Patents

Literature

40results about How to "Good volume resistivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

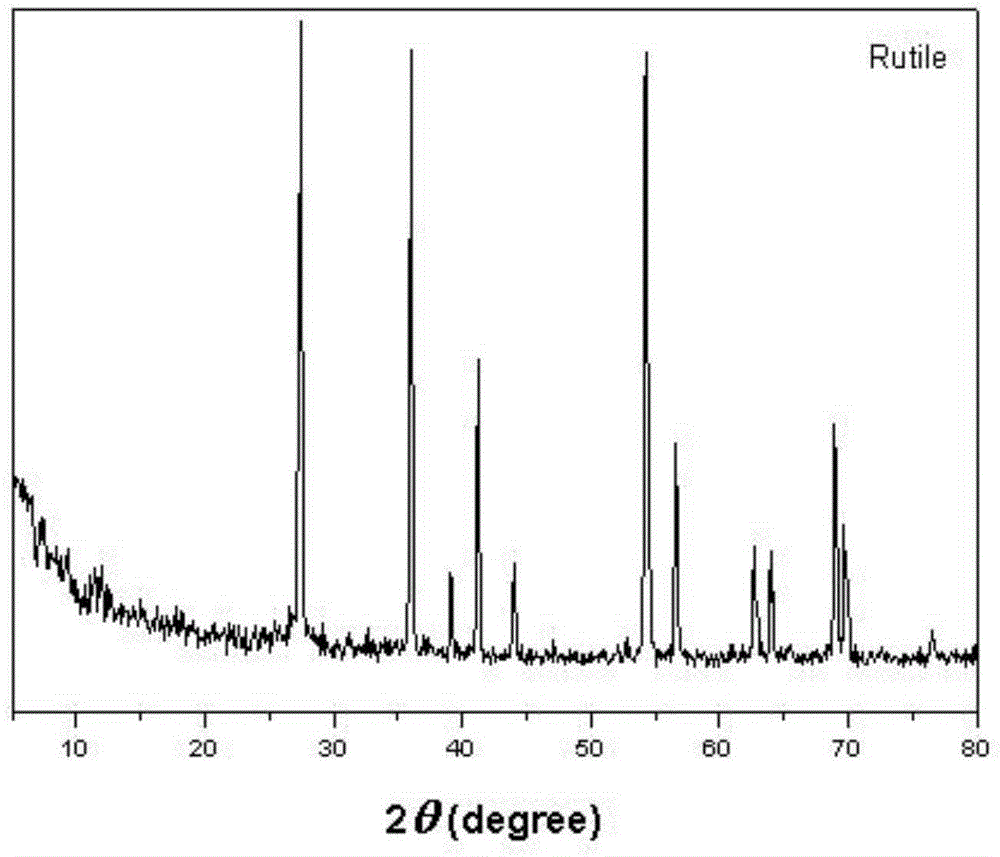

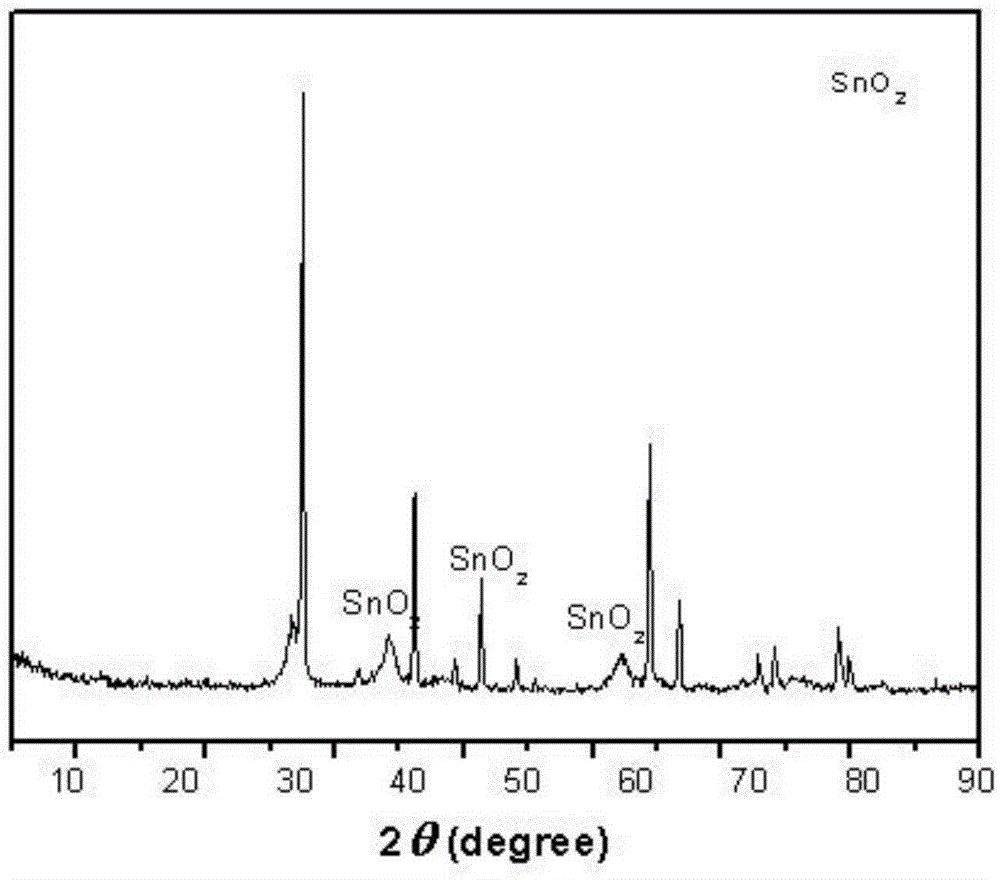

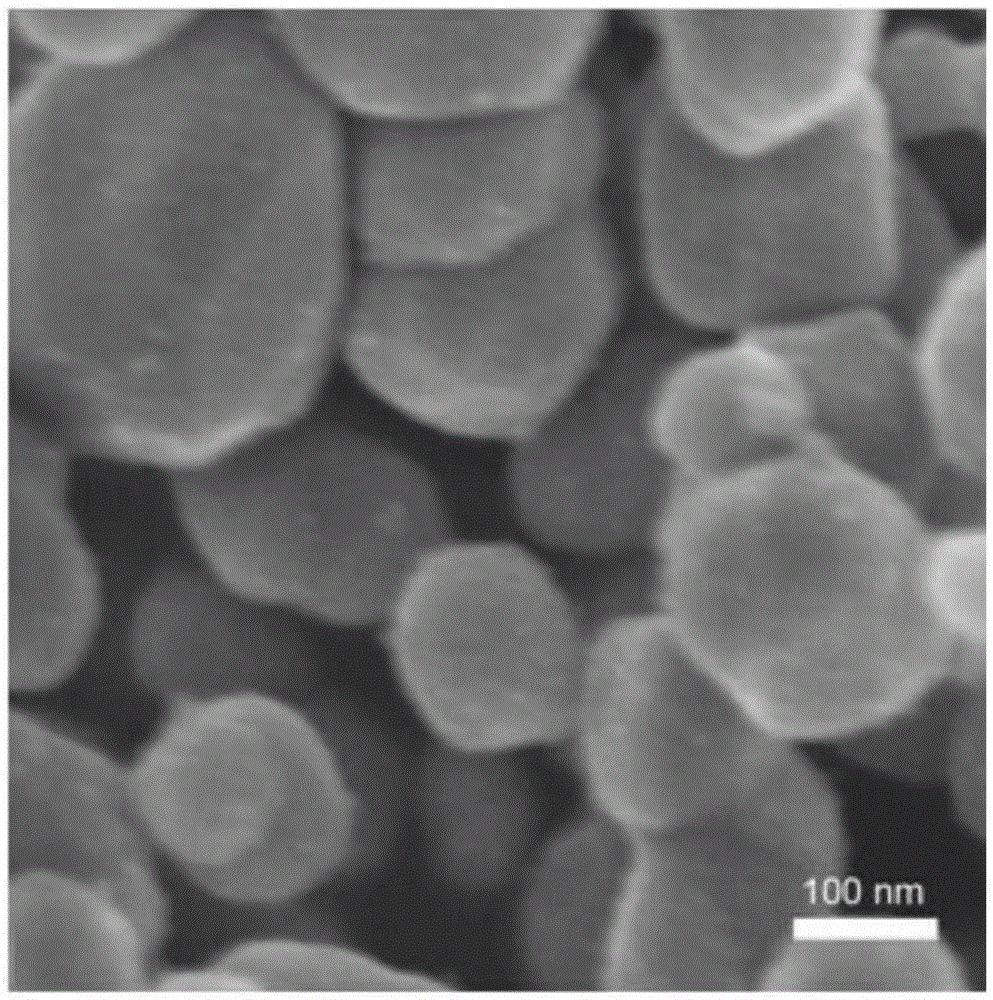

Preparation method of conductive titanium dioxide powder

ActiveCN105271389AThe synthesis process is simpleLow cost of preparationTitanium dioxideWeather resistanceTitanium dioxide

A preparation method of conductive titanium dioxide powder comprises the following preparation steps: 1), rutile type titanium dioxide is added to distilled water and beaten, slurry containing titanium dioxide with the mass concentration being 20%-30% is formed, titanium dioxide slurry is obtained after uniform stirring, then a zirconium salt solution is added dropwise to the titanium dioxide slurry, and a mixed solution A is obtained; 2), the mixed solution A is heated to 60-80 DEG C; 3), certain amount of a tin salt and antimony salt mixed acid solution prepared in advance is added to the mixed solution A, alkali liquor is added simultaneously to control the pH value to be 1-3, the adding time is 3-5 h, and a yellow suspension is obtained; 4), the conductive titanium dioxide powder is obtained from curing the suspension, washing, drying, grinding to 280-300 nm, and calcining. Conductive titanium dioxide prepared with the method has the performance of excellent conductivity, whiteness, hiding power, weather resistance, glossiness and the like when applied to the application fields of coatings, plastics, fibers and the like and is a novel material with broad application prospect.

Owner:中信钛业股份有限公司

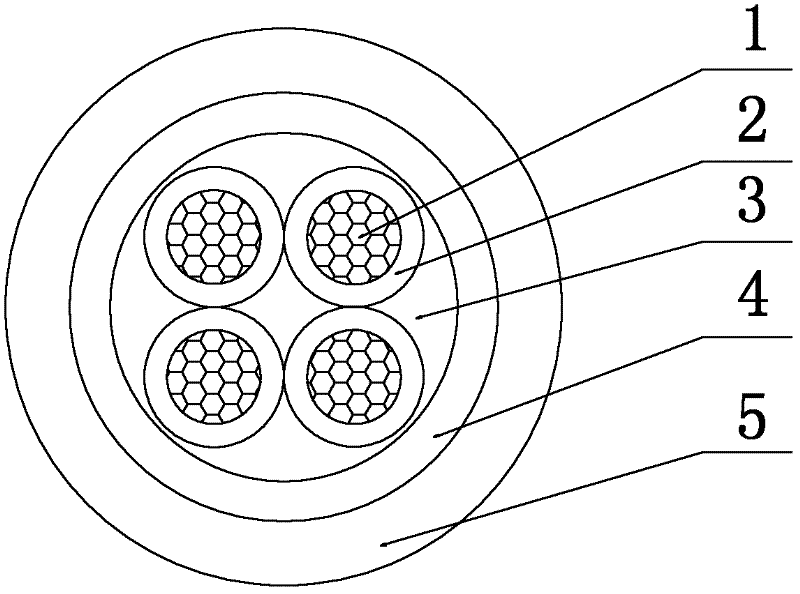

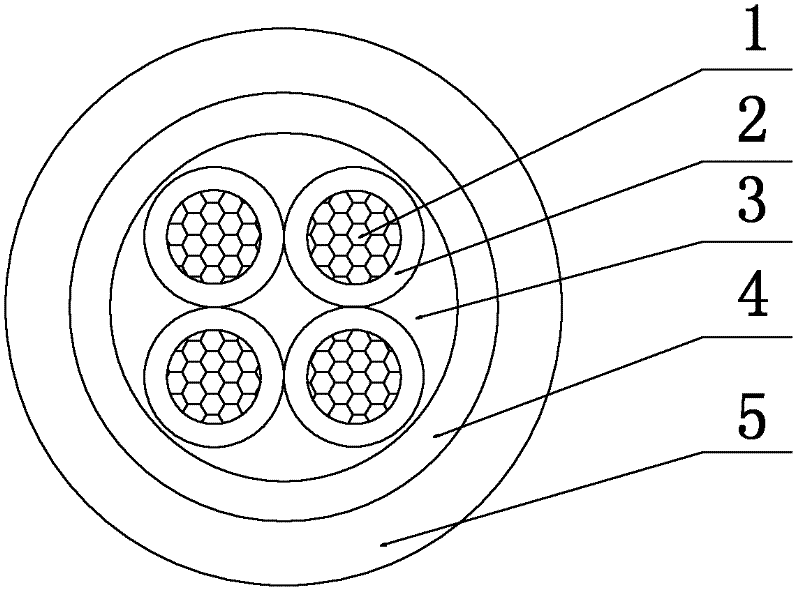

Silane halogen-free flame retardant cross-linking polyolefine cable and manufacturing method thereof

InactiveCN102509577AMeet performance requirementsGuaranteed temperature resistanceNon-insulated conductorsInsulated cablesCross-linkElectrical conductor

The invention relates to a silane halogen-free flame retardant cross-linking polyolefine cable. The cable is successively composed of a conductor, an insulating layer, a packing layer, a flame retardant oxygen barrier layer and an outer protective layer, and is characterized in that the insulating layer adopts a low-fume halogen-free flame retardant silane cross-linking polyolefine material, a halogen-free high flame retardant bag belt is wrapped outside a cable core so as to form the oxygen barrier layer, and the outer protective layer adopts a thermoplastic low-fume halogen-free flame retardant silane cross-linking polyolefine material; low-fume halogen-free flame retardant silane cross-linking polyolefine is prepared by a two-step method, namely adding a grafted silane copolymer into a catalysis master batch at the mass ratio of 95:5 and then extruding out by virtue of a common extruding machine with the phi of 90 / 25; and cross linkage is realized through any of the following methods: a, immerging in hot water at 90-90DEG C, and performing cross linkage for 2-4 hours; and b, exposing to low pressure steam humidity at 0.15bar, and performing cross linkage for 3-5 hours. The cable provided by the invention has the advantages of greatly improving the insulating property, and meeting the requirements of an environmentally-friendly cable.

