Positive electrode silver paste for back passivation silicon solar cell and preparation method thereof

A technology of silicon solar cells and positive electrodes, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problem of narrow low-temperature sintering window, reduced conversion efficiency, and affecting the etching effect of SiNx silver The quality of wire sintering and the formation of ohmic contacts can achieve the effects of ensuring etching ability, improving compactness, improving fluidity and wetting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] In addition, the present invention also provides a preparation method of Pb-V-Te glass, comprising the following steps:

[0046] 1) According to the design ratio, PbO, V 2 o 5 , TeO 2 、 Bi 2 o 3 , B 2 o 3 、WO 3 and SiO 2 Mix the oxides evenly and put them in platinum crucibles;

[0047] 2) Put the platinum crucible with the above-mentioned oxide into a high-temperature sintering furnace, melt it at a temperature of 700°C-1000°C, and keep it warm for 0.5-2hrs to obtain a uniform molten glass;

[0048] 3) Quenching the molten glass by using a double-roller flaker to obtain glass shards with uniform thickness;

[0049] 4) Put the above-mentioned glass flakes into a planetary ball mill for ball milling to obtain Pb-V-Te glass powder with a particle size meeting the requirements. The median particle size D50 of the glass powder is distributed between 1 μm and 3 μm, and D100 is less than 10 μm.

[0050] In addition, the present invention also provides a preparation ...

Embodiment 1

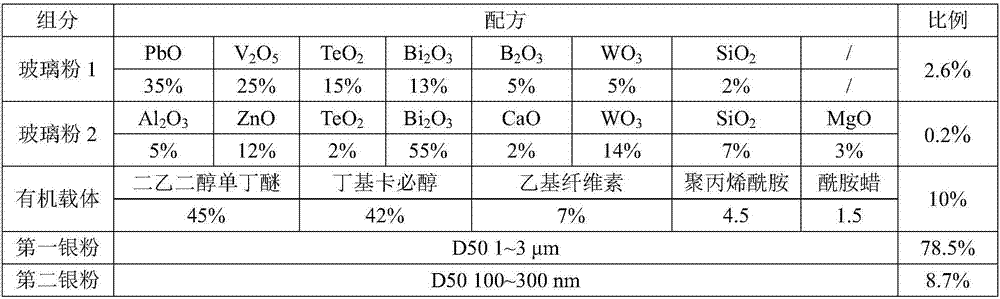

[0064] Prepare glass powder, silver powder, and organic vehicle according to the proportions of the components in Table 1, and further mix them to obtain positive electrode silver paste, which is printed on the front surface of the Perc cell by screen printing, and after drying Dry sintering to obtain a positive electrode.

[0065] Table 1 embodiment one each component ratio

[0066]

Embodiment 2

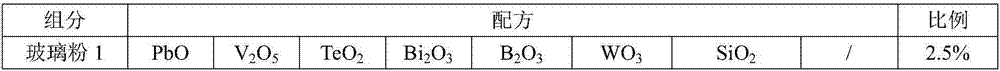

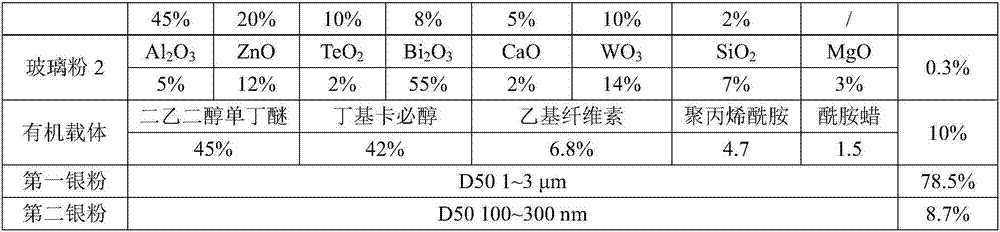

[0068] Prepare glass powder, silver powder and organic vehicle according to the proportions of the components in Table 2, and further mix them to obtain positive electrode silver paste, which is printed on the front surface of the Perc cell by screen printing, and after drying Dry sintering to obtain a positive electrode.

[0069] Table 2 embodiment two each component ratio

[0070]

[0071]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com