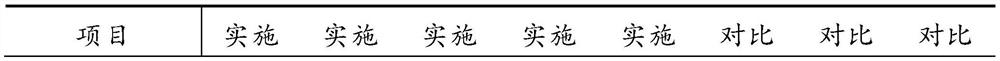

Patents

Literature

82results about How to "Improve welding tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

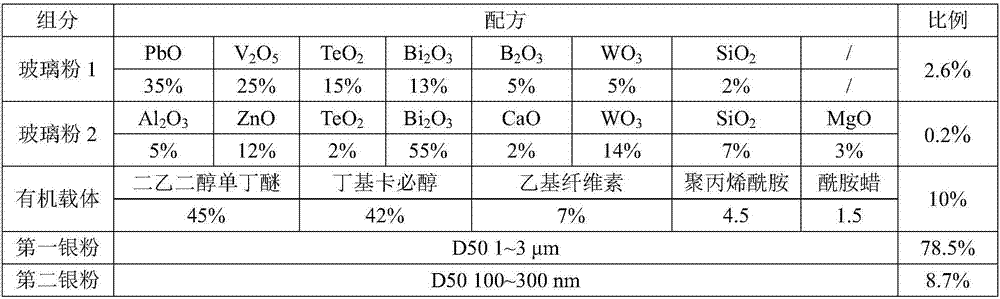

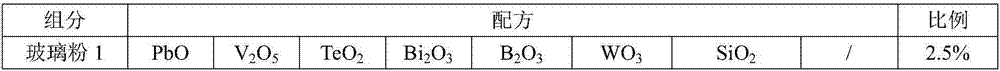

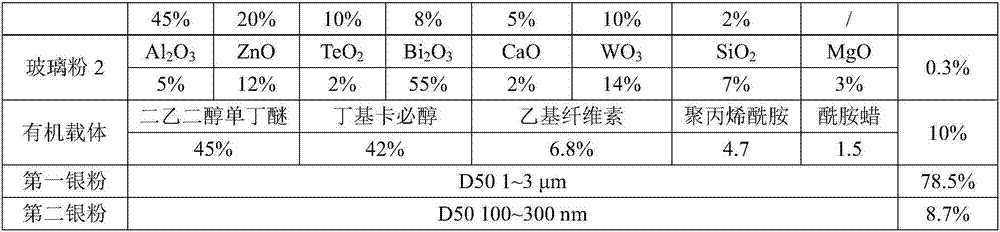

Positive electrode silver paste for back passivation silicon solar cell and preparation method thereof

ActiveCN107195354AHigh sintering activityImprove liquidityNon-conductive material with dispersed conductive materialCable/conductor manufactureSilicon solar cellColloidal particle

The invention discloses positive electrode silver paste for a back passivation silicon solar cell and a preparation method thereof. The positive electrode silver paste comprises, in mass percent, 3%-15% of organic carriers, 80%-95% of silver powders and 1%-5% of inorganic glass materials. The inorganic glass materials are prepared by compounding Pb-V-Te glass and Bi-W-Si glass; and the silver powders are prepared by compounding first silver powders and second silver powders. Through introduction of nanometer silver powders, sintering activity of a silver powder system is improved, and compactness of silver grid lines under low-temperature sintering is improved; by adjusting softening temperature, viscosity and surface tension of the glass materials, liquidity and wetting ability of glass liquid are improved, etching capacity of the glass liquid to a front-surface antireflection layer is ensured and silver powder fusion and reprecipitation capability is improved; precipitation of silver nanometer colloid particles on the surface of a silicon wafer helps to promote the glass layer to form good ohmic contact with the silicon wafer, and thus conversion efficiency is improved; and through introduction of the second component glass powders, bonding strength between the glass layer and a silicon substrate is enhanced.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH CO LTD

Solar cell front-side silver paste and preparation method thereof

ActiveCN103000249AImprove conversion efficiencyImprove welding tensionNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteOrganic solvent

The invention provides solar cell front-side silver paste and a preparation method thereof. The solar cell front-side silver paste comprises the following components by weight: 80-90% of silver powder, 0.5-5% of leaded glass powder, 0.05-3% of inorganic additive and 5-15% of organic carrier, wherein the percentage mass content of lead in the leaded glass powder is 30-90%, the inorganic additive comprises TeO2 micro powder, and the organic carrier comprises resin and organic solvent. The silver paste is applied to the surface of the high-square-resistance silicon-based solar cell and can form good ohmic contact on the high-square-resistance silicon-based solar cell. Therefore, conversion efficiency of the solar cell is greatly improved, and welding tensile force of the high-lead silver paste subjected to sintering on the solar cell is remained. Besides, by means of the preparation of the solar cell front-side silver paste, the preparation process of the silver paste is greatly simplified, and production cost is reduced.

Owner:SHANGHAI TRANSCOM ELECTRONICS TECH

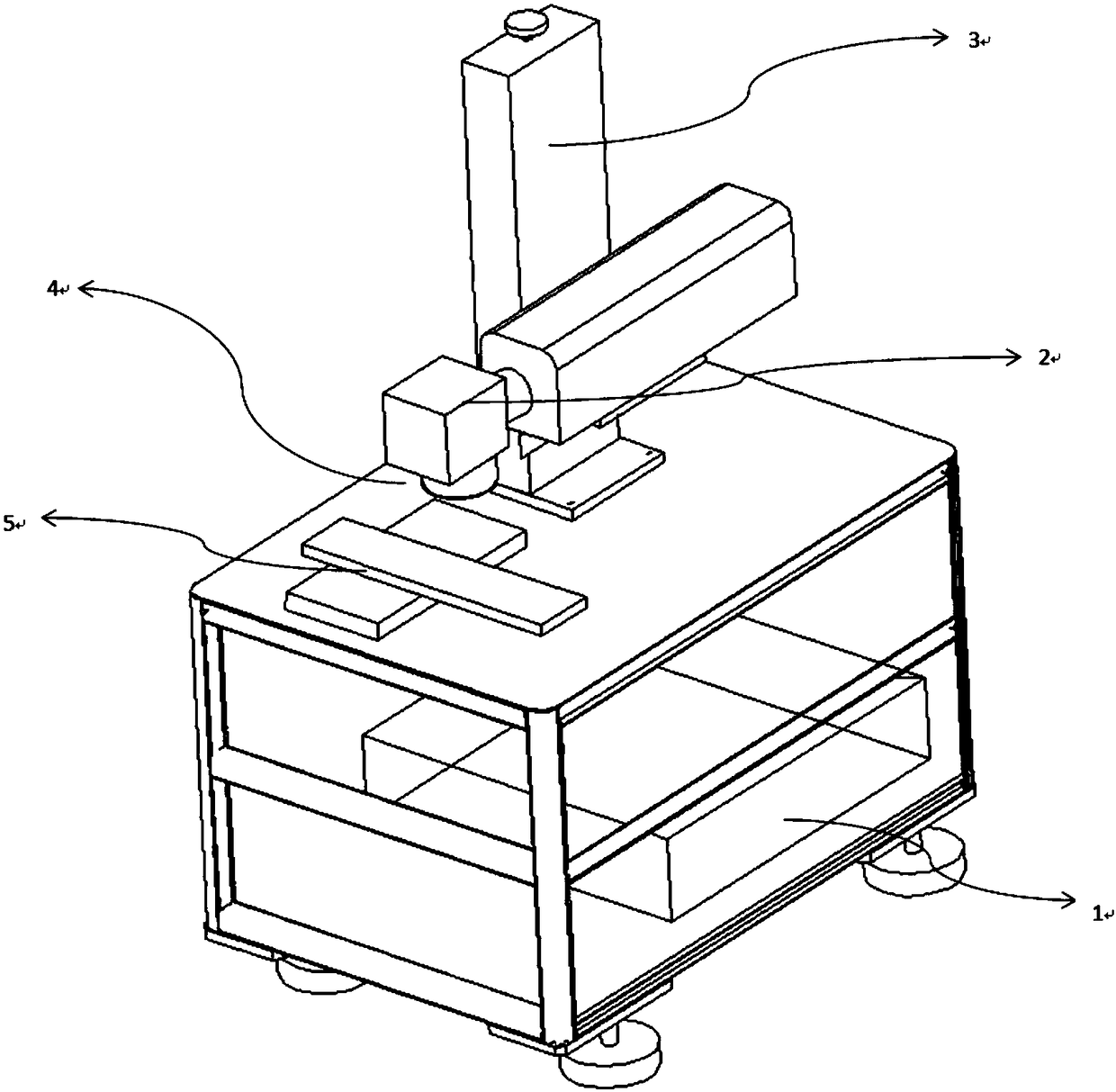

Automobile air conditioner compressor hollow piston and production method thereof

ActiveCN104805339AHigh tensile strengthHigh yield strengthPositive displacement pump componentsPositive-displacement liquid enginesPorosityWeld seam

The invention discloses an automobile air conditioner compressor hollow piston, which comprises aluminum alloy prepared from the following ingredients in percentage by weight: 11 to 13 percent of Si, 3.5 to 4.5 percent of Cu, 0.2 to 0.5 percent of Mg, 0.8 to 1.5 percent of Ni, 0.1 to 0.3 percent of Cr, 0.1 to 0.3 percent of C, 0 to 0.1 percent of Mn, 0 to 0.5 percent of Zn, 0 to 0.15 percent of Ti, 0.1 to 0.3 percent of RE and the balance Al. The invention also provides a production method of the automobile air conditioner compressor hollow piston. Through the selection and the control on elements in the aluminum alloy for the hollow piston, the intensity and the hardness of the piston are improved; through further improvement on the laser welding process, the welding seam fine porosity rate is reduced, the welding tension is enhanced, and the welding quality is improved, so the use performance of the hollow piston is improved, and the service life of the hollow piston is prolonged.

