High-welding-tension main grid low-temperature silver paste for solar heterojunction battery and preparation method of high-welding-tension main grid low-temperature silver paste

A heterojunction battery and solar energy technology, applied in cable/conductor manufacturing, circuit, photovoltaic power generation, etc., can solve the problems of high volume resistivity, low welding tension, poor printing, etc., and achieve good aging tension, high welding tension, The effect of strong solderability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

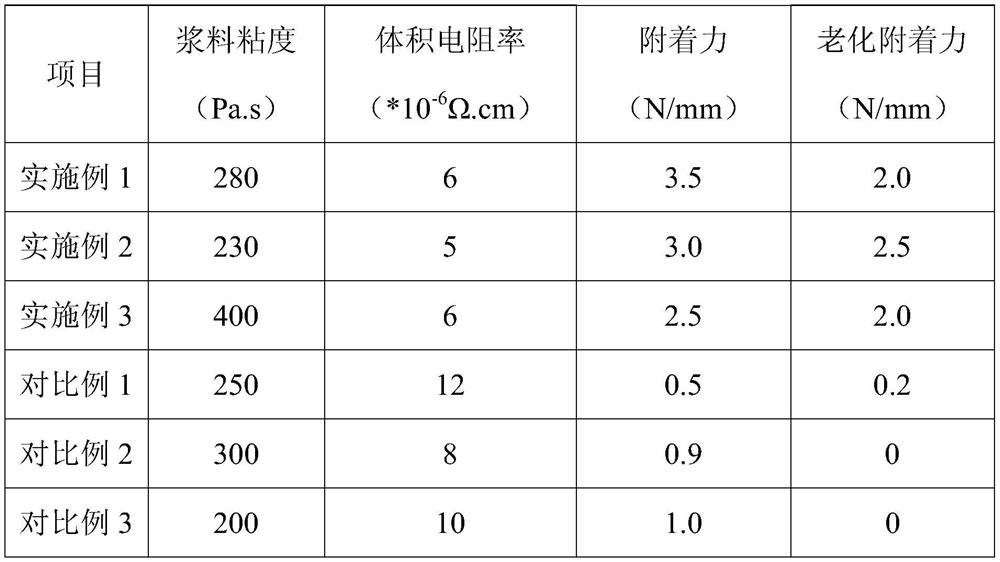

Examples

Embodiment 1

[0023] A low-temperature silver paste for high welding tension busbar for solar heterojunction cells, comprising the following components: 43wt% of low melting point flake silver powder, 46.8wt% of high sintering activity spherical silver powder, 3wt% of low melting point alloy powder, organic binder phase 2wt%, inorganic binder phase 1.2wt%, organic solvent 3wt%, leveling agent 1wt%. Among them, the low melting point alloy powder is 2wt% of tin powder, 1wt% of indium powder; the organic resin in the organic binder phase is bisphenol A type epoxy resin 1wt%, the latent curing agent is blocked isocyanate 1wt%; the organic solvent is diethylene glycol Diol butyl ether acetate 2wt%, 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate 1wt%; leveling agent is silicone leveling agent; high sintering activity spherical silver powder The diameter distribution is D100≤600nm, D50≤400nm, D10≥200nm, tap density 5~6g / cm 3 , specific surface area 0.5~1.0m 2 / g, silver powder active temperatur...

Embodiment 2

[0029] A low-temperature silver paste for high welding tension busbar for solar heterojunction cells, comprising the following components: 65wt% of low melting point flake silver powder, 24.8wt% of high sintering activity spherical silver powder, 3wt% of low melting point alloy powder, organic binder phase 2.1wt%, inorganic binder phase 1.1wt%, organic solvent 3wt%, leveling agent 1wt%. Among them, the low melting point alloy powder is 2wt% of tin powder, 1wt% of indium powder; the organic resin in the organic binder phase is bisphenol A type epoxy resin 1.1wt%, and the latent curing agent is blocked isocyanate 1.0wt%; the organic solvent is Diethylene glycol butyl ether acetate 2wt%, 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate 1wt%; leveling agent is silicone leveling agent; high sintering activity spherical Silver powder particle size distribution is D100≤600nm, D50≤400nm, D10≥200nm, tap density 5~6g / cm 3 , specific surface area 0.5~1.0m 2 / g, silver powder active temp...

Embodiment 3

[0032]A low-temperature silver paste for high welding tension busbar for solar heterojunction cells, comprising the following components: 24.8wt% of low melting point flake silver powder, 65wt% of high sintering activity spherical silver powder, 3wt% of low melting point alloy powder, organic binder phase 2.7wt%, inorganic binder phase 0.5wt%, organic solvent 3wt%, leveling agent 1wt%. Among them, the low melting point alloy powder is 2wt% of tin powder, 1wt% of indium powder; the organic resin in the organic binder phase is bisphenol A type epoxy resin 1.4wt%, and the latent curing agent is blocked isocyanate 1.3wt%; the organic solvent is Diethylene glycol butyl ether acetate 2wt%, 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate 1wt%; leveling agent is silicone leveling agent; high sintering activity spherical Silver powder particle size distribution is D100≤600nm, D50≤400nm, D10≥200nm, tap density 5~6g / cm 3 , specific surface area 0.5~1.0m 2 / g, silver powder active tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com