Owner:南洋电缆集团有限公司

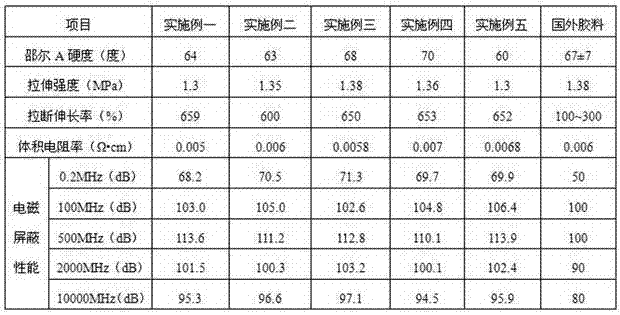

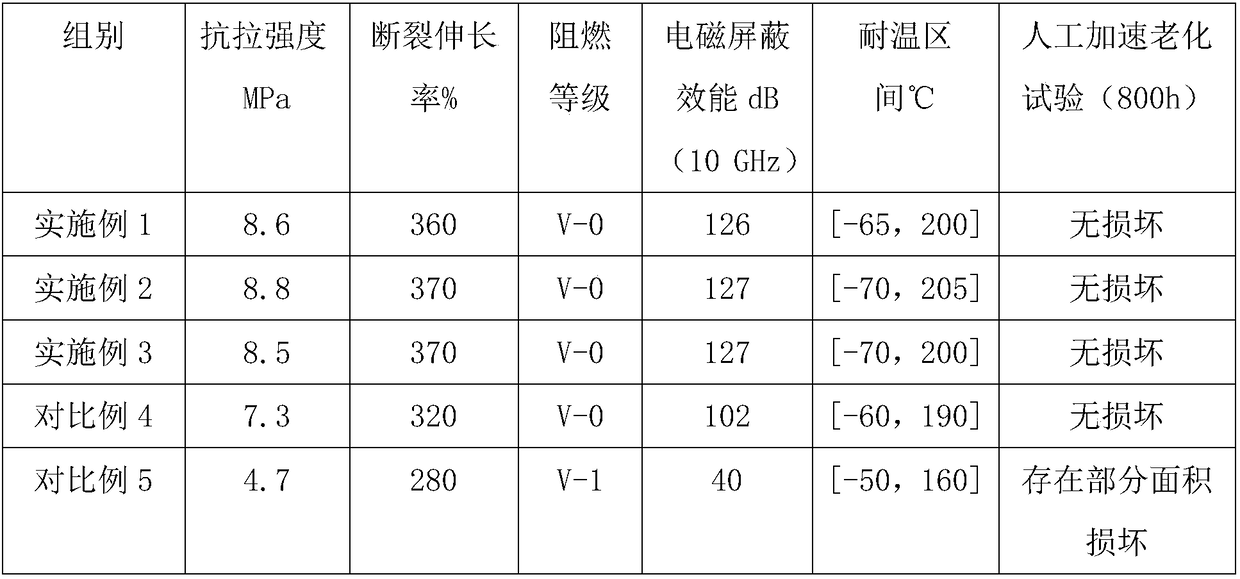

Electromagnetic shielding sealing product and manufacturing technology thereof

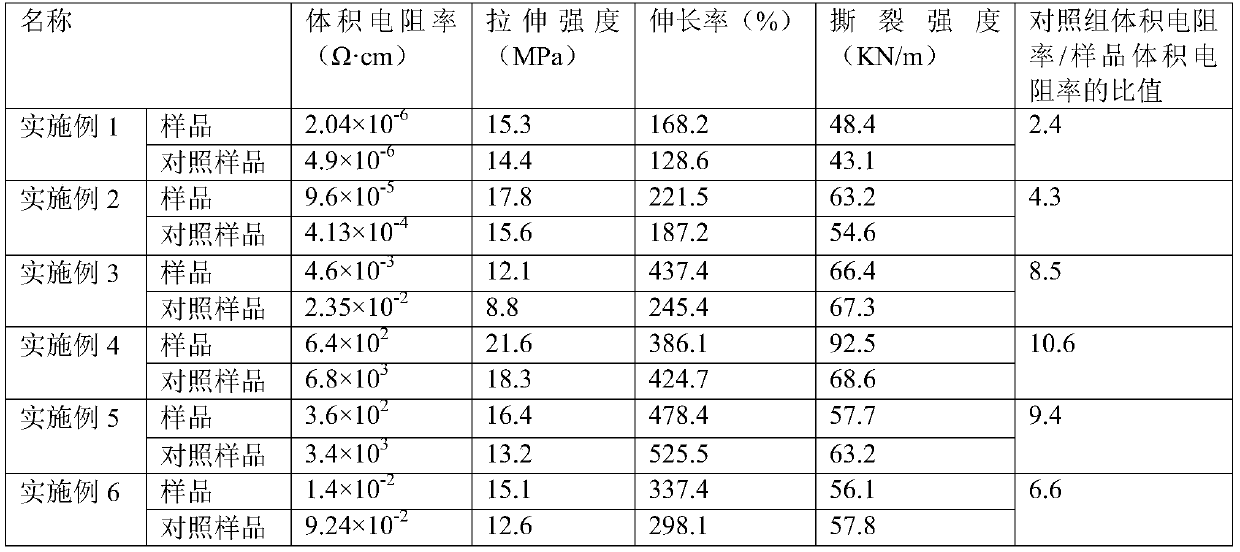

ActiveCN107057367AIt will not affectHigh elongation at breakDomestic articlesRubber materialManufacturing technology

The invention discloses an electromagnetic shielding sealing product and a manufacturing technology thereof and belongs to the technical field of an electromagnetic shielding material. The electromagnetic shielding sealing product comprises an aluminum alloy framework, wherein an electromagnetic shielding rubber material is arranged on the aluminum alloy framework and comprises the following components in parts by weight: 80-100 parts of methyl vinyl silicone rubber, 50-300 parts of silvering conducive filler, 2-8 parts of DCBP grease and 2-8 parts of a coupling agent; the components are mixed, refined and sheeted and then are compounded and vulcanized with the aluminum alloy framework, so as to acquire the electromagnetic shielding sealing product. The manufacturing technology disclosed by the invention is simple; low-temperature vulcanization is adopted, so that the aluminum alloy framework is not influenced; the shore A hardness of an electromagnetic shielding rubber material on the sealing product surface is not higher than 70 degrees, the volume resistivity is 0.005-0.01 omega.cm and the electromagnetic shielding property is excellent; the precedent of a high-conductive rubber material is started; the blanking of a high-conductive rubber material is filled; the requirements on electromagnetic shielding and sealing property of equipment are met.

Owner:青岛颐科密封材料有限公司

Synthetic method of castor oil based enclosed type waterborne polyurethane

The invention belongs to the technical field of chemical synthesis, and particularly relates to a synthetic method of castor oil based enclosed type waterborne polyurethane. The synthetic method comprises steps as follows: castor oil, polyethylene glycol and a hydrophilic chain extender are adopted to react with diisocyanate in a hydrophilic solvent, and a polyurethane prepolymer with a terminal NCO group is obtained; a sealing agent is adopted to be in an end capping reaction with the prepolymer, and an enclosed type polyurethane prepolymer is obtained; finally, after the enclosed type polyurethane prepolymer is in a neutralization reaction with a neutralizer, a product is dispersed in deionized water, and castor oil based enclosed type waterborne polyurethane is obtained. The adopted castor oil is an important renewable resource, and enclosed type waterborne polyurethane synthesized with the castor oil as a raw material has the characteristic of high self-crosslinking; a polyurethane coating prepared from the product has better heat resistance, volume resistivity, tensile strength and breaking elongation.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

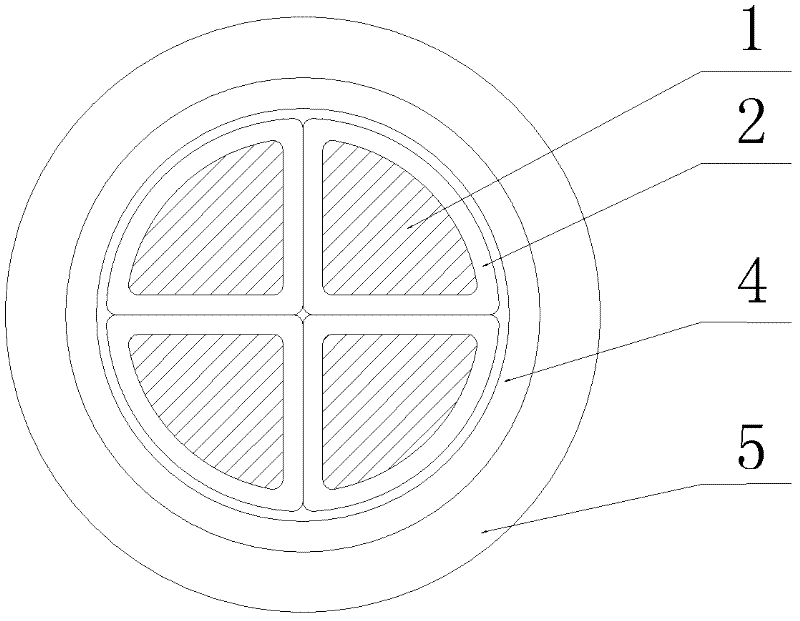

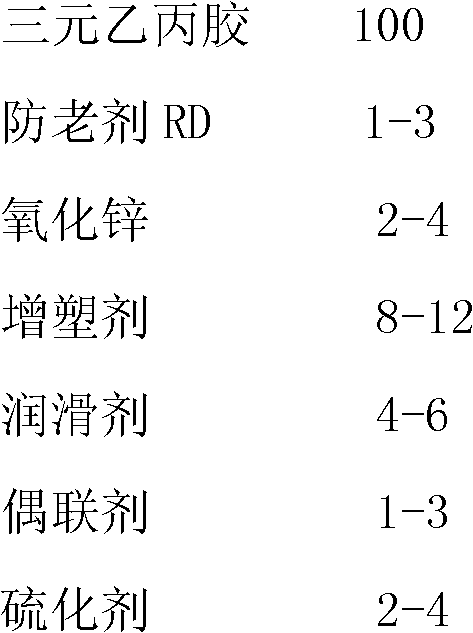

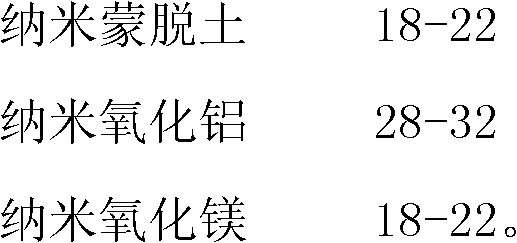

Modified ethylene propylene diene monomer

The invention provides a modified ethylene propylene diene monomer which is low in cost and excellent in performance. The modified ethylene propylene diene monomer is prepared from the following raw materials in part by weight: 100 parts of ethylene propylene diene monomer, 1 to 3 parts of age resister RD, 2 to 4 parts of zinc oxide, 8 to 12 parts of plasticizer, 4 to 6 parts of lubricating agent, 1 to 3 parts of coupling agent, 2 to 4 parts of vulcanizer, 18 to 22 parts of nano-montmorillonite, 28 to 32 parts of nano aluminum oxide, and 18 to 22 parts of nano magnesium oxide. The modified ethylene propylene diene monomer is excellent in flame retardant property, and high in tensile strength and high-temperature resistance, and can be widely applied to the field of mine cables.

Owner:中特华星电缆股份有限公司

Stretchable Interconnects for Flexible Electronic Surfaces

ActiveUS20170200527A1Large formatGood volume resistivityTransportation and packagingNon-conductive material with dispersed conductive materialConductive pastePolyester

A conductive paste and method of manufacturing thereof. The conductive paste comprises conductive particles dispersed in an organic medium, the organic medium comprising: (a) a solvent; and (b) a binder comprising a polyester. The conductive paste typically comprises silver and may contain various other additives. A stretchable conductive layer can be formed by curing the conductive paste.

Owner:FRY S METALS INC

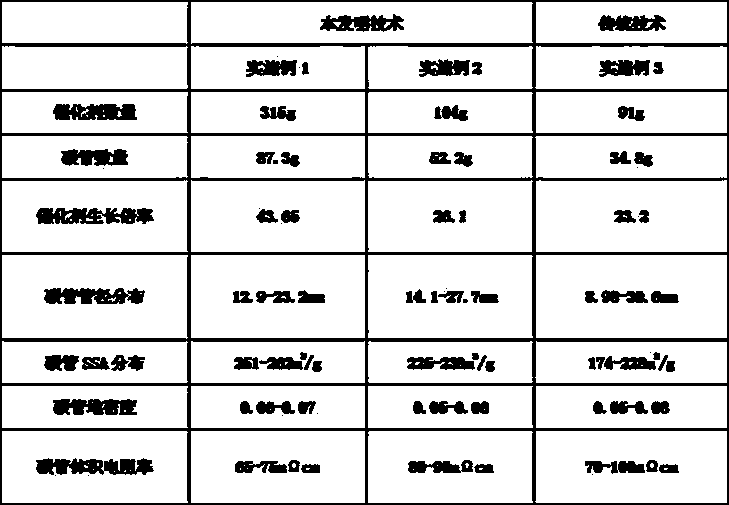

Method for continuously preparing multi-metal oxide pore structure catalyst for carbon nanotube

InactiveCN108079999AUniform areaImprove yield rateMaterial nanotechnologyCatalyst activation/preparationCarbon nanotubeSolvent

The invention relates to the technical field of synthesis of multi-metal oxide catalysts for carbon nanotubes, in particular to a method for continuously a preparing multi-metal oxide pore structure catalyst for a carbon nanotube. The method comprises the following steps: preparing a solution from different raw materials, and preparing the multi-metal oxide pore structure catalyst for a carbon nanotube by using a micro channel reactor, namely continuously pumping an active metal salt solution and an alkali solution of an inert metal salt into the micro channel reactor, under certain conditions, performing a precipitation reaction in the micro channel reactor to prepare a precursor, filtering a reactant, washing, drying, roasting, and screening, thereby obtaining a multi-metal oxide pore catalyst. Compared with a conventional process, the method has the advantages that the stability and the consistence of catalyst production are greatly improved, and the yield is increased; in the reaction process, the amount of a solvent is greatly reduced, and the environment is well protected; and nanotubes catalyzed by using the catalyst are concentrated in tube diameter distribution and good inindex parallelism, and the market competitiveness of products is improved.

