PERC crystalline silicon solar cell back silver paste and preparation method and application thereof

A technology of solar cells and crystalline silicon, applied in the field of solar cells, can solve the problems of unsatisfactory electrical properties of the cells, silver paste cannot guarantee welding tension, etc., and achieve good photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with specific examples.

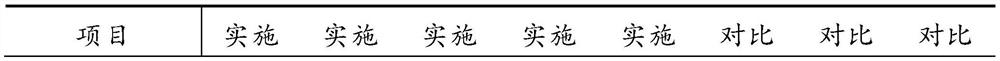

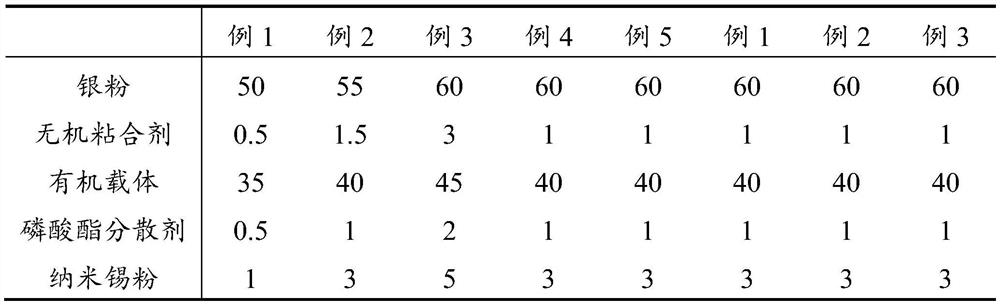

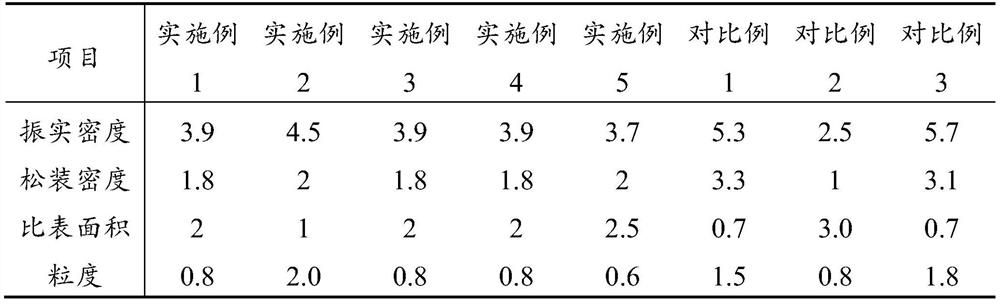

[0020] Embodiments 1 to 5 are all silver pastes of the present invention, and comparative examples 1 to 3 are different from the silver pastes of the present invention for the silver powder used in the preparation of silver pastes. The formula of the above silver pastes is as shown in Table 1. The performance parameters are shown in Table 2. Wherein, the formula of the organic carrier in the embodiment and the comparative example is: 2 parts of modified epoxy resin, 8 parts of ethyl cellulose, 22 parts of diethyl phthalate, 18 parts of diethylene glycol butyl ether acetate, 20 parts of tributyl citrate and 25 parts of butyl oxalate; the formula of the inorganic binder is: SiO 2 9 parts, H 3 BO 3 25 parts, V 2 o 5 10 parts, PbO 10 parts, ZnO 15 parts, ZrO 2 1 part a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com