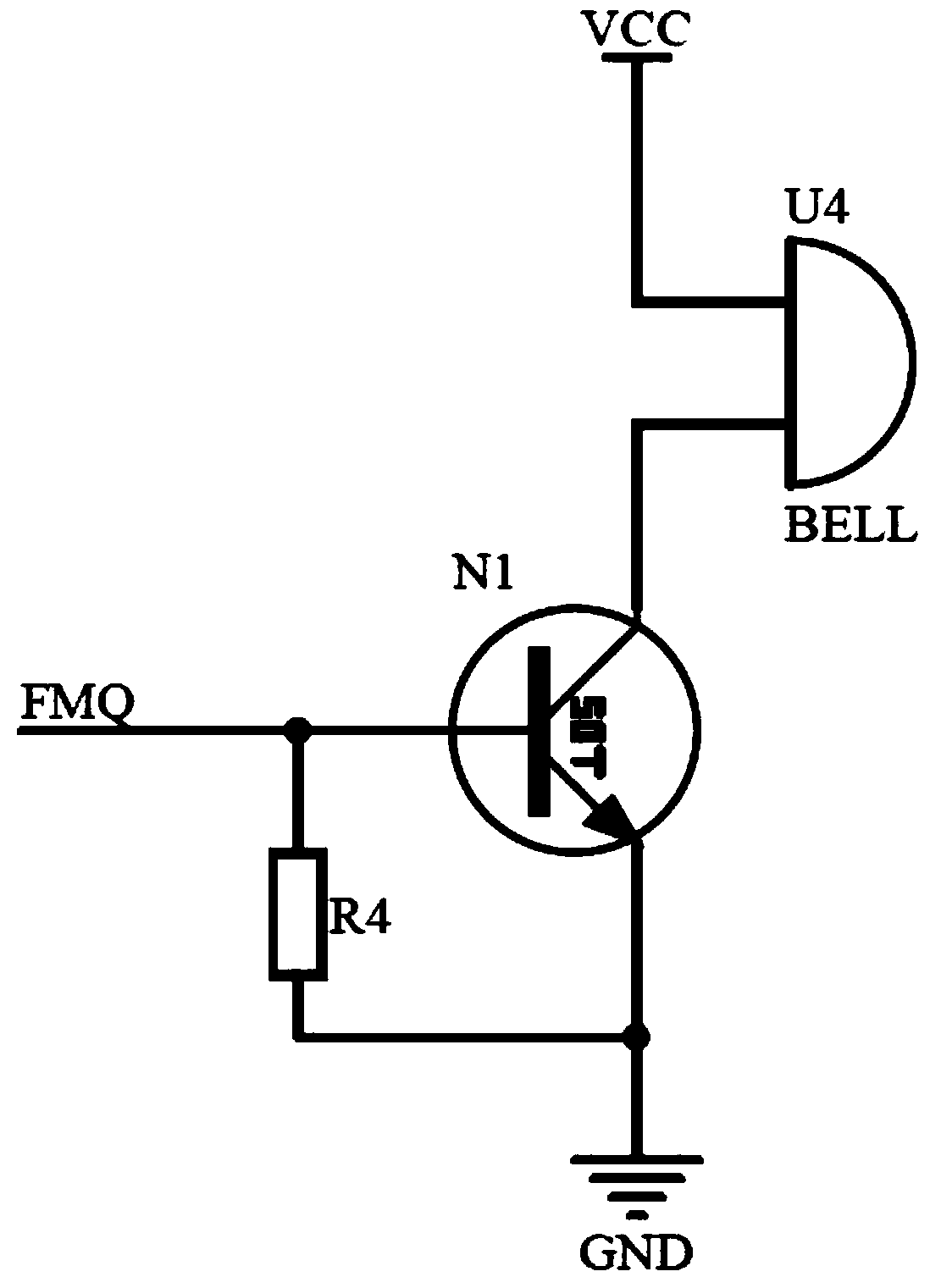

Intelligent Bluetooth padlock control device and intelligent Bluetooth padlock

PendingCN109667480ASimple structure and processSimple production processNon-mechanical controlsPadlocksElectricityMotor drive

The invention provides an intelligent Bluetooth padlock control device and an intelligent Bluetooth padlock. The control device comprises a Bluetooth control unit, and a touch panel interface, a motordriving circuit, a motor and a battery which are electrically connected with the Bluetooth control unit separately; an output shaft of the motor is mechanically connected with a moving lock part of apadlock, and the touch panel interface is used for receiving user touch signals so that the Bluetooth control unit is activated; the Bluetooth control unit is in Bluetooth communication with a user mobile terminal in the activated state, and the motor driving circuit is controlled according to unlocking signals of the user mobile terminal for driving the motor to rotate; the motor is rotated fordriving the moving lock part of the padlock to move so that the unlocking of the padlock is achieved; and the battery is used for providing working power to the intelligent Bluetooth padlock control device.