Owner:SHANDONG HUICHUAN AUTO PARTS

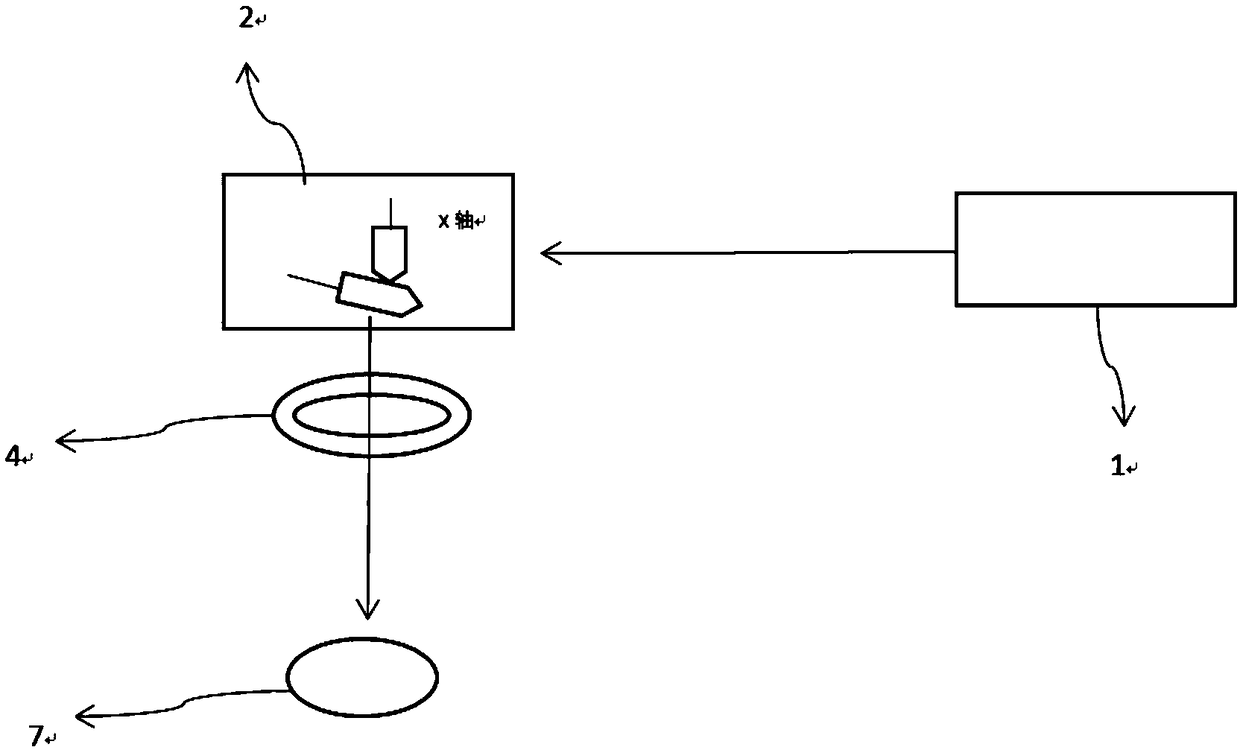

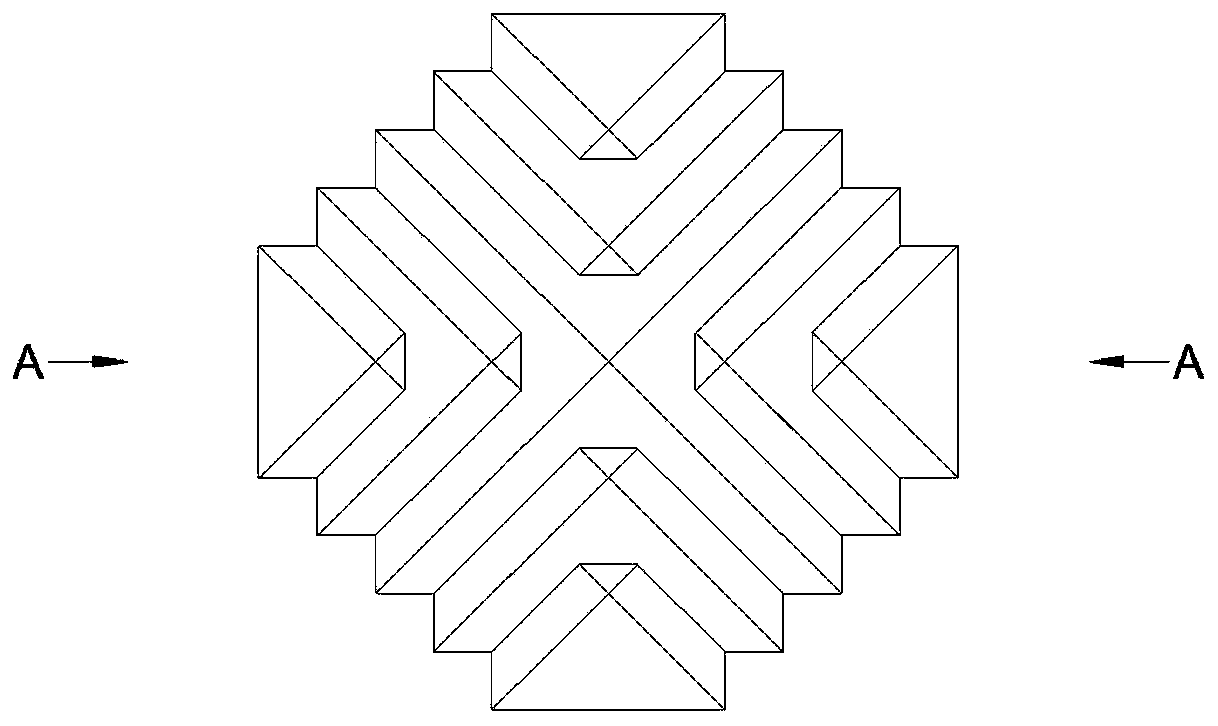

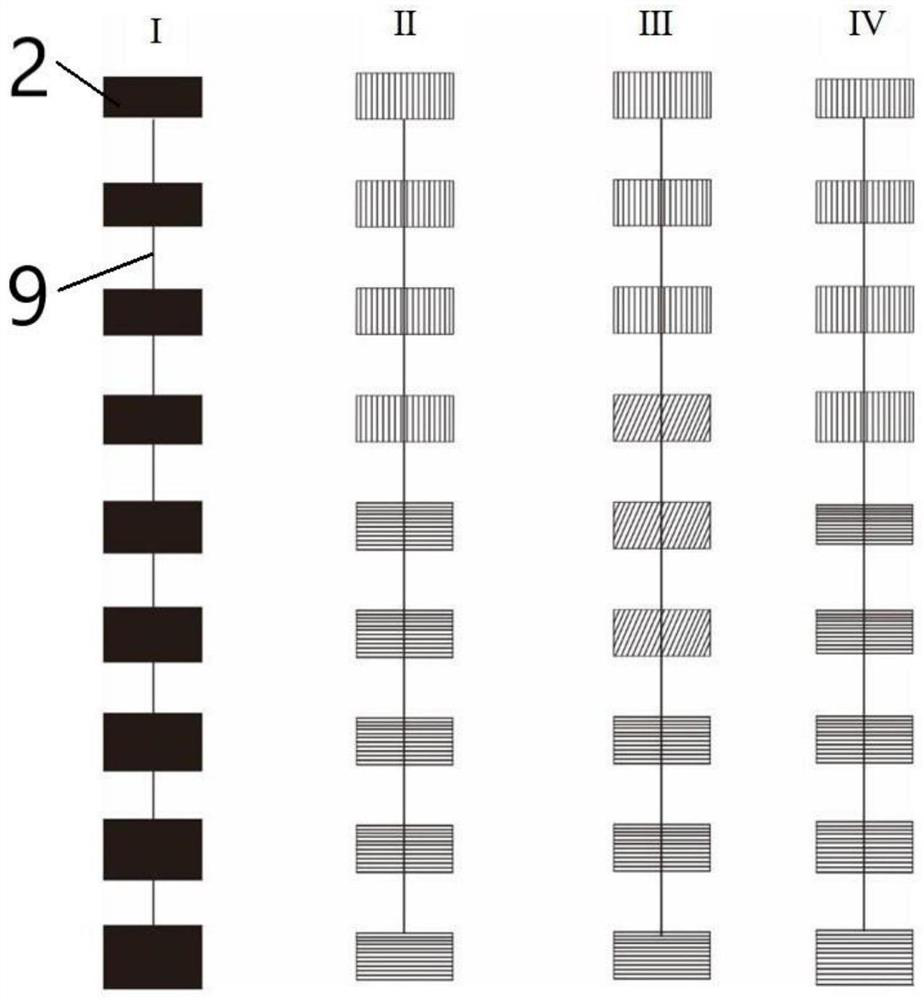

Laser path of laser welding point, and laser welding method

ActiveCN108356414AStrong pullControllable stacking timesLaser beam welding apparatusShielding gasLaser scanning

The invention discloses a laser path of a laser welding point, and a laser welding method. The laser welding method comprises the steps of fixing a product to be welded onto a two-dimensional platformthrough a fixture, utilizing a pulse laser for scanning welding a welding point in a welding area of the product to be welded, and dividing a laser scanned path graph of the welding point into threesegments, wherein the first segment is a straight-line segment or a curved segment, the second segment is formed by multiple reciprocating disjoint straight-line segments or curved segments, startingpoints of each two adjacent straight-line segments or curved segments are connected through a transition segment, the third segment is a straight-line segment or a curved segment, and the first segment, the second segment and the third segment are sequentially connected; and crossing the straight-line segments or the curved segments of the first segment and the second segment, crossing the straight-line segments or the curved segments of the third segment and the second segment, and during a laser scanning welding process, blowing a protection gas to the welding point. According to a speciallyedited point-shaped welding graph, a thin slice is welded through a single-pulse superposition track manner, multiple small molten pools are formed in the thin slice material, and the welding point with a large tensile force is obtained.

Owner:WUHAN LINGYUN PHOTOELECTRONICS SYST

Back electrode silver paste for silicon solar cell, and preparation method for back electrode silver paste

InactiveCN106803441AImprove welding tensionNon-conductive material with dispersed conductive materialPhotovoltaic energy generationLithium oxideCopper oxide

The invention discloses a back electrode silver paste for a silicon solar cell, and the silver paste contains the following components by mass percentage: 39%-60% of silver powder, 1%-5% of inorganic glass phase, and 35%-60% of organic carrier. The inorganic glass phase comprises main glass phase and inorganic additives. The main glass phase comprises bismuth oxide, aluminium oxide and silicon oxide. The mass percentages of the components in the main glass phase are as follows: 10%-40% of bismuth oxide, 20%-60% of aluminium oxide and 10%-30% of silicon oxide. At least two of copper oxide, zinc oxide, titanium dioxide, manganese dioxide, antimony oxide, magnesium oxide, stannic oxide, lithium oxide and nickel oxide are selected as the inorganic additives. The invention also provides a preparation method for the back electrode silver paste.

Owner:KANGZHUN ELECTRONICS TECH KUNSHAN +5

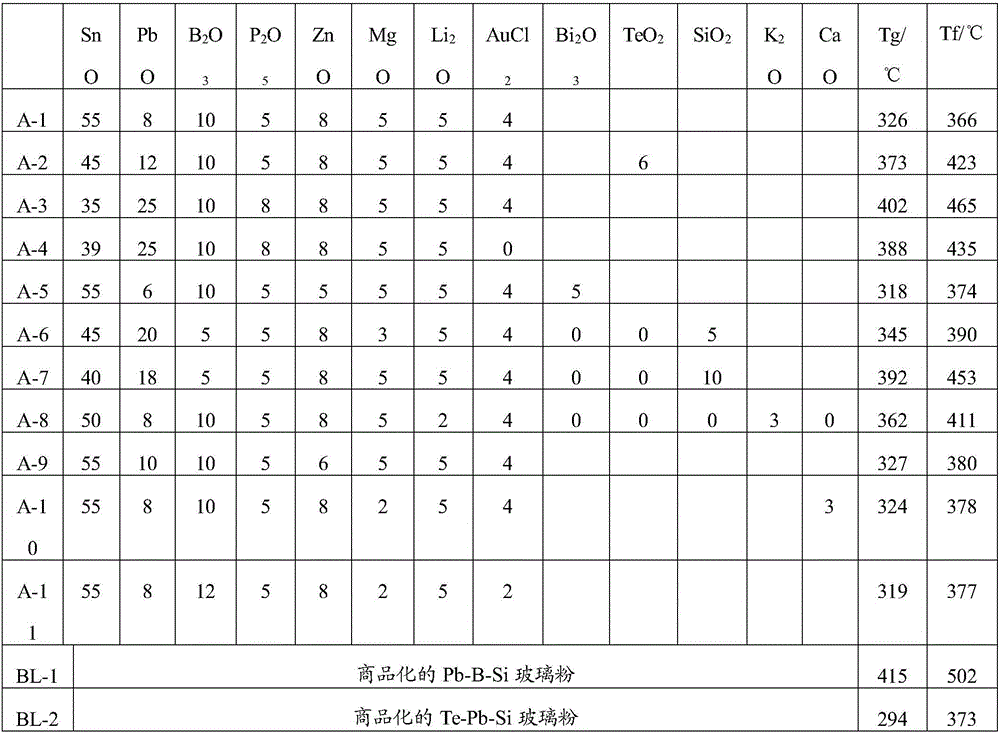

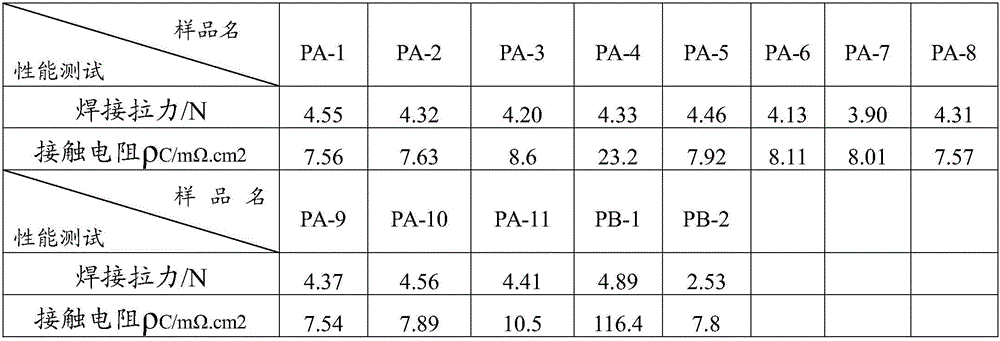

Glass material with low melting point and silver paste prepared from same

ActiveCN105924015AImprove electrical performanceImprove welding tensionNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilver pasteAlkaline earth metal

The invention discloses a glass material with low melting point and a silver paste prepared from the same. The glass material is prepared from the following components: 30-60wt% of SnO, 8-25wt% of PbO or a mixture of PbO and any one of Bi2O3 and TeO2, 10-20wt% of B2O3 or a mixture of B2O3 and SiO2, 5-10wt% of P2O5, 1-10wt% of ZnO, 0-5wt% of one or more alkaline earth metal oxides, 0-5wt% of one or more alkali metal oxide and 0-5wt% of AuCl2. The glass material can be used for preparing a silver paste for silicon solar cell N-type emitting electrodes and improving contact resistance and electrode pull force between a silver electrode and a silicon emitting electrode.

Owner:CHANGZHOU JUHE NEW MATERIAL CO LTD

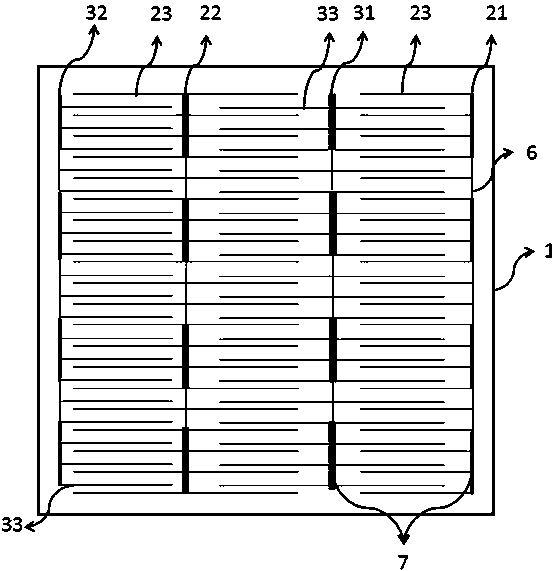

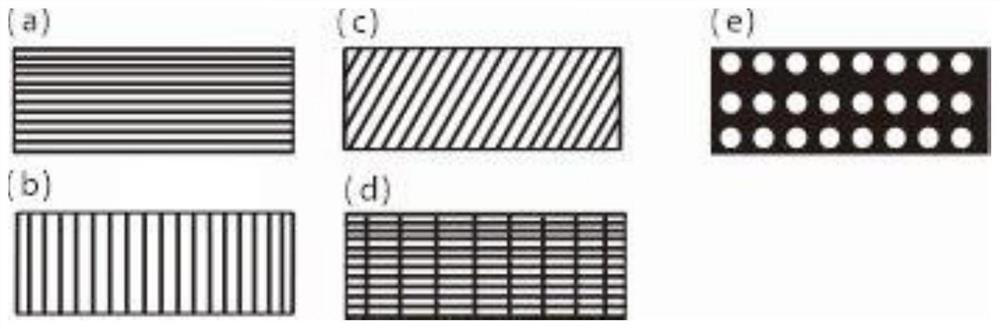

Interdigital electrode for solar battery

ActiveCN104362190AIncrease passivation areaImprove efficiencyPhotovoltaic energy generationSemiconductor devicesElectrical batterySolar battery

The invention discloses an interdigital electrode for a solar battery. The interdigital electrode is disposed on the shady face of a solar cell and composed of a positive pole and a negative pole; each of the positive pole and the negative pole is composed of main grid lines and auxiliary grid lines; the main grid lines are perpendicular to and connected with the auxiliary grid lines; each main grid line is made by connecting more than two thick grid segments though thin grid lines; the auxiliary grid lines of the positive pole and those of the negative pole are mutually parallel and are mutually spaced. The interdigital electrode with the structure has the advantages that current of the solar battery can be guided out in a balanced way, series and parallel connection of the solar batteries is favored, and welding tension of the interdigital electrode on back-contact solar batteries is higher.

