Cable polymer material with good flame retardation performance, and preparation method thereof

A polymer material, flame retardant technology, applied in the direction of circuits, electrical components, organic insulators, etc., can solve problems such as environmental pollution, base material machinery, physical performance decline, suffocation death, etc., to achieve a wide range of sources, meet the needs of use, The effect of good tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

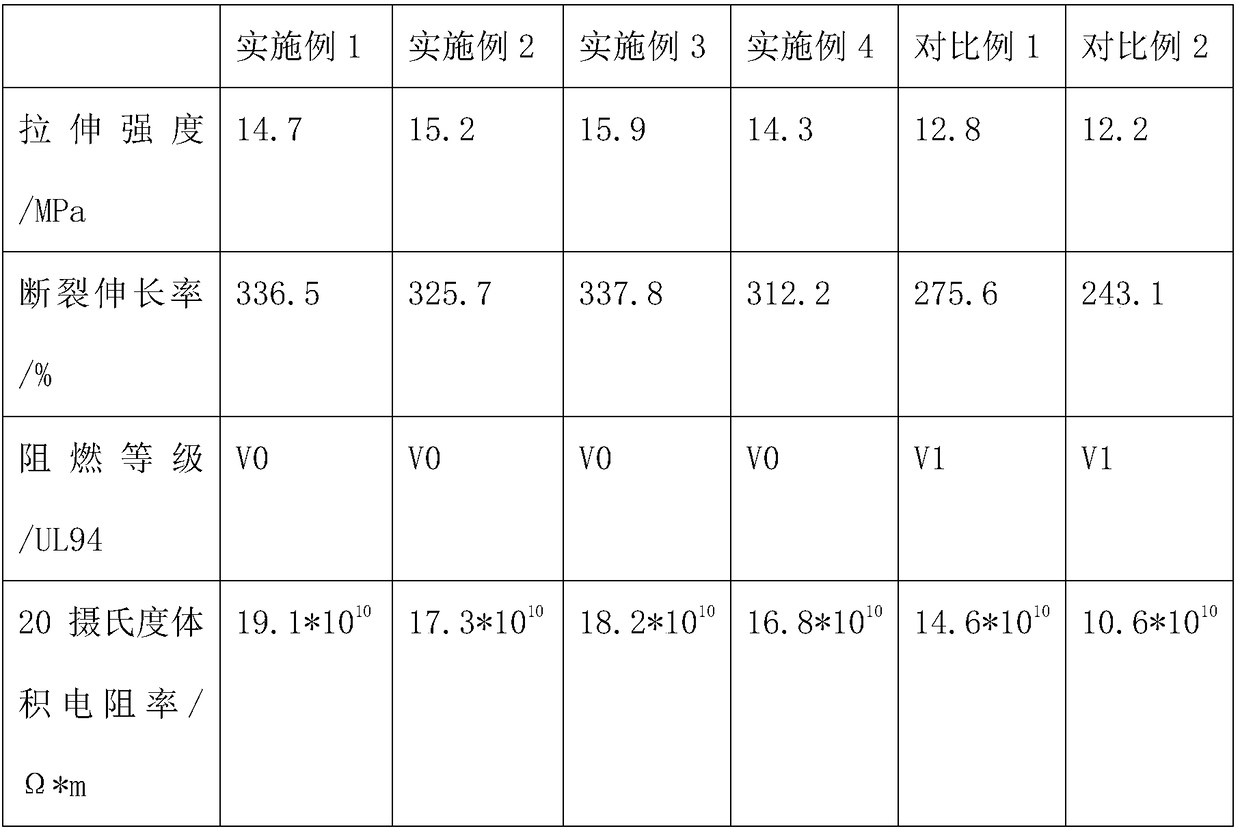

Examples

Embodiment 1

[0022] A polymer material with good flame retardancy for cables, comprising the following raw materials in parts by weight: 19 parts of light calcium carbonate, 6 parts of coupling agent, 115 parts of linear low-density polyethylene, 0.8 part of calcium stearate, methyl 66 parts of vinyl phenyl silicone rubber, 38 parts of epoxy resin, 12 parts of vegetable starch, 10 parts of styrene-acrylic emulsion, 4 parts of glass fiber and 5 parts of forsythin. The mass fraction of phenyl in the methyl vinyl phenyl silicone rubber is 15-24%. The epoxy resin adopts bisphenol A type epoxy resin, and the vegetable starch adopts soybean starch.

[0023] The preparation method of the polymer material with good flame retardant performance for the cable, the specific steps are as follows:

[0024] Step 1, grinding light calcium carbonate and glass fiber into 1350 mesh powder in a grinding device to obtain light calcium carbonate powder and glass fiber powder for subsequent use;

[0025] Step ...

Embodiment 2

[0031] A polymer material with good flame retardancy for cables, comprising the following raw materials in parts by weight: 23 parts of light calcium carbonate, 8.8 parts of coupling agent, 124 parts of linear low-density polyethylene, 1.2 parts of calcium stearate, methyl 73 parts of vinyl phenyl silicone rubber, 41 parts of epoxy resin, 14.5 parts of vegetable starch, 12.5 parts of styrene-acrylic emulsion, 4.9 parts of glass fiber and 6.5 parts of forsythin. The length of the glass fiber is 5.6mm. The epoxy resin adopts novolac epoxy resin, and the vegetable starch includes a mixture of wheat starch and potato starch.

[0032] The preparation method of the polymer material with good flame retardant performance for the cable, the specific steps are as follows:

[0033] Step 1, grinding light calcium carbonate and glass fiber into 1500-mesh powder in a grinding device to obtain light calcium carbonate powder and glass fiber powder for subsequent use;

[0034] Step 2, add li...

Embodiment 3

[0040] A polymer material with good flame retardancy for cables, comprising the following raw materials in parts by weight: 26 parts of light calcium carbonate, 11 parts of coupling agent, 139 parts of linear low-density polyethylene, 1.5 parts of calcium stearate, methyl 80 parts of vinyl phenyl silicone rubber, 44 parts of epoxy resin, 17.5 parts of vegetable starch, 15.2 parts of styrene-acrylic emulsion, 5.6 parts of glass fiber and 7.6 parts of forsythin. Epoxy resin adopts bisphenol A type epoxy resin, and vegetable starch includes the mixture of soybean starch, sorghum starch and potato starch.

[0041] The preparation method of the polymer material with good flame retardant performance for the cable, the specific steps are as follows:

[0042] Step 1, grinding light calcium carbonate and glass fiber into 1200-mesh powder in a grinding device to obtain light calcium carbonate powder and glass fiber powder for subsequent use;

[0043] Step 2, add light calcium carbonate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com