Owner:SHENZHEN POWER SUPPLY BUREAU

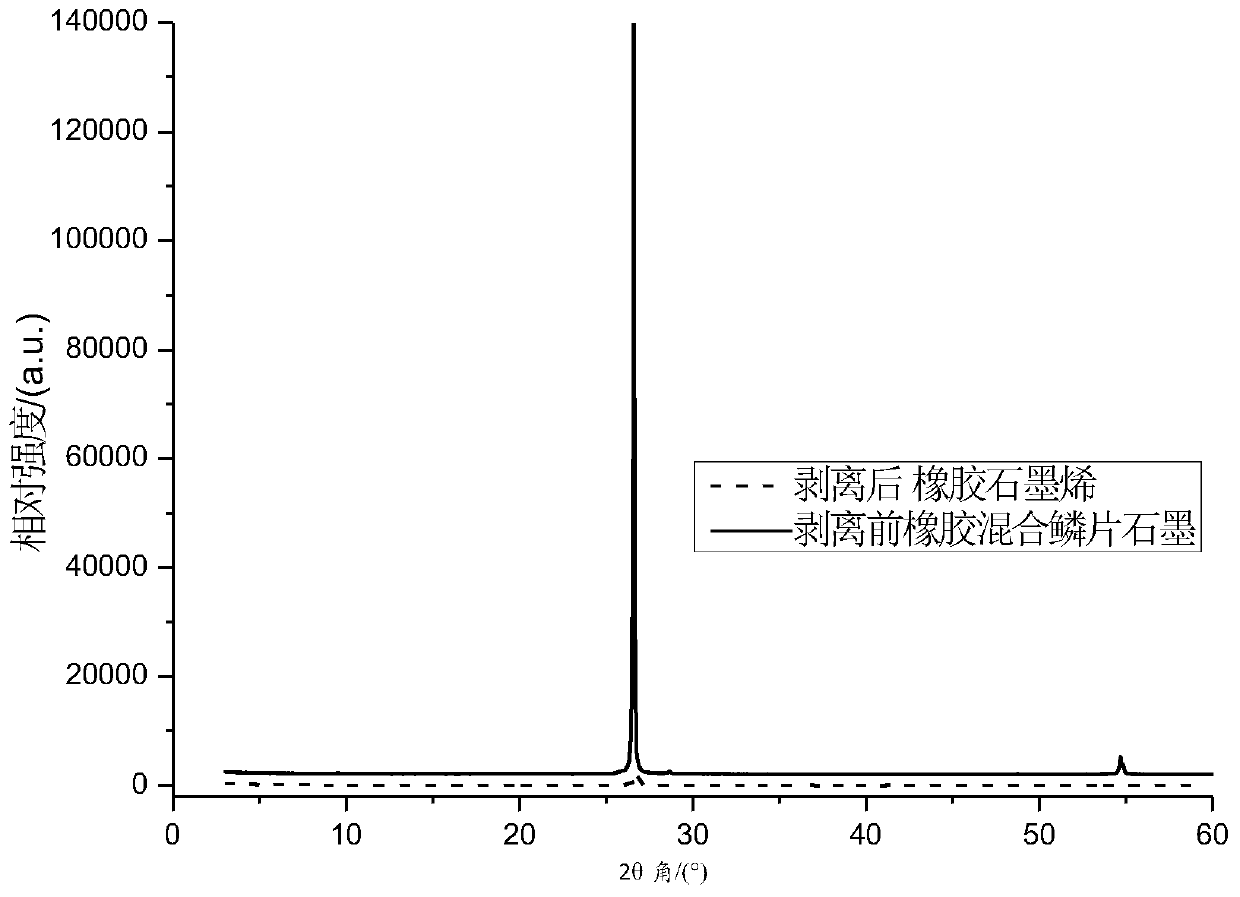

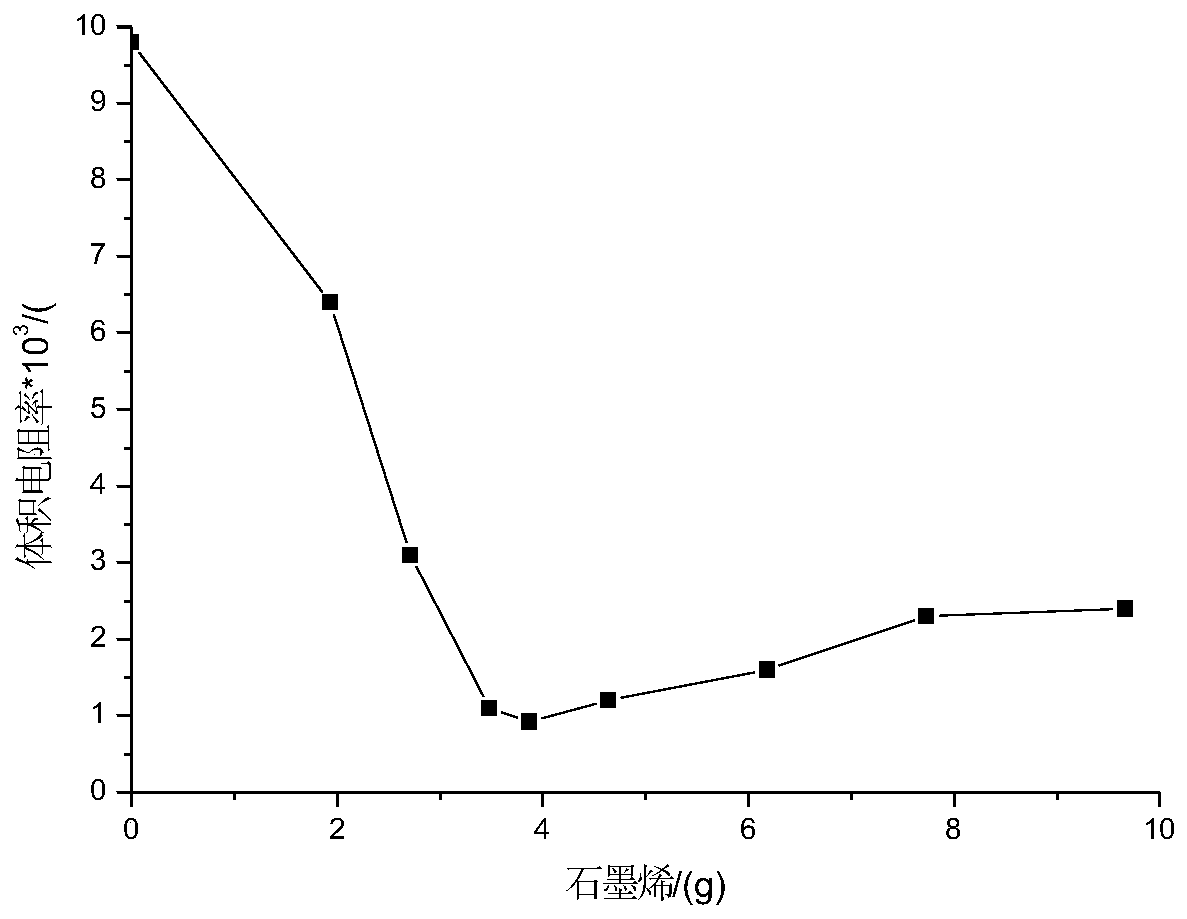

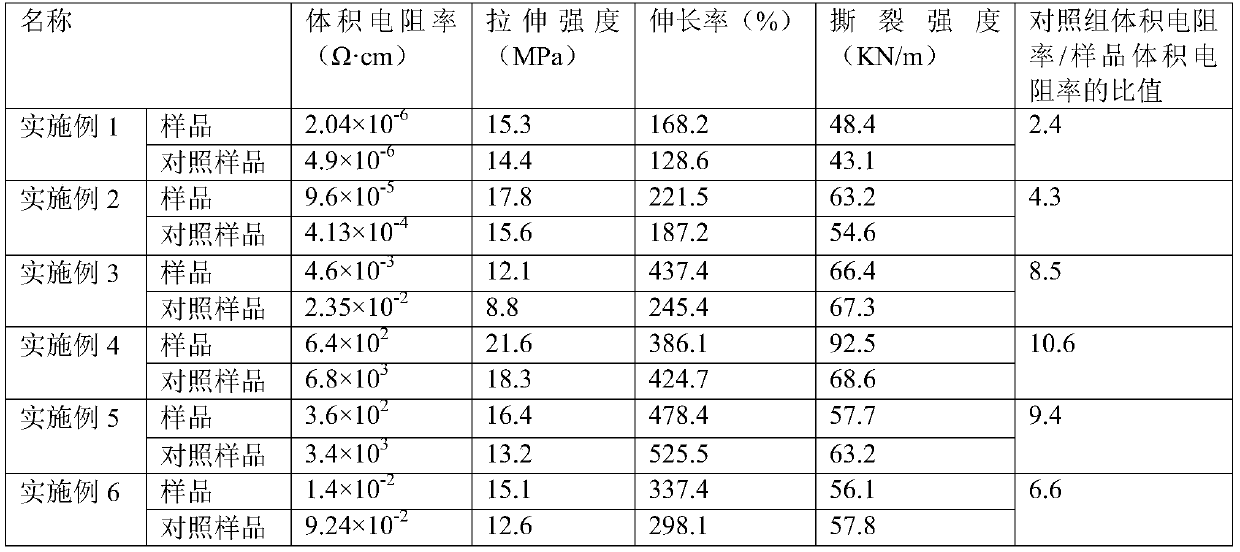

Preparation method of rubber stripping graphene composite conductive rubber

The invention relates to a preparation method of rubber stripping graphene composite conductive rubber. The preparation method comprises the steps that after rubber is mixed with crystalline flake graphite, rubber graphene composite rubber blocks formed by using rubber to strip the crystalline flake graphite are used as conductive reinforcement materials, the graphene rubber blocks are evenly dispersed in a substrate of the conductive rubber through a blending composite technology, and the high-performance series graphene composite conductive rubber material with wide purposes is prepared. Thevolume resistivity can be greatly decreased through the product obtained through the preparation method, the conductivity and the mechanical property of the material are improved exponentially, and the rubber stripping graphene composite conductive rubber has the characteristics that the cost is low, the technology is simple, the efficiency is high, dispersing is uniform, and scale production canbe achieved.

