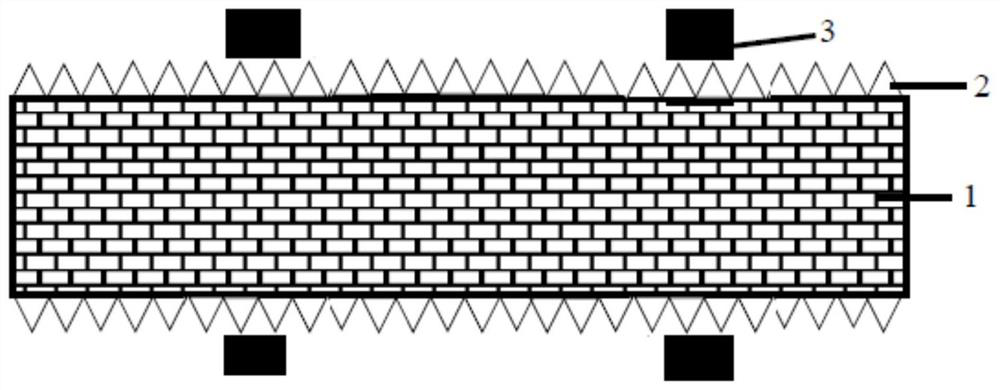

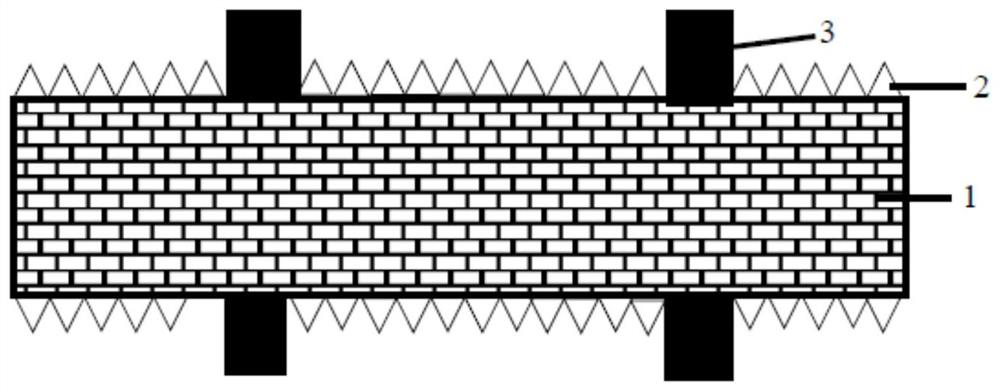

Heterojunction solar cell and preparation method thereof

A solar cell and heterojunction technology, which is applied in chemical instruments and methods, circuits, photovoltaic power generation, etc., can solve the problems of low efficiency of solar cells and achieve the effects of improving contact, increasing welding tension, and reducing widening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

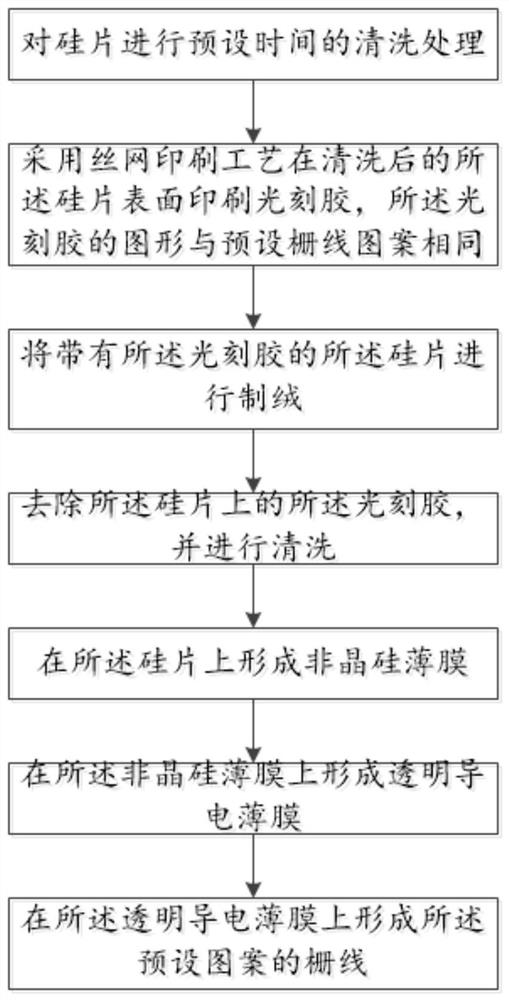

[0059] 1. N-type monocrystalline silicon wafers are initially cleaned. Ultrasonic cleaning is used for cleaning. The solution is

[0060] Acetone for 5 minutes;

[0061] 2. Use a screen printing machine to print photoresist on the surface of the battery. The pattern of the photoresist is the same as that of the subsequent grid lines;

[0062] 3. Put the silicon wafer with photoresist into the texturing tank for texturing. The texturing solution is NaOH and texturing additive at a temperature of 80°C for 20 minutes; in the area covered by the photoresist, the texturing solution It cannot be in contact with the silicon wafer, so it will not form a pyramid-shaped textured structure at the corresponding position on the silicon wafer, and the area not covered by the photoresist can be in contact with the texturing liquid to form a normal textured surface;

[0063] 4. After texturing, remove the photoresist, and then put the silicon wafer into the cleaning tank for cleaning. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com