Lithium-sulfur battery

A lithium-sulfur battery, lithium sulfide technology, applied in lithium batteries, battery electrodes, battery pack components, etc., can solve the problems of ether-based electrolyte decomposition and deterioration of electrochemical performance, high sulfur loading, and poor electronic conductivity of sulfur positive electrodes. , to suppress the shuttle effect, improve the electronic conductivity, and achieve the effect of high electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

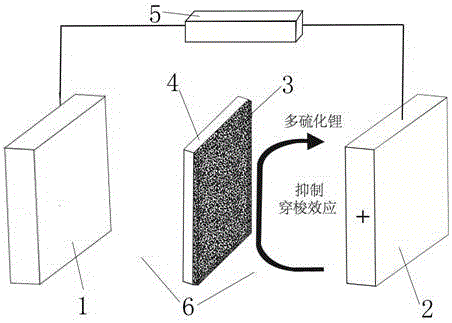

[0028] In this example, see figure 1 , a lithium-sulfur battery, comprising a positive electrode 2, a negative electrode 1, a separator 4 and an electrolyte 6, the positive electrode 2 uses a three-dimensional porous graphene loaded nano-lithium sulfide material to form a composite positive electrode, and the separator 4 is made of a polyolefin material, and is oxidized The diaphragm 4 covered by the graphene film 3 forms a modified composite diaphragm, the negative electrode 1 is made of a lithium sheet, and the electrolyte 6 uses 1mol / L bistrifluoromethanesulfonylimide lithium as the solute, and the volume ratio is 0.1:1:1 A mixed solution prepared by mixing 1-butyl-1-methylpyrrolidinium bis(trifluoromethanesulfonyl)imide salt, 1,3-dioxolane and ethylene glycol dimethyl ether as solvents.

[0029] In this example, see figure 1 , the lithium sulfide nanoparticles are combined with the oxygen-containing functional groups on the surface of three-dimensional porous graphene in ...

Embodiment 2

[0037] This embodiment is basically the same as Embodiment 1, especially in that:

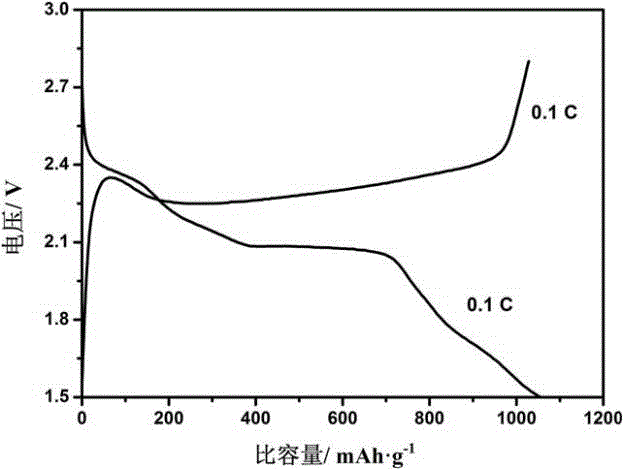

[0038] In this embodiment, only graphene oxide is coated on the surface of the separator 4 facing the positive electrode 2 when the battery is assembled to form a graphene oxide film 3 . The polysulfides formed due to the charging and discharging of the positive electrode of the lithium-sulfur battery will dissolve in the electrolyte, causing a shuttle effect, and this graphene oxide-modified separator, due to the abundant oxygen-containing functional groups on the surface of graphene oxide, can be effectively fixed and prevented. Lithium polysulfides shuttle from cathode to anode. At the same time, this layer of graphene oxide does not hinder the passage of lithium ions, and improves the electronic conductivity of the lithium sulfide positive electrode to a certain extent. Therefore, the modified diaphragm prepared in this example can suppress the shuttle effect of the battery, and effectivel...

Embodiment 3

[0041] This embodiment is basically the same as the previous embodiment, and the special features are:

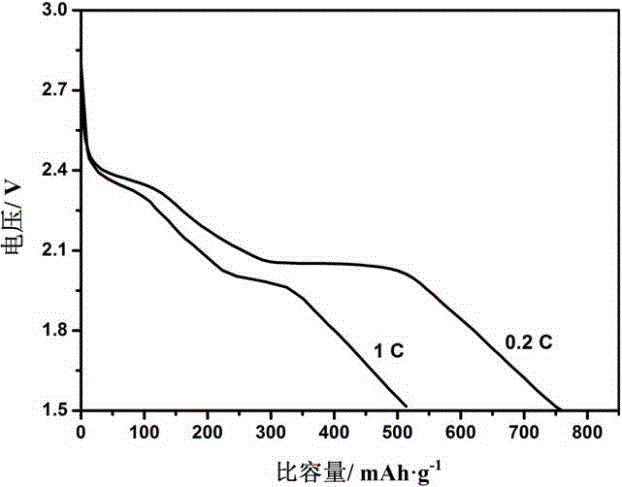

[0042] In this embodiment, a lithium-sulfur battery includes a positive electrode 2, a negative electrode 1, a diaphragm 4, and an electrolyte 6. The positive electrode 2 uses three-dimensional porous graphene to support nano-lithium sulfide materials to form a composite positive electrode, and the diaphragm 4 is made of polyolefin materials. and the diaphragm 4 coated with the graphene oxide film 3 forms a modified composite diaphragm, the negative electrode 1 is made of a lithium sheet, and the electrolyte 6 adopts 1 mol / L lithium bistrifluoromethanesulfonylimide as the solute, and the volume ratio It is prepared by mixing 1-butyl-1-methylpyrrolidinium bis(trifluoromethanesulfonyl)imide salt, 1,3-dioxolane and ethylene glycol dimethyl ether at a ratio of 1:1:1 into a mixed solution.

[0043] In this embodiment, lithium sulfide nanoparticles are combined with oxygen-conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com