Owner:山东力诺阳光电力科技有限公司

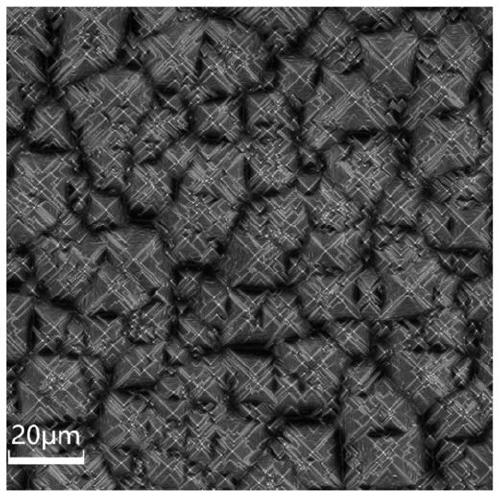

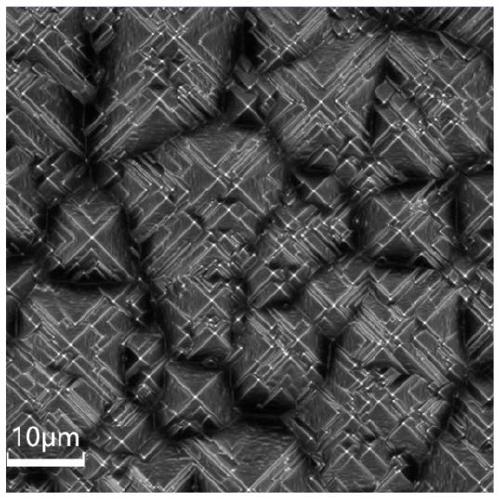

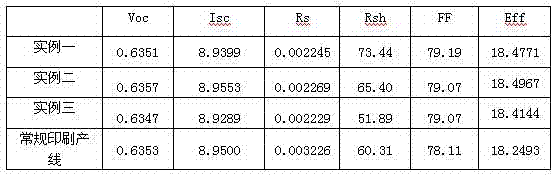

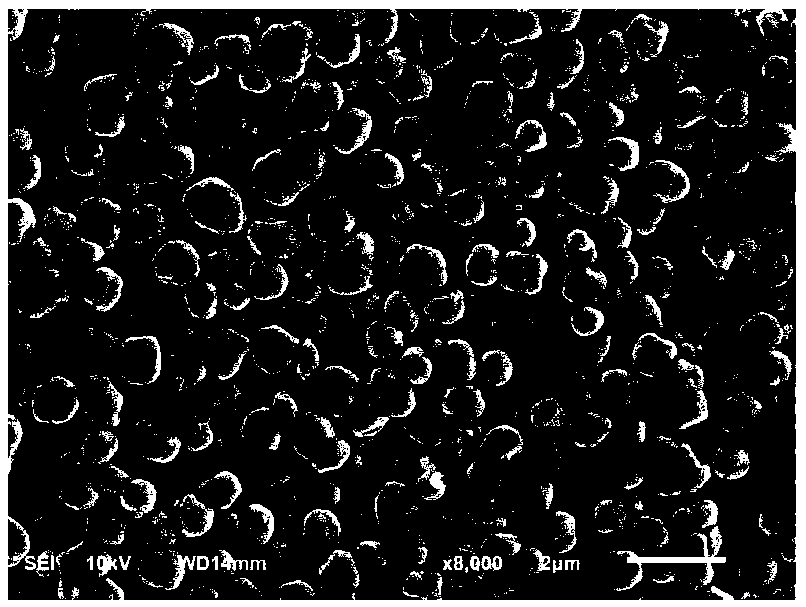

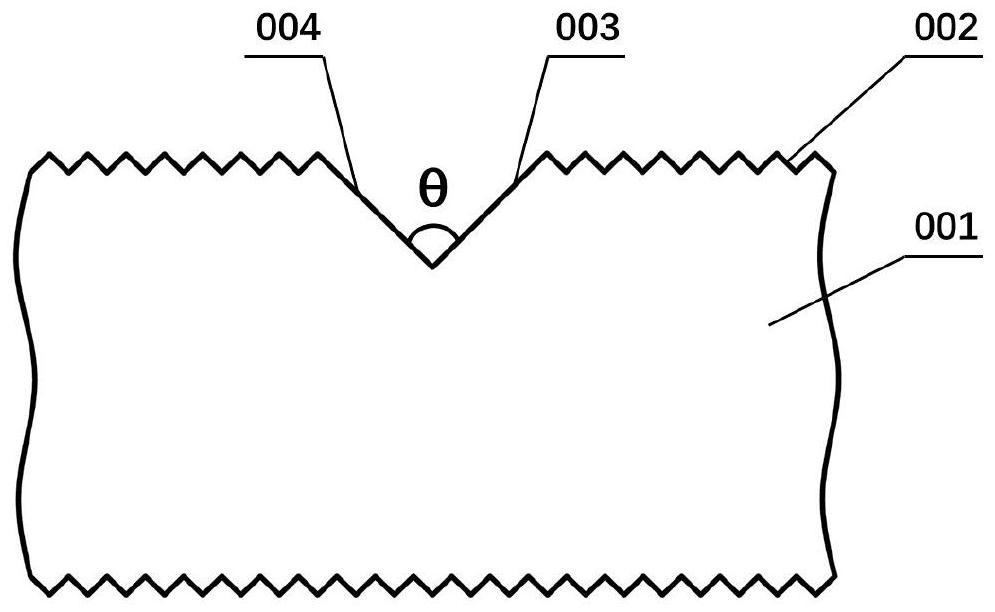

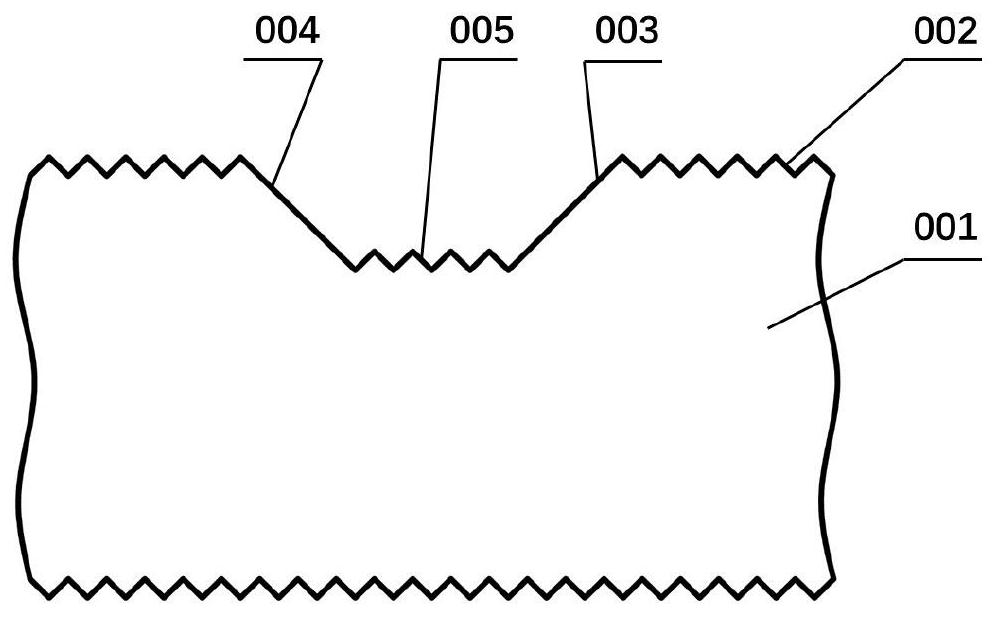

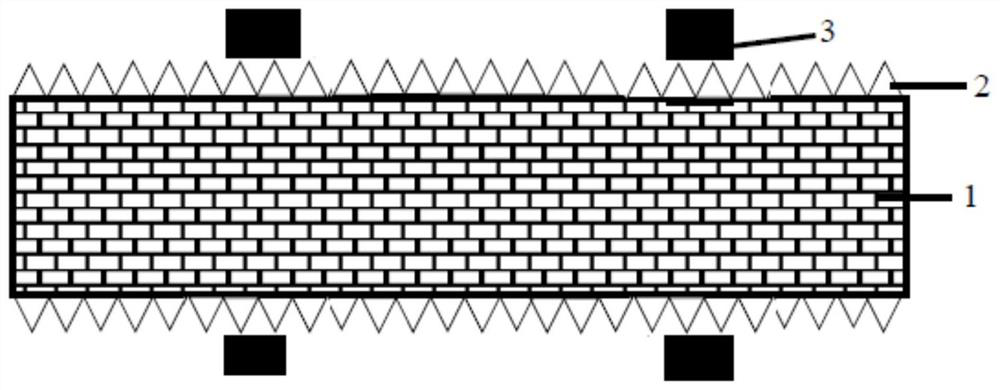

Monocrystalline silicon wafer with pyramid superposition structure and preparation method

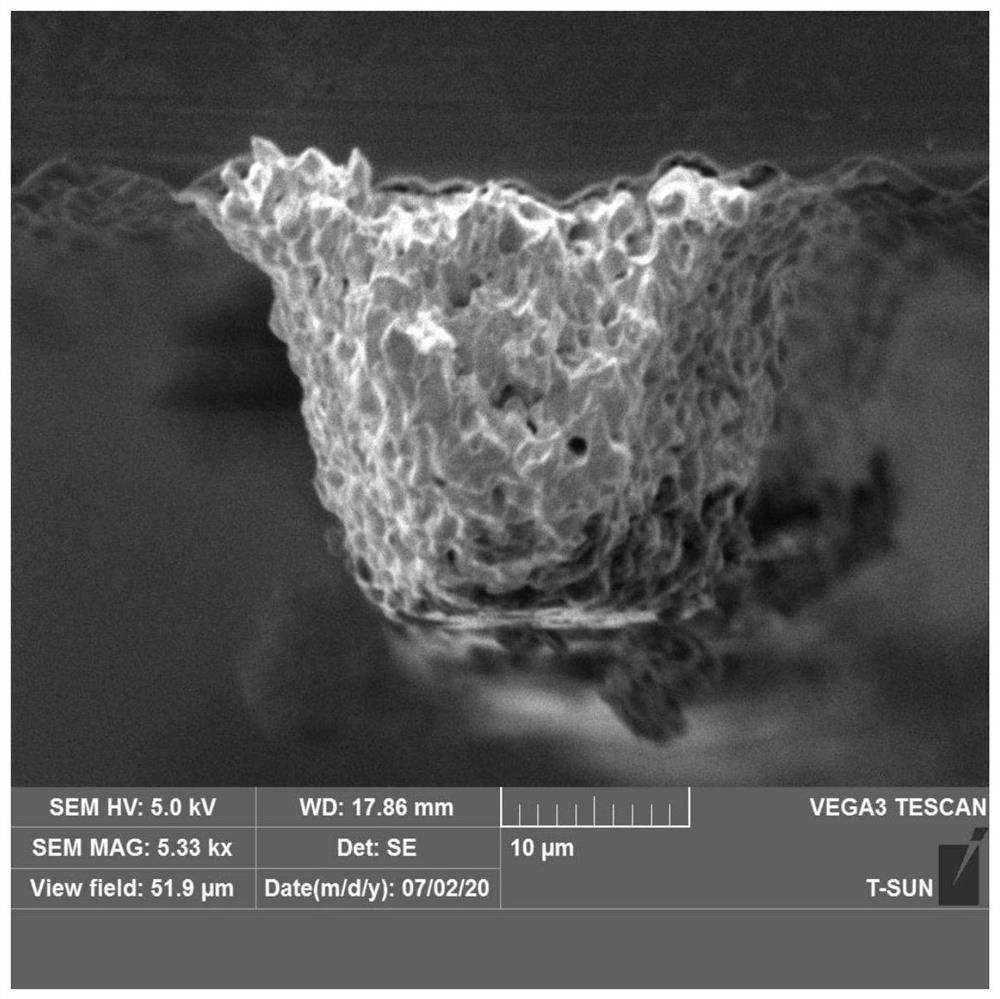

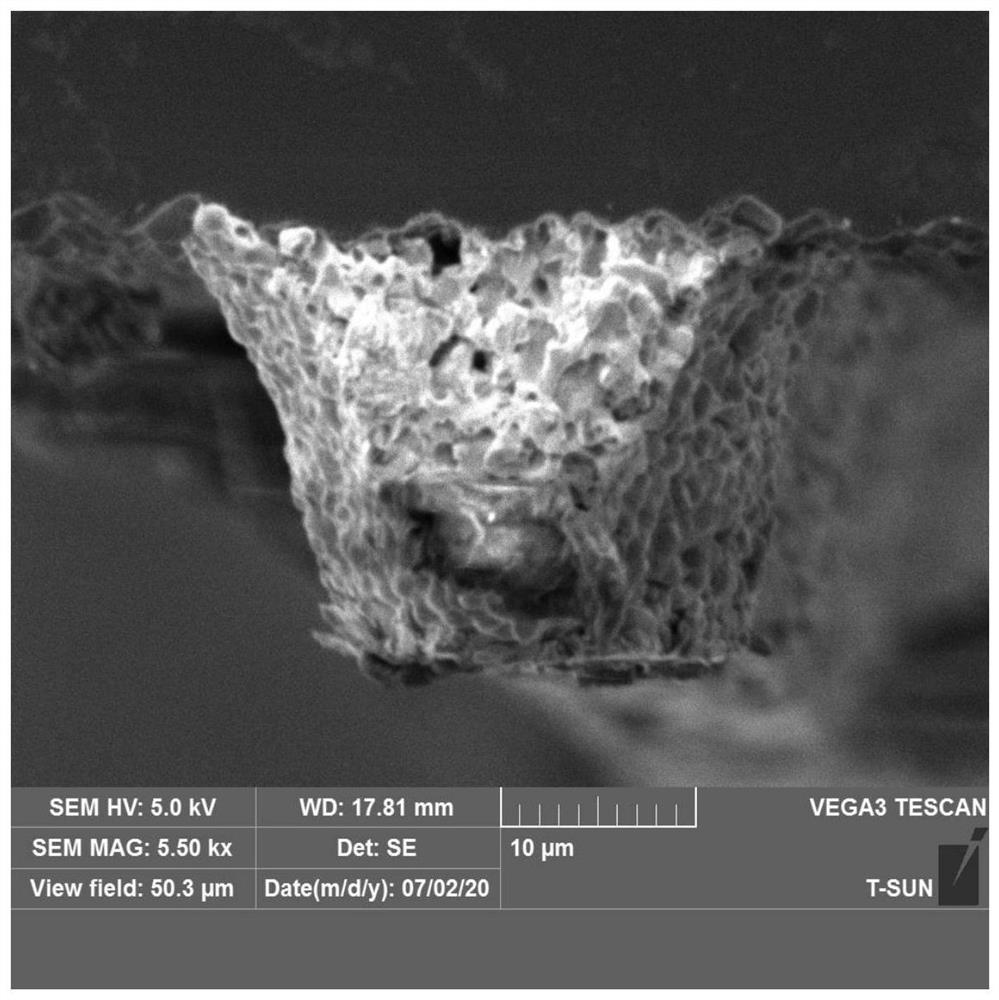

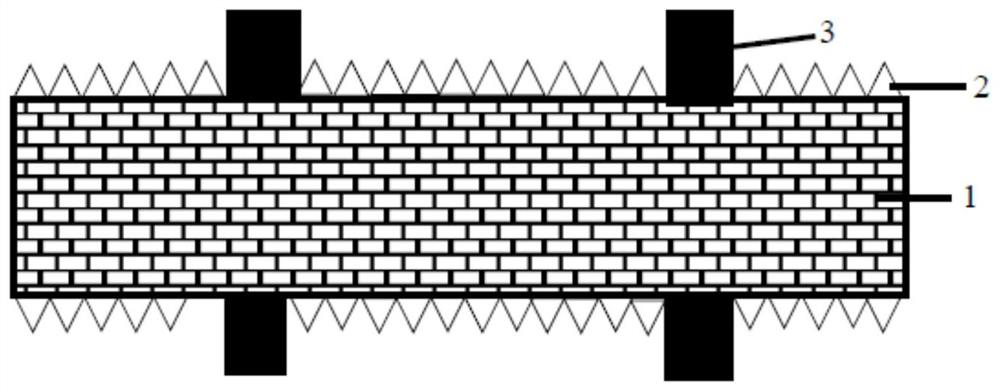

InactiveCN111180538AImprove welding tensionReduce reflectivityFinal product manufacturePhotovoltaic energy generationSingle crystal silicon waferCorrosion

The invention relates to the field of solar cells and discloses a monocrystalline silicon wafer with a pyramid superposition structure and a preparation method. After an original silicon wafer is cleaned through a solution a, anisotropic corrosion is carried out through a solution b to obtain a large pyramid textured surface, and then, secondary texturing is carried out through a solution c, so that a small pyramid textured surface with a smaller size is formed on the original large pyramid textured surface, small pyramids are sequentially stacked on the surface of the large pyramid from top to bottom to form pyramid units; since the pyramid units cover the surface of the silicon wafer and are superposed, the monocrystalline silicon wafer not only has the advantages of good contact betweenthe large pyramid and the conductive grid line and high welding tension, but also has the advantages of low reflectivity of the small pyramid and high short-circuit current. The textured surface of the monocrystalline silicon wafer is of a pyramid superposition structure with different sizes, so that the monocrystalline silicon wafer not only has the advantages of good contact between the large pyramid and the conductive grid line and high welding tension, but also has the advantages of low reflectivity of the small pyramid and high short-circuit current.

