Patents

Literature

39results about How to "Guaranteed etching effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Positive electrode silver paste for back passivation silicon solar cell and preparation method thereof

ActiveCN107195354AHigh sintering activityImprove liquidityNon-conductive material with dispersed conductive materialCable/conductor manufactureSilicon solar cellColloidal particle

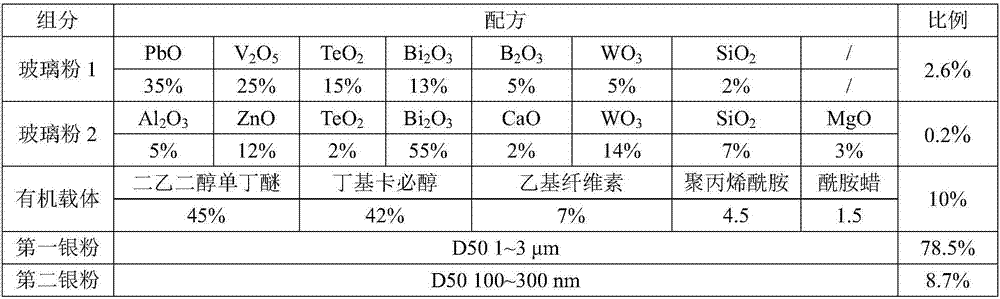

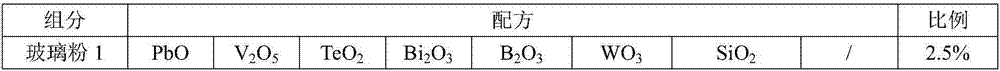

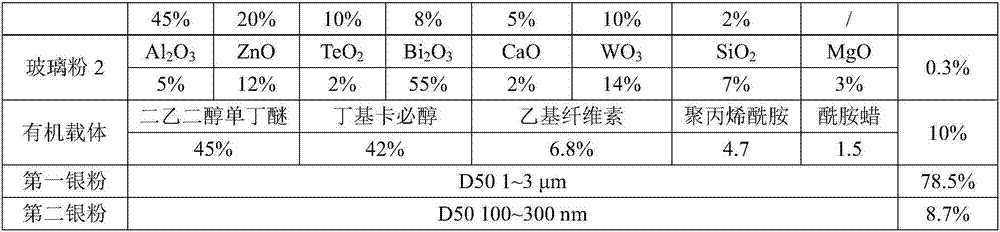

The invention discloses positive electrode silver paste for a back passivation silicon solar cell and a preparation method thereof. The positive electrode silver paste comprises, in mass percent, 3%-15% of organic carriers, 80%-95% of silver powders and 1%-5% of inorganic glass materials. The inorganic glass materials are prepared by compounding Pb-V-Te glass and Bi-W-Si glass; and the silver powders are prepared by compounding first silver powders and second silver powders. Through introduction of nanometer silver powders, sintering activity of a silver powder system is improved, and compactness of silver grid lines under low-temperature sintering is improved; by adjusting softening temperature, viscosity and surface tension of the glass materials, liquidity and wetting ability of glass liquid are improved, etching capacity of the glass liquid to a front-surface antireflection layer is ensured and silver powder fusion and reprecipitation capability is improved; precipitation of silver nanometer colloid particles on the surface of a silicon wafer helps to promote the glass layer to form good ohmic contact with the silicon wafer, and thus conversion efficiency is improved; and through introduction of the second component glass powders, bonding strength between the glass layer and a silicon substrate is enhanced.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH CO LTD

