A kind of heat conduction plate material for electronic equipment and preparation method thereof

A technology of electronic equipment and thermal conductive plate, which is applied in the field of thermal conductive plate-like materials for electronic equipment and its preparation, can solve the problems such as very high requirements for two-phase compatibility, complicated synthesis methods, and the inability of plate-like thermally conductive materials to meet the needs of industrialization. To achieve the effect of good curing effect, reasonable composition and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

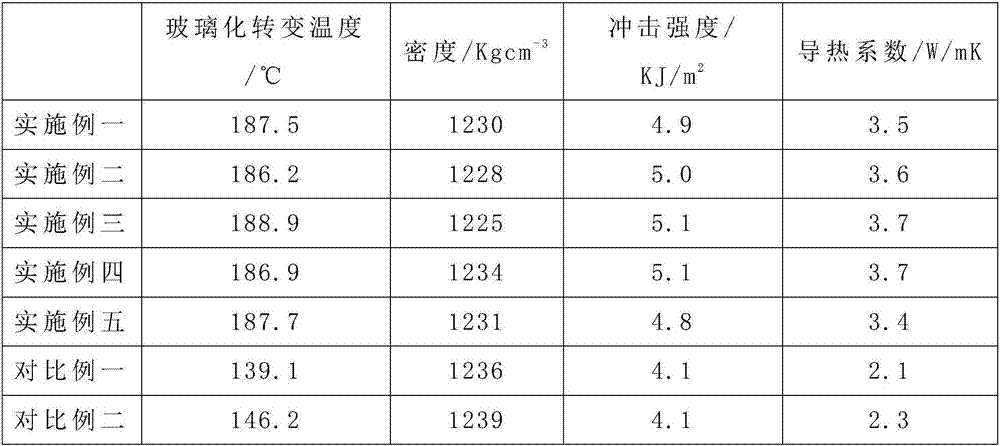

Examples

Embodiment 1

[0018] (1) Mix 18g of graphene and 1g of polyvinylpyrrolidone to obtain pretreated graphene; add 36g of N-methylphenethylamine to 50g of ethanol, stir and mix for 20 minutes, then add 12g of silicon nitride, mix for 1 hour, and then add The above-mentioned pretreated graphene was stirred at 50°C for 25 minutes to obtain a mixture;

[0019] (2) Add 100g of bis((3,4-epoxycyclohexyl)methyl)adipate to 150g of ethylene glycol, stir at 150°C for 15 minutes, then add 6g of 3-tridecafluorohexyl propylene, adjust the temperature At 90°C, add 0.1g of magnesium chips, stir at 90°C for 2 hours; then add 6g of alumina; stir to obtain fluorine-containing epoxy;

[0020] (3) Add 50 g of the mixture prepared in step (1) to 100 g of the fluorine-containing epoxy prepared in step (2); after stirring for 40 minutes, add 0.3 g of thiocyano-1-(2-aminophenyl)ethanone, Stir for 1 hour to obtain a precursor; the precursor is subjected to rotary evaporation to remove the solvent, then placed in a mold, an...

Embodiment 2

[0022] (1) Mix 18g of graphene and 1g of polyvinylpyrrolidone to obtain pretreated graphene; add 36g of N-methylphenethylamine to 50g of ethanol, stir and mix for 20 minutes, then add 12g of silicon nitride, mix for 1 hour, and then add The above-mentioned pretreated graphene was stirred at 50°C for 25 minutes to obtain a mixture;

[0023] (2) Add 100g of bis((3,4-epoxycyclohexyl)methyl)adipate to 150g of ethylene glycol, stir at 150°C for 15 minutes, then add 6g of 3-tridecafluorohexyl propylene, adjust the temperature At 90°C, add 0.1g of magnesium chips, stir at 90°C for 2 hours; then add 6g of alumina; stir to obtain fluorine-containing epoxy;

[0024] (3) Add 50 g of the mixture prepared in step (1) to 150 g of the fluorine-containing epoxy prepared in step (2); after stirring for 40 minutes, add 0.3 g of thiocyano-1-(2-aminophenyl)ethanone, Stir for 1 hour to obtain a precursor; the precursor is subjected to rotary evaporation to remove the solvent, then placed in a mold, an...

Embodiment 3

[0026] (1) Mix 18g of graphene and 1g of polyvinylpyrrolidone to obtain pretreated graphene; add 36g of N-methylphenethylamine to 50g of ethanol, stir and mix for 20 minutes, then add 12g of silicon nitride, mix for 1 hour, and then add The above-mentioned pretreated graphene was stirred at 50°C for 25 minutes to obtain a mixture;

[0027] (2) Add 100g of bis((3,4-epoxycyclohexyl)methyl)adipate to 150g of ethylene glycol, stir at 150°C for 15 minutes, then add 6g of 3-tridecafluorohexyl propylene, adjust the temperature At 90°C, add 0.1g of magnesium chips, stir at 90°C for 2 hours; then add 6g of alumina; stir to obtain fluorine-containing epoxy;

[0028] (3) Add 50 g of the mixture prepared in step (1) to 125 g of the fluorine-containing epoxy prepared in step (2); after stirring for 40 minutes, add 0.3 g of thiocyano-1-(2-aminophenyl)ethanone, Stir for 1 hour to obtain a precursor; the precursor is subjected to rotary evaporation to remove the solvent, then placed in a mold, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com