Conductive ceramic composite diaphragm and solid-state battery

A technology of conductive ceramics and composite diaphragms, applied in the field of conductive ceramic composite diaphragms and solid-state batteries, can solve the problems of poor mechanical properties of composite electrolytes, high cost of inorganic solid electrolytes, and large interface resistance, so as to facilitate the diffusion of lithium ions and improve interface stability Sex and electrochemical working window, increasing the effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034]There is no special limitation on the preparation method of the nano inorganic solid electrolyte, as long as it can have the above particle size. For example, the submicron-sized inorganic electrolyte can be pulverized by planetary ball milling and / or high-energy ball milling to obtain a nano-sized inorganic solid-state electrolyte that meets the particle size requirements.

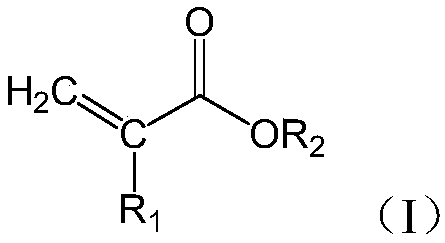

[0035] The polymer graft-modified ceramics may be ceramic particles graft-modified with acrylic acid polymers. Here, the acrylic polymer refers to a homopolymer or a copolymer formed by homopolymerization or copolymerization of acrylic monomers.

[0036] The glass transition temperature (Tg) of the acrylic polymer may range from 50°C to 200°C, preferably from 80°C to 180°C. For example, the acrylic polymer may be polymethyl methacrylate, or methyl methacrylate and methyl methacrylate selected from methacrylic acid, ethacrylic acid, ethyl acrylate, ethyl methacrylate, propyl methacrylate, methyl On...

Embodiment 1

[0087] Preparation of polymer graft modified ceramics:

[0088] Under a nitrogen atmosphere, add 6g of benzoyl peroxide into 400ml of tetrahydrofuran, stir until completely dissolved, then add 30g of methyl methacrylate and 300g of alumina particles (D50=1.0μm), reflux at 80°C for 5h, cool, After suction filtration and vacuum drying for 10 h, modified ceramic particles (D50=1.5 μm) were obtained.

[0089] Preparation of nano inorganic solid electrolyte:

[0090] Submicron LLZO was pulverized by planetary ball milling and high energy ball milling to obtain nano LLZO with a particle size D50 of 210nm.

[0091] Preparation of conductive ceramic composite separator:

[0092] The modified ceramics (150g) and nanometer LLZO (800g) prepared above are dispersed into the deionized water of 2Kg, then add 600g polyoxyethylene as organic polymer, 240g as the solid content of binding agent is 50wt% styrene-butadiene latex and 3 g of polyoxyethylene alkylamine as a wetting agent were mix...

Embodiment 2

[0097] Preparation of polymer graft modified ceramics:

[0098] Under nitrogen atmosphere, add 6g benzoyl peroxide in 400ml acetone, stir until fully dissolved, then add the mixture of 30g methyl methacrylate and ethacrylic acid (molar ratio 1:1) and 300g magnesium oxide particles ( D50=0.9 μm), reflux reaction at 80° C. for 6 hours, cooling, suction filtration, and vacuum drying for 8 hours to obtain modified ceramic particles (D50=1.3 μm).

[0099] Preparation of nano inorganic solid electrolyte:

[0100] Submicron LLZO is pulverized by planetary ball milling and high energy ball milling to obtain nano LLZO with a particle size D50 of 240nm.

[0101] Preparation of conductive ceramic composite separator:

[0102] The modified ceramics (150g) and nano LLZO (800g) prepared above were dispersed into 2Kg of deionized water, and then 600g of polyvinylidene fluoride as an organic polymer, 120g of polyvinyl alcohol as a binder, and 3g of polyvinyl alcohol as a binder were added. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com