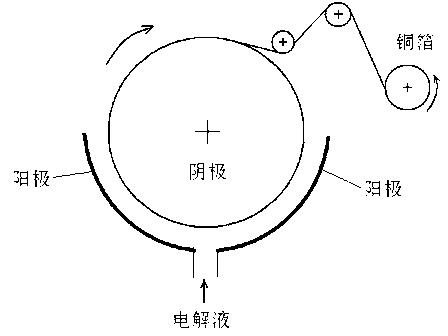

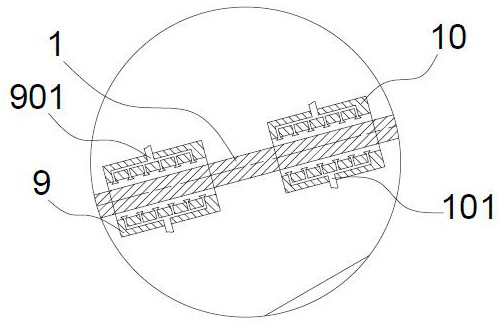

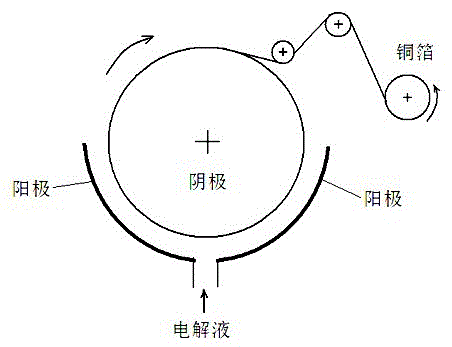

Mixed additive for removing internal stress of electrolytic copper foil and method for producing low-stress copper foil

ActiveCN103173812AThe production process is easy to controlProduct quality is stableCopper foilHydroxyethyl cellulose

The invention relates to a mixed additive for removing internal stress of an electrolytic copper foil and a method for producing a low-stress copper foil and belongs to the technical field of production of a high-precision electrolytic copper foil. The mixed additive for removing internal stress of the electrolytic copper foil comprises gelatin, hydroxyethyl cellulose and liquid additive. The method for producing the low-stress copper foil by using the mixed additive comprises the steps of preparing high-purity cathode copper and sulfuric acid into mixed solution of sulfuric acid and copper sulfate at 60-95 DEG C under the condition of stirring in the presence of air, wherein Cu<2+> is 85-100g / L and H2SO4 is 100-120g / L; adjusting the temperature of electrolyte to 45-60 DEG C and the flow to 50-70m<3> / h; adding 20-50mg / L of Cl<->, adding the mixed additive, with a drum titanium tube which continuously rotates as a cathode and arc titanium as an anode, carrying out copper electrolytic deposition and lastingly stripping to obtain 12-70 microns copper foil under the condition of the direct current of which the current density is 55-70A / dm<2>. The thickness of the copper foil is controlled by adjusting the rotation speed of the cathode; and the obtained copper foil has excellent performances.