Owner:HEBEI UNIV OF TECH

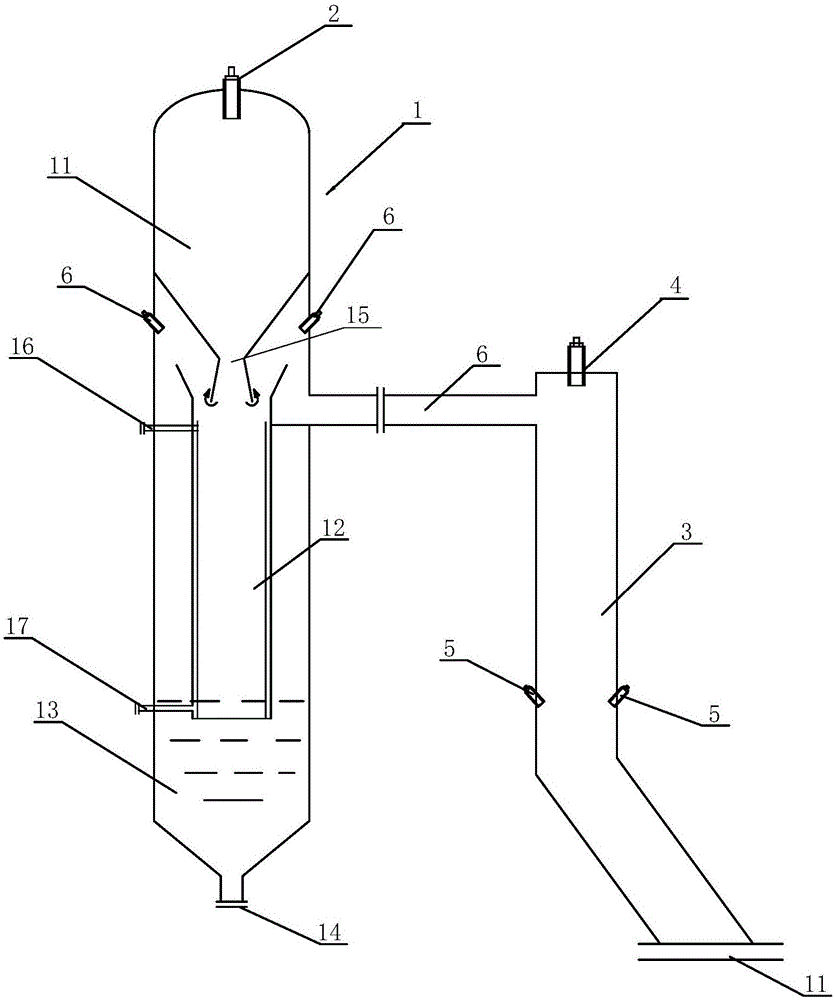

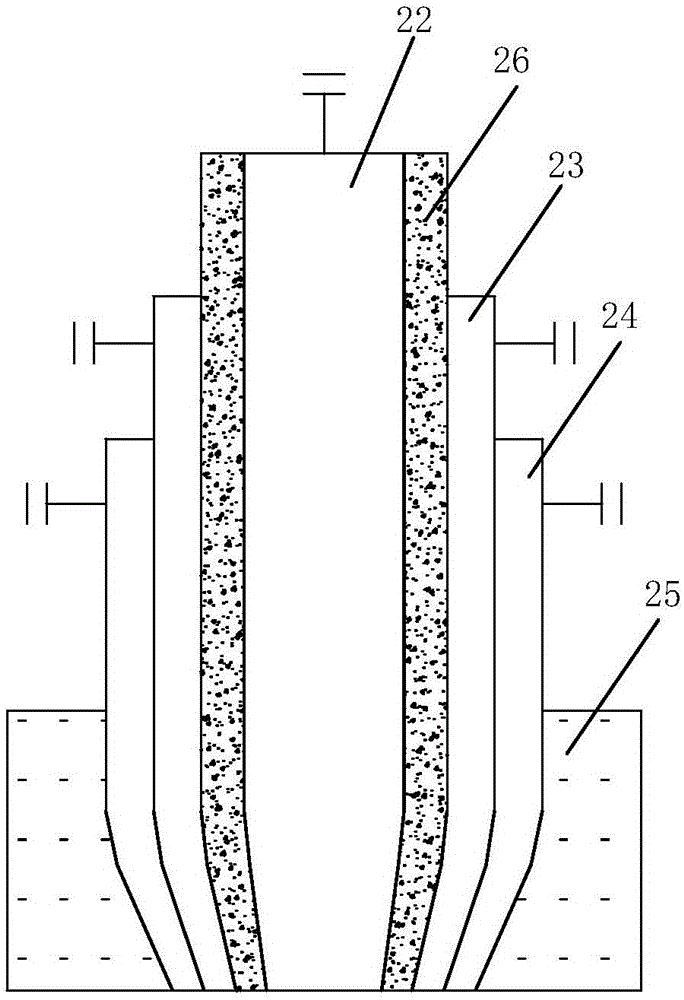

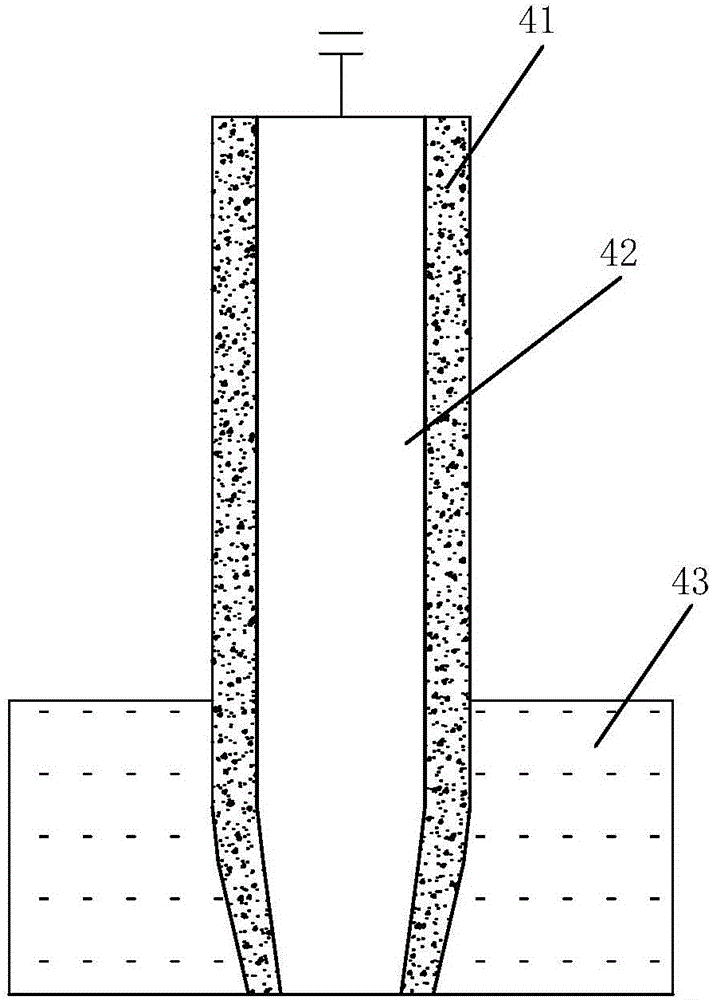

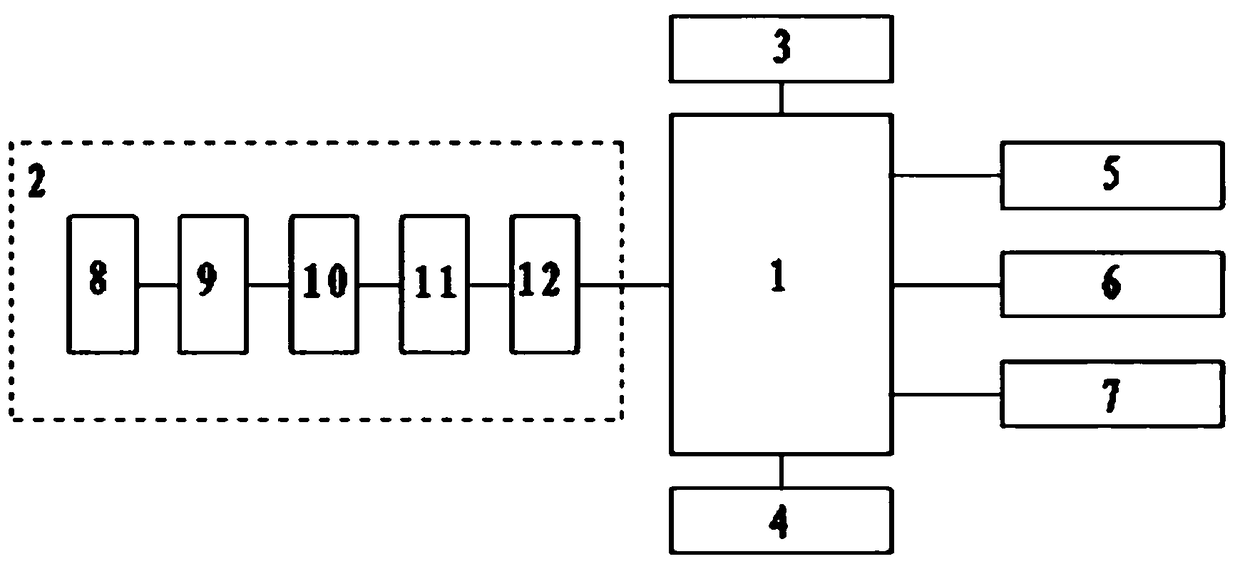

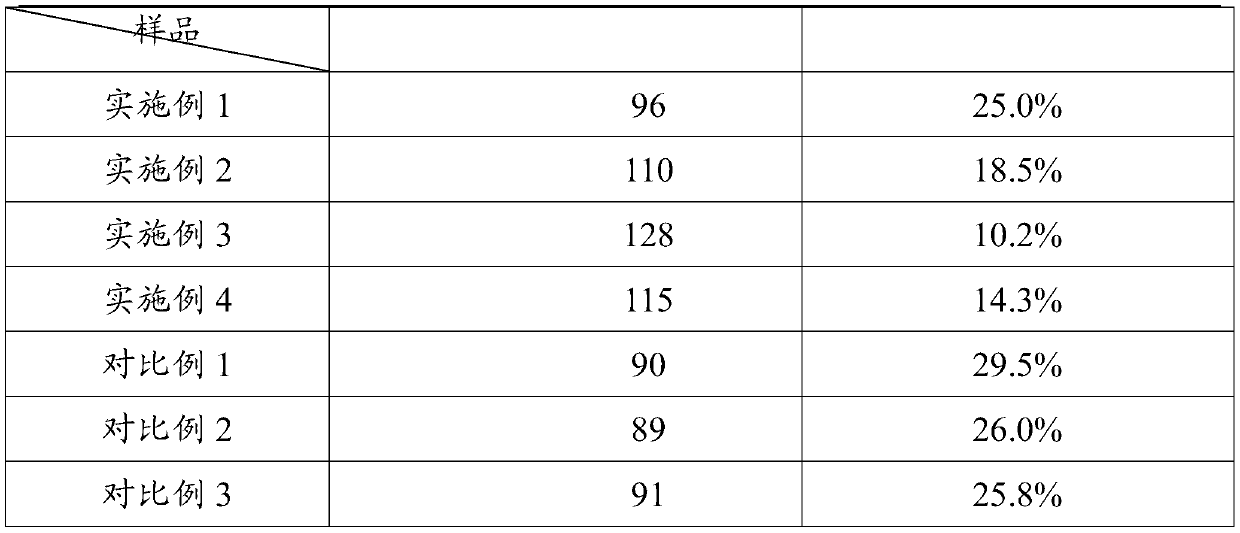

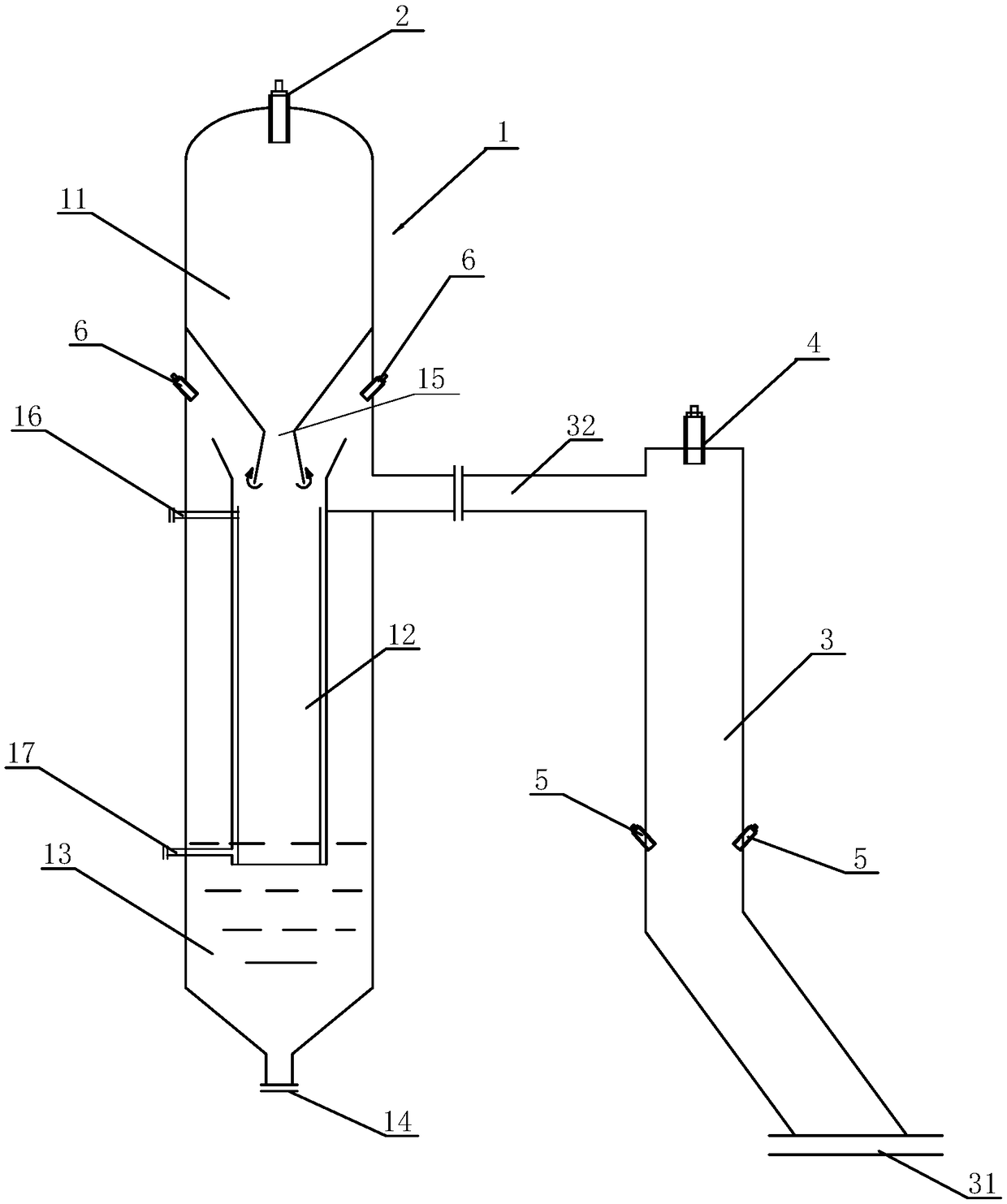

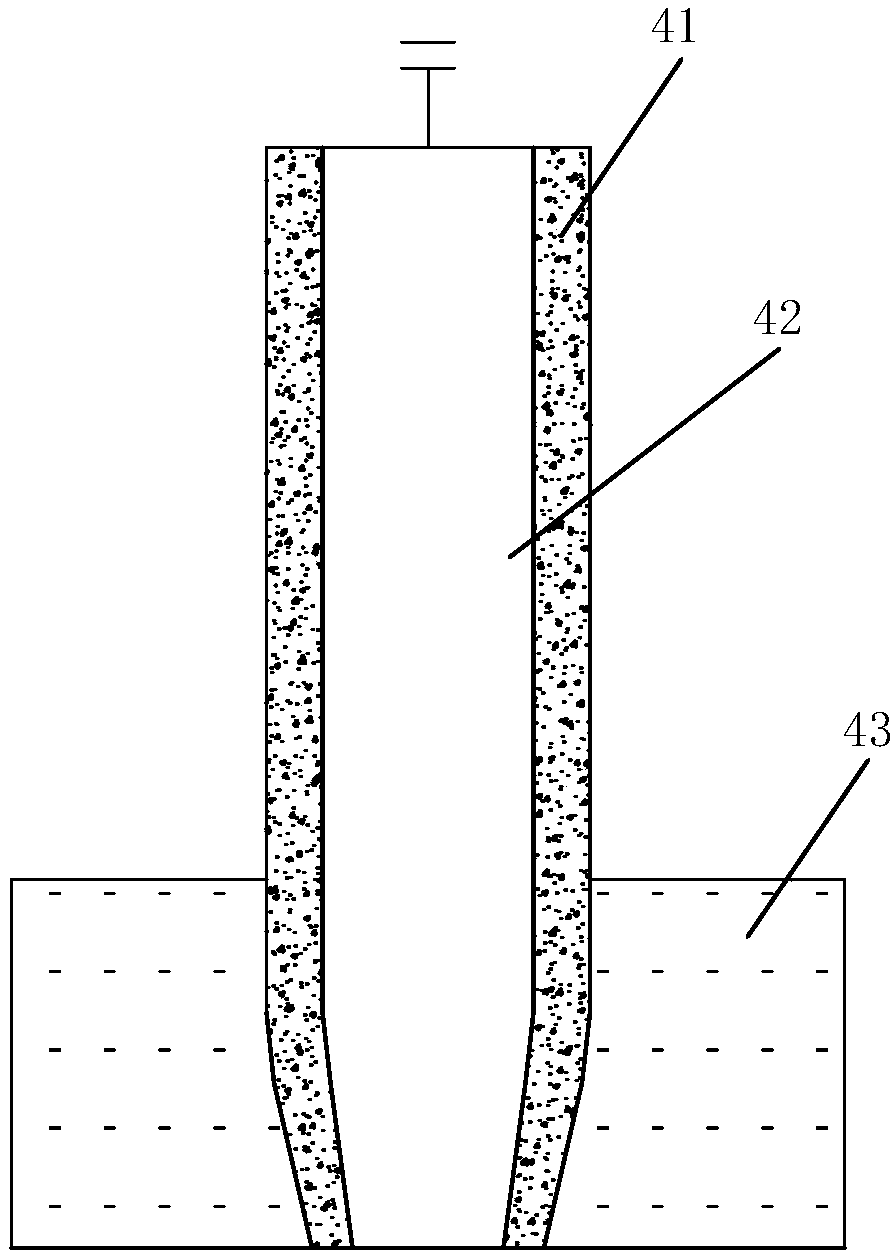

Apparatus and method for producing oil by means of coal pyrolysis

ActiveCN106281399AMeet industrial applicationsGuaranteed uptimeGasification processes detailsLiquid hydrocarbon mixture productionHydrogenProcess engineering

The invention relates to an apparatus and a method for producing oil by means of coal pyrolysis. The apparatus comprises a gasification furnace. A gasification nozzle is arranged on the top of the gasification furnace, a gasification chamber is arranged on the upper portion of the gasification furnace, a chilling chamber is arranged at the bottom of the gasification chamber, a bottom outlet of the gasification chamber is communicated with the chilling chamber via a downcomer, and a residue outlet is formed in the bottom of the gasification furnace. The apparatus is characterized in that the gasification furnace is connected with a pyrolysis chamber by a synthesis gas delivery passage, a coal nozzle is arranged on the top of the pyrolysis chamber, temperature reducing nozzles are arranged in the middle of the pyrolysis chamber, and a product outlet is formed in the bottom of the pyrolysis