Owner:SHANDONG DAZHAN NANO MATERIALS

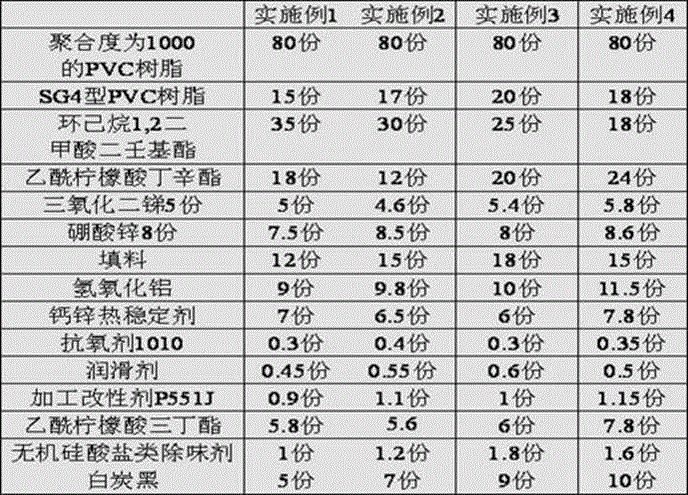

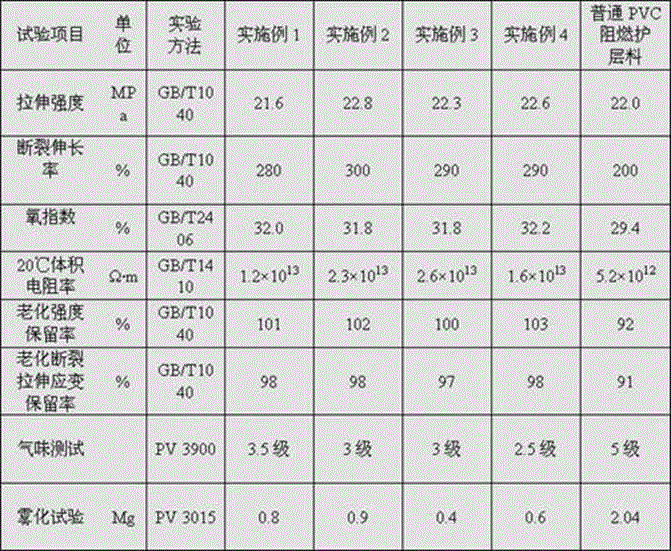

Low-volatile environment-friendly polyvinyl chloride (PVC) cable material and manufacturing process thereof

InactiveCN104403232ANo pollution in the processGood volume resistivityPlastic/resin/waxes insulatorsPolyesterZinc borate

The invention provides a low-volatile environment-friendly polyvinyl chloride (PVC) cable material and a preparation method thereof. The PVC cable material includes the following components in part by weight: 80 parts of PVC resin with a polymerization degree of 1,000, 15 to 20 parts of SG4 PVC resin, 10 to 40 parts of di-isononyl-cyclohexane-1,2-dicarboxylate, 20 to 35 parts of polyester plasticizer GX-68, 4 to 6 parts of antimonous oxide, 7 to 9 parts of zinc borate, 10 to 20 parts of fillers, 8 to 12 parts of aluminum hydroxide, 5 to 8 parts of a calcium-zinc heat stabilizer, 0.2 to 0.4 part of antioxidant 1010, 0.4 to 0.6 part of a lubricant, 0.8 to 1.2 parts of processing modifier ACR (acrylic resin), 5 to 8 parts of polyester plasticizer TX-50, 1 to 2 parts of modified silicon dioxide, and 0.2 to 0.5 part of sulfur. The PVC cable material provided by the invention has the low-volatile and low-odor effects under a high-temperature environment, the fogging value reaches 0.44 milligram, high volatility resistance and low product odor are achieved, and both the volume resistivity and aging strength retention of the cable material are improved.

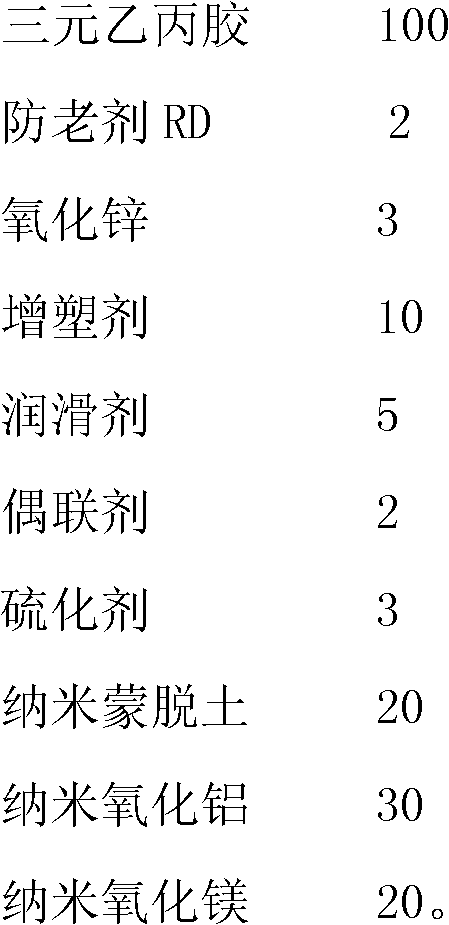

Modified ethylene-propylene diene copolymer cable material and preparation method thereof

InactiveCN102911438AHigh oxygen indexHigh mechanical strengthInsulated cablesInsulated conductorsPolymer scienceMeth-

The invention discloses a modified ethylene-propylene diene copolymer cable material and a preparation method thereof. The cable material is composed of a mixture A and a mixture B, wherein the mixture A comprises, by weight, 90-110 parts of ethylene-propylene diene copolymer, 1-3 parts of antiager RD, 2-4 parts of zinc oxide, 8-12 parts of dioctyl phthalate, 4-6 parts of ethylenebisoctadecanamide, 1-3 parts of 3-aminopropyltrimethoxysilane, 2-4 parts of triallyI isocyanurate, 18-22 parts of nano-montmorillonite, 28-32 parts of nano-aluminum oxide and 18-22 parts of nano-magnesium oxide; the mixture B comprises, by weight, 50-70 parts of maleic anhydride grafted ethylene-ethyl acetate copolymer, 20-30 parts of methyl vinyl silicon rubber, 20-30 parts of modified nano-powder, 0.3-05 part of poly(4-methyl-1-pentene), 5-10 parts of polycaprolactone, 1-3 parts of N, N'-m-phenylenedimaleimide, 1.5-2.5 parts of vinyl-tri-(beta-methoxyethoxy)- silicane, 2-3 parts of sodium dibutylnaphthalenesulfonate, 1-3 parts of acrylic emulsion and 10-15 parts of zinc borate. Compared with the conventional ethylene-propylene diene copolymer cable material, the modified ethylene-propylene diene copolymer cable material has the advantages of high oxygen index, high mechanical strength, excellent elongation at break and high volume resistivity.

Owner:TONGLING CITY TONGDOU SPECIAL CABLE CO LTD

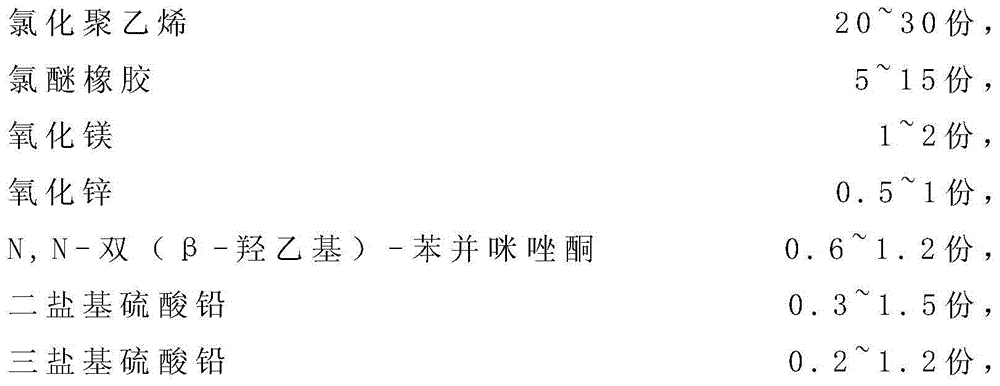

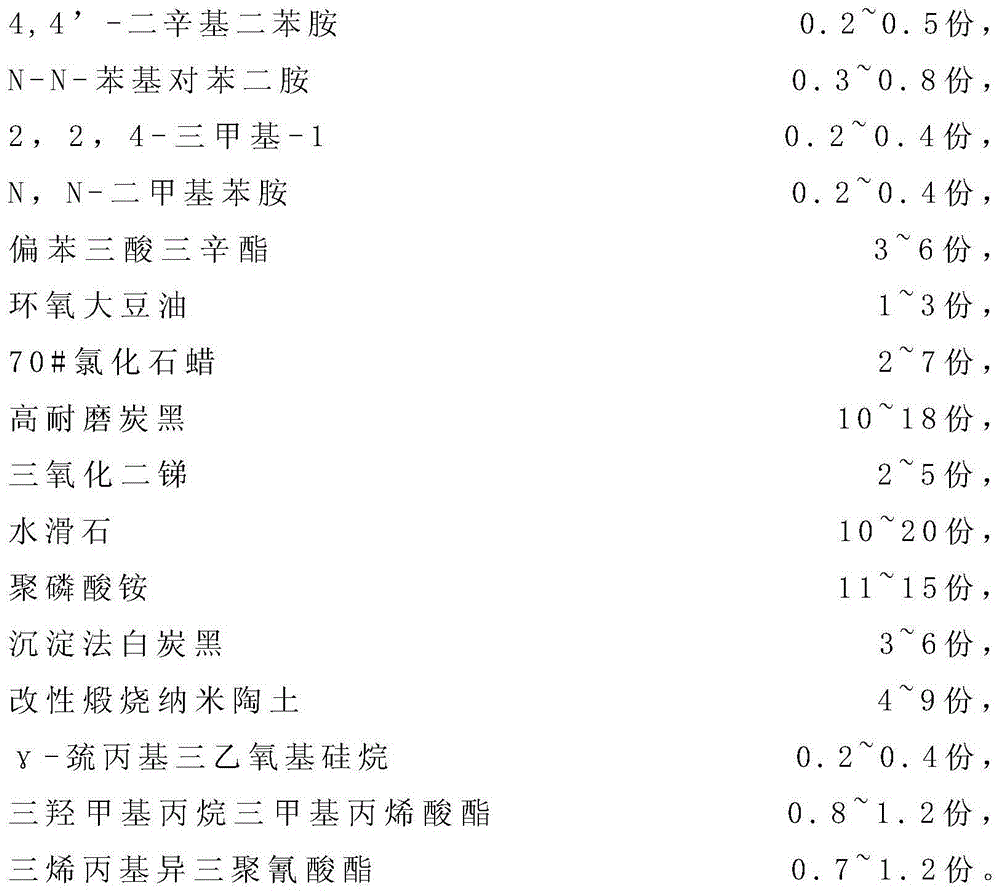

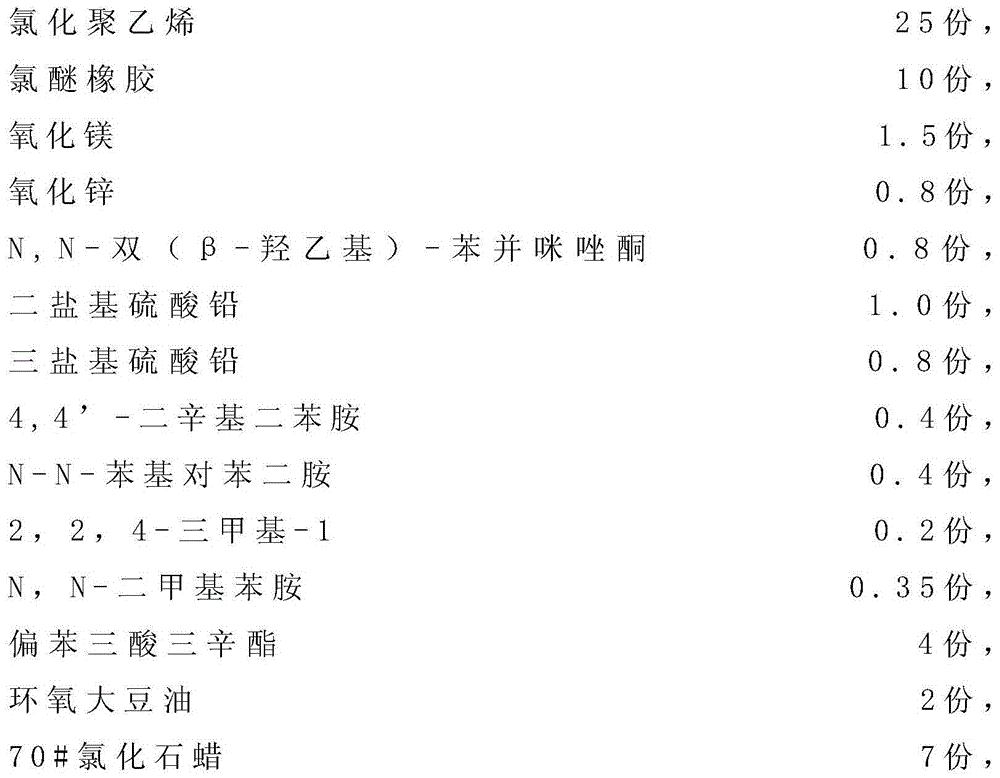

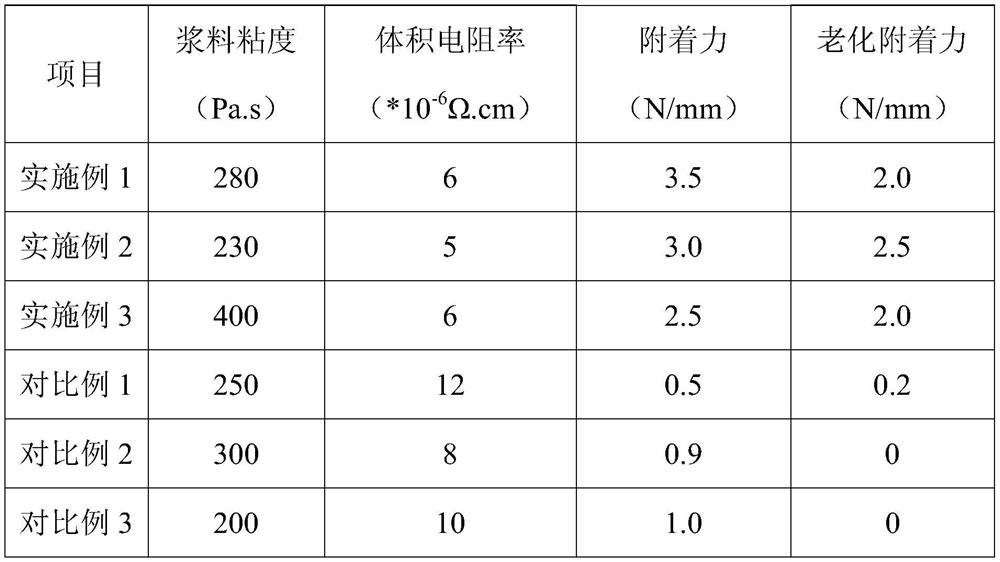

Components of anti-tensile insulated cable sheath and preparation process thereof

InactiveCN104910534AHigh tensile strengthHigh elongation at breakPlastic/resin/waxes insulatorsInsulated cablesPolymer scienceDimethylaniline N-oxide

The invention discloses components of an anti-tensile insulated cable sheath. The components comprise chlorinated polyethylene, epichloro-hydrin rubber, magnesium oxide, zinc oxide, N,N-bis(beta-hydroxyethyl)-benzimidazolone, dibasic lead sulphate, tribasic lead sulphate, 4,4'-dioctyldiphenylamine, N-N-phenyl p-phenylenediamine, 2,2,4-trimethyl-1, N-N-dimethylaniline, trioctyl trimellitate, epoxidized soybean oil, 70# chlorinated paraffin, high abrasion furnace carbon black, antimonous oxide, gamma-mercaptopropyltriethoxysilane, trimethylol propane trimethacrylate, triallyl tricarbimide ester, triallyl cyanurate and the like. The invention further discloses a preparation process for preparing a cable sheath by virtue of the formula. The cable sheath prepared by the components and the preparation process provided by the invention has a tensile strength of greater than 12Mpa and an elongation at break of greater than 350%, the ageing performance and the wear resistance of the sheath are improved, a good weather resistance is achieved, and the volume resistivity of the material is also improved.

