Fireproof coating and preparation method thereof

A technology of fire-resistant coatings and raw materials, applied in fire-resistant coatings, coatings, etc., can solve problems such as a large amount of smoke, affecting personnel evacuation and escape, and low fire resistance limit, so as to reduce usage, prevent smoke from escaping, and achieve ultra-high ratio The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

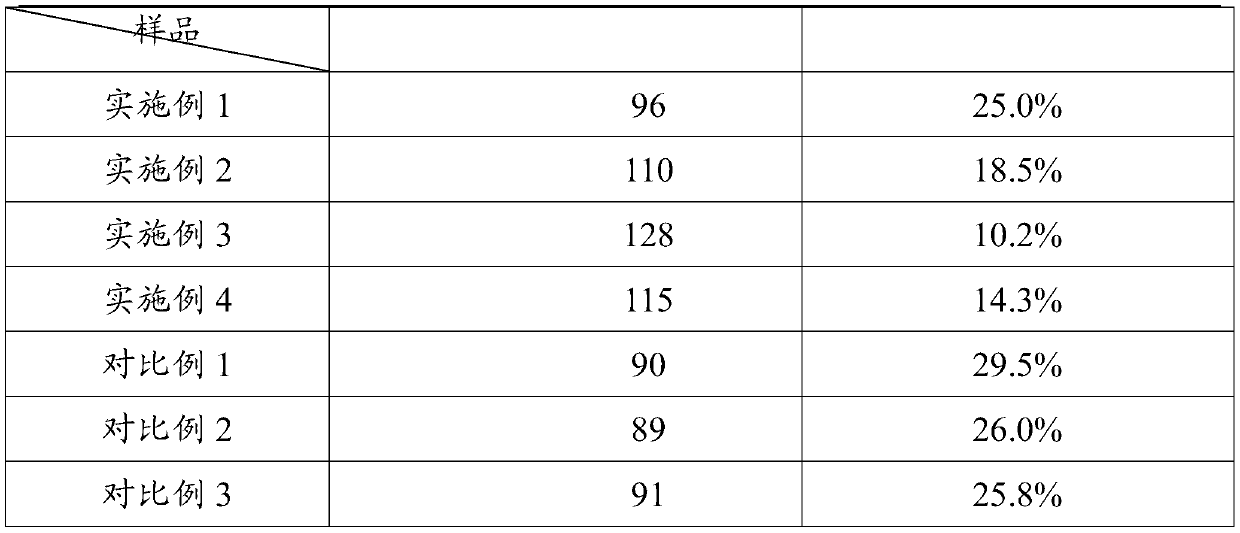

Embodiment 1

[0035] Step 1), preparation of modified white graphene: get 0.5 part of white graphene powder and join in the round bottom flask, and add 100 parts of distilled water in the round bottom flask, then ultrasonically disperse, add 0.1 part of ten Sodium dialkyl sulfate, ultrasonically stirred at high speed to obtain a lipophilic modified white graphene dispersion; after heating the lipophilic modified white graphene dispersion to 60°C, add 0.5 parts of initiator ammonium persulfate, and stir for 10 minutes Start to add 0.05 parts of methyl methacrylate dropwise, and drop it in 0.5h. After the dropwise addition, keep warm for 0.5h until the reaction is complete. After the reaction is completed, adjust the pH value to 7 with ammonia water, quickly cool to room temperature, filter under reduced pressure, wash the filter cake with distilled water for 3 to 4 times, then wash with alcohol once, and vacuum dry and grind at 60°C to obtain polymethyl methacrylate Coated modified white gr...

Embodiment 2

[0040] Step 1), preparation of modified white graphene: get 2 parts of white graphene powder and join in the round bottom flask, and add 100 parts of ethanol in the round bottom flask, then ultrasonically disperse, add 0.2 part of ten Sodium dialkylsulfate, ultrasonically stirred at high speed to obtain a lipophilic modified white graphene dispersion; after heating the lipophilic modified white graphene dispersion to 90°C, add 1 part of initiator ammonium persulfate, and stir for 15 minutes Start to add 0.5 parts of methyl acrylate dropwise, and finish dropping in 0.6h. After the dropwise addition, keep warm for 1 h until the reaction is complete. After the reaction is completed, adjust the pH value to 7 with ammonia water, quickly cool to room temperature, filter under reduced pressure, wash the filter cake with distilled water for 3 to 4 times, then wash with alcohol once, and vacuum dry and grind at 70°C to obtain polymethyl acrylate coating Modified white graphene.

[00...

Embodiment 3

[0045] Step 1), preparation of modified white graphene: get 5 parts of white graphene powder and join in the round bottom flask, and add 100 parts of glycerol in the round bottom flask, then ultrasonic dispersion, add 0.3 parts in the round bottom flask One part oleylamine, ultrasonically stirred at high speed to obtain a lipophilic modified white graphene dispersion; after heating the lipophilic modified white graphene dispersion to 90°C, add 2 parts of initiator azobisisobutyronitrile, and stir for 20min Afterwards, 1 part of glycidyl acrylate was added dropwise, and the drop was completed within 0.7 hours. After the dropwise addition, keep warm for 1.5 h until the reaction is complete. After the reaction is completed, adjust the pH value to 7 with ammonia water, quickly cool to room temperature, filter under reduced pressure, wash the filter cake with distilled water for 3 to 4 times, then wash with alcohol once, dry and grind in vacuum at 90°C to obtain polyglycidyl methac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com