chamber. The apparatus and the method have the advantages that coal gasification and coal hydrogenation requirements can be simultaneously met without additional hydrogen sources; a gasification system and a pyrolysis system are independent from each other, accordingly, the apparatus and the method are favorable for stable running of reactors, and the apparatus can be advantageously enlarged.

Owner:SINOPEC NINGBO ENG +2

Water-based paint in-can preservative

ActiveCN113150591AGood stabilityStable storage timeAntifouling/underwater paintsPaints with biocidesEnvironmental chemistryFormaldehyde free

The invention provides an application of a compound shown in a formula I in a water-based in-can preservative, and the novel water-based in-can preservative, which is prepared by taking the compound shown in the formula I as an active component and adding a solvent. The preservative has the advantages of being environmentally friendly, long in stable storage time, good in compatibility with a conventional water-based paint system, wide in pH value application range, free of ionization in a solvent system, excellent in inactivation capacity for common microorganisms in the water-based paint, free of generation of formaldehyde gas, capable of being ecologically decomposed after being used and the like. The basic requirements of green paint are met, and the product is suitable for industrial application.

Owner:张元泽

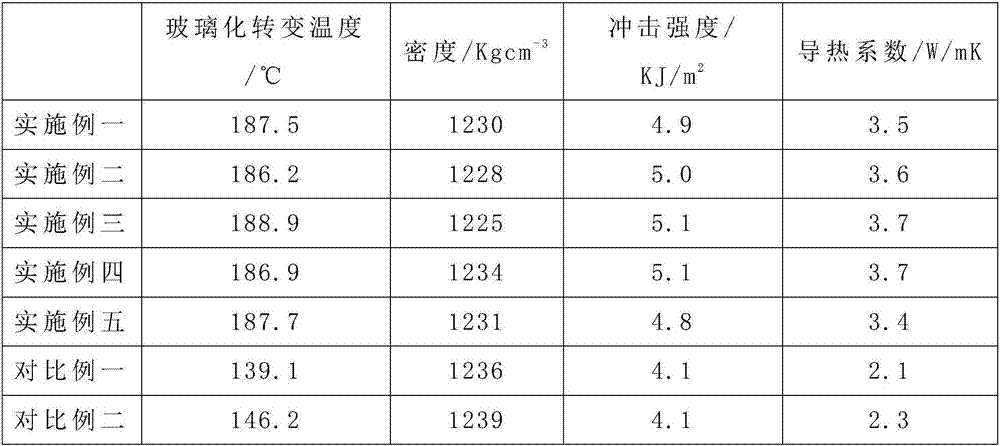

High thermal conductive and insulating material and preparation method thereof

The invention relates to a high thermal conductive and insulating material and a preparation method thereof.Bis((3,4-epoxy cyclohexyl)methyl)adipate is added into ethylene glycol, 3-tridecafluoro hexyl propylene and N-(3-hydroxyphenyl)acetamide are added, stirring is performed, then, glutaryl hydrazide and 4-tert-butyl benzene acetylene are added, and stirring is performed; then, aluminum oxide is added; stirring is performed to obtain an epoxy material; graphene and polyvinyl pyrrolidone are mixed to obtain preprocessed graphene; N-acetyl p-aminophenol is added into ethyl alcohol, then, silicon nitride is added, the preprocessed graphene is added, and stirring is performed to obtain a filler mixture; the filter mixture is added into the epoxy material; stirring is performed, then, thiocyanato-1-(2-aminophenyl)ethanone is added, stirring is performed for 3 h, a solvent is removed, and the high thermal conductive and insulating material is obtained; the high thermal conductive and insulating material is placed into a mold, and thermocuring is performed to obtain thermal conductive and insulating materials of different specifications.According to the preparation method, raw materials are wide in source, the preparation process is simple and controllable, only normal operation is needed, and industrialization is easy.