Owner:SHANDONG JINBAO ELECTRONICS

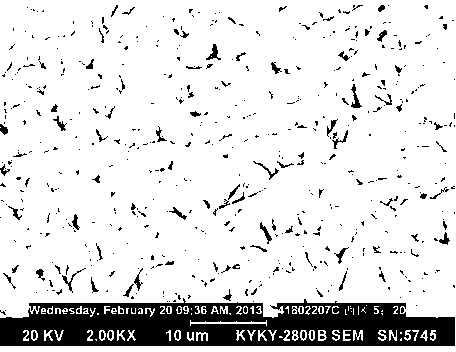

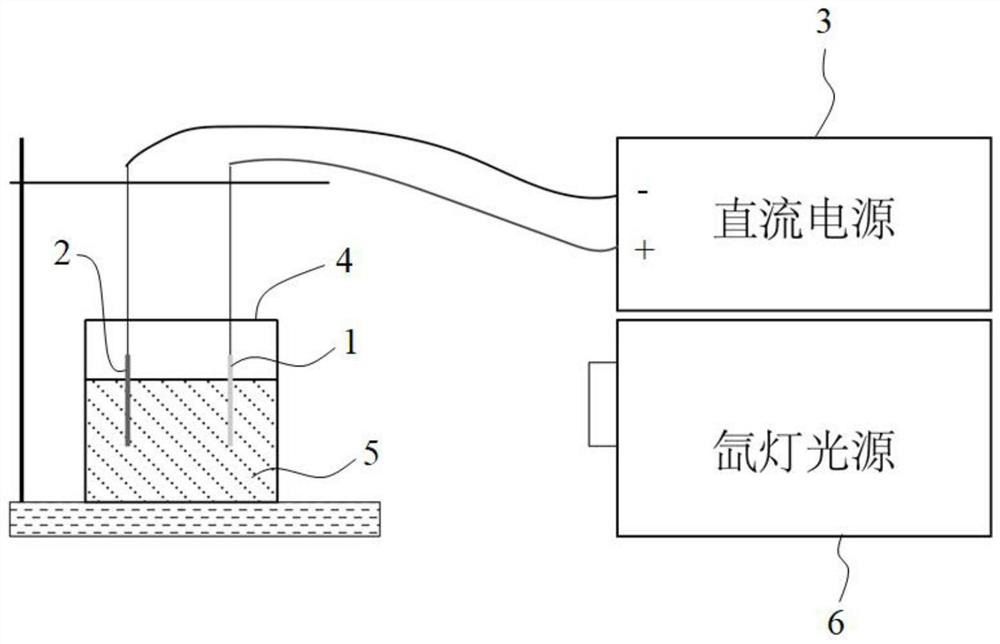

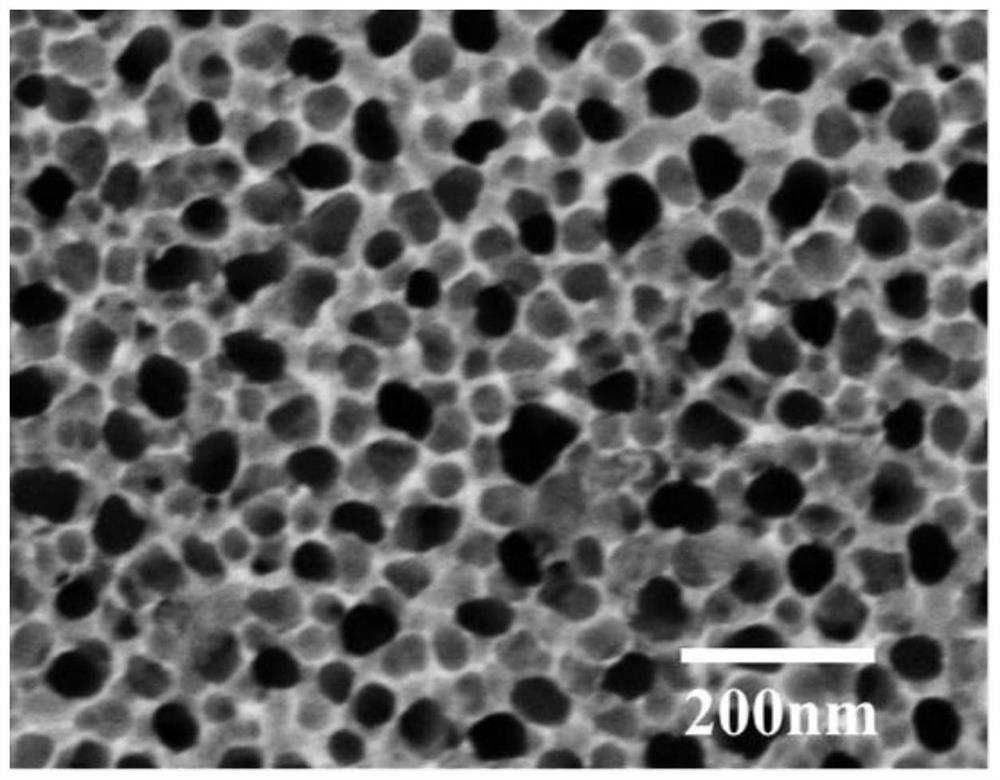

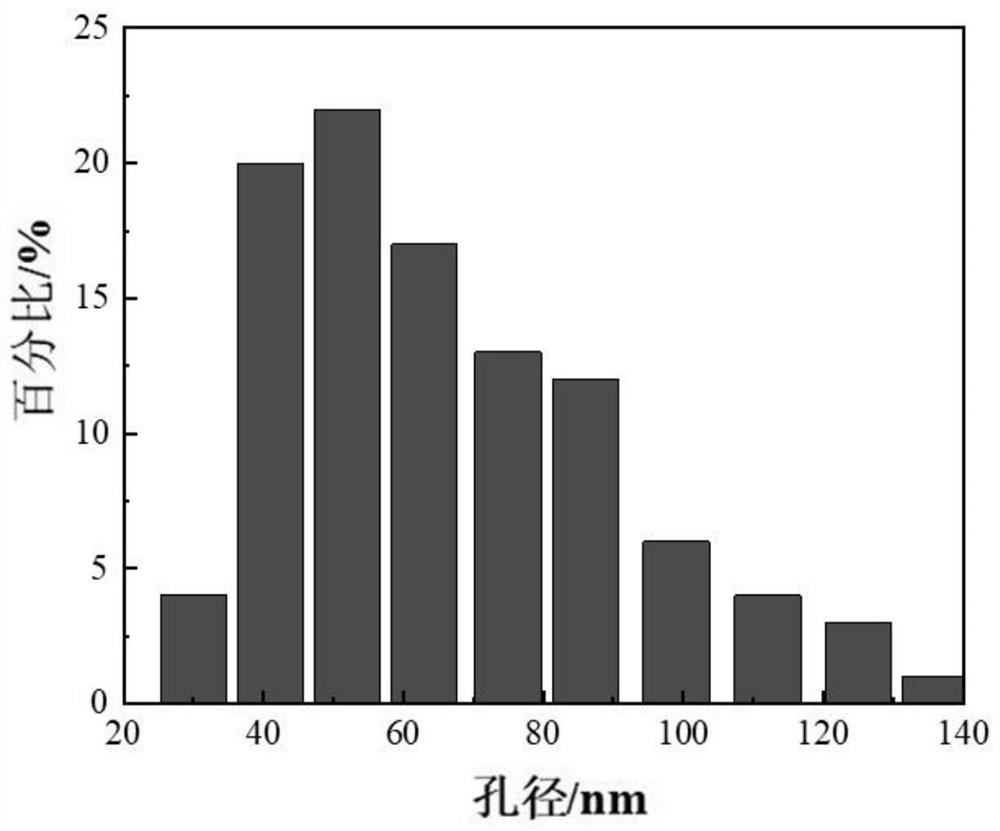

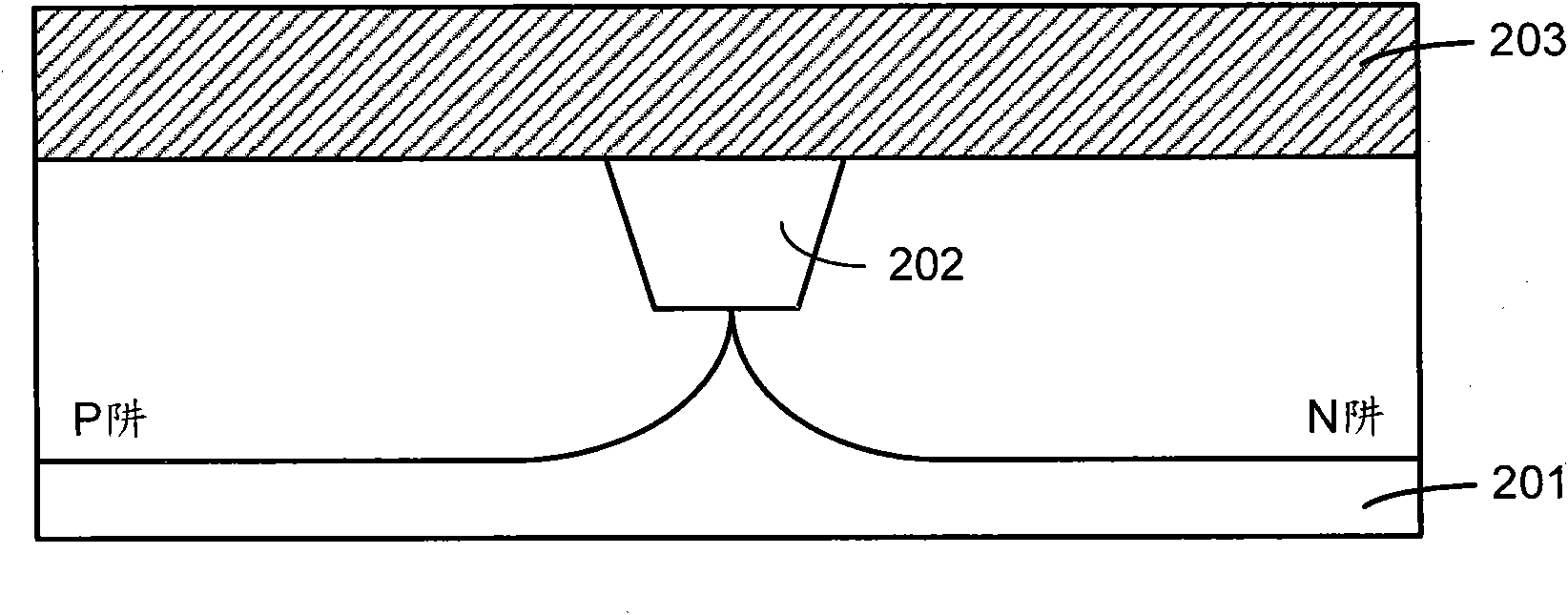

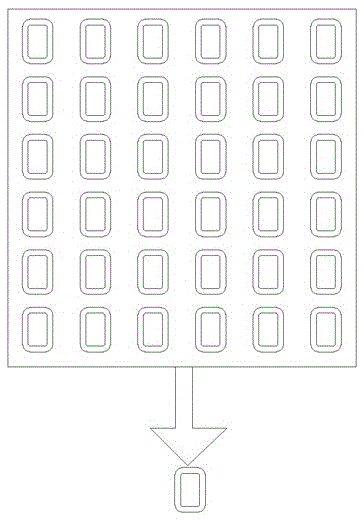

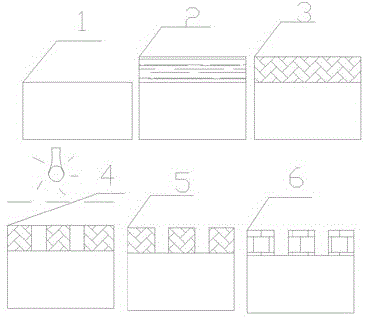

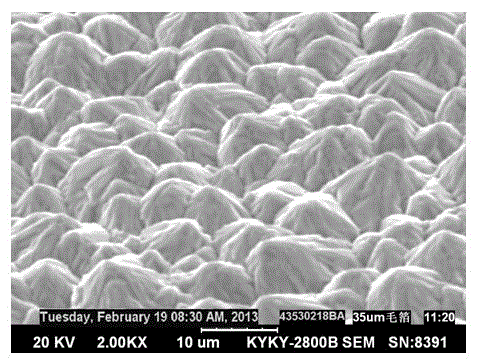

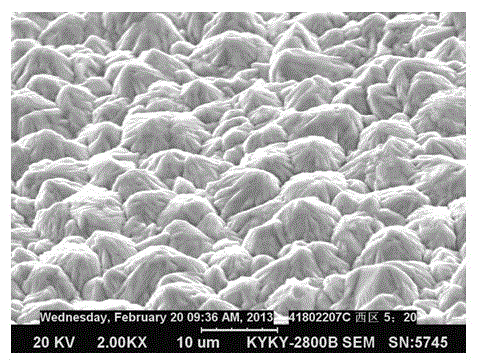

Preparation method of silicon thin film surface antireflection structure

InactiveCN102694076AGuaranteed etching effectImprove performanceFinal product manufactureVacuum evaporation coatingPhysicsThin membrane

The invention relates to a preparation method of a silicon thin film surface antireflection structure, and the method comprises the following steps of: 1, preparation of a silicon thin film: firstly sequentially packaging a silicon target with the purity of 99.9999%, a silver target with the purity of 99.999% and a cheap silicon wafer base into a vacuum chamber, then vacuumizing the vacuum chamber, then introducing argon into the vacuum chamber, and finally depositing a polycrystalline