Water-based paint in-can preservative

A technology for in-tank preservatives and water-based coatings, used in antifouling/underwater coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc. , to achieve the effect of wide pH adaptation range, stable storage time and excellent inactivation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1, the preparation of preservative in water-based paint tank of the present invention

[0044] Weigh 200.0 g of the solid compound of formula I, add 400.0 g of absolute ethanol, and stir to dissolve at room temperature. After the dissolution is complete, add 400.0 g of deionized water and stir evenly to prepare a 20% transparent solution of preservative in a water-based paint tank, hereinafter referred to as CHT-1 preservative.

Embodiment 2

[0045] Embodiment 2, the preparation of preservative in water-based paint tank of the present invention

[0046] Weigh 200.0 g of the solid compound of formula I, 8.0 g of Cathone, add 400.0 g of absolute ethanol, and stir to dissolve at room temperature. After the dissolution is complete, add 400.0 g of deionized water and stir evenly to prepare a 20% transparent solution of preservative in a water-based paint tank, hereinafter referred to as CHT-2 preservative.

Embodiment 3

[0047] Embodiment 3, the preparation of water-based paint of the present invention interior wall latex paint

[0048] formula:

[0049]

[0050]

[0051] Remarks: The solid content of this formula is 50% Process flow: Add part of deionized water into the dispersion tank, add antifreeze, cellulose, dispersant, wetting agent, defoamer (half) while stirring at about 800r / min , evenly dispersed. Put in talcum powder, kaolin, light calcium carbonate, heavy calcium carbonate, titanium dioxide in turn, and disperse at a high speed of 1500r / min or more for 30min. Adjust the rotation speed to about 600r / min, add the remaining water and sequentially add emulsion, film-forming aid, pH regulator, defoamer (the remaining half), thickener, leveling agent, and disperse for 10-15min. Take the paint with the total amount of the above formula of 100g, when the system temperature drops below 55°C, add 0.25g of CHT-1 preservative at about 600r / min, and stir for 5-10min.

PUM

| Property | Measurement | Unit |

|---|---|---|

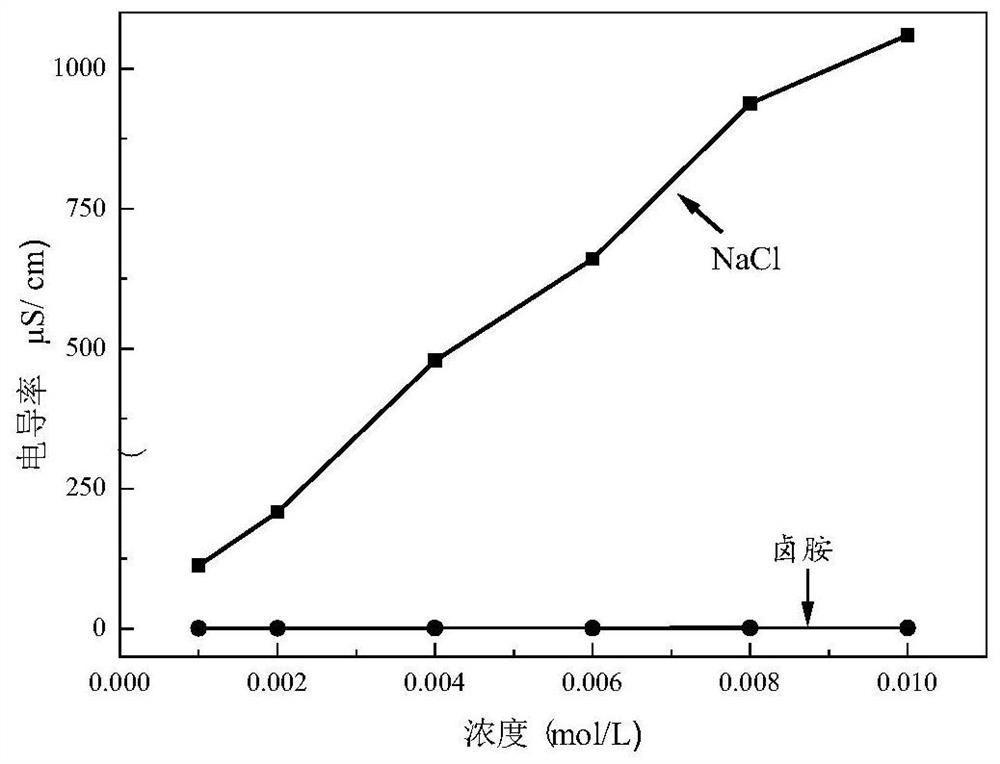

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com