Owner:ZHONGWEI NEW ENERGY CHENGDU CO LTD

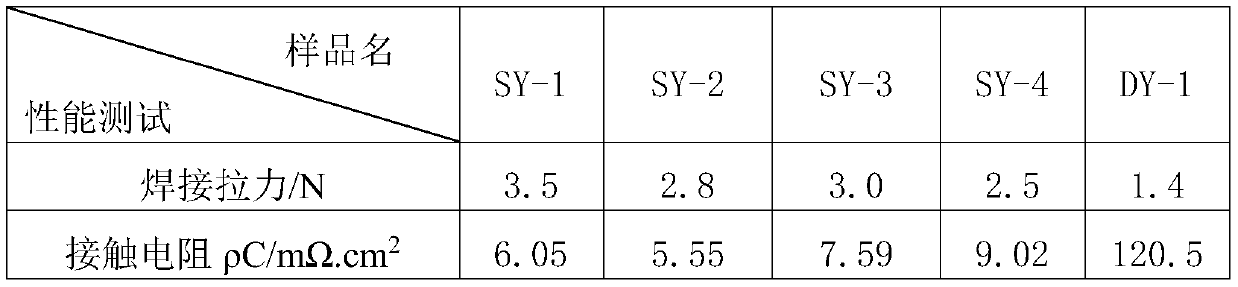

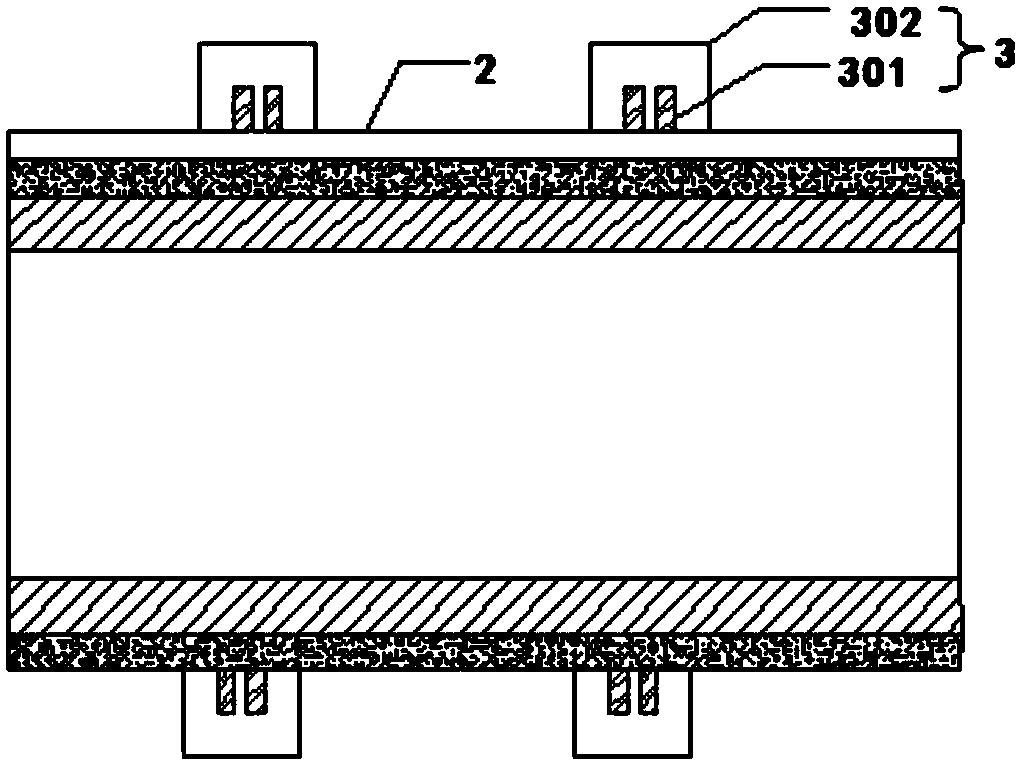

Positive silver paste of crystalline silicon solar cell laminated printing and preparation method thereof

ActiveCN106601328AImprove welding tensionHigh light conversion efficiencyNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteFill factor

The present invention relates to the technical field of solar cells and especially relates to a positive silver paste of crystalline silicon solar cell laminated printing and a preparation method thereof. A first positive silver paste is characterized for first positive silver printing and is formed by, by weight, 75% to 90% of silver powder, 1% to 8% of glass powder, 5 % to 15% of organic carriers 1, 0% to 1.5% of auxiliaries, 0.1% to 3% of adhesion promoters, and balance of solvent. A second positive silver paste is characterized for second positive silver printing and is formed by, by weight, 75% to 90% of silver powder, 1% to 8% of glass powder, 5 % to 15% of organic carriers 2, 0% to 1.5% of auxiliaries, 0.1% to 3% of pulling agent, and balance of solvent. The positive silver paste of crystalline silicon solar cell laminated printing comprises special first positive silver paste and second positive silver paste, the contact resistance of a cell can be reduced, the short circuit current and open circuit voltage are raised, a fill factor is raised, and thus the light conversion efficiency of the cell is improved.

Owner:北京市合众创能光电技术有限公司

Conductive silver paste and preparation method and application thereof

ActiveCN109545424ANot burned throughImprove adhesionNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteSilicon oxide

The invention provides a conductive silver paste and a preparation method and an application thereof. The raw materials of the conductive silver paste include a conductive silver paste base material and an organic silicon compound. There are 0.1-5 parts of the organic silicon compound by weight, and the total mass of the conductive silver paste is 100 parts. The organic silicon compound is used toform a silicon oxide protective layer. The conductive silver paste of the invention can be used to prepare a back electrode and a main gate electrode. The conductive silver paste can improve the bonding strength of a silicon substrate without destroying the passive film of a battery pole piece.

Owner:SUZHOU ISILVER MATERIALS

Photovoltaic module and manufacturing method thereof

PendingCN114765225AImprove welding tensionImprove reliabilitySemiconductor devicesStructural engineeringMechanical engineering

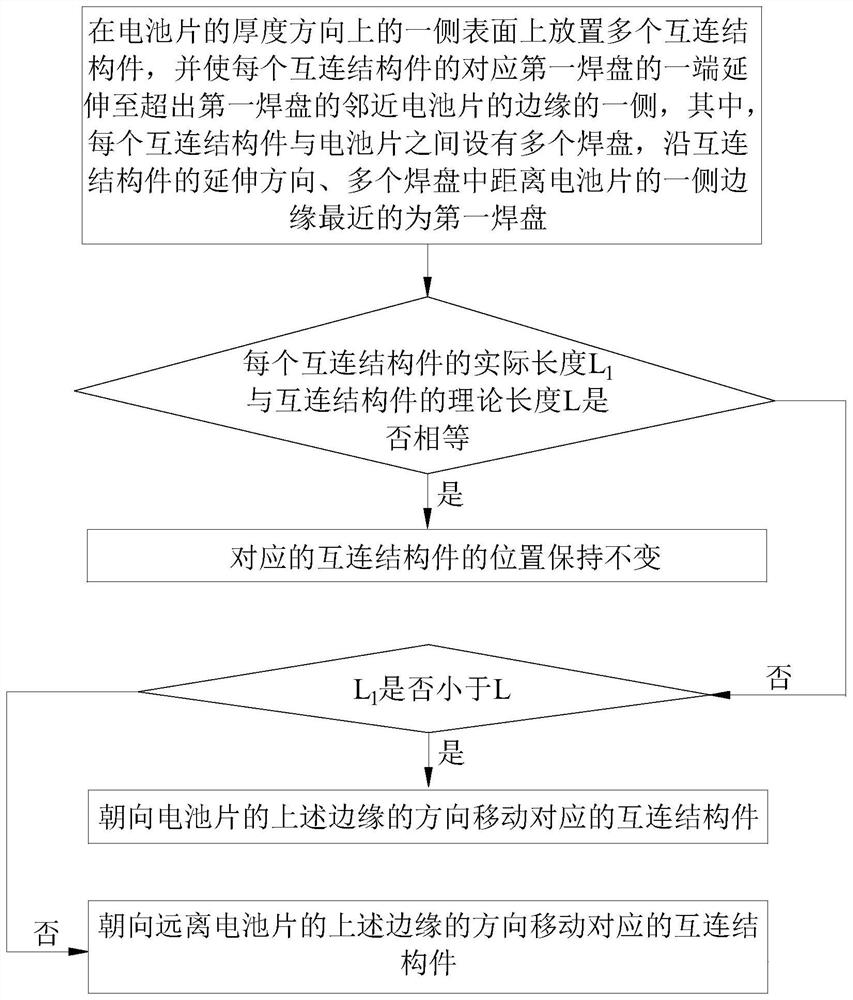

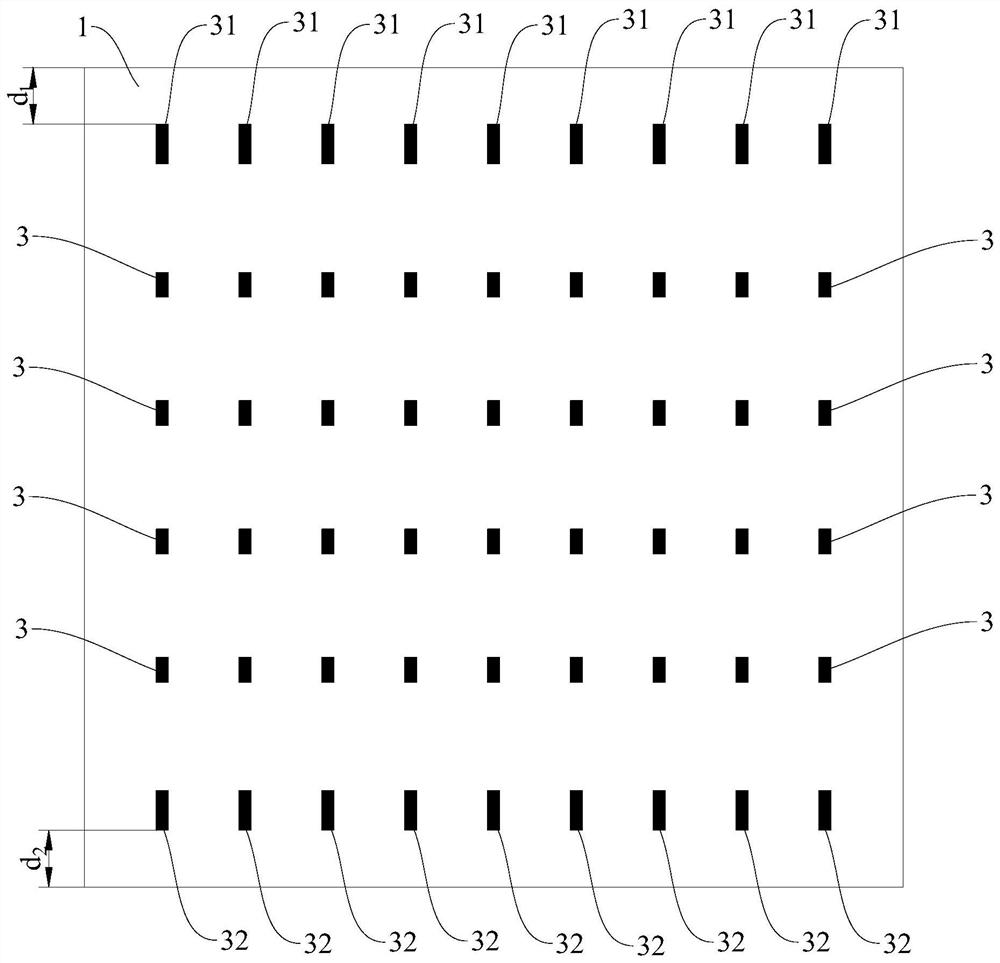

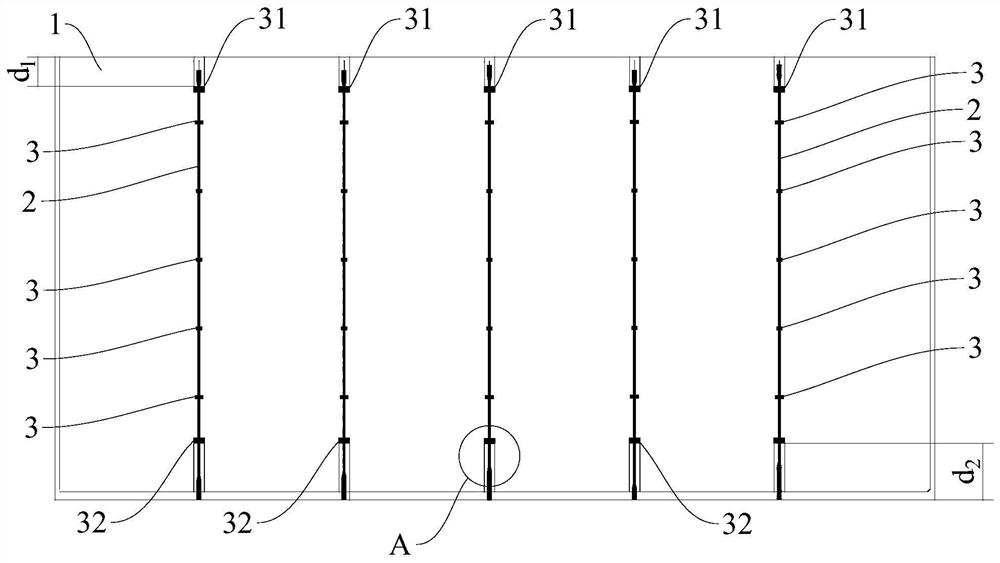

The invention discloses a photovoltaic module and a manufacturing method thereof, and the method comprises the following steps: placing a plurality of interconnection structural members on the surface of one side of a battery piece, enabling one end, corresponding to a first bonding pad, of each interconnection structural member to extend to one side, which exceeds the edge, adjacent to the battery piece, of the first bonding pad, a plurality of bonding pads are arranged between each interconnection structural member and the battery piece, and the bonding pad closest to the edge of one side of the battery piece in the plurality of bonding pads is a first bonding pad; judging whether the actual length L1 of each interconnection structural member is equal to the theoretical length L of the interconnection structural member or not; if L1 is equal to L, keeping the position of the corresponding interconnection structural member unchanged; if L1 is less than L, moving the corresponding interconnection structural member towards the direction of the edge of the battery piece; and if L1 is greater than L, moving the corresponding interconnection structural member towards the direction far away from the edge of the battery piece. According to the manufacturing method of the photovoltaic module provided by the invention, the deviation correction of the interconnected structural member can be realized, and the reliability of the photovoltaic module is improved.