silicon thin film with the thickness of 0.3-5Mum on the base; 2, deposition of silver nano particles: continuously depositing silver nano particles on the polycrystalline silicon thin film obtained in the step one, wherein the thickness of the deposited silver nano particle layer is 2-20nm; 3, catalytic etching of precious metal silver nano particles; and 4, removal of the silver nano particles: soaking a black silicon thin film obtained in the step three with a salpeter solution with the mass fraction of 20-40% for 10-30 minutes at room temperature, so as to remove the silver nano particles reserved on the black silicon thin film, then washing with distilled water and ethyl alcohol successively, and drying with cold air. The silicon thin film surface antireflection structure disclosed by the invention is of a porous structure and has the characteristics of low cost, good antireflection effect and high stability.

Owner:SHENYANG UNIV

OGS (one glass solution) capacitive touch screen cover glass processing method

ActiveCN103226425AGuaranteed edge qualityGuaranteed edge strengthInput/output processes for data processingEngineeringTouchscreen

The invention relates to a touch screen cutting method for an electronic product, and mainly relates to an OGS (one glass solution) capacitive touch screen cover glass processing method. The OGS capacitive touch screen cover glass processing method comprises the following steps: step 1: manufacturing a protective layer with the thickness of 20-30 mm on a large OGS toughened glass plate, and sequentially drying the protective layer by roasting, exposing and developing the protective layer and toughening a membrane of the protective layer; and step 2: immersing the large OGS toughened glass plate processed in the step 1 into an etching solution with the temperature of 21-25 DEG C for etching the large OGS toughened glass plate into small OGS toughened glass plates. By the OGS capacitive touch screen cover glass processing method, the large OGS toughened glass plate can be etched into the single small OGSs, without a repairing process after the etching process; and the etched single small OGSs are high in size precision and high in qualified rate.

