High-voltage stable electrolyte for lithium-ion battery

A lithium-ion battery and electrolyte technology, which is applied to the high-voltage stable ion battery electrolyte and the electrolyte field that is stable under high pressure, can solve the problems of easy oxidative decomposition, battery performance decline, poor stability, etc., to meet the needs of industrial production. requirements, improve high voltage performance, improve performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

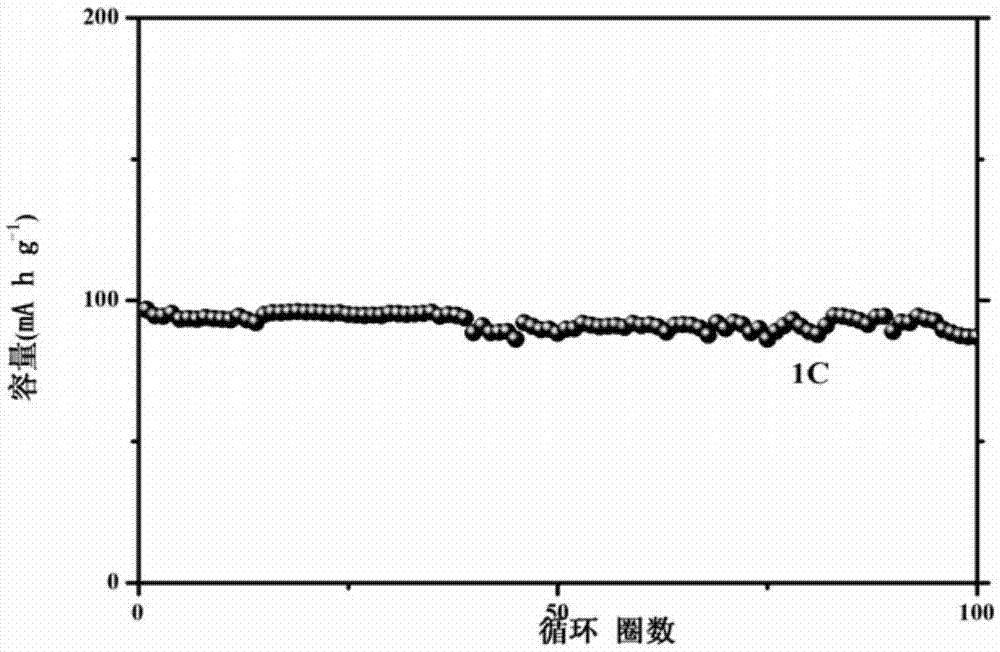

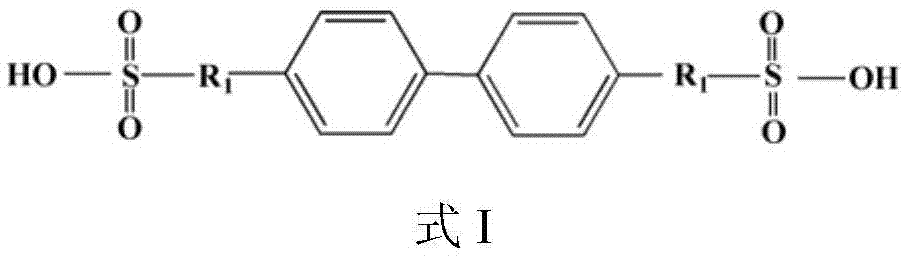

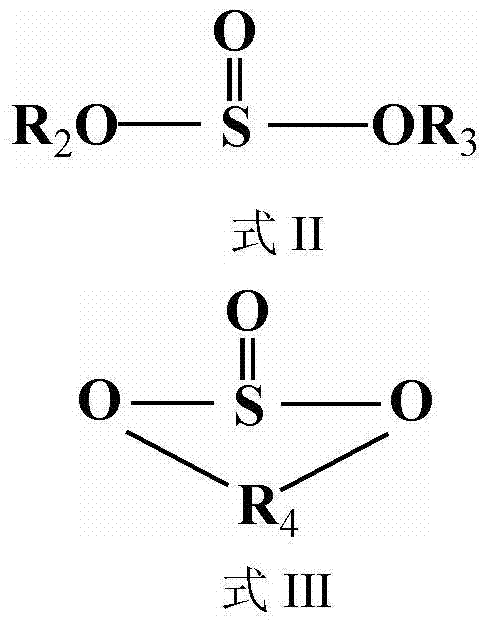

[0035] In a glove box filled with argon (moisture 6 , the concentration is 1.0mol / L to obtain a conventional electrolyte; then add (addition amount 0.5wt%) biphenyl-4,4'-dimethylsulfonic acid and (addition amount is 0.5 wt%) to the prepared conventional electrolyte solution wt%) dimethyl fluorosulfite to obtain a high-voltage electrolyte for lithium secondary batteries.

[0036]Preparation of lithium ion battery: place the obtained positive electrode sheet and negative electrode sheet in an oven to dry them at a certain temperature, and then move them into a glove box. Then put the processed positive electrode sheet, separator, and negative electrode sheet in order, pack it into a CR2025 button battery, and inject the above-mentioned prepared electrolyte.

Embodiment 2

[0038] In a glove box filled with argon (moisture 6 , the final concentration is 0.8mol / L, to obtain conventional electrolyte; then add (addition amount is 0.5wt%) biphenyl-4,4'-dihexylidene sulfonic acid and (addition amount is 0.5%) diethyl fluorosulfite to obtain a high-voltage electrolyte for lithium secondary batteries.

[0039] Preparation of lithium ion battery: place the obtained positive electrode sheet and negative electrode sheet in an oven to dry them at a certain temperature, and then move them into a glove box. Then put the processed positive electrode sheet, separator, and negative electrode sheet in order, pack it into a CR2025 button battery, and inject the above-mentioned prepared electrolyte.

Embodiment 3

[0041] In a glove box filled with argon (moisture 4 , the final concentration is 1.5mol / L, to obtain conventional electrolyte; then add (addition amount is 1.0wt%) biphenyl-4,4'-dimethylene butanesulfonic acid and ( The addition amount is 0.5wt%) fluoroethylene sulfite to obtain a high-voltage electrolyte solution for lithium secondary batteries.

[0042] Preparation of lithium ion battery: place the obtained positive electrode sheet and negative electrode sheet in an oven to dry them at a certain temperature, and then move them into a glove box. Then put the processed positive electrode sheet, separator, and negative electrode sheet in order, pack it into a CR2025 button battery, and inject the above-mentioned prepared electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com