Owner:CSI CELLS CO LTD +1

Frit for crystalline silicon solar cells, preparation method thereof, and silver paste

InactiveCN110590168ALower glass transition temperatureLow softening temperatureNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilver pasteConductive paste

The invention belongs to the technical field of conductive paste, and particularly relates to a frit for crystalline silicon solar cells, a preparation method of the frit, and a silver paste. The fritis prepared from the following components in percentage by mass: 5 to 20wt% of Tl2O3, 5 to 10wt% of PbO, 20 to 30 wt% of TeO2, 5 to 10 wt% of Bi2O3, 5 to 15 wt% of WO3, 0 to 5 wt% of SiO2, 10 to 15 wt% of ZnO and 5 to 15 wt% of alkali metal oxide R2O. The frit provided by the invention is used for preparing front silver paste suitable for crystalline silicon solar cells, so that the silver pasteis provided with excellent electrical properties and welding tension.

Owner:四川东树新材料有限公司

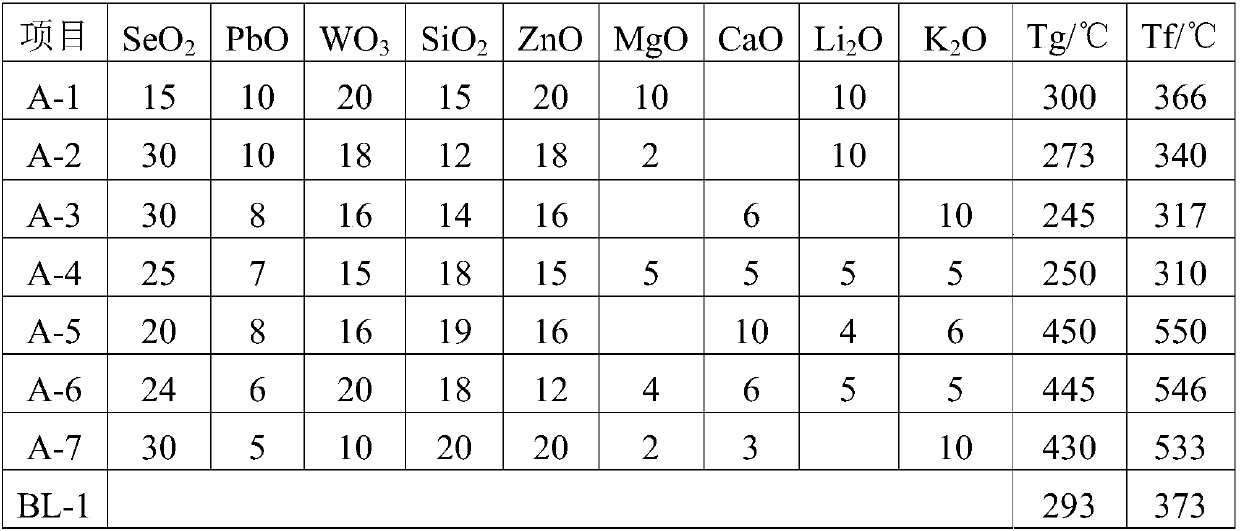

Glass material for high-sheet-resistance shallow crystallized silicon solar cell as well as preparation method and slurry thereof

ActiveCN107759093AReduce the temperatureLow softening temperatureNon-conductive material with dispersed conductive materialPhotovoltaic energy generationAlkaline earth metalSilicon solar cell

The invention discloses a glass material for a high-sheet-resistance shallow crystallized silicon solar cell. The glass material is prepared from the following raw materials: 10 weight percent to 30 weight percent of SeO2, 5 weight percent to 10 weight percent of PbO, 10 weight percent to 20 weight percent of WO3, 10 weight percent to 20 weight percent of SiO2, 10 weight percent to 20 weight percent of ZnO, 0 weight percent to 10 weight percent of alkaline earth metal oxide RO and 0 weight percent to 10 weight percent to alkaline earth metal oxide R2O. The invention further discloses a preparation method of the glass material, slurry prepared from the glass material and a preparation method of the slurry. The glass material disclosed by the invention is a Se-Pb-Si-W-Zn oxide system; the glass system has low glass transition temperature and softening temperature and has a relatively good wetting property on silver and silicon; the glass system is applied to a high-sheet-resistance shallow crystallized silicon wafer so that contact resistance is easy to improve; the glass material also has a very good wetting capability on silver powder and can be firmly combined with the silicon wafer, so that the welding pulling force of a silver electrode is improved.

Owner:CHANGZHOU JUHE NEW MATERIAL CO LTD

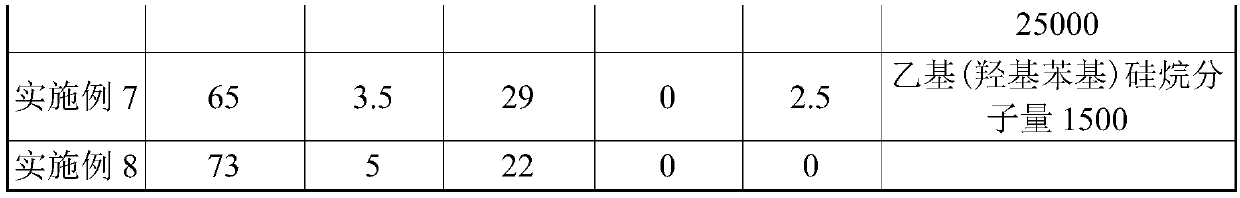

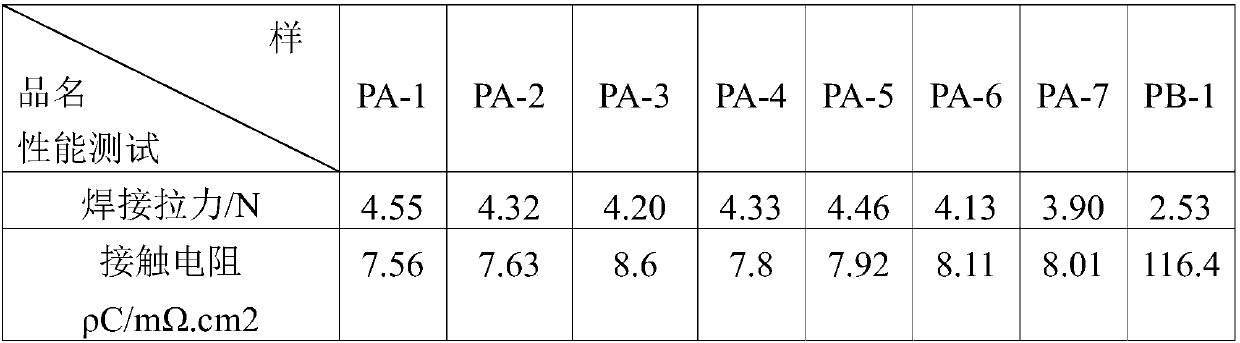

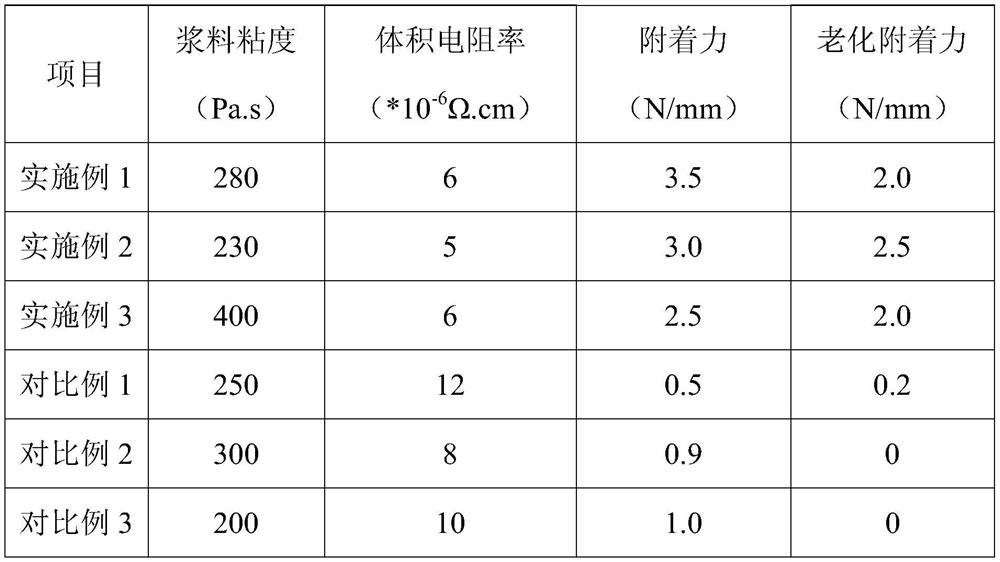

High-welding-tension main grid low-temperature silver paste for solar heterojunction battery and preparation method of high-welding-tension main grid low-temperature silver paste

ActiveCN112562885AImprove welding reliabilityImprove welding tensionNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilver pasteOrganic solvent

The invention provides high-welding-tension main grid low-temperature silver paste for a solar heterojunction battery and a preparation method of the high-welding-tension main grid low-temperature silver paste, which aim to overcome the related technical defects that the main grid silver paste in the field is relatively low in welding tension, relatively poor in weldability, relatively high in volume resistivity or relatively poor in printability after being cured, and almost zero in aging tension under certain conditions at present. The silver paste comprises low-melting-point flake silver powder, high-sintering-activity spherical silver powder, low-melting-point alloy powder, an organic bonding phase, an inorganic bonding phase, an organic solvent and a leveling agent, and is prepared through premixing, temperature control, stirring and grinding, so that the low-temperature silver paste which is high in basic welding tension, good in aging tension, high in weldability after being cured and is especially suitable for preparing the main gate electrode of the heterojunction battery is obtained, and the welding reliability of the heterojunction battery assembly is greatly improved.

Owner:四川东树新材料有限公司

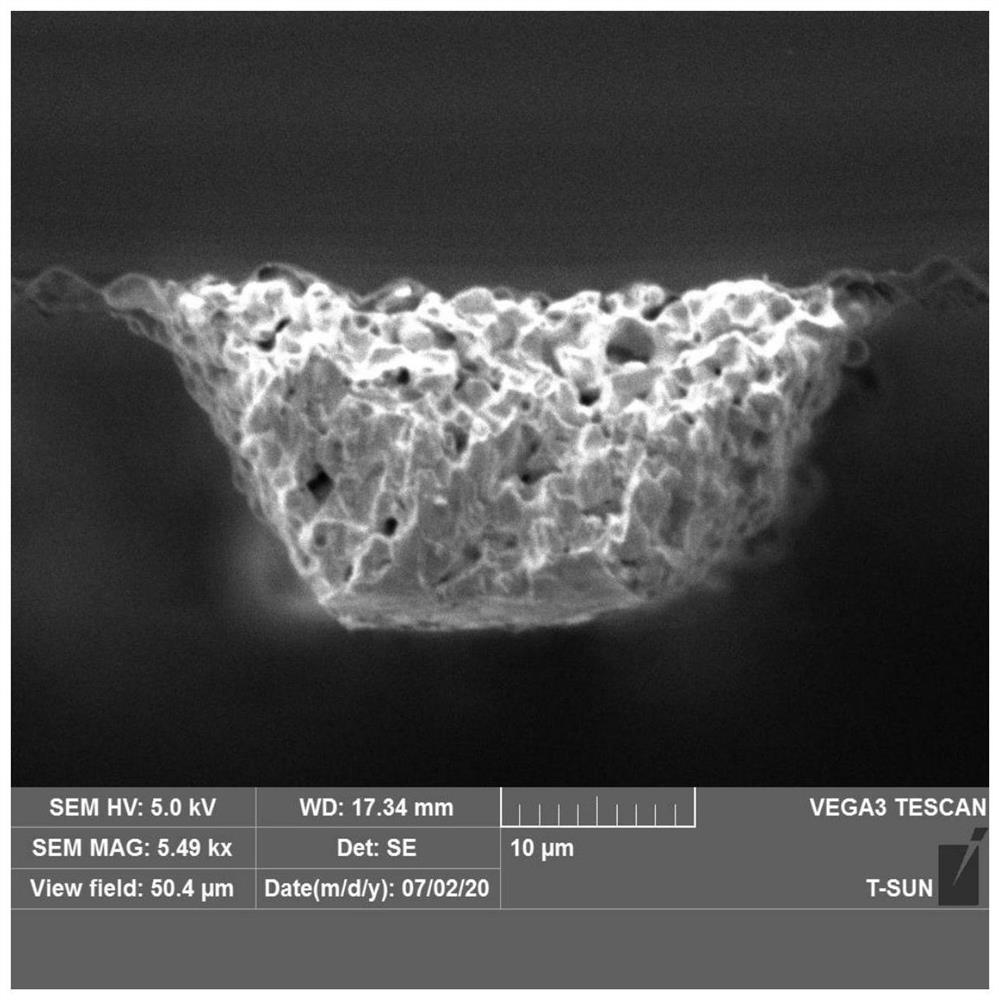

High-tension main grid silver paste applied to N-type solar cell and preparation method thereof

ActiveCN111863309AImprove photoelectric conversion efficiencyImprove welding tensionNon-conductive material with dispersed conductive materialPhotovoltaic energy generationAcrylic resinPolyvinyl alcohol

The invention discloses high-tension main grid silver paste applied to an N-type solar cell and a preparation method thereof. The high-tension main grid silver paste applied to the N-type solar cell is prepared from silver powder (the value particle size is 700-900nm, the tap density of the spherical silver powder A is 5-6 g / mL, the median particle size of the spherical silver powder A is 280-450nm, and the tap density is a mixture of 4-5 g / mL spherical silver powder B), an organic carrier (a mixture of 3-5 wt% polyvinyl butyral ester resin and 5-10 wt% acrylic resin as main resin) and glasspowder (the median particle size is 0.7-1 [mu]m, and the copper-bismuth-manganese-tellurium series glass powder with the softening temperature of 600-800 DEG C) through mixing. The formula system canenable the silver paste to be good in adhesion with the surface of the n-type silicon wafer after sintering, enables the welding tension of the silver paste to be large, enables the welding tension ofa front main grid line to be 4N or above, is good in compactness of the paste, and is high in photoelectric conversion efficiency.

