Preparation method of rubber stripping graphene composite conductive rubber

A technology of exfoliating graphene and compound conduction, which is applied in the field of preparing high-performance conductive compound rubber, can solve the problems of difficulty in effectively improving the conduction efficiency of composite materials, inability to effectively reduce the cost of composite materials, and reducing the volume resistivity of compound conductive adhesives. Controllable process and process conditions, abundant raw materials, and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

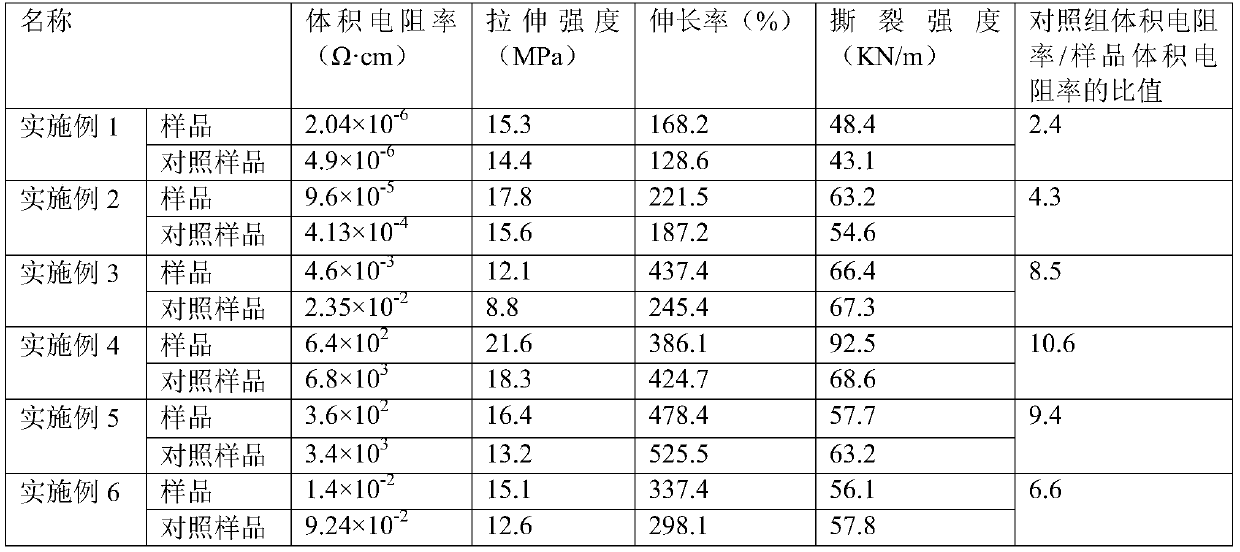

Embodiment 1

[0031] Step 1 Wetting of flake graphite

[0032] Weigh 20g of dibutyl phthalate into a 500ml beaker, pour 10g of isopropyl alcohol to dilute it, stir well, add 100g of flake graphite, stir evenly, cover with a watch glass, soak for 20h, stir twice during this period, and put it in a microwave oven 120s, transfer to an oven for drying at 105°C to obtain 110g of flake graphite with enhanced wetting of dibutyl phthalate;

[0033] Step 2 Preparation of Graphene Conductive Composite Filler

[0034] Put 100 g of styrene-butadiene rubber on the running counter-roll mill, roll the rubber to wrap the roll and form a stacking glue on the top of the counter-roll, and gradually strengthen the wetting of the flake graphite with dibutyl phthalate prepared in step 1. 110g was added to the stacking rubber and mixed for 10min. During the period, all the wet flake graphite that fell outside the rollers was returned to the stacking rubber on the opposite rollers to form the primary mixed rubber...

Embodiment 2

[0043] Step 1 Wetting of flake graphite

[0044] Weigh 10g of dioctyl phthalate into a 500ml beaker, pour 20g of anhydrous ethanol to dilute it, stir evenly, add 100g of flake graphite, stir evenly, cover with a watch glass, soak for 20h, stir 1-2 times during this period, put it aside Put it in a microwave oven, turn it on for 15s, and transfer it to an oven for drying at 105°C. After cooling, it is bagged for later use to obtain about 109 g of flake graphite reinforced with dioctyl phthalate;

[0045] Step 2 Preparation of Graphene Conductive Composite Fillers

[0046] Put 100g of neoprene rubber on the running counter-roll mill, roll the rubber to wrap the roll, and form a stacking glue on the upper part of the counter-roll, and gradually add 60g of the dioctyl phthalate prepared in step 1 to strengthen the wetting. The flake graphite is continuously mixed for 7 minutes. During this period, all the wetted flake graphite spilled out of the rollers should be returned to the ...

Embodiment 3

[0053] Step 1 Wetting of flake graphite

[0054] Weigh 2g of castor oil into a 500ml beaker, pour 28g of isopropanol to dilute, stir well, add 100g of flake graphite, stir well, cover with a watch glass, soak for 20h, stir 1-2 times during this period, put it in a microwave oven, and turn it on Intensified infiltration for 30s, transferred to an oven for drying at 105°C, cooled, and bagged for later use to obtain 100.6 g of flake graphite intensified and wetted by castor oil;

[0055] Step 2 Preparation of Graphene Conductive Composite Fillers

[0056] Put 100g of nitrile rubber on the running counter-roll mill, roll the rubber to wrap the roll, and form a stacking glue on the top of the counter-roll, and gradually add about 10g of the castor oil prepared in step 1 to strengthen the wetting of the flake graphite. Mixing for 5 minutes, during which all the wet flake graphite spilled out of the rollers should be returned to the accumulated rubber on the opposite rollers to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com