Owner:WUXI INST OF ARTS & TECH

High-welding-tension main grid low-temperature silver paste for solar heterojunction battery and preparation method of high-welding-tension main grid low-temperature silver paste

ActiveCN112562885AImprove welding reliabilityImprove welding tensionNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilver pasteOrganic solvent

The invention provides high-welding-tension main grid low-temperature silver paste for a solar heterojunction battery and a preparation method of the high-welding-tension main grid low-temperature silver paste, which aim to overcome the related technical defects that the main grid silver paste in the field is relatively low in welding tension, relatively poor in weldability, relatively high in volume resistivity or relatively poor in printability after being cured, and almost zero in aging tension under certain conditions at present. The silver paste comprises low-melting-point flake silver powder, high-sintering-activity spherical silver powder, low-melting-point alloy powder, an organic bonding phase, an inorganic bonding phase, an organic solvent and a leveling agent, and is prepared through premixing, temperature control, stirring and grinding, so that the low-temperature silver paste which is high in basic welding tension, good in aging tension, high in weldability after being cured and is especially suitable for preparing the main gate electrode of the heterojunction battery is obtained, and the welding reliability of the heterojunction battery assembly is greatly improved.

Owner:四川东树新材料有限公司

Process for producing metal-containing particles having their surface coated with at least two dispersants different in vaporization temperature

ActiveUS7390440B2Improve dispersion stabilityGood volume resistivityConductive layers on insulating-supportsConductive materialDispersion stabilityVaporization

To provide metal-containing fine particles having good dispersion stability, which have their surface coated with dispersants vaporizable even during firing at low temperatures, a fine particle dispersion having the above metal-containing fine particles dispersed therein, and an electroconductive metal-containing material having an excellent volume resistivity formed by using the fine particle dispersion. Metal-containing fine particles with their surface coated with at least two dispersants having different vaporization temperatures.

Owner:AGC INC

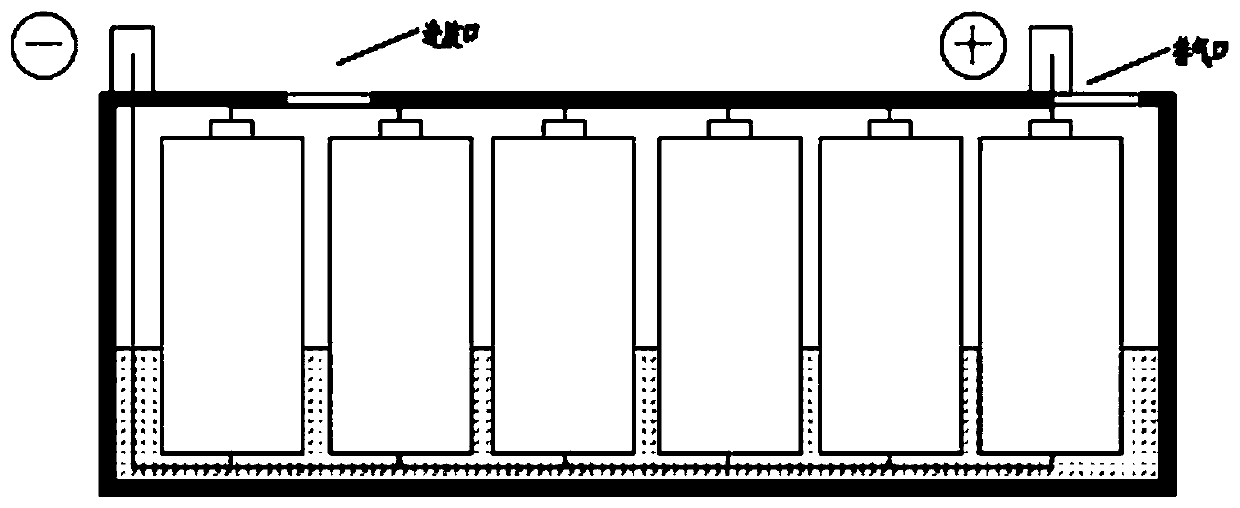

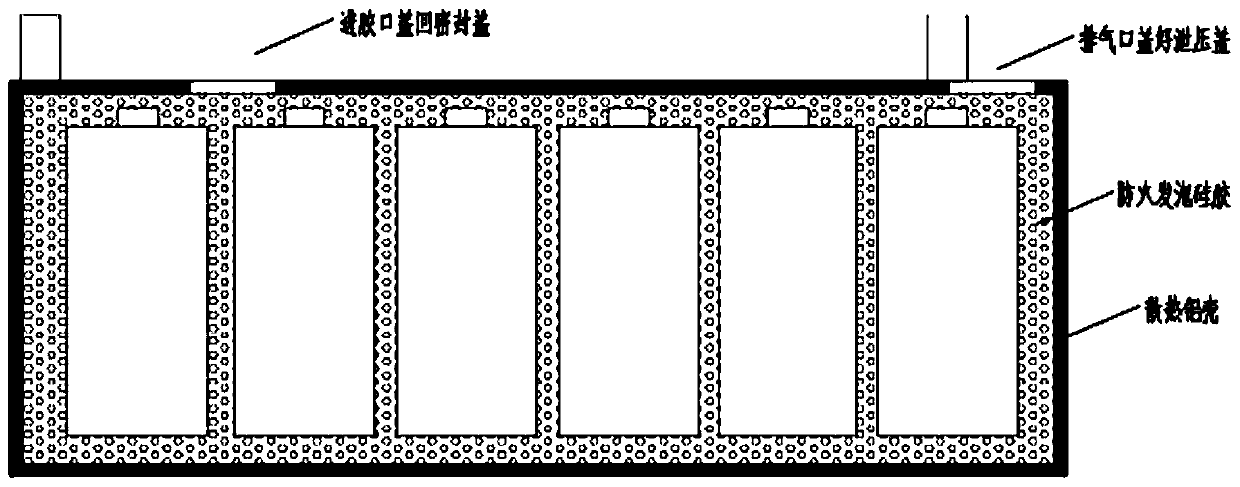

Filling foaming potting silicon rubber for new energy power battery, preparation method and application

The invention discloses a filling foaming potting silicon rubber for a new energy power battery. The silicon rubber is prepared from the following raw materials in percent by mass: 25%-35% of vinyl silicone oil; 5%-15% of alpha,omega-dihydroxylpolydimethylsiloxane; 12.5%-15% of a crosslinking agent; 5%-7.5% of aluminum hydroxide; 20%-30% of a flame-retardant powder; 10%-15% of antimony hydroxide;0.5%-0.7% of a treatment agent; 0.1%-0.18% of a delay agent; 0.2%-0.6% of a catalyst; 0.1%-0.18% of ethynyl cyclohexanol; and 0.1%-0.15% of a dyeing filler. The above-mentioned material is subjected to rubber potting into a paper battery pack, and thereby the entire space in the battery pack can be well filled. At the same time, the obtained filling foaming potting silicon rubber for a new energypower battery has excellent performance.

Owner:东莞市跨越电子有限公司

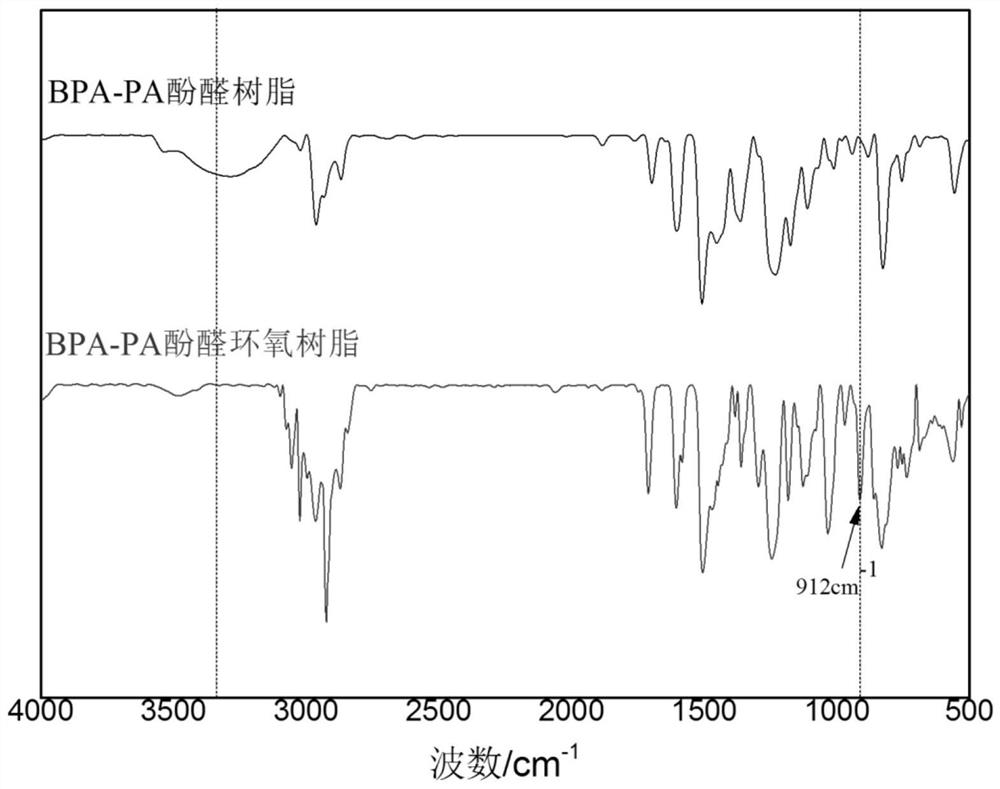

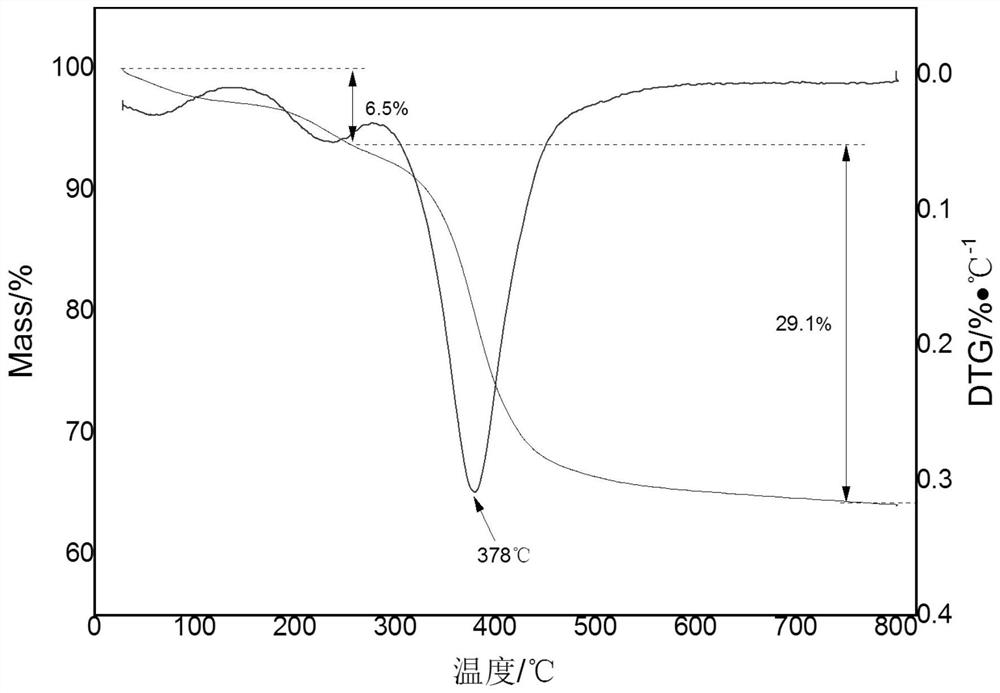

Bisphenol A paraformaldehyde novolac epoxy resin conductive adhesive and preparation method thereof

ActiveCN113185932ALower volume resistivityGood volume resistivityEpoxynovolac adhesivesElectrically-conducting adhesivesPolymer scienceMethylhexahydrophthalic acid

The invention relates to a bisphenol A paraformaldehyde novolac epoxy resin conductive adhesive and a preparation method thereof. The method comprises the following steps: step 1, uniformly mixing 20-25 parts by mass of bisphenol A paraformaldehyde novolac epoxy resin, 2-3 parts by mass of 1, 4-butanediol diglycidyl ether, methylhexahydrophthalic anhydride and a curing accelerator to obtain a mixed system; and step 2, adding a dispersing agent and a conductive filler treated by KH560 into the mixed system, then uniform mixing is conducted, wherein the mass ratio of the dispersing agent to the conductive filler treated by KH560 to the 1,4-butanediol diglycidyl ether in the mixed system is (4-5):(50-60):(2-3), and the bisphenol A paraformaldehyde novolac epoxy resin conductive adhesive is obtained. The bisphenol A paraformaldehyde novolac epoxy resin has excellent heat resistance and curing shrinkage rate, the volume resistivity of the conductive adhesive can be reduced, and the conductive adhesive with high thermal stability and excellent conductivity can be obtained.

Owner:SHAANXI UNIV OF SCI & TECH

Thermoplastic resin-based conductive composite material and preparation method thereof

The invention relates to the technical field of engineering plastics, and provides a thermoplastic resin-based conductive composite material and a preparation method thereof. The thermoplastic resin-based conductive composite material comprises the following components in parts by weight: 98.6-67 parts of thermoplastic resin; 1-15 parts of a carbon nanotube; 0-6 parts of a compatilizer; 0-5 parts of a nucleating agent; 0.2 to 1 part of an antioxidant; 0-2 parts of a coupling agent; and 0.2-4 parts of other additives; the content of the compatilizer, the content of the nucleating agent and the content of the coupling agent are all not zero. The thermoplastic resin-based conductive composite material provided by the invention is excellent in mechanical property and processability, and has the advantage of low volume resistivity.

Owner:SHENZHEN XIWAN TECH CO LTD

Cable polymer material with good flame retardation performance, and preparation method thereof

InactiveCN108517070AWide variety of sourcesImprove flame retardant performancePlastic/resin/waxes insulatorsEpoxyLinear low-density polyethylene

The invention discloses a cable polymer material with a good flame retardation performance, and a preparation method thereof. The polymer material comprises, by weight, 19-28 parts of light calcium carbonate, 6-12 parts of a coupling agent, 115-148 parts of linear low density polyethylene, 0.8-1.7 parts of calcium stearate, 66-84 parts of methyl vinyl phenyl silicone rubber, 38-46 parts of epoxy resin, 12-19 parts of vegetable starch, 10-16 parts of a styrene-acrylic emulsion, 4-6 parts of glass fibers and 5-8 parts of phillygenin. Above raw materials have wide sources, different raw materialsare processed by different preparation processes, and obtained different products are synergistically reacted, so the prepared finished product has the good flame retardation performance, also has good tensile strength, good elongation at break, and good volume resistivity at 20 DEG C, and can meet the use demands of cable protection.