Owner:SUZHOU JIN TENG ELECTRONICS TECH

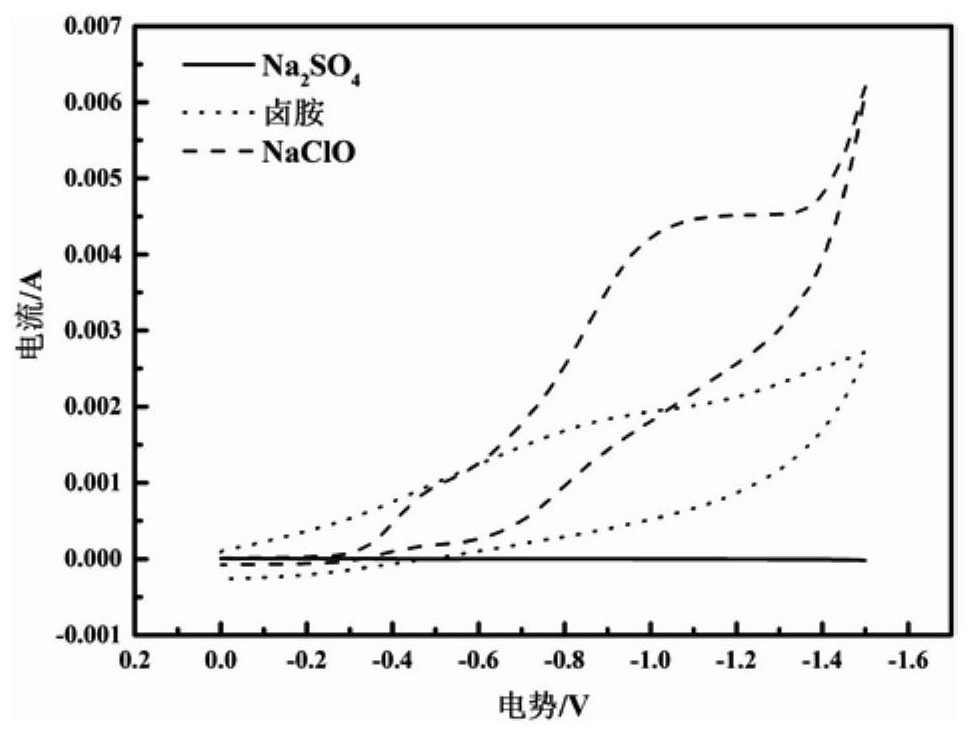

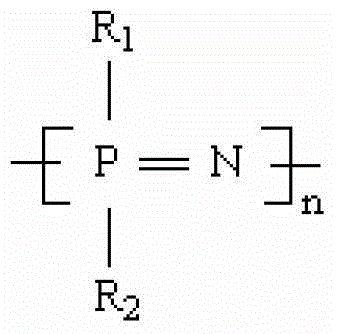

Method for purifying aryloxy polyphosphazene

The invention relates to aryloxy polyphosphazene and provides a method for purifying the aryloxy polyphosphazene. According to the method, 'impurities' in the aryloxy polyphosphazene are removed by a solvent swelling extraction method. Inorganic substances and organic substances in the aryloxy polyphosphazene are respectively dissolved by washing, preliminary alcohol washing, absolute ethyl alcohol and acetone compounded solution washing and secondary alcohol washing, and finally the absolute ethyl alcohol and water in sizing material are removed by a vacuum kneading technology. The method for purifying the aryloxy polyphosphazene has simple steps, low cost, and short total purification time, and the obtained aryloxy polyphosphazene solves the problems of degradation and incapability of crosslinking, and can meet the requirement on industrialized application.

