Crystalline silicon solar cell positive silver paste and preparation method therefor

A technology of solar cells and silver paste, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve problems such as microcracks and increased contact resistance, and achieve improved service life and improved Welding tension, the effect of high welding tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

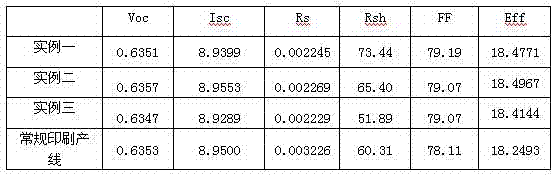

Examples

Embodiment 1

[0020] The composition and weight percent of the positive silver conductive paste in this embodiment: 80% silver powder, 3% glass powder, 6% organic vehicle, Co 2 o 3 0.02%, Pd 2 S 3 0.01%, BYK110 0.2%, and the rest is solvent, in which the particle size of silver powder is 1-3.5 microns, and the tap density is 4-6g / m 3 The spherical silver powder; the glass powder is PbO-TeO 2 A series of glass powders with a particle size of 0.5-3 microns.

[0021] Preparation of organic vehicle: 1% rosin, 2% ethyl cellulose, 5% polyester, 50% ethylene glycol phenyl ether, 20% butyl carbitol acetate, 20% alcohol ester twelve, at a temperature of 80 ° C Dissolved for 2 hours to obtain a uniform organic carrier;

[0022] Weigh 80% of silver powder, 3% of glass powder, 6% of organic carrier, Co 2 o 3 0.02%, Pd 2 S 3 0.01%, BYK110 0.2%, and the rest is solvent. Mix evenly in a planetary mixer or other mixer, and then disperse on a three-roller machine to less than 10μm to make front ...

Embodiment 2

[0025] The composition and weight percentage of front silver conductive paste of this embodiment: silver powder 78%, glass powder 4.5%, organic vehicle 8%, W 2 o 3 0.05%, the rest is solvent, in which the particle size of the silver powder is spherical silver powder with a particle size of 1.5-3.5μm and a tap density of 4-6g / m3; the glass powder is PbO-TeO 2 A series of glass powder, the particle size is 0.5~3μm.

[0026] Preparation of organic vehicle: acrylic resin 3%, polyamide 2%, cellulose acetate 10%, terpineol 20%, propylene glycol butyl ether 20%, tributyl citrate 30%, dissolved at 80°C for 2 hours to obtain Uniform organic carrier;

[0027] Weigh 78% of silver powder, 4.5% of glass powder, 8% of organic carrier, W 2 o 3 0.05%, the rest is solvent, mixed evenly in a planetary mixer or other mixer, and then dispersed on a three-roller machine to less than 10μm, and then the front silver paste for crystalline silicon solar cells can be made. The slurry is filtered...

Embodiment 3

[0030] The composition and weight percentage of front silver conductive paste in this embodiment: silver powder 85%, glass powder 4%, organic vehicle 7%, Os 2 SO 3 0.02%, Re 2 CO 3 0.02%. Among them, the particle size of the silver powder is spherical silver powder with a particle size of 1.5-3.5 μm and a tap density of 4-6 g / m3; the glass powder is PbO-TeO 2 A series of glass powders with a particle size of 0.5-3μm.

[0031] Preparation of organic vehicle: 3% acrylic resin, 8% polyester, 50% propylene glycol butyl ether, and 40% terpineol were dissolved at 80°C for 2 hours to obtain a uniform organic vehicle;

[0032] Weigh 85% of silver powder, 4% of glass powder, 7% of organic carrier, Os 2 SO 3 0.02%, Re 2 CO 3 0.02%, mix evenly in a planetary mixer or other mixer, and then disperse on a three-roller machine to less than 10μm to make a front silver paste for crystalline silicon solar cells. The slurry is filtered through a 400-mesh sieve to obtain a very unifo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com