Owner:肇庆益晟商贸有限公司

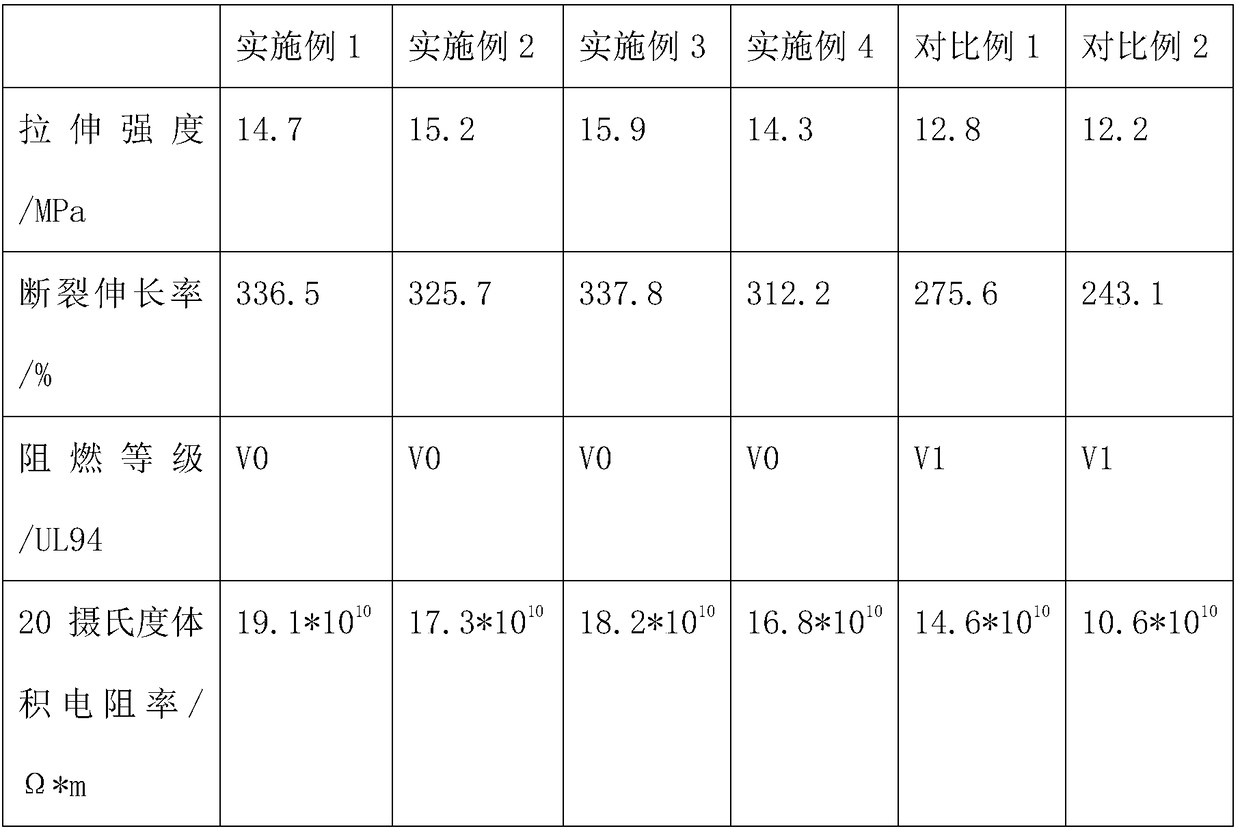

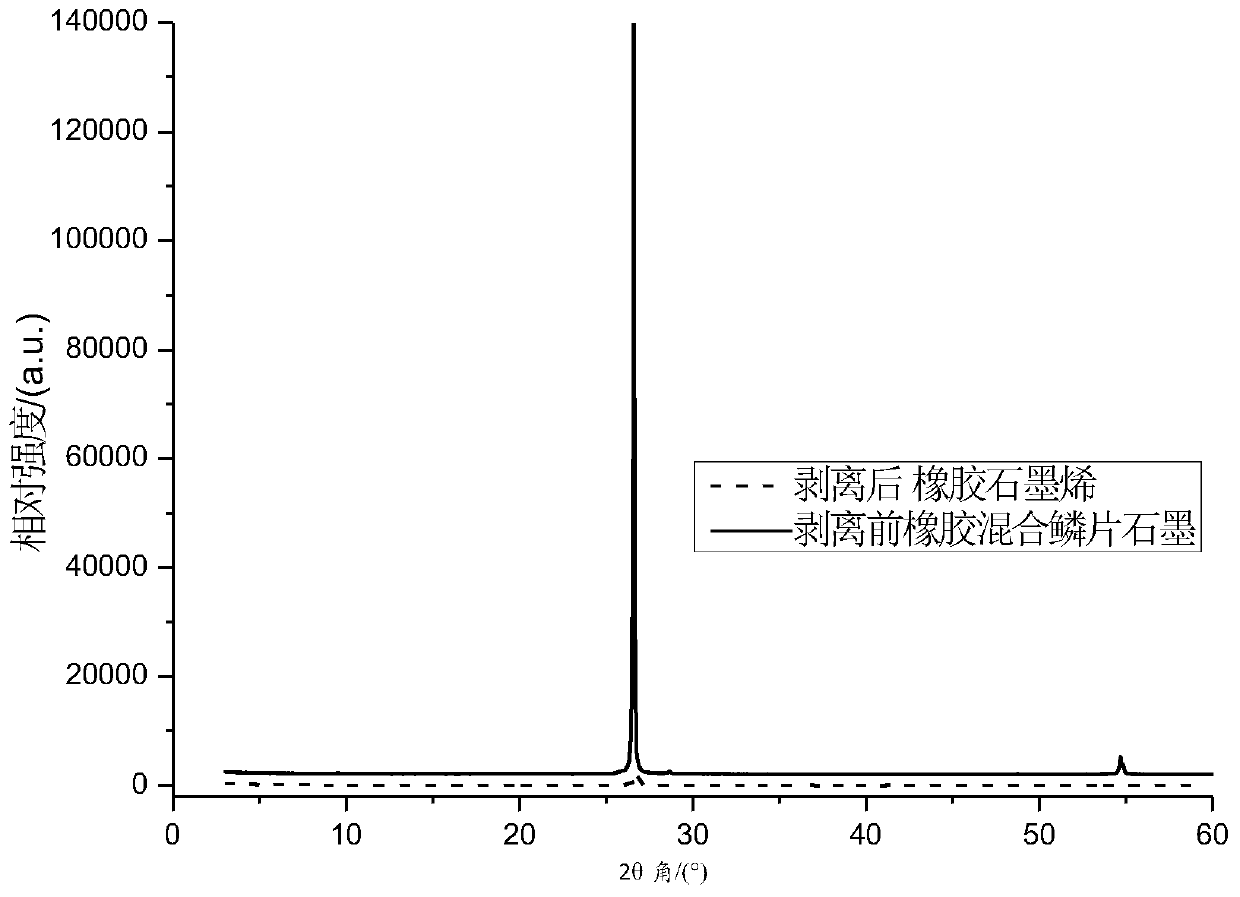

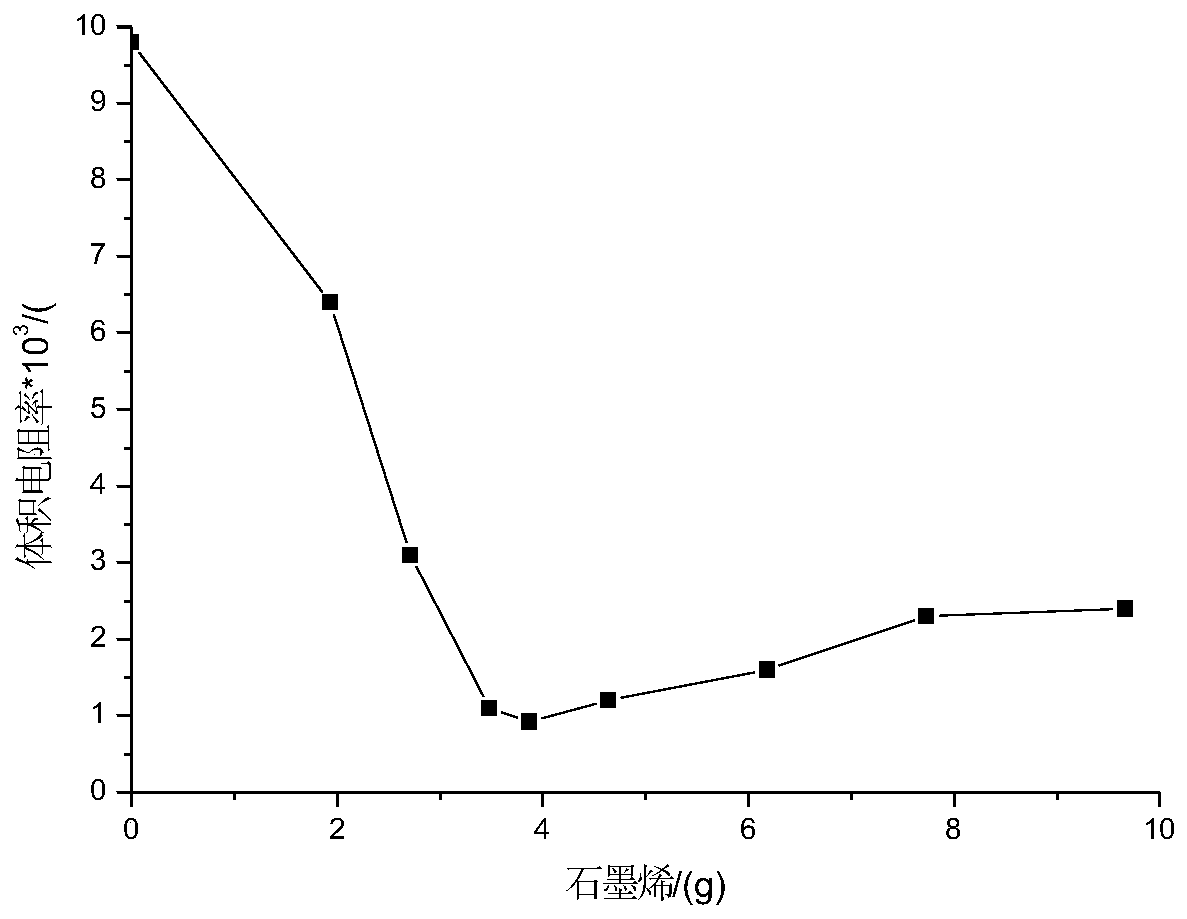

Preparation method of rubber stripping graphene composite conductive rubber

The invention relates to a preparation method of rubber stripping graphene composite conductive rubber. The preparation method comprises the steps that after rubber is mixed with crystalline flake graphite, rubber graphene composite rubber blocks formed by using rubber to strip the crystalline flake graphite are used as conductive reinforcement materials, the graphene rubber blocks are evenly dispersed in a substrate of the conductive rubber through a blending composite technology, and the high-performance series graphene composite conductive rubber material with wide purposes is prepared. Thevolume resistivity can be greatly decreased through the product obtained through the preparation method, the conductivity and the mechanical property of the material are improved exponentially, and the rubber stripping graphene composite conductive rubber has the characteristics that the cost is low, the technology is simple, the efficiency is high, dispersing is uniform, and scale production canbe achieved.

Owner:HEBEI UNIV OF TECH

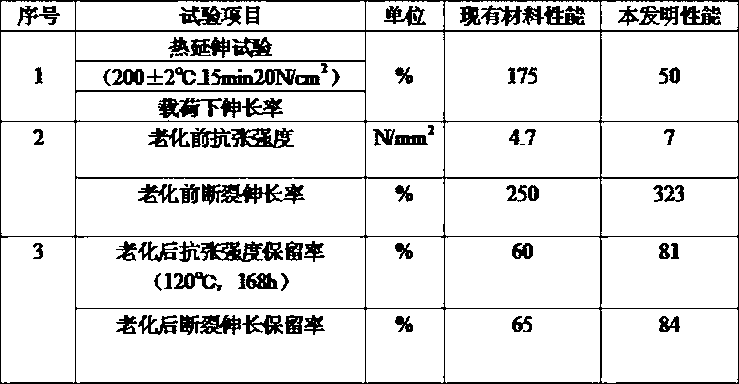

Flame-retardant cable

InactiveCN102074289AGood volume resistivityHigh dielectric strengthInsulated cablesInsulated conductorsInsulation resistanceIec standards

The invention relates to a flame-retardant cable, in particular to a flame-retardant and fireproofing cable used by power stations and power plants, and belongs to the technical field of cables. The cable provided by the invention has three leads encapsulated in an insulation rubber skin, wherein each lead is covered with an insulation layer outside; and the three leads are twisted together and coated with flame-retard coating outside. The cable product provided by the invention has very high physical, mechanical, temperature-resistant and flame-retardant properties; and the performance indexes such as 200 DEG C thermal stabilization time, a breakage extension ratio, the stretching strength of temperature-resistant and flame-retardant materials, impact brittle temperature, volume resistivity, dielectric strength and the like are superior to both the international standard and the national standard. According to the standard test of International Electrotechnical Commission (IEC), a high-temperature resistant flame-retardant formula reaches or is superior to the IEC standard in terms of the performance indexes such as mechanical performance, aging performance, low-temperature resistant performance, insulation performance, darkness of smog, damage indexes of fume damage, toxicity indexes, the acid value of smog and the like.