Owner:XIAN MODERN CHEM RES INST

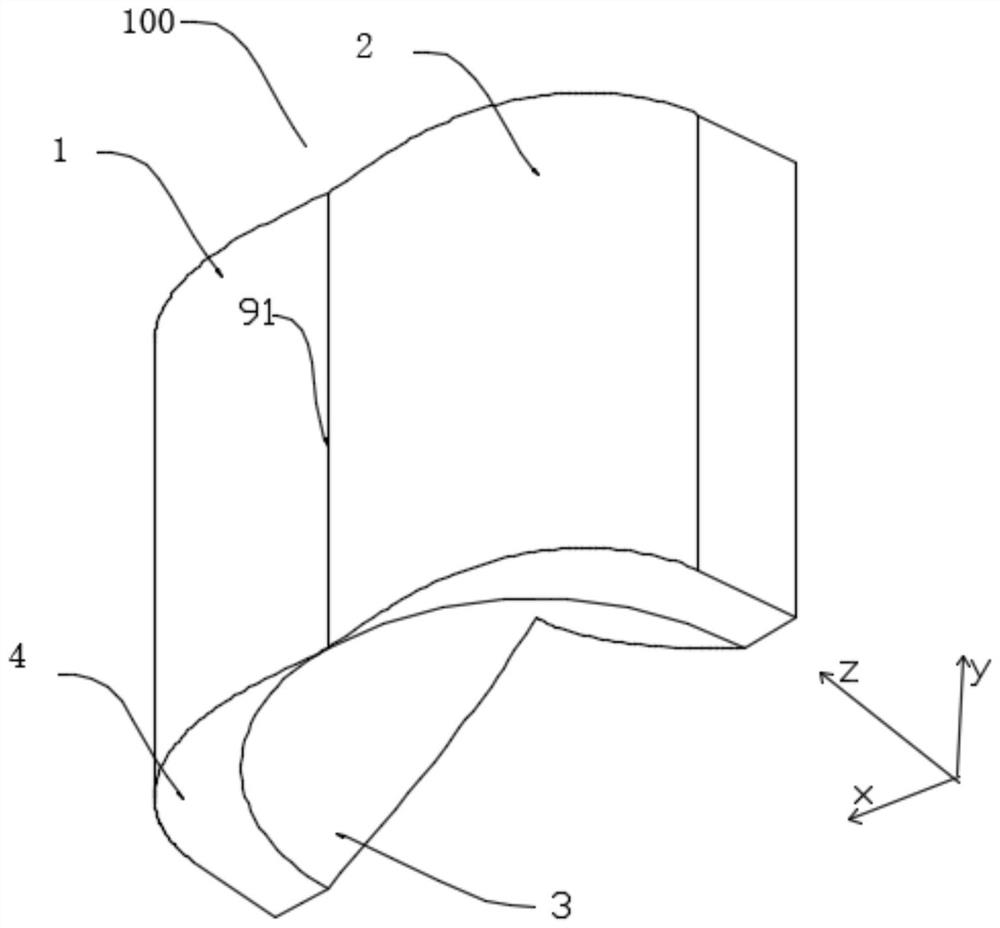

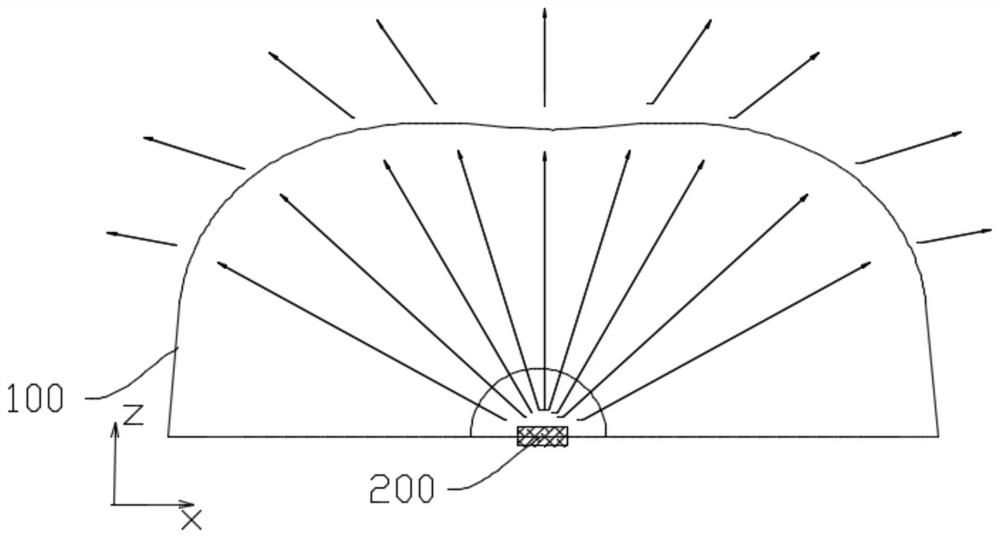

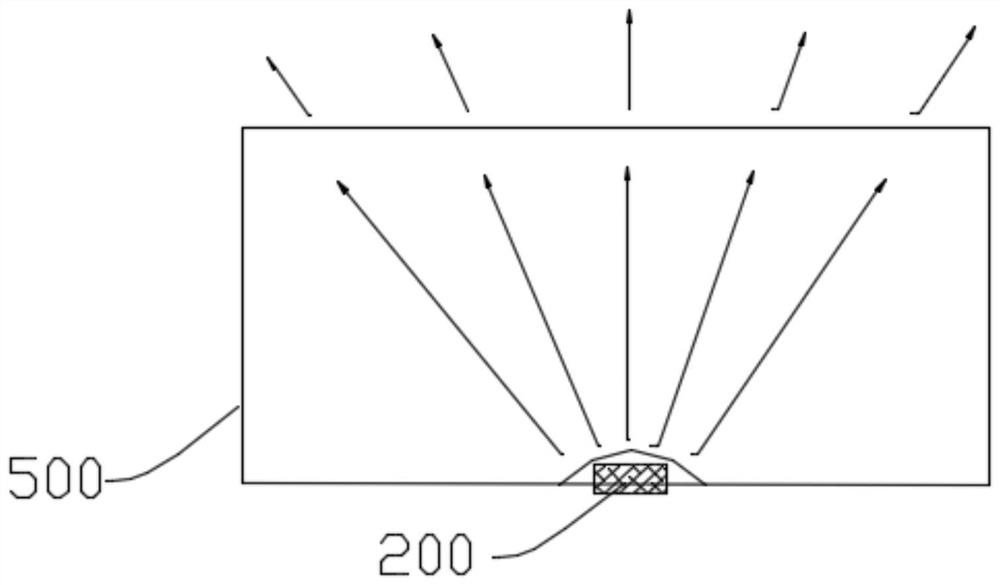

Lens and optical system

InactiveCN112682761AReasonable distributionMeet industrial applicationsRefractorsFirst lightOptic system

The invention provides a lens and an optical system with the lens. The lens comprises a mounting surface, a light incoming surface, a first light outgoing surface, a second light outgoing surface and a reflecting surface, wherein the mounting surface is used for achieving mounting of the lens, a light source cavity is formed in the center of the mounting surface and used for holding a light source, the inner surface of the light source cavity is the light incoming surface, one end of the first light outgoing surface is connected with the mounting surface, the other end of the first light outgoing surface is connected with the second light outgoing surface, and the reflecting surface is used for reflecting light rays which are emitted from the light incoming surface to the reflecting surface to the first light outgoing surface or the second light outgoing surface to exit. According to the lens, the positions and structures of the mounting surface, the light incoming surface, the first light outgoing surface, the second light outgoing surface and the reflecting surface of the lens are reasonably arranged, and therefore large-angle projection of the light rays can be achieved, the energy of the projected light rays on the large-angle edge is sufficient, and the optical performance requirement of large-angle industrial application for a large field angle can be met.

Owner:NANCHANG OUFEI BIOLOGICAL IDENTIFICATION TECH

A method for separating waste mixed plastics

ActiveCN104511369BEasy to separateHigh recovery ratePlastic recyclingWet separationLiquid mediumChemistry

The invention discloses a method for waste mixed plastic separation. The method comprises the following steps: crushing waste mixed plastic into mixed plastic particles, adding the obtained mixed plastic particles into a liquid medium I to perform sinking and floating separation, obtaining light-component plastic particles which are smaller than the liquid medium I in density and heavy-component plastic particles which are larger than that of the liquid medium I in density through the sinking and floating separation, adding the heavy-component plastic particles into a liquid medium II to perform surface treatment at a temperature of 70-100 DEG C and performing flotation separation on the heavy-component plastic particles subjected to surface treatment through a floating agent. According to the method, a variety of plastics in waste plastics can be efficiently and selectively separated. The method is simple to operate, is low in cost and meets the industrial application and production.

Owner:CENT SOUTH UNIV

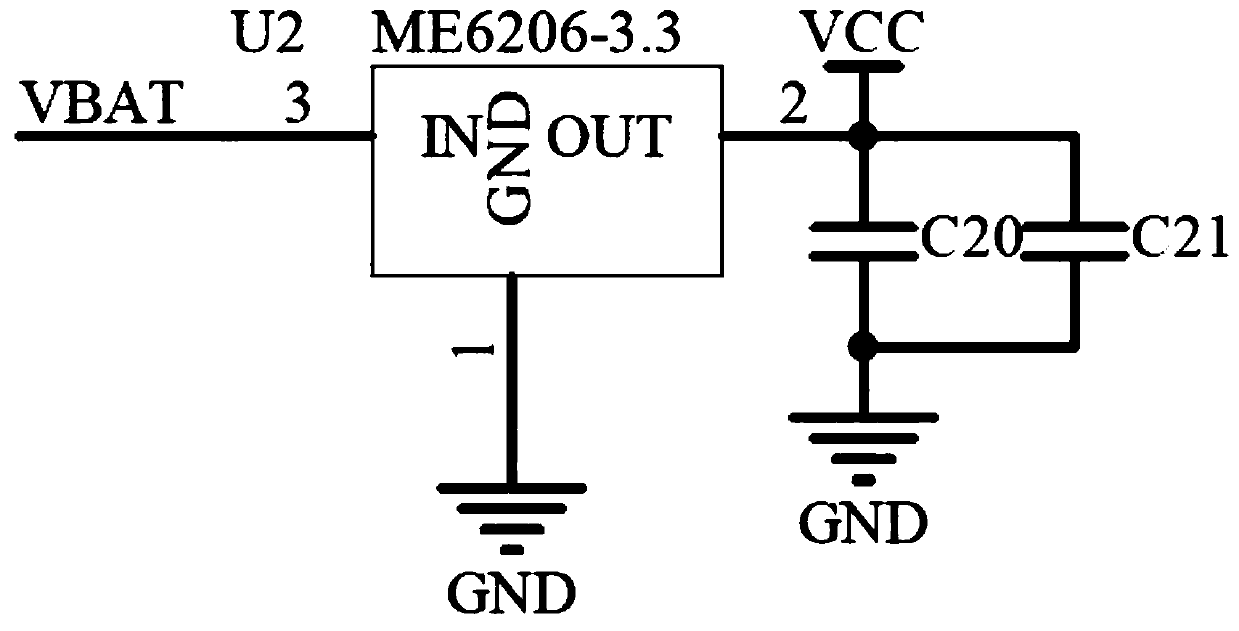

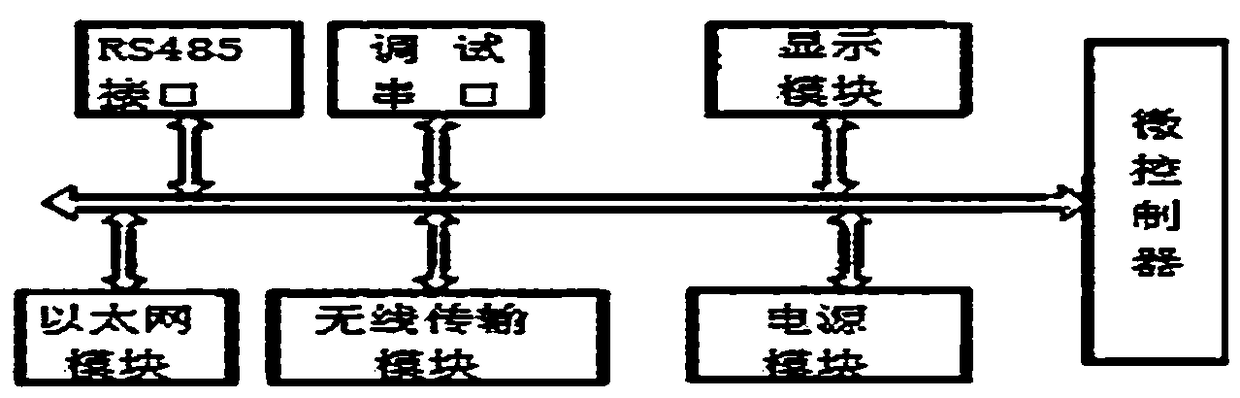

Intelligent power distribution system

InactiveCN108123542AImprove work efficiencySignal acquisition error is smallCircuit arrangementsSustainable buildingsMicrocontrollerWireless transmission

