Frit for crystalline silicon solar cells, preparation method thereof, and silver paste

A technology of solar cells and glass frit, applied in conductive materials, circuits, photovoltaic power generation and other directions dispersed in non-conductive inorganic materials, can solve the problems of large shading loss, excessive loss, reducing the shading area of electrodes, etc., reaching the glass transition temperature Low, improve the contact resistance, improve the effect of welding tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the glass frit for crystalline silicon solar cells is prepared by high-temperature melting and quenching method or sol-gel method.

[0030] The high-temperature melting and quenching method includes the following steps: taking the raw materials of each component, mixing them, and then melting them at a temperature of 1100-1300° C. for 30-80 minutes. After the melting, quenching the glass melt, Finally, it is pulverized and dried to obtain glass frit.

[0031] Preferably, the mixing can be carried out by using a three-dimensional mixer; stirring is carried out during the melting process for further homogenization.

[0032] Wherein, quenching adopts deionized water quenching or iron plate quenching.

[0033] Preferably, the crushing is carried out by planetary ball mill ball milling.

[0034]The present invention also provides a silver paste prepared by using the glass frit for crystalline silicon solar cells.

[0035] The silver paste is prep...

Embodiment 1

[0041] Embodiment 1 Preparation of glass frit for crystalline silicon solar cells

[0042] Take the raw materials according to the components in Table 1, mix and homogenize the raw materials with a three-dimensional mixer, then transfer them to an alumina crucible, and melt them at 1300°C for 60 minutes, stirring during the melting process; after the melting, The glass melt is quenched with deionized water, and finally ball milled and dried using a planetary ball mill to obtain powdered glass frits S1-S4 with a particle size distribution D50≤5 μm.

[0043] The glass transition temperature Tg and glass softening temperature Tf of the prepared powdered glass frits S1-S4 and commercially available glass frits were tested, and the results are shown in Table 1.

[0044] Table 1

[0045]

Embodiment 2

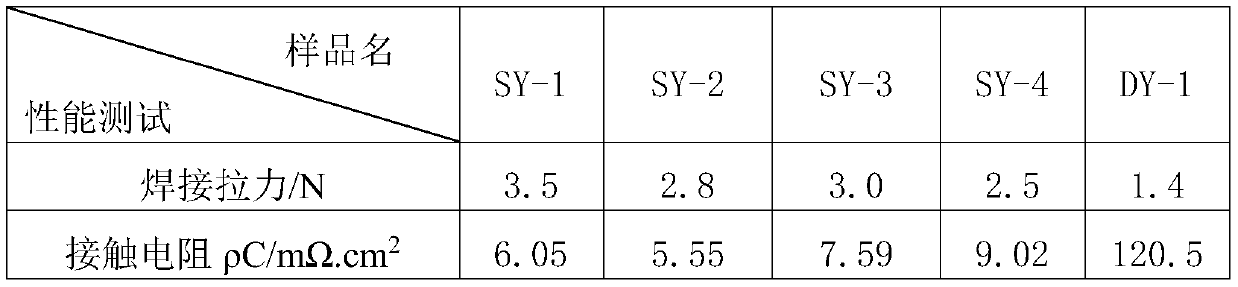

[0047] The glass frits of S1-S4 and D1 were respectively prepared according to the following methods to obtain SY1-SY4 and DY1 silver paste coatings.

[0048] Preparation method: fully mix 86.5wt% conductive silver powder, 2.5wt% glass frit, and 11wt% organic vehicle, use a three-roll mill to grind the slurry, use a scraper fineness agent to test the grinding fineness, and the slurry The grinding fineness is below 10μm to make silver paste. Among them, the number of silver paste paint made by using S1 glass frit is SY1, the number of silver paste paint made by using S2 glass frit is SY2, and the number of silver paste paint made by using S3 glass frit is SY3, which is made by using S4 glass frit The number of the silver paste coating is SY4, and the number of the silver paste coating made of D1 glass frit is DY1.

[0049] Wherein, the organic carrier is a mixture of ethyl cellulose, wood rosin, dibutyl phthalate and butyl carbitol acetate in a mass percentage of 1:1:5:4.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com