Owner:广东电缆厂有限公司

Preparation method of polyolefin-based composite material

The invention discloses a preparation method of a polyolefin-based composite material. The preparation method comprises the following steps: dissolving polyolefin in an excessive solvent in a stirringstate at 120-250 DEG C; adding a modifying material, and carrying out stirring and mixing; transferring the mixture into a separator to separate solid from liquid; putting the separated solid into melting equipment; adding an additive into the melting equipment, and carrying out melting and preforming at 110-260 DEG C; and carrying out processing and forming, wherein the solvent is at least one of a liquid silane coupling agent, a liquid titanate coupling agent, a liquid aluminate coupling agent, a liquid phthalic acid ester, a liquid terephthalic acid ester, a liquid trimellitic acid ester,a liquid citric acid ester, salicylic acid, white oil, p-phenylenediamine, fatty acid and maleic anhydride. The prepared composite material is more stable in performance, and the volume resistivity, the thermal deformation temperature and the elongation at break are improved.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

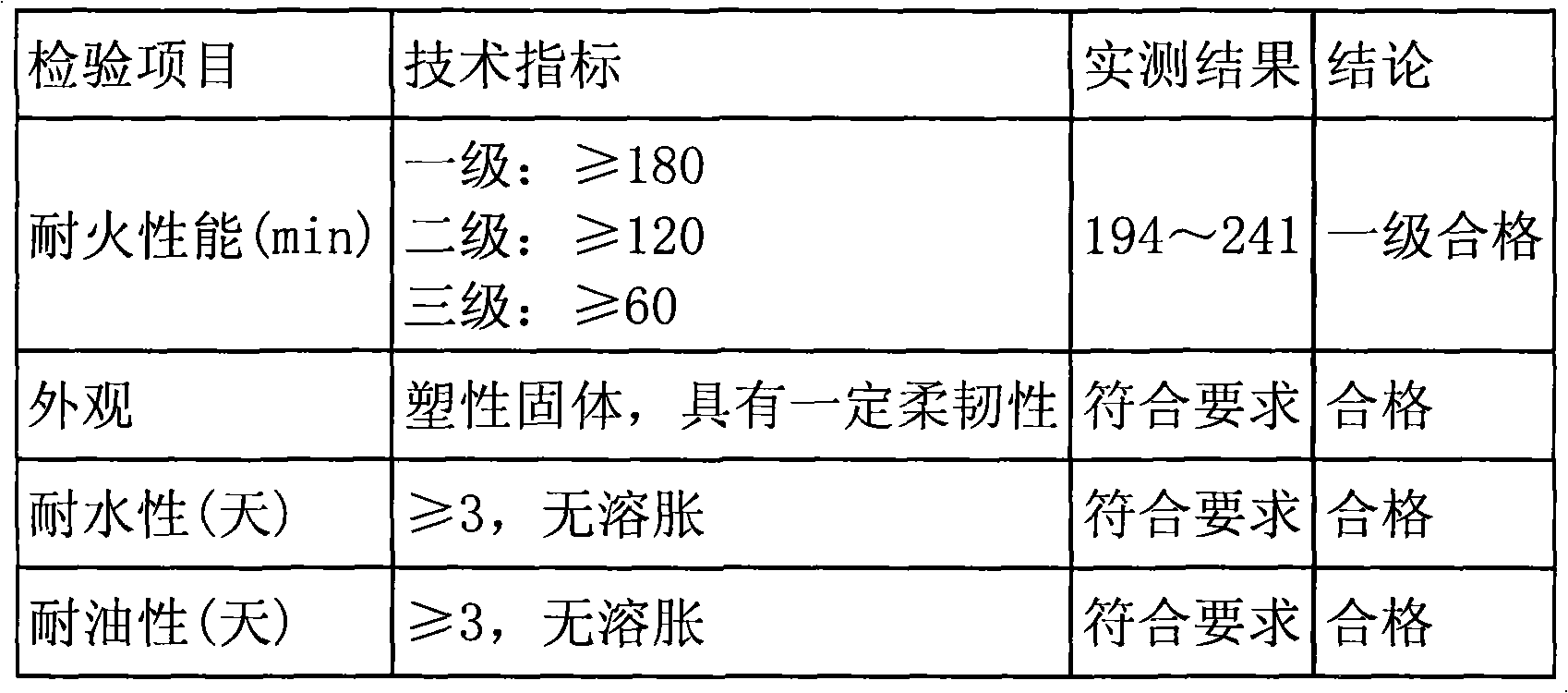

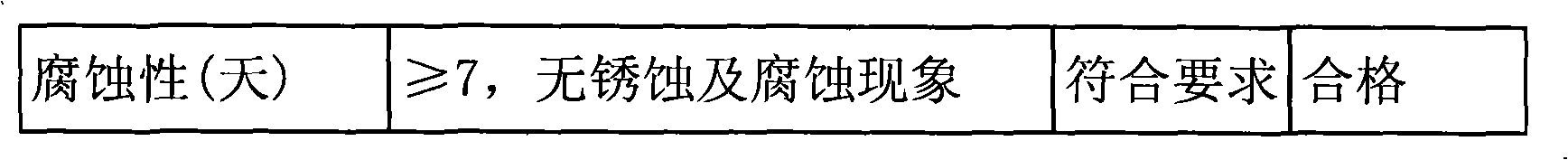

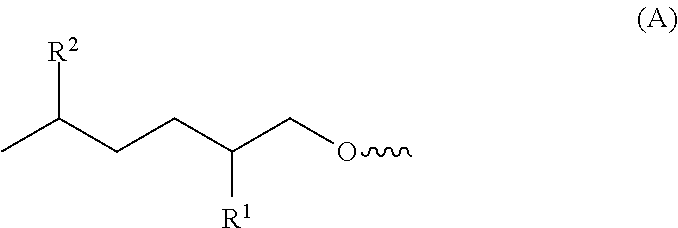

Insulation material

ActiveUS20170271042A1Good volume resistivityPlastic/resin/waxes insulatorsInsulated cablesHeat resistancePlasticizer

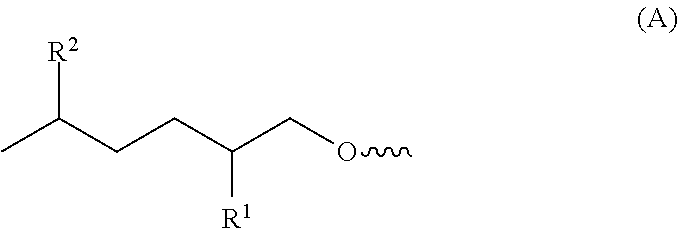

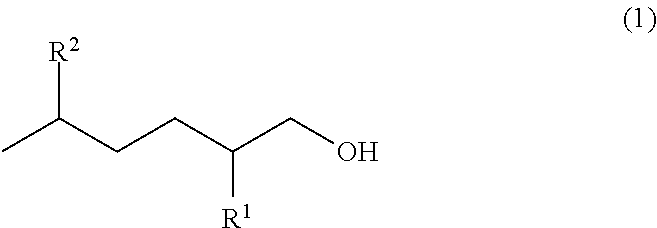

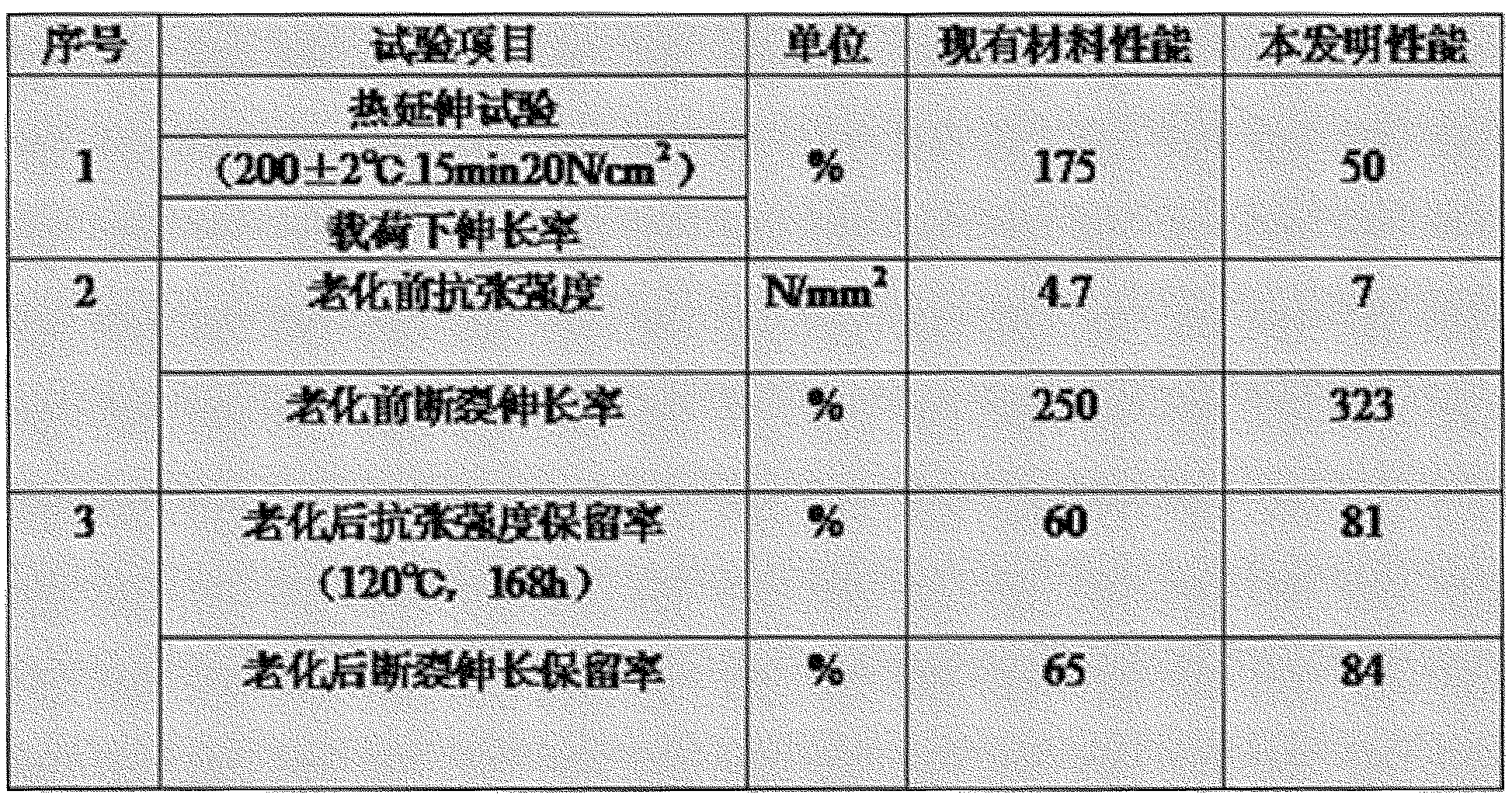

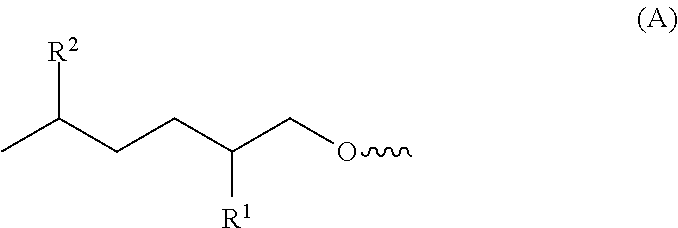

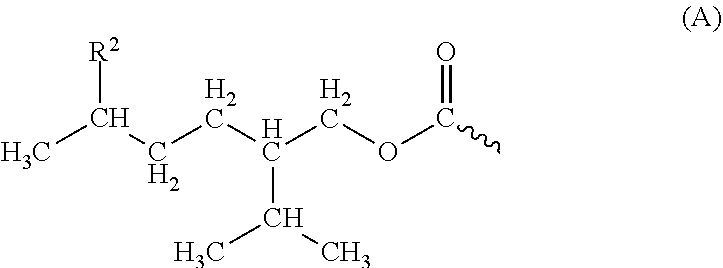

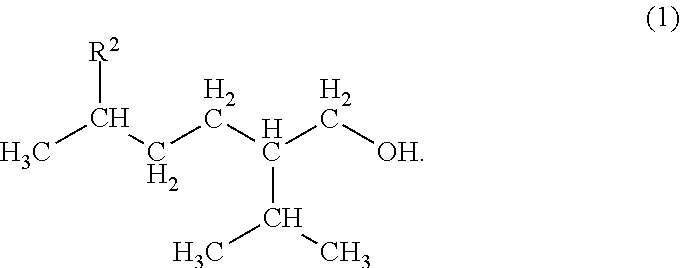

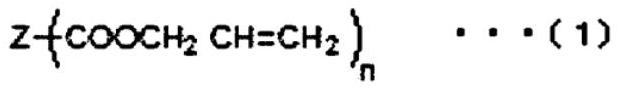

[Problem] To provide an insulation material that has an excellent volume resistivity while retaining the balance among various capabilities including the mechanical strength, the heat resistance, the oil resistance, the bleed-out resistance, the plasticizer migration resistance, and the like, equivalent to a resin composition containing an ordinary phthalate ester.[Solution] An insulation material containing a resin composition containing: an ester (i) having one or more constitutional unit represented by the following formula (A) (wherein R1 and R2 each independently represent an alkyl group having from 1 to 4 carbon atoms); and a resin (ii).

Owner:KURARAY CO LTD

Modified ethylene-propylene diene copolymer cable material and preparation method thereof

InactiveCN102911438BHigh oxygen indexHigh mechanical strengthInsulated cablesInsulated conductorsPolymer scienceMeth-

The invention discloses a modified ethylene-propylene diene copolymer cable material and a preparation method thereof. The cable material is composed of a mixture A and a mixture B, wherein the mixture A comprises, by weight, 90-110 parts of ethylene-propylene diene copolymer, 1-3 parts of antiager RD, 2-4 parts of zinc oxide, 8-12 parts of dioctyl phthalate, 4-6 parts of ethylenebisoctadecanamide, 1-3 parts of 3-aminopropyltrimethoxysilane, 2-4 parts of triallyI isocyanurate, 18-22 parts of nano-montmorillonite, 28-32 parts of nano-aluminum oxide and 18-22 parts of nano-magnesium oxide; the mixture B comprises, by weight, 50-70 parts of maleic anhydride grafted ethylene-ethyl acetate copolymer, 20-30 parts of methyl vinyl silicon rubber, 20-30 parts of modified nano-powder, 0.3-05 part of poly(4-methyl-1-pentene), 5-10 parts of polycaprolactone, 1-3 parts of N, N'-m-phenylenedimaleimide, 1.5-2.5 parts of vinyl-tri-(beta-methoxyethoxy)- silicane, 2-3 parts of sodium dibutylnaphthalenesulfonate, 1-3 parts of acrylic emulsion and 10-15 parts of zinc borate. Compared with the conventional ethylene-propylene diene copolymer cable material, the modified ethylene-propylene diene copolymer cable material has the advantages of high oxygen index, high mechanical strength, excellent elongation at break and high volume resistivity.

Owner:TONGLING CITY TONGDOU SPECIAL CABLE CO LTD

Insulation material

ActiveUS10811165B2Good volume resistivityPlastic/resin/waxes insulatorsInsulated cablesPolymer sciencePlasticizer

[Problem] To provide an insulation material that has an excellent volume resistivity while retaining the balance among various capabilities including the mechanical strength, the heat resistance, the oil resistance, the bleed-out resistance, the plasticizer migration resistance, and the like, equivalent to a resin composition containing an ordinary phthalate ester.[Solution] An insulation material containing a resin composition containing: an ester (i) having one or more constitutional unit represented by the following formula (A) (wherein R1 and R2 each independently represent an alkyl group having from 1 to 4 carbon atoms); and a resin (ii).