The invention belongs to the power equipment technical field and relates to an intelligent power distribution system. The intelligent power distribution system includes a control device, an RS-485 bus, a display module, a power source module, a debugging serial port, a wireless transmission module, an Ethernet module and an RS-485 interface; and the display module, the power source module, the debugging serial port, the wireless transmission module, the Ethernet module, and the RS-485 interface are connected with a microcontroller through the RS-485 bus. Compared with a general power distribution system, the power distribution system of the present invention has the advantages of high work efficiency, minimal signal acquisition error and network communication function, and can meet the need of automated development in the power distribution field.

Owner:辽宁东鹰航空装备科技股份有限公司

System and method for treating waste liquid generated in carbonyl-process acetic acid synthesis and application of such method

InactiveCN106810448AEmission reductionReduce contentOrganic compound preparationCarboxylic acid esters preparationPropanoic acidAlcohol

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Anti-sticking material

ActiveCN110527950AQuick responseReduce adhesionVacuum evaporation coatingSputtering coatingEpoxyMetal

The present specification provides an anti-sticking material. The anti-sticking material comprises at least one hard phase material and at least one soft phase metal, and the atomic percentage contentof the soft phase metal is 10% or above. The anti-sticking material is prepared by a physical vapor deposition method and has the relatively stronger anti-sticking performance. A hard anti-sticking coating prepared from the anti-sticking material has the relatively lower total surface energy and a relatively lower friction coefficient, and the sticking problem between the plastics, such as an epoxy molding compound (EMC-Epoxy Molding Compound), etc., and an injection mold, can be effectively solved.

Owner:CITY UNIVERSITY OF HONG KONG

Resourceful treatment method for membrane filtration concentrated solution in coal chemical industry

PendingCN112759134AMeet industrial applicationsWater treatment parameter controlWater softeningCoal chemical industryNanofiltration

The invention provides a resourceful treatment method for a coal chemical membrane filtration concentrated solution, and relates to the technical field of sewage treatment. The method comprises the following steps: adding CaO, MgO, PAC and PAM into the coal chemical membrane filtration concentrated solution to carry out passivation reaction so as to obtain a passivation treatment solution, and then adding Na2CO3, PAC and PAM to carry out complexation reaction so as to obtain a complexation treatment solution; adding FeSO4 and Na2CO3 into the complexing treatment solution for a precipitation reaction, and obtaining a precipitation treatment solution; adjusting the pH value of the precipitation treatment liquid to 9-10, introducing mixed gas of ozone and air, performing catalytic ozonation under the catalytic action of the activated iron shavings, and performing catalytic ozonation effluent; and carrying out nanofiltration and evaporative crystallization on the ozone catalytic oxidation effluent to obtain sodium chloride crystals and sodium sulfate crystals. According to the method provided by the invention, the coal chemical membrane filtration concentrated solution can be effectively treated, hazardous waste reduction is realized, and separation and resource utilization of carnallite are realized.

Owner:EAST CHINA UNIV OF SCI & TECH

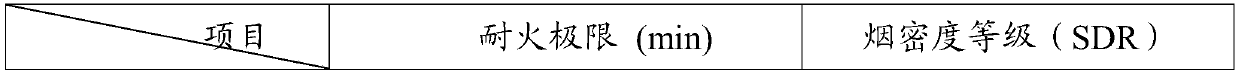

Fireproof coating and preparation method thereof

ActiveCN108485347BImprove fire performanceHigh smoke suppression effectFireproof paintsPolymer scienceMelamine phosphate

The invention discloses a fireproof coating and a preparation method thereof, wherein, in parts by weight, the fireproof coating comprises the following raw material components: 20-27 parts of matrix resin, 16-20 parts of melamine phosphate, 12-15 parts of pentaerythritol, 7-10 parts part of borax, 1 to 5 parts of chlorinated paraffin, 0.5 to 8 parts of modified white graphene, 3 to 8 parts of smoke suppressant, 0.1 to 0.8 part of defoamer, and 11.5 to 34 parts of solvent A; wherein, the modified The white graphene is a white graphene coated and modified by a polymer, and the polymerized monomer of the polymer is styrene or an acrylic ester monomer. The fire retardant coating has excellent fire resistance and smoke suppression properties, and the coating formed by using the fire retardant coating has a fire resistance limit of more than 96 minutes and a smoke density level of less than 25% under the condition of a thickness of 1.5 mm.

Owner:GUANGDONG NANOLUTION SCI & TECH CO LTD

A method for separating chlorine-containing plastics from waste mixed plastics

ActiveCN104589545BEfficient recyclingLow costPlastic recyclingFlotationOxidative treatmentOxidizing agent

The invention discloses a method of separating chlorine-containing plastics from waste mixed plastics. The method comprises the following steps: crushing at least one kind of chlorine-containing plastics and at least one kind of plastic without containing chlorine into mixed plastic particles, carrying out oxidation treatment on the mixed plastic particles by virtue of an oxidant, and carrying out flotation separation on the mixed plastic particles after oxidation treatment by virtue of a flotation agent to obtain the chlorine-containing plastics and the plastics without containing the chlorine, wherein the densities of the plastics are close. The method is capable of efficiently and selectively separating out the chlorine-containing plastics from waste plastics and meeting industrial application and production and is simple in operation and low in cost.

Owner:CENT SOUTH UNIV

Coal pyrolysis oil production device and method

ActiveCN106281399BMeet industrial applicationsGuaranteed uptimeGasification processes detailsLiquid hydrocarbon mixture productionHydrogenProcess engineering

Owner:SINOPEC NINGBO ENG +2

A kind of heat conduction plate material for electronic equipment and preparation method thereof

The invention relates to a heat conduction plate-shaped material for electronic equipment and a preparation method thereof. The method comprises the steps that graphene and povidone are mixed, N-methyl phenyl ethylamine is added into ethyl alcohol, then, silicon nitride is added, and then the preprocessed graphene is added to obtain a mixture; bi((3,4-epoxy cyclohexyl)methyl)adipate is added into ethylene glycol, 3-tridecafluorohexyl propylene and magnesium chips are added, and then aluminum oxide is added; stirring is performed to obtain fluorinated epoxide; the mixture is added into the fluorinated epoxide; stirring is performed, and then thiocyanate-1-(2-aminophenyl)ketone is added to obtain a precursor; rotary evaporation is performed on the precursor to remove a solvent, then, the precursor is placed into a mold for performing thermocuring for 0.5 h at the temperature of 120 DEG C, 1 h at the temperature of 150 DEG C and 1.5 h at the temperature of 180 DEG C to obtain the heat conduction plate-shaped material for the electronic equipment. The preparation method is wide in raw material source, the preparation process is simple and controllable, only conventional operation is needed, and industrialization is facilitated.

Owner:苏州宝达冷热设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com