Owner:NANTONG T SUN NEW ENERGY CO LTD

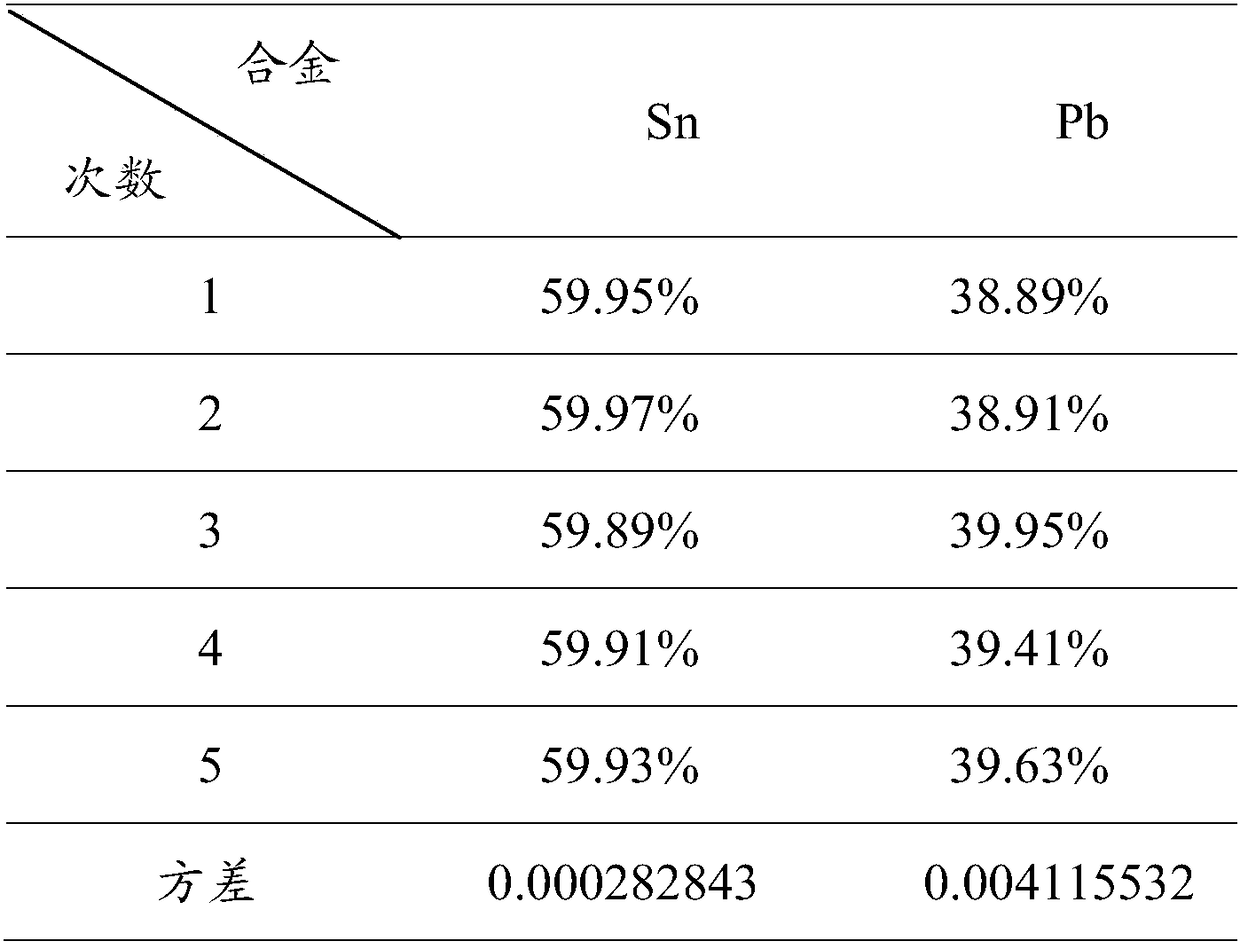

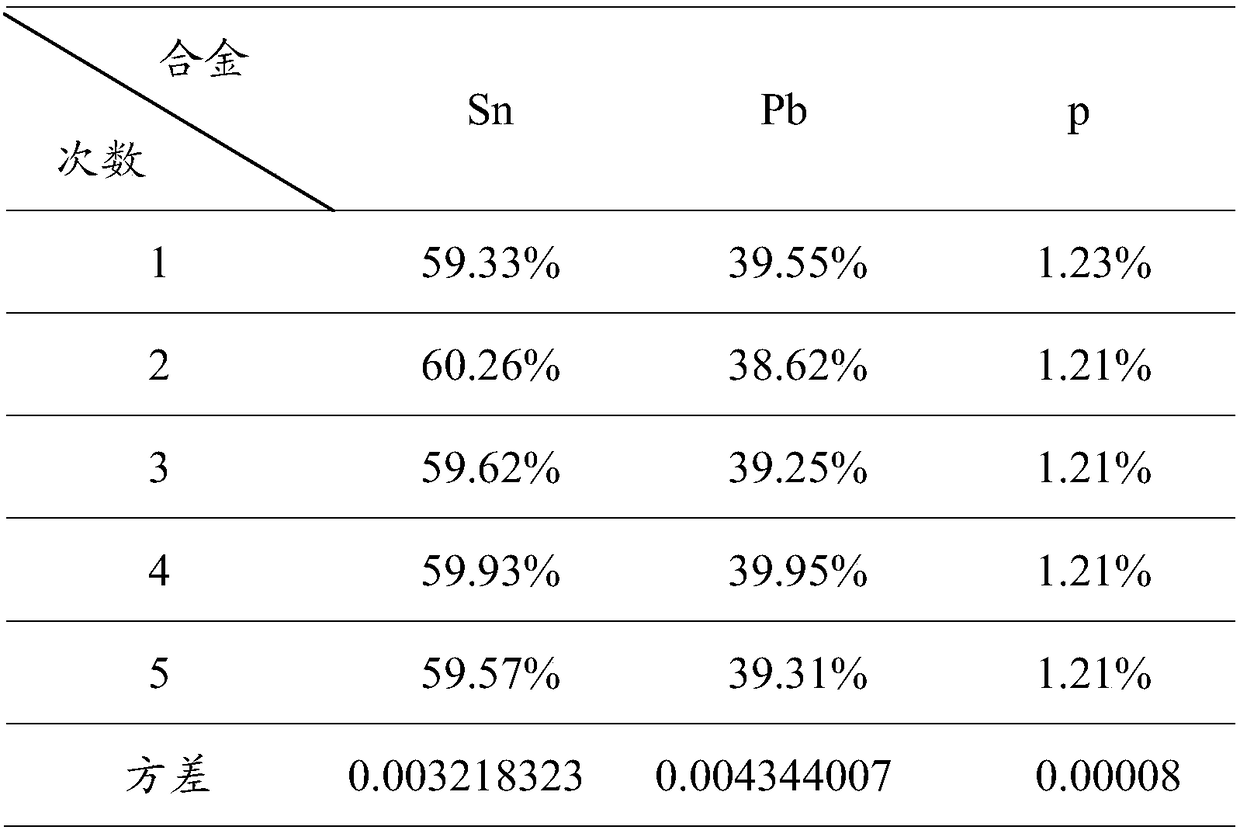

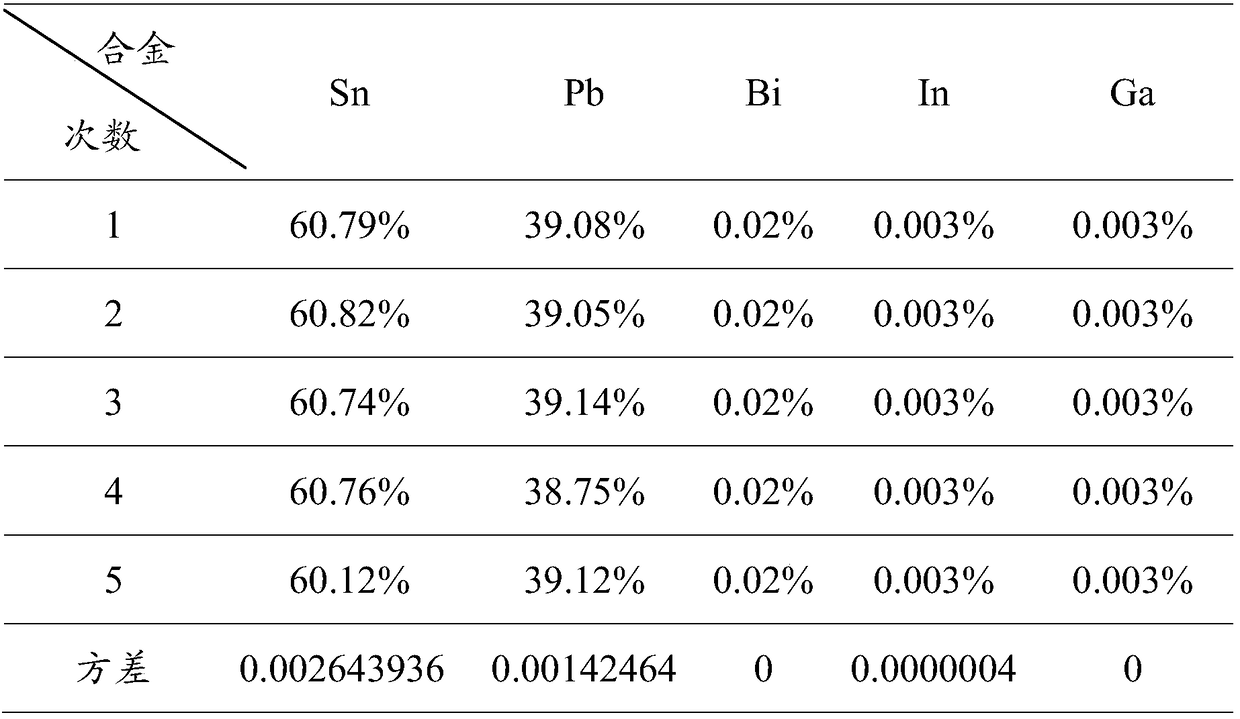

Photovoltaic welding strip alloy solder and preparation method thereof

ActiveCN108555472ALow melting pointImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaTinningEnvironmental resistance

The invention provides photovoltaic welding strip alloy solder and a preparation method thereof. The raw material of the photovoltaic welding strip alloy solder comprises tin-lead alloy, bismuth, indium, phosphorus, cerium, neodymium and germanium. According to the photovoltaic welding strip alloy solder, the bismuth, indium, neodymium, cerium, germanium, gallium, phosphorus and copper are added into the tin-lead alloy, the melting point of the photovoltaic welding strip alloy solder is effectively reduced, the oxidation resistance, welding tension, expansion rate and fluidity of the photovoltaic welding strip alloy solder are improved, and the generation of slag soil is reduced. According to the photovoltaic welding strip alloy solder, the yield of tin products is improved, the productivity of hot tinning products is improved, the wettability of tin plating solution is improved, and other physical and mechanical properties of tin plating products are not affected; and the preparationmethod is simple, the cost is low, the daily maintenance and curing of an existing equipment are not affected, the environmental protection requirements are met, and the working environment of the production site is not affected.

Owner:XIAN TELISON NEW MATERIAL

Front silver paste for crystalline silicon solar cell and preparation method and application thereof

ActiveCN109119181AImprove welding tensionMeet the pull demandFinal product manufactureNon-conductive material with dispersed conductive materialSilver pasteSilver electrode

The invention discloses front silver paste for a crystalline silicon solar cell, and a preparation method and application thereof. The front silver paste for crystalline silicon solar cell includes anorganic carrier, an organic auxiliary agent, glass powder and silver powder, wherein the raw material of the glass powder comprises TeO2, an adhesion additive, Bi2O3, MgO, Ag2O and ZnO, and optionally includes one or more of Al2O3, ZrO2, R2O, PtO2 and MoO; the adhesion additive is one or more selected from oxides of Si, P, B or Ge; and R2O is one or more selected from oxides or salts of Li, Na orK. The preparation method of the front silver paste for a crystalline silicon solar cell includes the steps: weighing each component according to the formula, mixing the components, grinding the mixture until the particle size of the paste is less than 5 mu m, and controlling the viscosity of the paste, thus completing preparation. The invention also relates to an application for preparation of the passivation crystalline silicon solar cell. The front silver paste for a crystalline silicon solar cell can realize high welding adhesion between a front silver electrode and a welding strip whilemaximizing the electrical performance of the solar cell, and the cell pack has a long service life.

Owner:苏州博望新能源科技有限公司

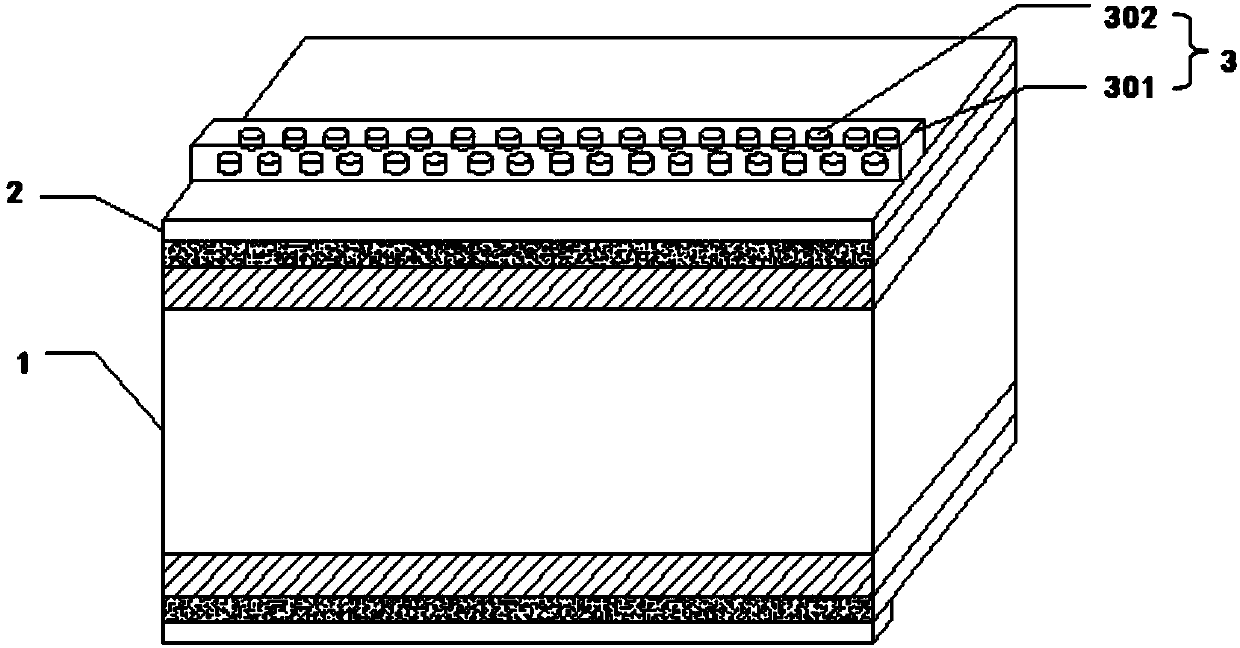

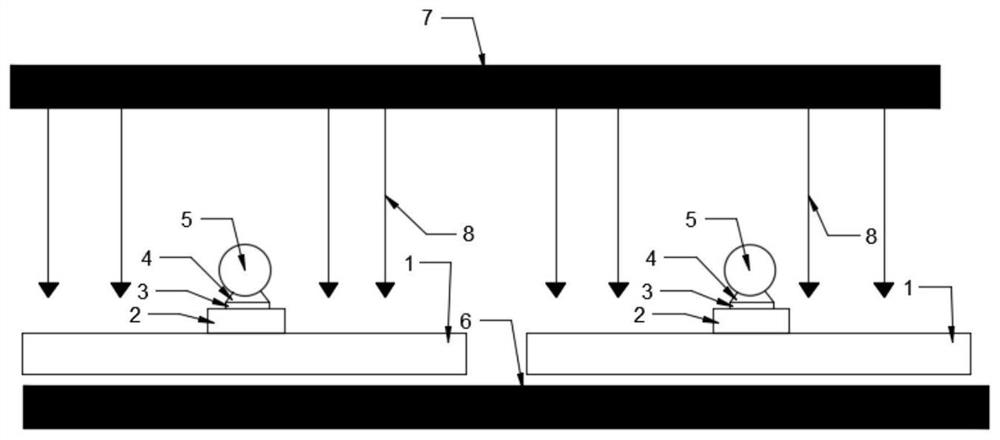

Method for manufacturing electrode of HIT solar cell

InactiveCN108054222ASave metal pasteImprove welding tensionPhotovoltaic energy generationSemiconductor devicesSizingEngineering

The invention discloses a method for manufacturing an electrode of an HIT solar cell. The method includes a silicon wafer used for manufacturing the solar cell, a layer of transparent conductive oxidation film is deposited on the surface of the silicon wafer, and the specific manufacturing process is as follows: first a punctiform sizing agent A is printed in an area of main grids and fine grids for manufacturing the electrode on the reverse side of the silicon wafer for manufacturing an electrode; then a sizing agent B is printed above the sizing agent A; afterwards, the steps of S1 and S2 are repeated on the front side of the silicon wafer; and finally, the silicon wafer is put in a curing oven of 100 DEG C to 200 DEG C to be cured for 20 to 40 min. Through the method provided by the invention, metal sizing agents required for manufacturing the electrode can be greatly saved, and welding tension of the electrode can be improved at the same time.

