Photovoltaic module main grid structure and preparation method and application thereof

A photovoltaic module and busbar technology, which is applied in the field of its preparation and photovoltaic module busbar structure, can solve problems such as inconsistent welding tension, achieve uniform welding pad tension, control tin temperature, and increase welding tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

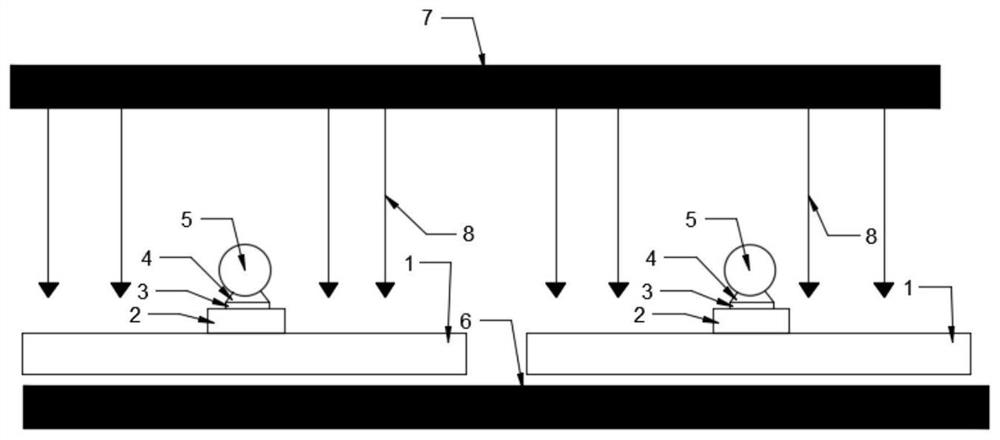

[0055] In another specific embodiment, the present invention provides a preparation method of the above-mentioned photovoltaic module busbar structure, such as image 3 As shown, the preparation method specifically comprises the following steps:

[0056] The busbar 9 is printed on the substrate 1 of the photovoltaic module, the substrate 1 with the busbar 9 is placed on the heating table 6 at 25-100° C., and the soldering layer is placed on the pad 2 in turn, and the soldering is performed under lamp heating. Then, the busbar structure of the photovoltaic module is prepared. Among them, in the process of lamp heating, the lamp tube 7 is used to emit heating light 8 for irradiation heating.

[0057] The present invention also provides a photovoltaic assembly, the photovoltaic assembly includes a substrate 1 and a grid line, and the busbar 9 in the grid line adopts the above-mentioned photovoltaic assembly busbar structure.

Embodiment 1

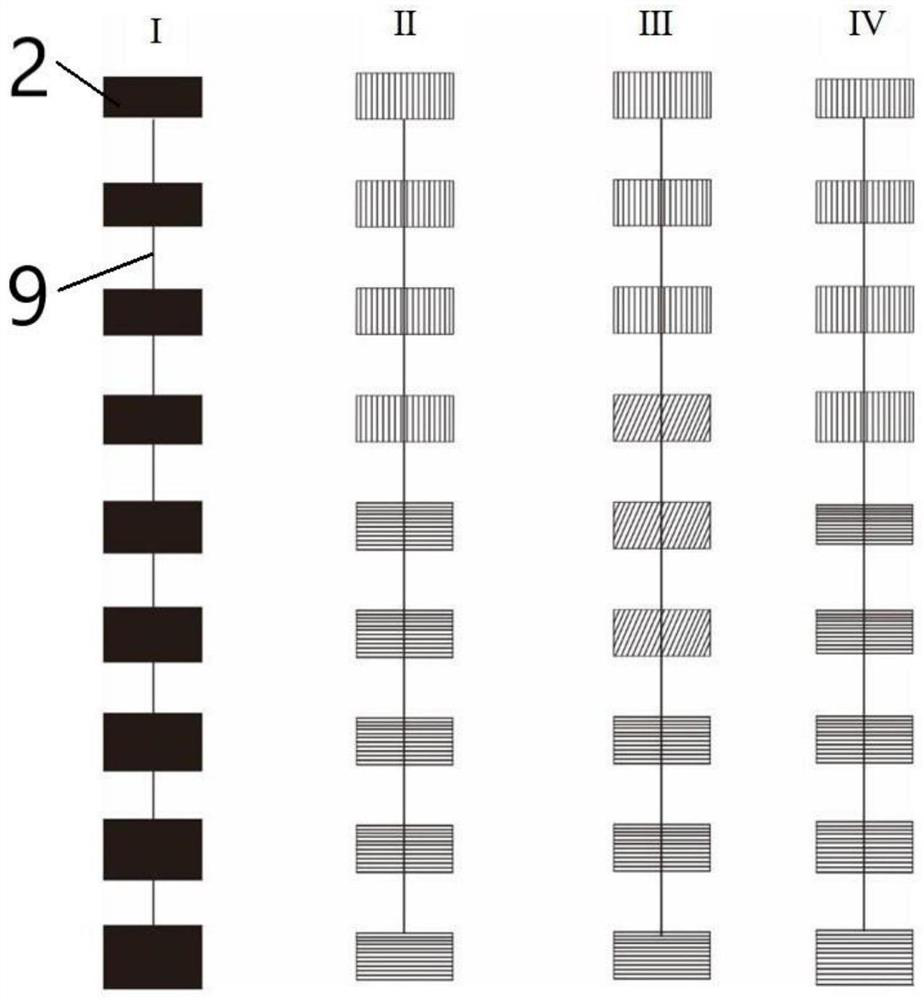

[0059] This embodiment provides a photovoltaic module busbar structure, based on a specific implementation, such as figure 1 As shown in I, the area of the pad 2 increases sequentially along the direction of the busbar 9 close to the central area of the soldering box.

Embodiment 2

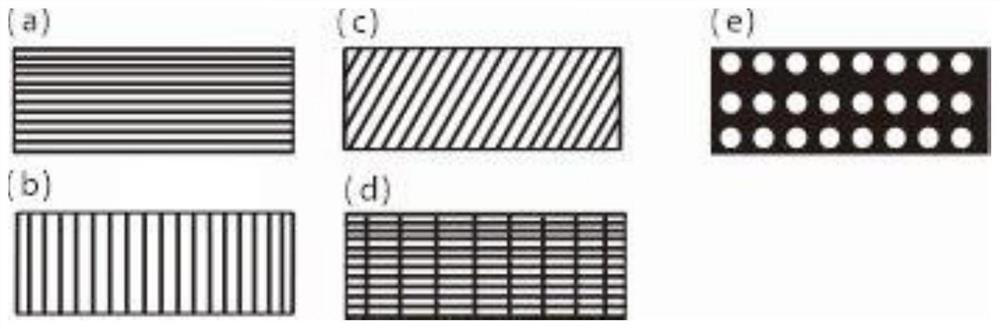

[0061] This embodiment provides a photovoltaic module busbar structure, compared with Embodiment 1, such as figure 1 As shown in II, along the direction of the main grid 9 close to the central area of the soldering box, the area of the pad 2 increases in turn, and a linear hollow is set on the pad 2, which is divided into 4 longitudinal linear hollows and 5 horizontal hollows. Linear cutout.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com