Owner:KURARAY CO LTD

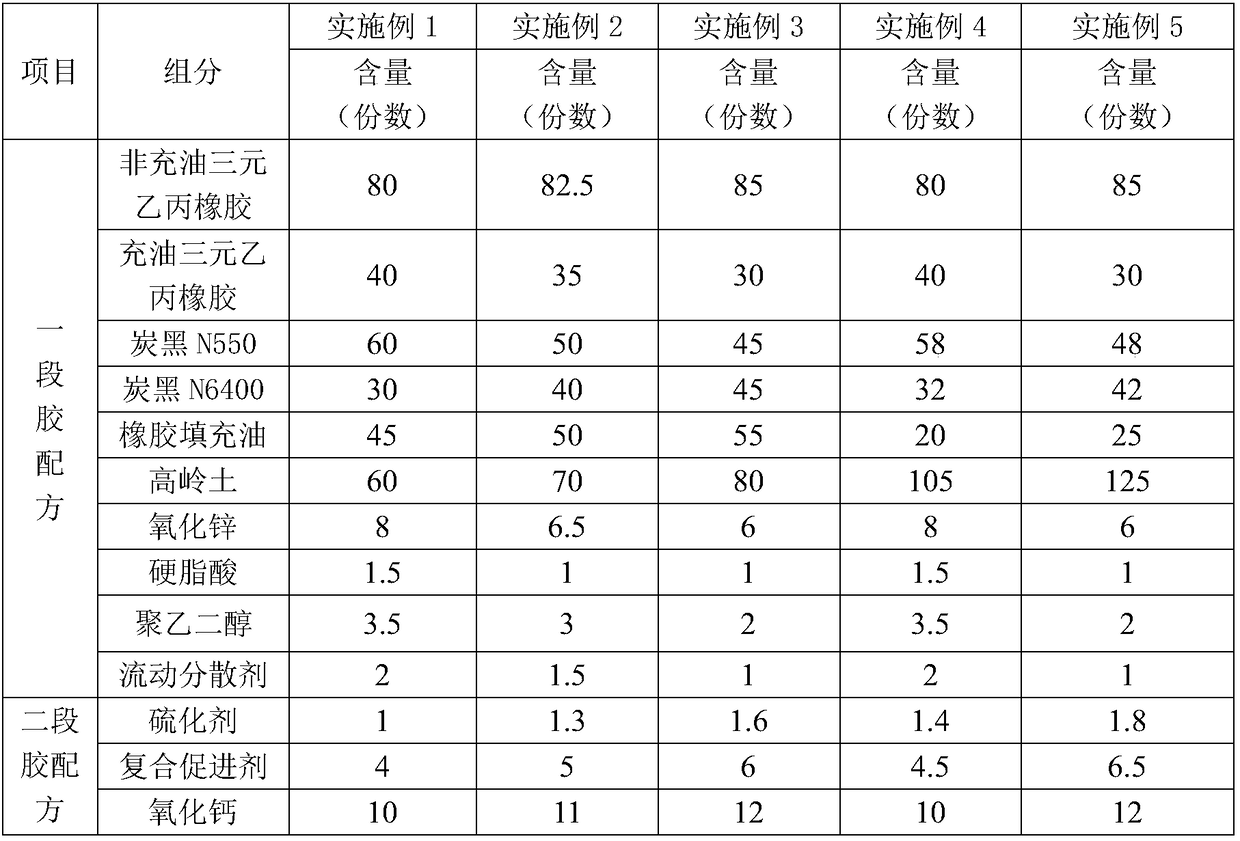

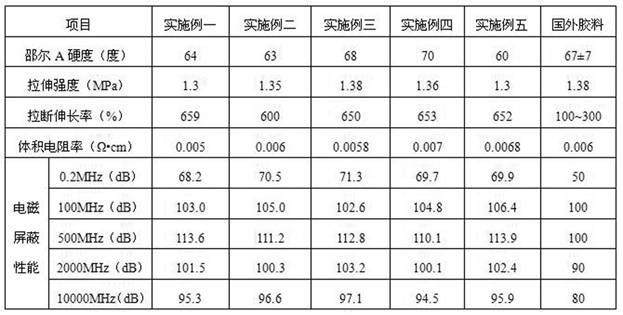

Preparation method of low-hardness high-volume resistance rubber water cutting strips

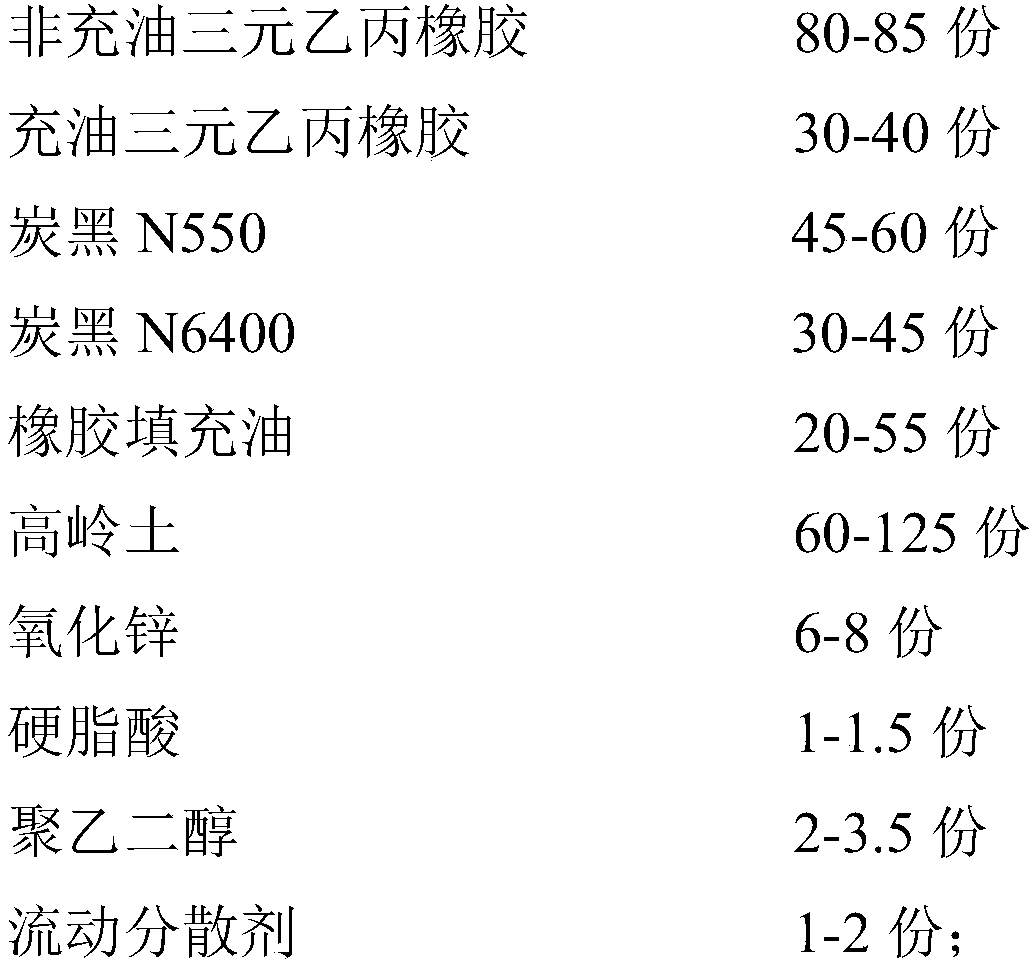

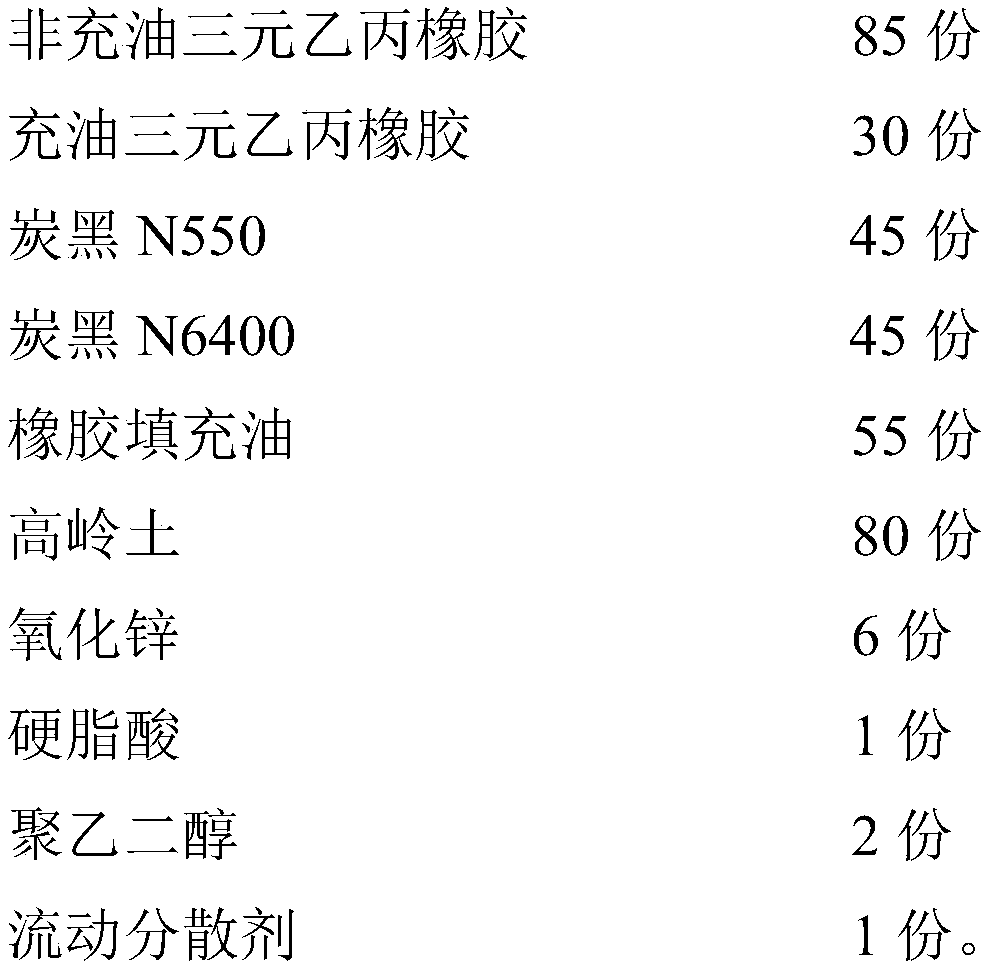

InactiveCN109456541AEasy to processGood processability, oil-extended EPDM rubber has good performanceRubber insulatorsLiquid surface applicatorsPolymer scienceHardness

The invention discloses a preparation method of low-hardness high-volume resistance rubber water cutting strips. The method includes the steps: 1) raw rubber plasticating; 2) primary rubber mixing; 3)primary rubber thinning; 4) secondary rubber open mixing; 5) secondary rubber cutting strip latex collecting; 6) aluminum core gold preforming; 7) rubber extruding; 8) rubber pre-vulcanization; 9) rubber decoration strip flocking; 10) flocking curing. The prepared low-hardness high-volume resistance rubber water cutting strips meet requirements of volume resistivity higher than or equal to 10^6 omega*cm, the hardness is in shore A (60-75) degrees, materials are mixed according to a formula, extruded and vulcanized in a drying oven to prepare the rubber water cutting strips which meet requirements of sectional shapes, the section air holes of the water cutting strips are omitted, and appearance burrs of the water cutting strips are avoided.

Owner:武汉东海敏实汽车零部件有限公司

Environmentally friendly and high flame-retardant polyvinyl chloride insulating material for high-frequency communication cables and preparation method thereof

ActiveCN105175938BImprove flame retardant performanceGood flexibilityPlastic/resin/waxes insulatorsElastomerPolyolefin

The invention discloses an environment friendly high flame-retardant polyvinyl chloride insulation material for a high frequency communication cable and a preparation method of the environment friendly high flame-retardant polyvinyl chloride insulation material. The environment friendly high flame-retardant polyvinyl chloride insulation material is prepared from the following raw material components: 80 to 100 parts of polyvinyl chloride resin, 5 to 15 parts of plasticizer, 5 to 10 parts of secondary plasticizer, 2 to 5 parts of antimony trioxide, 15 to 30 parts of polymer modifier, 0. 2 to 0.5 part of antioxidant, 8 to 10 parts of elastomer, 2 to 4 parts of polyolefin, 5 to 20 parts of inorganic flame retardant and 0.01 to 20 parts of inorganic filler; the raw materials are weighed according to respective parts by mass, and then are subject to kneading, fully melt-mixing by a double screw, and extruding for pelleting, so as to obtain the environment friendly high flame-retardant polyvinyl chloride insulation material. The polyvinyl chloride insulation material is very low in dielectric constant, good in volume resistivity and lower in impact brittleness temperature, is high in flame retardant property, and is widely used as an insulating layer of a communication cable and a power cable, and the flame-retardant polyvinyl chloride can be applied to the high frequency communication field.

Owner:NANJING ZHONGCHAO NEW MATERIALS

An electromagnetic shielding sealing product and its manufacturing process

ActiveCN107057367BIt will not affectHigh elongation at breakDomestic articlesRubber materialVulcanization

The invention discloses an electromagnetic shielding sealing product and a manufacturing technology thereof and belongs to the technical field of an electromagnetic shielding material. The electromagnetic shielding sealing product comprises an aluminum alloy framework, wherein an electromagnetic shielding rubber material is arranged on the aluminum alloy framework and comprises the following components in parts by weight: 80-100 parts of methyl vinyl silicone rubber, 50-300 parts of silvering conducive filler, 2-8 parts of DCBP grease and 2-8 parts of a coupling agent; the components are mixed, refined and sheeted and then are compounded and vulcanized with the aluminum alloy framework, so as to acquire the electromagnetic shielding sealing product. The manufacturing technology disclosed by the invention is simple; low-temperature vulcanization is adopted, so that the aluminum alloy framework is not influenced; the shore A hardness of an electromagnetic shielding rubber material on the sealing product surface is not higher than 70 degrees, the volume resistivity is 0.005-0.01 omega.cm and the electromagnetic shielding property is excellent; the precedent of a high-conductive rubber material is started; the blanking of a high-conductive rubber material is filled; the requirements on electromagnetic shielding and sealing property of equipment are met.

Owner:青岛颐科密封材料有限公司

Thermosetting resin composition

InactiveCN111868123AImprove impact resistanceExcellent impact resistance (impact strengthPolymer scienceAlicyclic Hydrocarbons

The purpose of the present invention is to provide a thermosetting resin composition which does not cause environmental issues such as VOC and has excellent curability (in particular, curability at low temperatures) comparable to the case in which a diallyl phthalate monomer is used as a crosslinking agent. A thermosetting resin composition of the present invention is characterized by containing:an unsaturated polyester resin; an alicyclic polyfunctional allyl ester represented by formula (1) (in the formula, n represents an integer of 2-4, and Z is an n-valent alicyclic hydrocarbon group); one kind of initiator selected from the group consisting of peroxy ketals, peroxy esters, dialkyl peroxides, and peroxy carbonates, and having a one-minute half-life temperature in the range of 100-250DEG C and a molecular weight of 100-400 has excellent curability at low temperatures.