Owner:南通苏民新能源科技有限公司

Welding method for solar cells and interconnectors

The invention discloses a welding method for solar cells and interconnectors, which is firm in welding and has no cold solder joints. Firstly spraying scaling powder on a main grid line of a cell and the front faces and rear faces of interconnectors, and then welding the interconnectors on the main grid line of the cell through an automatic welding machine. The welding method for the solar cells and the interconnectors has the advantages of enabling the scaling powder to be simultaneously sprayed on the cell and the interconnectors, well solving the contacting problem between the cell and the interconnectors, and enabling power loss of the cell to be reduced. Moreover, requirements of the automatic welding machine on interconnector performance and cell main grid line size can be lowered, Welding tension can be increased, and accordingly zero cold solder joints can be achieved. The welding method for the solar cells and interconnectors aims at increasing use ratio of the cells.

Owner:SUZHOU AIKANG PHOTOELECTRIC TECH CO LTD

Conductive slurry for photovoltaic battery back electrode

ActiveCN103915128ALow costImprove competitivenessNon-conductive material with dispersed conductive materialSemiconductor devicesSolventMicrometer

The invention discloses conductive slurry for a photovoltaic battery back electrode. The conductive slurry comprises, by mass, 50% to 55% of silver powder, 12% to 20% of complexing agent containing zinc, 2% to 3% of lead-free glass powder, and 30% to 32% of organic binding phase. The grain size of the silver powder ranges from 1 micrometer to 3 micrometers. The complexing agent containing zinc is a mixture formed by zinc powder and an organic zinc addition agent, wherein the grain size of the zinc powder ranges from 0.5 micrometer to 4 micrometers, and the weight part ratio of the zinc powder to the organic zinc addition agent is 4: 0.1 to 4: 1. The organic binding phase is organic binding formed by dissolving ethyecellulose into a component solvent composed of butyl carbitol acetic ester and terpineol. The weight part ratio of ethyecellulose to butyl carbitol acetic ester to terpineol is 1: 5: 4. The organic zinc addition agent is zinc methacrylate. The conductive slurry maintains the existing technical performance, the cost of the conductive slurry is greatly reduced, and therefore competitiveness of a silicon crystal solar battery is improved.

Owner:SUZHOU ISILVER MATERIALS

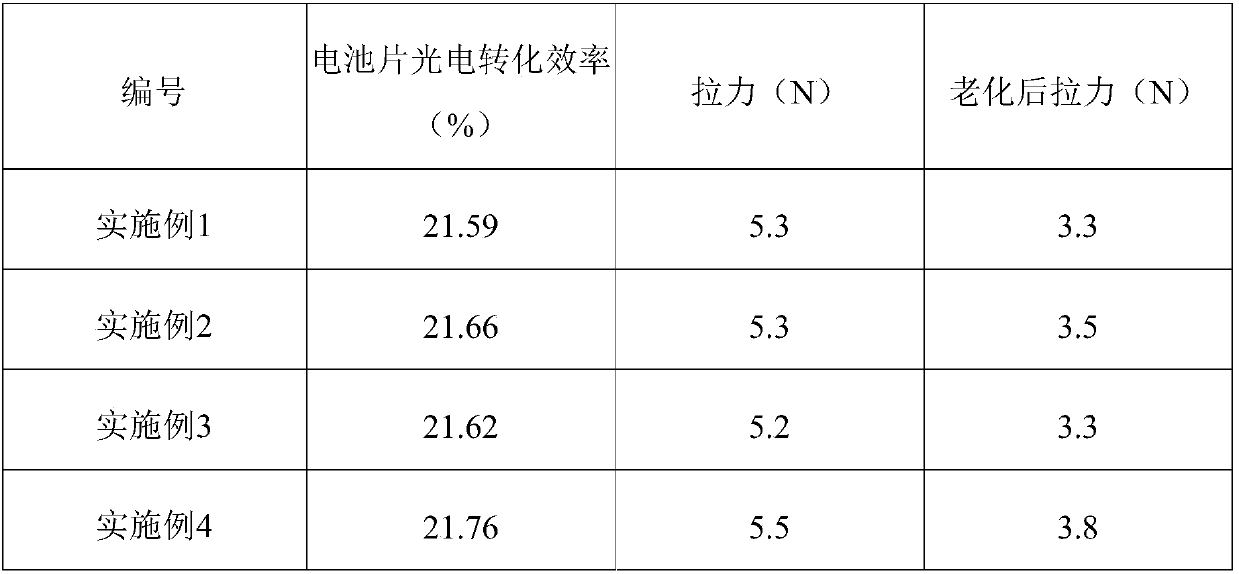

Crystalline silicon solar cell positive silver paste and preparation method therefor

InactiveCN107316674AImprove welding tensionImprove stabilityNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteCrystalline silicon

The invention relates to the technical field of an electronic material, and particularly relates to crystalline silicon solar cell positive silver paste and a preparation method therefor. The crystalline silicon solar cell positive silver paste comprises the following components based on mass percentages: 1-90% of silver powder, 5-15% of organic carrier, 1-8% of glass powder, 0-3% of auxiliaries, and 0.02-0.1% of sintering inhibitor, wherein the sum of the contents of the components is equal to 100%; the sintering inhibitor is one or several kinds of metals or metal oxides or metal resinate selected from Co, Ru, Rh, Pd, W, Re, Os, Ir or PT; and the paste is also added with metals or metal oxides or metal resinate, so that certain problems caused by paste shrinkage in the sintering process of the paste can be solved, and shortcomings generated in the sintering process can be avoided.

Owner:北京市合众创能光电技术有限公司

A preparation method and application of a back electrode of a solar cell

ActiveCN109004043ALow costReduce unit consumptionPhotovoltaic energy generationElectrically-conductive paintsSilver pastePull force

The invention discloses a preparation method and application of a back electrode of a solar cell, which comprises two parts, a back electrode barrier layer and a back silver paste. 20 to 80 part of metal nitride powder, nitrogen-silicon compound powder, oxide powder or low-melting-point metal powder, 0.5 to 5 parts of lead-free glass powder, 10 to 40 parts of organic carrier and 0.1 to 1 part of organic assistant. 10-80 part of silver powder, 0. 5-5 parts of lead-free glass powder, 15-50 parts of organic bind and 0. 01-1 part of organic assistant. The present invention ensures that it has considerable welding pulling force and aging pulling force, avoids serious electric leakage problem caused by metal defects caused by direct contact between silver and silicon wafer or aluminum paste, improves photoelectric conversion efficiency of crystalline silicon battery, adjusts back electrode width and printed pattern, and reduces back electrode paste cost.

Owner:NANTONG T SUN NEW ENERGY CO LTD

Electrocondution slurry for back electrode of solar battery

ActiveCN103871541ALow costReduce silver contentNon-conductive material with dispersed conductive materialSemiconductor devicesMetallurgyAmorphous silicon

The invention discloses electrocondution slurry for a back electrode of a solar battery. The electrocondution slurry consists of the following materials according to mass percentage composition: 30-40 % of silver powder, 25 % of zinciferous complexing agent, 1-2 % of unleaded glass dust, and 44-50 % of organic binding phase, wherein the grain diameter of the silver powder is 0.5-1 micron; the zinciferous complexing agent is a mixture which is formed by zinc powder with the grain diameter of 0.5-4 microns and zinc stearate according to a part by weight proportion of 4:0.1-1; the organic binding phase is organic cementation which is formed by dissolving ethyl cellulose into a mixed solvent which is formed by butyl carbitol acetic ester and terpineol; the part by weight proportion of the ethyl cellulose, the butyl carbitol acetic ester and the terpineol is 1:5:4. According to the electrocondution slurry for the back electrode of the solar battery, the existing technical feature is kept, the cost of the electrocondution slurry is greatly reduced, and the competitive power of the amorphous silicon solar battery is thus promoted.

Owner:SUZHOU ISILVER MATERIALS

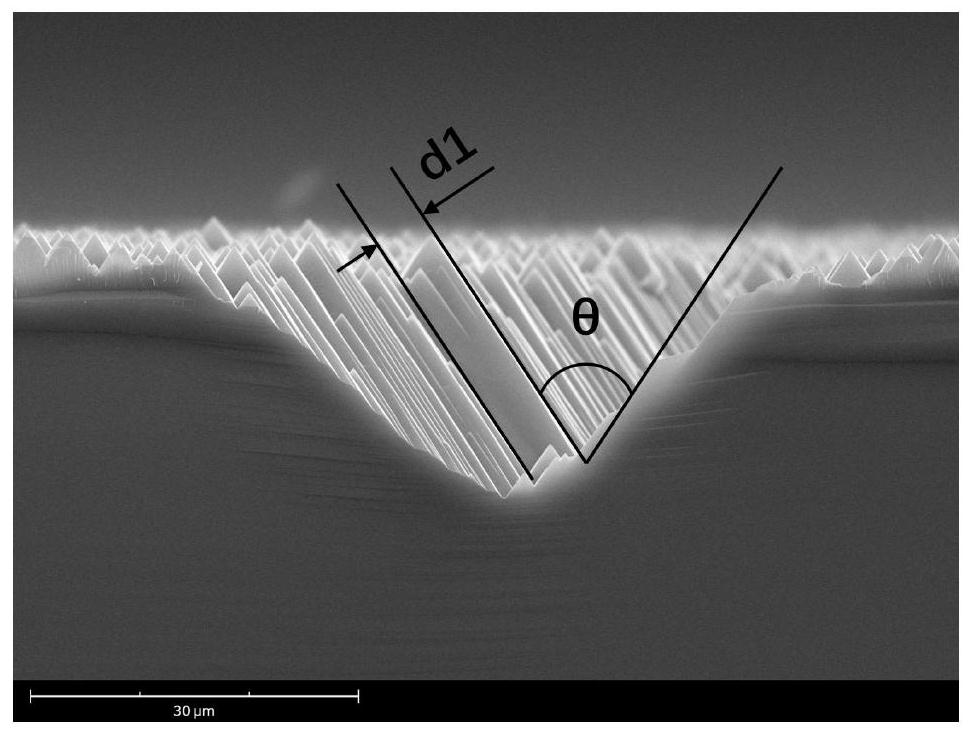

Monocrystalline silicon wafer with grooves in surface, heterojunction solar cell and preparation method

ActiveCN113327999AReduce consumptionRealize efficiency improvement and cost reductionFinal product manufacturePhotovoltaic energy generationHeterojunctionSilver paste

The invention provides a monocrystalline silicon wafer with grooves in the surface, a heterojunction solar cell and a preparation method. Grooves are formed in the front face and the back face of the silicon wafer, the depth of each groove ranges from 5 micrometers to 50 micrometers, the width of each groove ranges from 10 micrometers to 100 micrometers, the internal morphology of each groove comprises one or two of a step shape and a pyramid shape, the surface morphology of the monocrystalline silicon wafer outside the grooves comprises a pyramid shape, and the surfaces of the steps and the pyramid correspond to the crystal face (111) of the silicon crystal. The distance between adjacent step edges on the same inclined plane is 0.1-10 [mu]m, and the height of the pyramid is 0.1-10 [mu]m. When the method is used for preparing the heterojunction solar cell, the contact area of the grid line and the transparent conductive film can be increased, the filling factor FF of the solar cell and the welding tension of the electrode can be improved, the shading area of the grid line can be reduced, and the short-circuit current Isc can be obviously improved; meanwhile, consumption of silver paste can be reduced, and efficiency improvement and cost reduction of the solar cell are achieved. In addition, the conductive performance of the silver paste and the speed of silk-screen printing are improved, so that the productivity of equipment is improved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

High-density film for solar battery back sheet

InactiveCN109728114AGood heat resistanceExtend leveling timePhotovoltaic energy generationSemiconductor devicesPolyvinylidene fluorideButyl methacrylate

The invention relates to the technical field of new energy sources, in particular to a high-density film for a solar battery back sheet. The high-density film for a solar battery back sheet comprisesthe components as follows: 5-10 parts of butyl rubber, 20-32 parts of polyvinylidene fluoride PVDF, 10-15 parts of methacrylate-butyl methacrylate copolymer, 4-10 parts of dipropylene glycol, 1-10 parts of methyl isobutyl ketone, 5-10 parts of silver paste, 5-15 parts of silica, 5-8 parts of polyetherimide, 1-9 parts of dimethylamino methylphenol, 5-10 parts of carboxymethylcellulose, 2-5 parts ofpolytrimethyldihydroquinoline, 0.2-1.0 parts of antioxidant DLTP, 2-8 parts of hindered amine light stabilizer and 0.5-1.5 parts of dioctyl ester. The silver paste includes terpineol, butyl diglycolacetate and tributyl citrate in a ratio of 2:2:3. The high-density film for a solar battery back sheet is resistant to heat, resistant to aging, good in water vapor resistance effect, high in weldingtension and good in photoelectric performance.

