Modified ethylene-propylene diene copolymer cable material and preparation method thereof

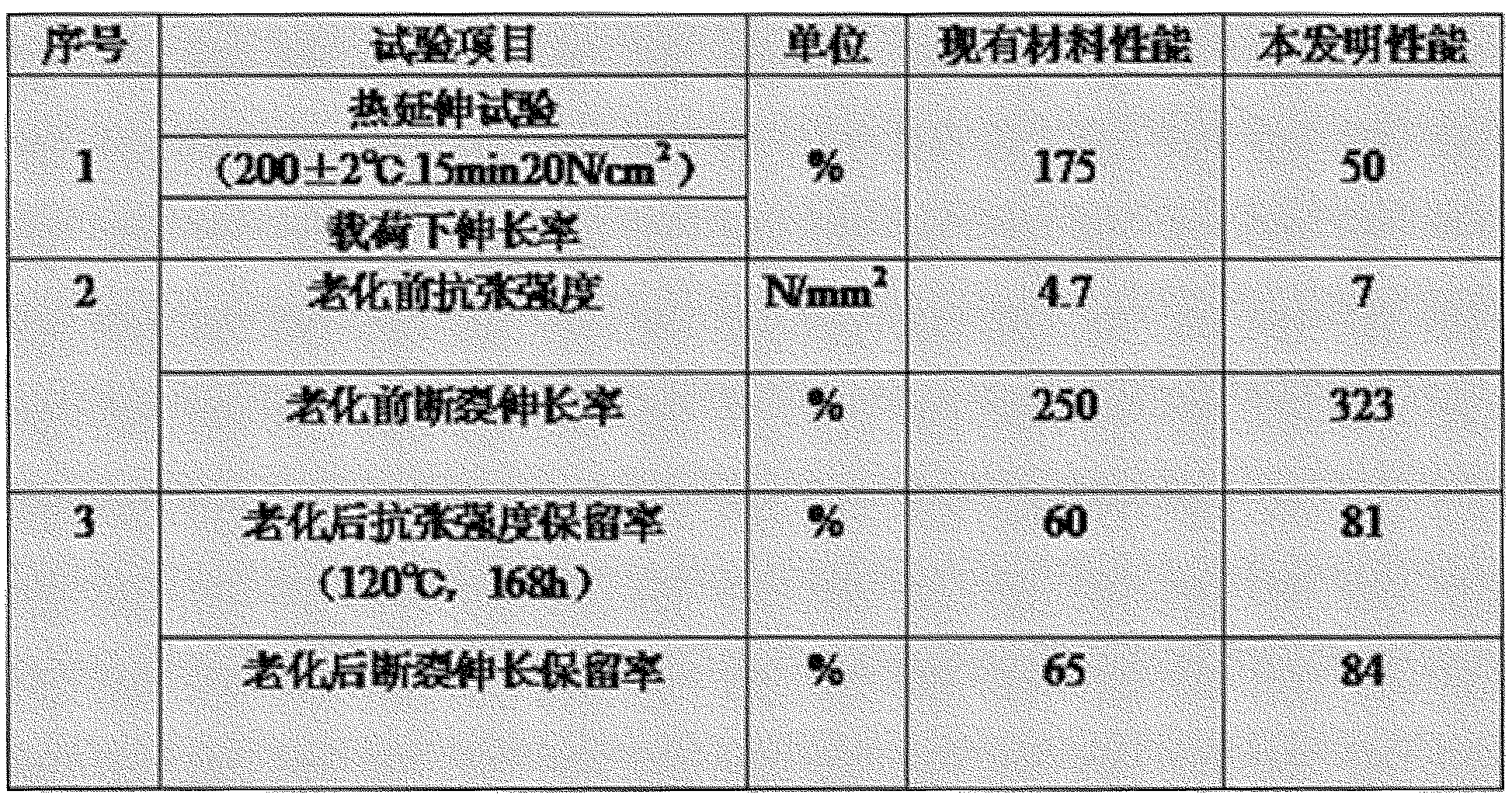

A technology of EPDM rubber and cable material, which is applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of low oxygen index of EPDM rubber and limit popularization and application, and achieve excellent elongation at break, good Effect of volume resistivity and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Modified EPDM rubber cable material, the parts by weight of the raw materials are:

[0018] Mixture A: EPDM rubber 100, anti-aging agent RD 2, zinc oxide 3, dioctyl ester 10, ethylene bisstearamide 5, 3-aminopropyl trimethoxysilane 2, triallyl isotri Polycyanate 3, Nano-montmorillonite 20, Nano-alumina 30, Nano-magnesia 20;

[0019] Mixture B: maleic anhydride grafted ethylene-ethyl acetate copolymer 60, methyl vinyl silicone rubber 25, modified nano powder 25, poly-4-methyl-1-pentene 0.4, polycaprolactone 8. N, N'-m-phenylene bismaleimide 2, vinyl tris(β-methoxyethoxy) silane 2, sodium dibutylnaphthalene sulfonate 2.5, acrylic emulsion 2 and zinc borate 12 .

[0020] The preparation method of modified EPDM rubber cable material comprises the following steps:

[0021] First, weigh all the raw materials of mixture A and B according to the weight of the raw materials; mix the raw materials of mixture A and B respectively at a temperature of 105-115°C for 4-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com