Owner:OSAKA SODA CO LTD

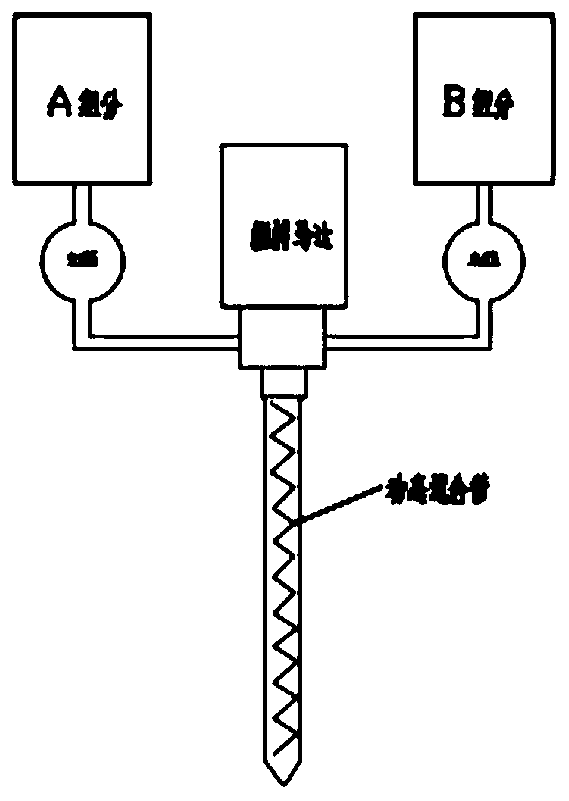

Common-mode radiation resistant cable material for computers and preparation method thereof

InactiveCN108517081AImprove reliabilityImprove stabilityPlastic/resin/waxes insulatorsPhosphateSlurry

The invention discloses a common-mode radiation resistant cable material for computers and a preparation method thereof, and relates to the technical field of computer cables. The cable material comprises the following raw materials: chlorinated polyethylene rubber, PBT resin, an acrylonitrile-butadiene-styrene copolymer, ZAO slurry, iron oxide powder, modified graphene, chlorinated paraffin, silicone master batch, ferrocene, trioctyl trimellitate, hindered phenol, t-butyl aryl phosphate, an aluminium-zirconium bimetallic coupling agent, a cross-linking agent, a promoter and an anti-aging agent. The preparation method comprises steps of mixing of the raw materials, extruding and granulation and the like. The cable material is convenient to prepare, is low-cost, is green and environmentally-friendly, has excellent functions of common-mode radiation resistance and resistance to electromagnetic interference, has stable and excellent physical and chemical properties, has long service life,and is safe and reliable.

Owner:HEFEI MINZHONGYIXING SOFTWARE DEV CO LTD

Stretchable interconnects for flexible electronic surfaces

ActiveUS10672531B2Large formatGood volume resistivityTransportation and packagingNon-conductive material with dispersed conductive materialConductive pastePolyester

Owner:FRY S METALS INC

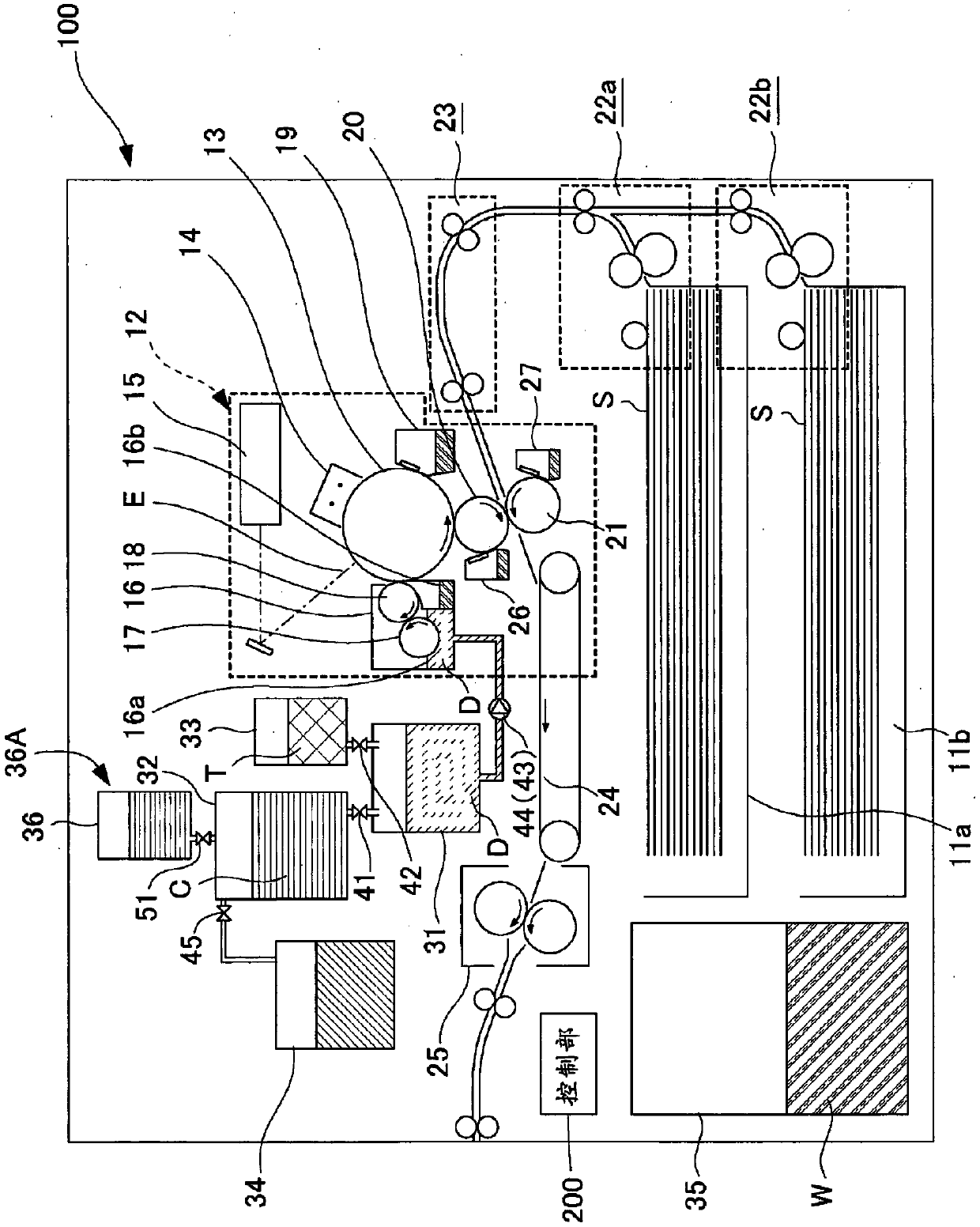

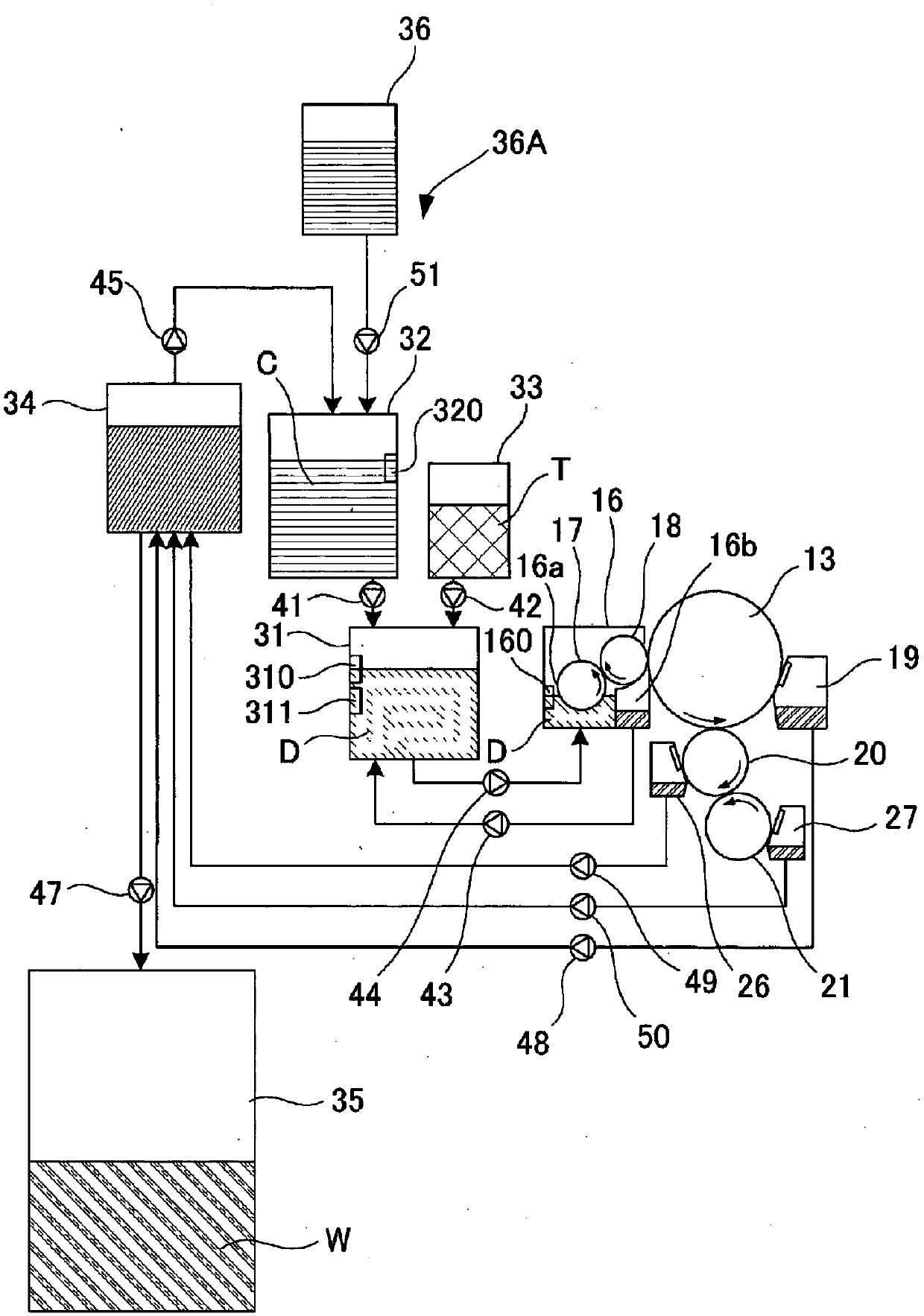

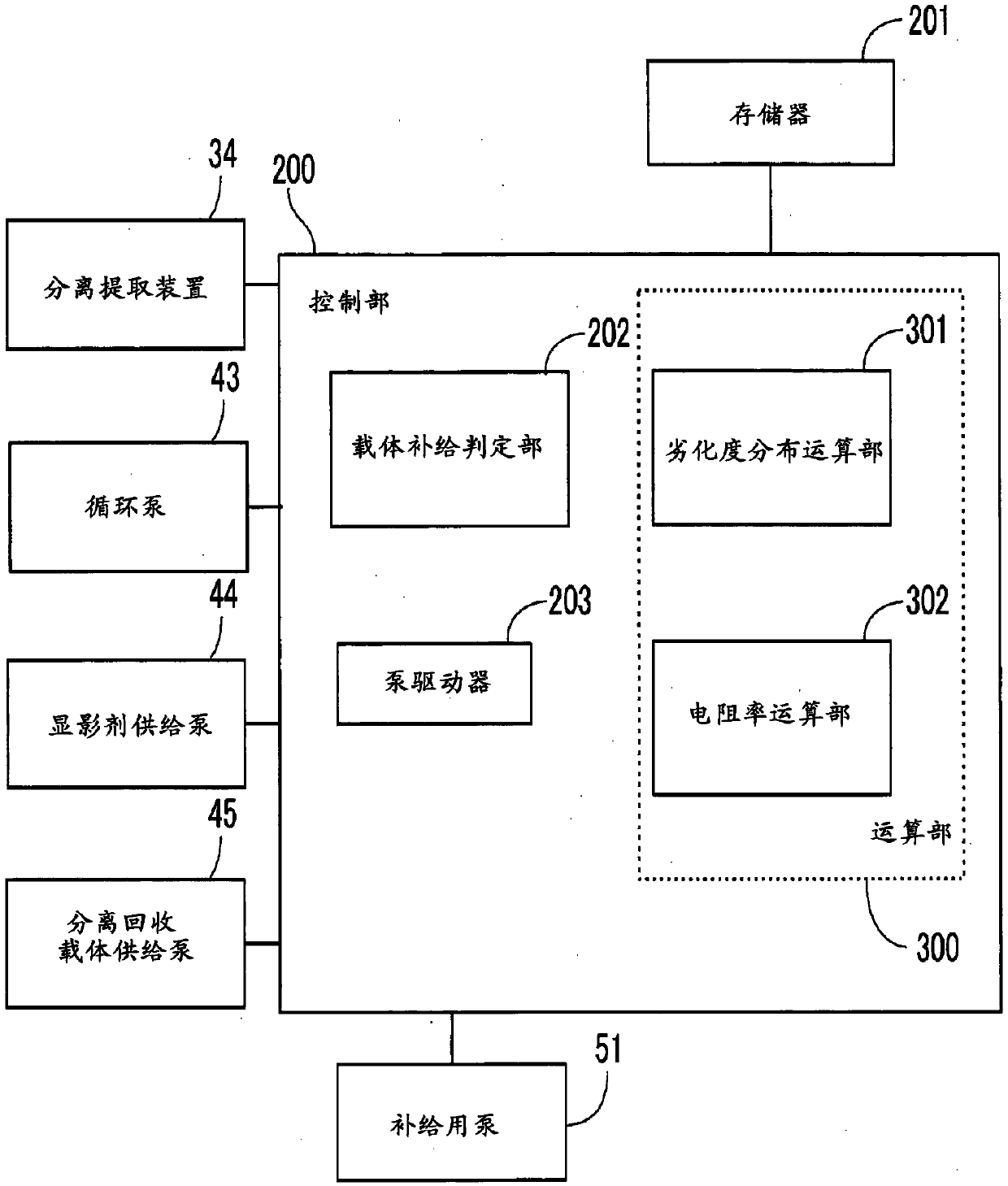

Image formation device

InactiveCN109643077AGood volume resistivityDevelopersElectrographic process apparatusImage formationEngineering

A computation unit (300) finds the resistivity of a carrier liquid in a carrier tank by computation. A resistivity computation unit (302) finds the resistivity of the carrier liquid on the basis of "the liquid quantity for each number of times of passage of the carrier liquid that has passed through a separation and extraction device" and "the resistivity for each number of times of passage of thecarrier liquid that has passed through the separation and extraction device". "The liquid quantity for each number of times of passage" is computed by a deterioration degree distribution computationunit 301 and stored in a memory (201). Regarding "the resistivity for each number of times of passage", the resistivity of the carrier liquid after the carrier liquid has passed through the separationand extraction device is prestored in the memory (201) for each number of times of passage. A carrier replenishment determination unit (202) determines, on the basis of the found resistivity of the carrier liquid, whether a replenishment carrier liquid is replenished or not. A control unit (200) controls a replenishment pump (51) on the basis of the determination.

Owner:CANON KK

Production process of PVC decorative film

InactiveCN112500657AImprove migration resistanceImprove thermal stabilityLaminationLamination apparatusEpoxyPolymer science

The invention discloses a production process of a PVC decorative film. The production process comprises the following steps: heating PVC resin to 50-90 DEG C to decompose hydrogen chloride, adding epoxy soybean oil and an organic tin stabilizer, carrying out ring-opening reaction to make the PVC resin positively charged, enhancing the electron deficiency, endowing the material with excellent spacecharges, enhancing the migration resistance and thermal stability of the material, and reacting with triglyceride trimellitate to obtain the PVC decorative film. The excellent volume resistivity is increased, the synergistic effect with existing space charges of the material is achieved, so that the insulating property of the material is better improved, the excellent ultraviolet irradiation resistance is improved, the environment is protected, and meanwhile, the subtle balance of the electrical property, the mechanical property and the stability is achieved; the finally prepared PVC decorative film is particularly outstanding when applied to the fields of electric appliance wrapping and decoration, and the material is more uniform after being heated twice by a reaction kettle and an extruder.

Owner:九江赛璐珞实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com