Owner:CHANGZHOU HUITIAN NEW MATERIALS

Conductive paste for back electrode in crystalline silicon solar cell

ActiveCN102693771ALow costReduce silver contentNon-conductive material with dispersed conductive materialSemiconductor devicesConductive pasteSolvent

The invention discloses a conductive paste for a back electrode in a crystalline silicon solar cell. The conductive paste consists of the following materials by mass percent: 30-60%of silver powder, 1-25%of zinc-containing complexing agent, 1-5% of lead-free glass powder and 25-50% of organic bonding phase, wherein the particle size of the silver powder is 0.5 to 4 mu m; the zinc-containing complexing agent is a mixture formed by zinc powder with the particle size of 0.5 to 4 mu m and an organic zinc additive according to a mass ratio of 4:(0.1-1); the organic bonding phase is an organic bonding phase formed by dissolving ethyl cellulose into a mixed solvent consisting of butyl carbitol acetate and terpineol; and the ratio of weight parts of the ethyl cellulose, the butyl carbitol acetate and the terpineol is 1:5:4. With the adoption of the conductive paste, the performance of the prior art is kept, and the cost of the conductive paste is greatly reduced, so that the competitiveness of the crystalline silicon solar cell is improved.

Owner:SUZHOU ISILVER MATERIALS

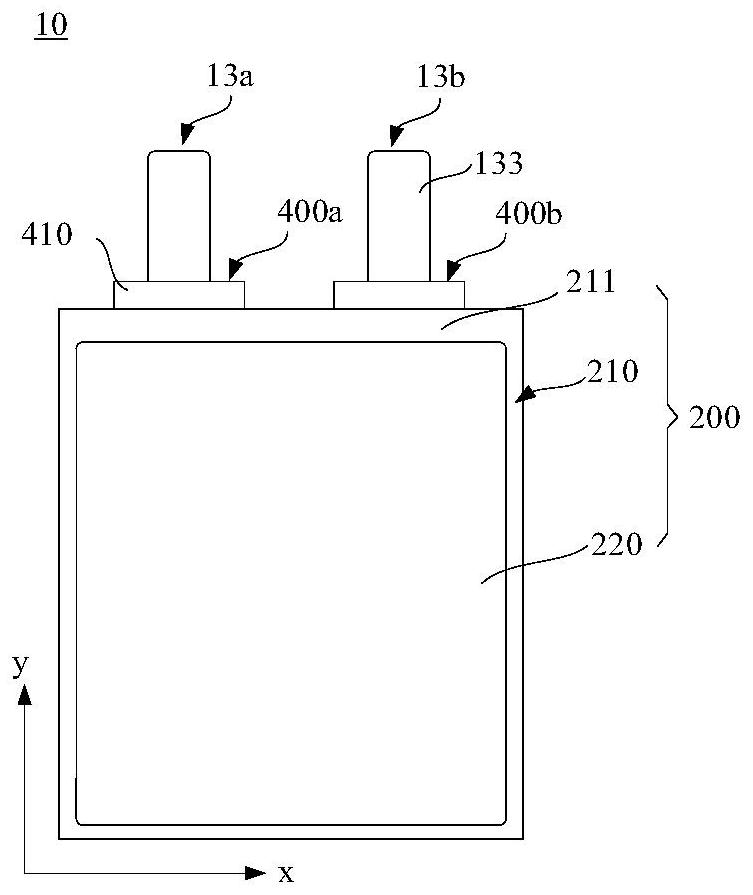

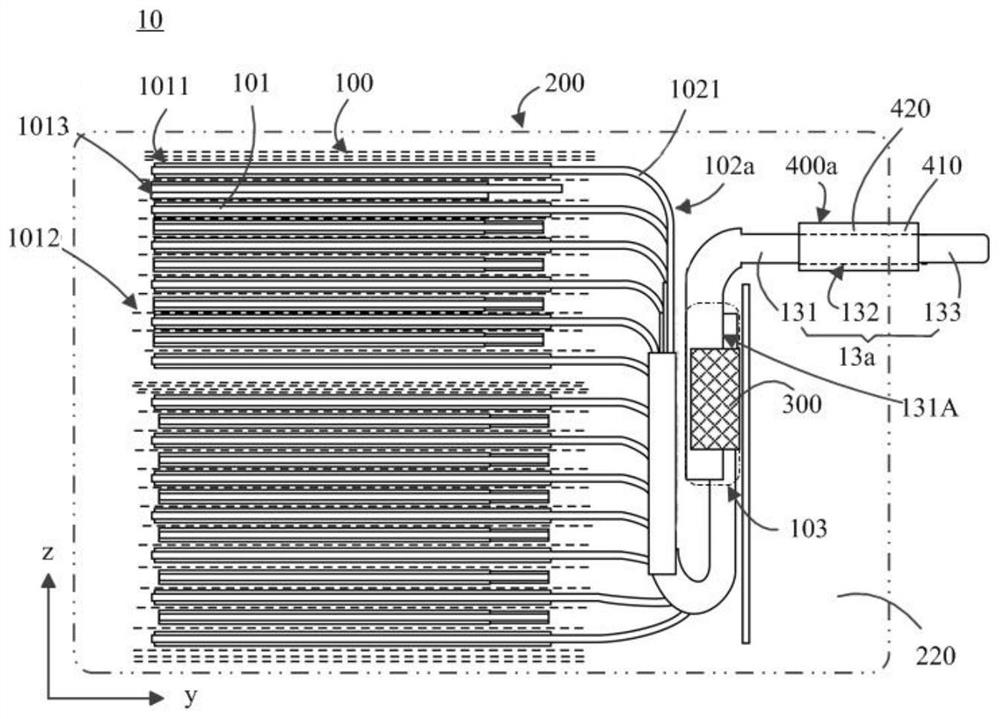

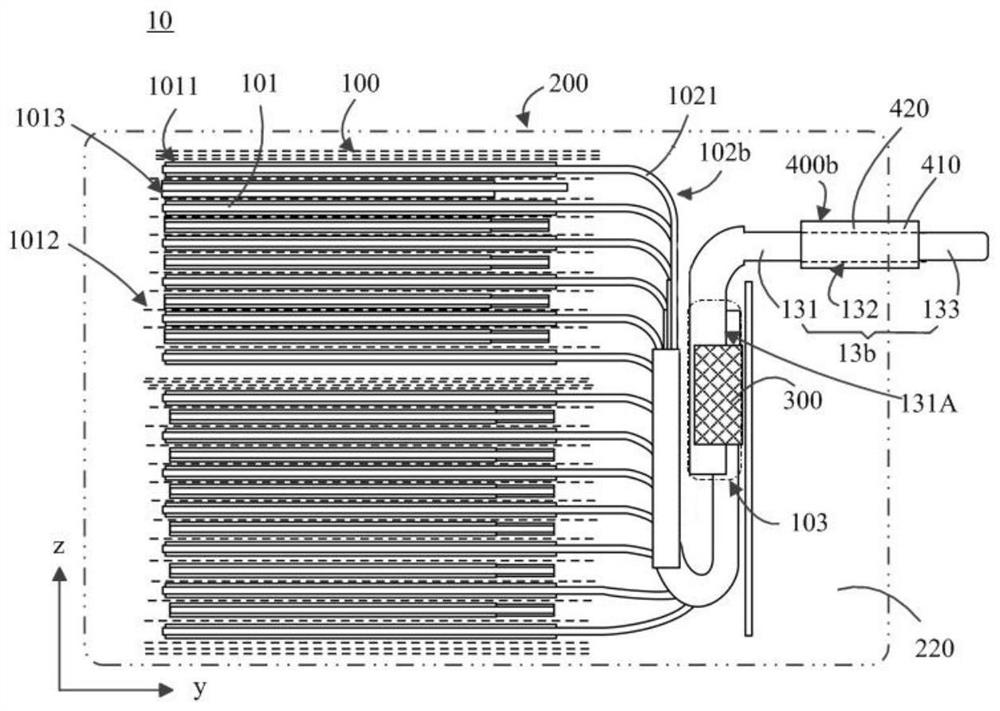

Electrochemical device and electronic device comprising same

ActiveCN113972448AImprove package reliabilityImprove bindingFinal product manufactureSecondary cellsPhysical chemistrySurface roughness

The embodiment of the invention provides an electrochemical device and an electronic device comprising the same. In the electrochemical device, a first area is arranged on a first surface, facing a welding printing area, of a first part, and the surface roughness F1ZS of the first area is smaller than the surface roughness F3S of a third part, so that the surface of the first area is smoother. Therefore, the welding energy transmitted to the first sealing part is reduced, the integration and wettability between the first sealing part and the first adapter are improved, the risk of a liquid leakage channel is reduced, and then the liquid leakage risk caused by the existence of the liquid leakage channel after the sealing area of the electrochemical device is sealed is reduced, and the packaging reliability of the electrochemical device is effectively improved.

Owner:DONGGUAN POWERAMP TECH LTD

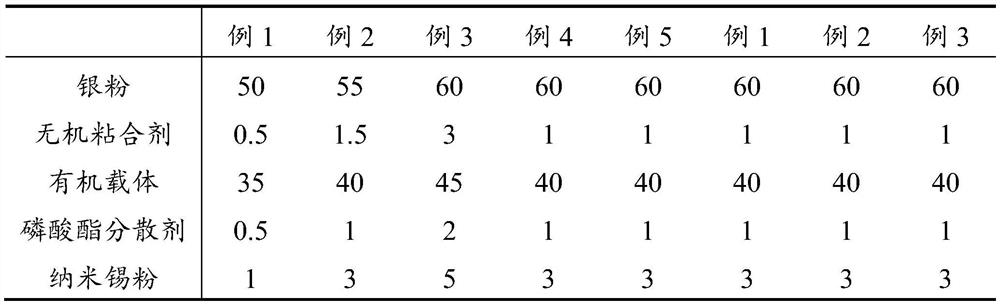

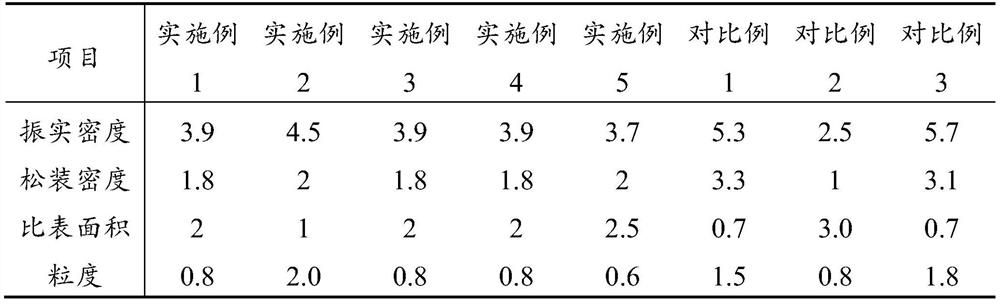

PERC crystalline silicon solar cell back silver paste and preparation method and application thereof

InactiveCN112216421AImprove welding tensionControl tap densityNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilver pasteAdhesive

The invention discloses PERC crystalline silicon solar cell back silver paste and a preparation method and application thereof, and belongs to the technical field of solar cells. The silver paste is prepared from silver powder, an inorganic adhesive, an organic carrier, a dispersing agent and an auxiliary agent, the tap density of the silver powder is 3-5 g / m < 3 >, the apparent density of the silver powder is 1.5-3 g / m < 3 >, the specific surface area of the silver powder is 1-2.5 m < 2 > / g, and the particle size of the silver powder is 0.5-2 micron. A crystalline silicon solar cell using thesilver paste on the back surface has relatively high welding tension and photoelectric conversion efficiency, and the silver paste is suitable for practical application.

Owner:GUANGZHOU RUXING TECH DEV +1

Photovoltaic module main grid structure and preparation method and application thereof

PendingCN114566555AUniform tensionTemperature controlPhotovoltaic energy generationSemiconductor devicesElectrical batteryEngineering

The invention provides a main grid structure of a photovoltaic module and a preparation method and application thereof, the main grid structure of the photovoltaic module comprises a main grid and at least two bonding pads arranged on the main grid at intervals, and the areas of the bonding pads are sequentially increased from low temperature to high temperature. According to the invention, the areas of the bonding pads in the main grid structure are different, so that the problem of inconsistent welding tension caused by non-uniform heating of the bonding pads in the welding process is effectively improved, and the welding tension of the battery is effectively improved.

Owner:TRINA SOLAR CO LTD

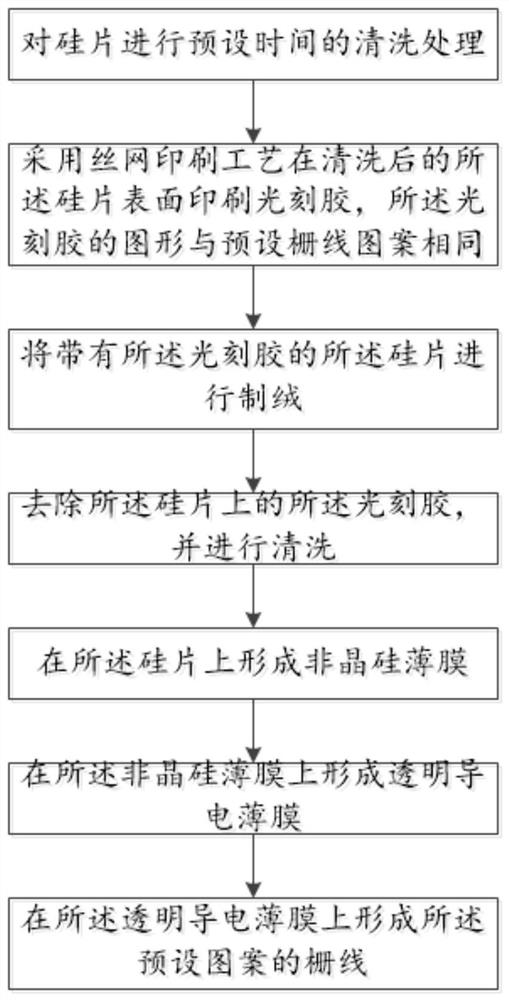

Heterojunction solar cell and preparation method thereof

PendingCN113421943AIncrease contactReduce wideningAfter-treatment detailsFinal product manufactureHeterojunctionEngineering

The invention provides a preparation method of a heterojunction solar cell, belongs to the technical field of a solar cell processing method, and at least partially solves the problem that the use efficiency of the solar cell is low due to the fact that silver paste cannot be in good contact with the bottom of a suede when the silver paste is printed in the prior art. The preparation method comprises the following steps: cleaning a silicon wafer for a preset time; printing photoresist on the surface of the cleaned silicon wafer by adopting a silk-screen printing process, wherein the pattern of the photoresist is the same as a preset grid line pattern; texturing the silicon wafer with the photoresist; removing the photoresist on the silicon wafer, and cleaning; forming an amorphous silicon film on the silicon wafer; forming a transparent conductive film on the amorphous silicon film; and forming a grid line of the preset pattern on the transparent conductive film. According to the processing scheme, the use efficiency of the heterojunction solar cell is improved.

Owner:宣城睿晖宣晟企业管理中心合伙企业(有限合伙)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com