Owner:深圳华视光电有限公司

Surface treatment process for enhancing low-temperature resistance of plastic

The invention relates to a surface treatment process for enhancing the low-temperature resistance of plastic. The surface treatment process specifically comprises the steps of degreasing plastic, swelling plastic, etching plastic, carrying out preliminary conditioning, activating plastic, preparing a low-temperature-resistant layer, carrying out treatment by oxidizing flame, plating the low-temperature-resistant layer, washing with water and drying. The surface treatment process disclosed by the invention has the advantages that the process is simple, the treatment time is shortened, the low-temperature resistance of plastic can be significantly improved, and the temperature brittleness of plastic is reduced; the treated plastic has the characteristics of relatively high surface smoothness and more beautiful appearance.

Owner:CHUZHOU HONGYUAN SPRAYING

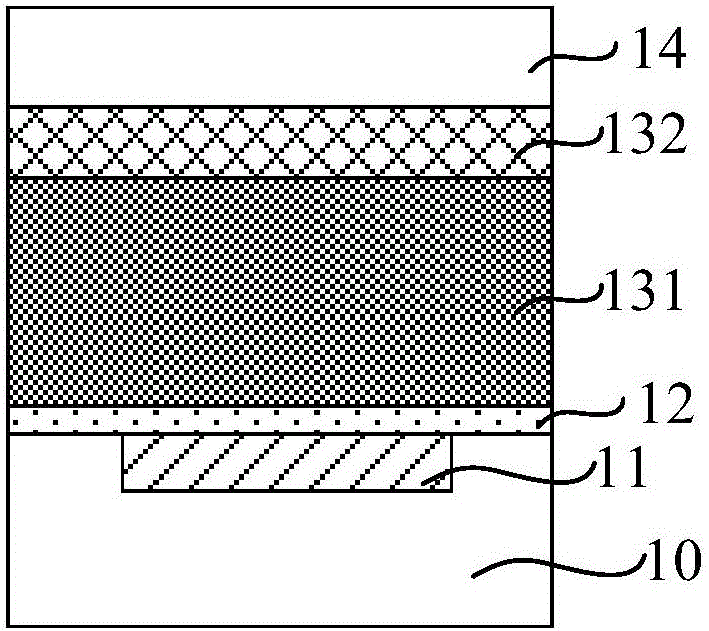

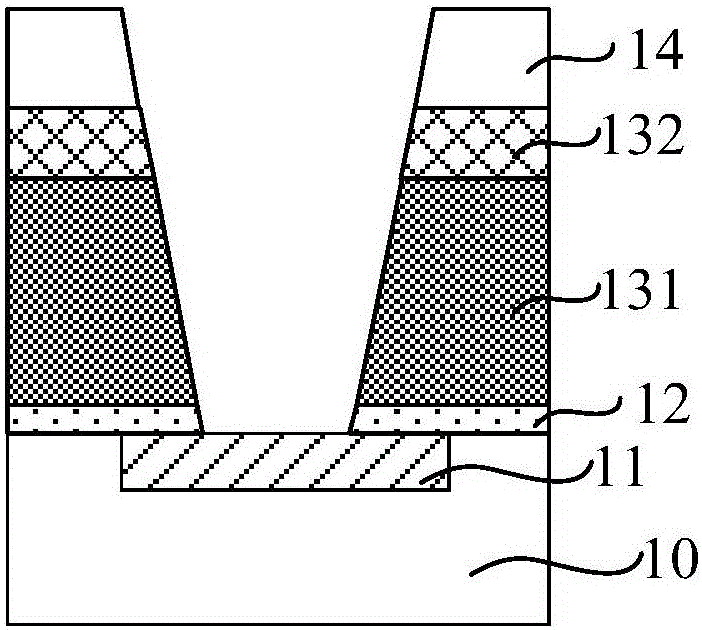

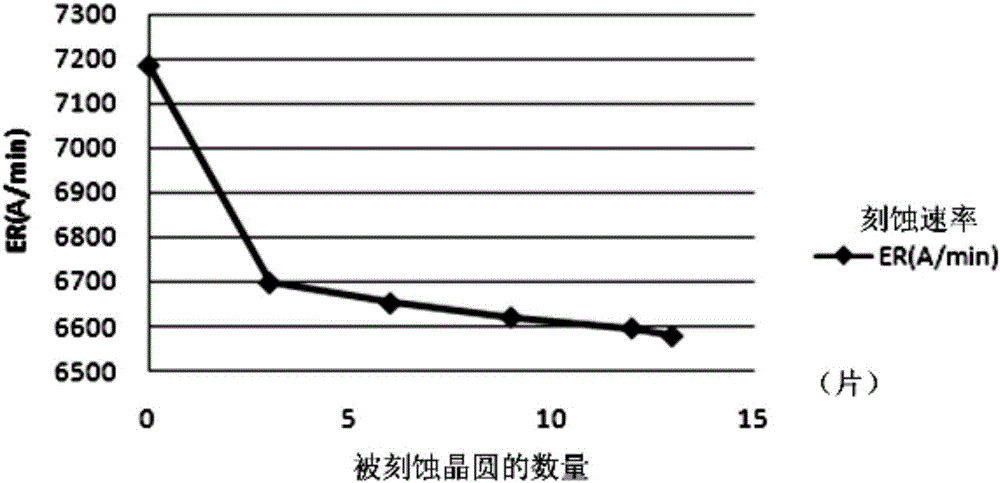

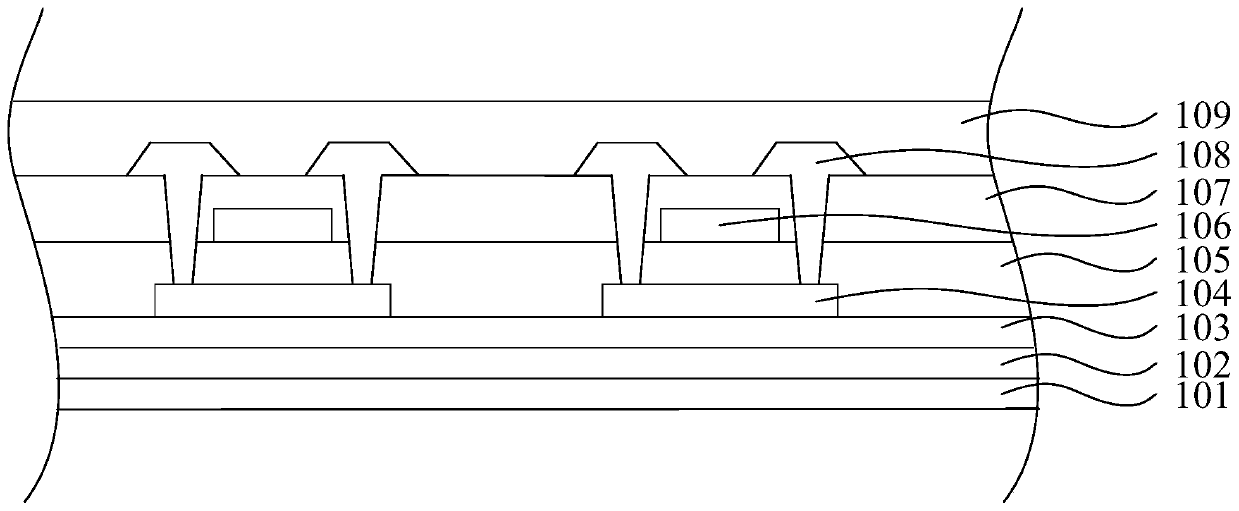

Passivation layer etching method, manufacture method of pad and manufacture method of semiconductor device

InactiveCN105977149AGuaranteed etching effectAvoid accumulationSemiconductor/solid-state device manufacturingEtchingFluorocarbon

The invention provides a passivation layer etching method, a manufacture method of a pad and a manufacture method of a semiconductor device. A first etching gas of relatively high fluorocarbon content is used to etch a passivation layer structure, an etching polymer can be prevented from accumulating in an etching cavity or in the sidewall of the passivation layer effectively, and the etching effect of the passivation layer is ensured; and a second etching gas of relatively low fluorocarbon content is used to etch an etching barrier layer under the passivation layer structure, over etching time of the etching barrier layer can be shortened greatly, top-layer metal below is prevented from excessive etching, and etched top-layer metal is prevented from accumulation in the etching cavity. Thus, the problem that the etching speed is decreased is solved effectively, and performances of the pad and the semiconductor device are ensured.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

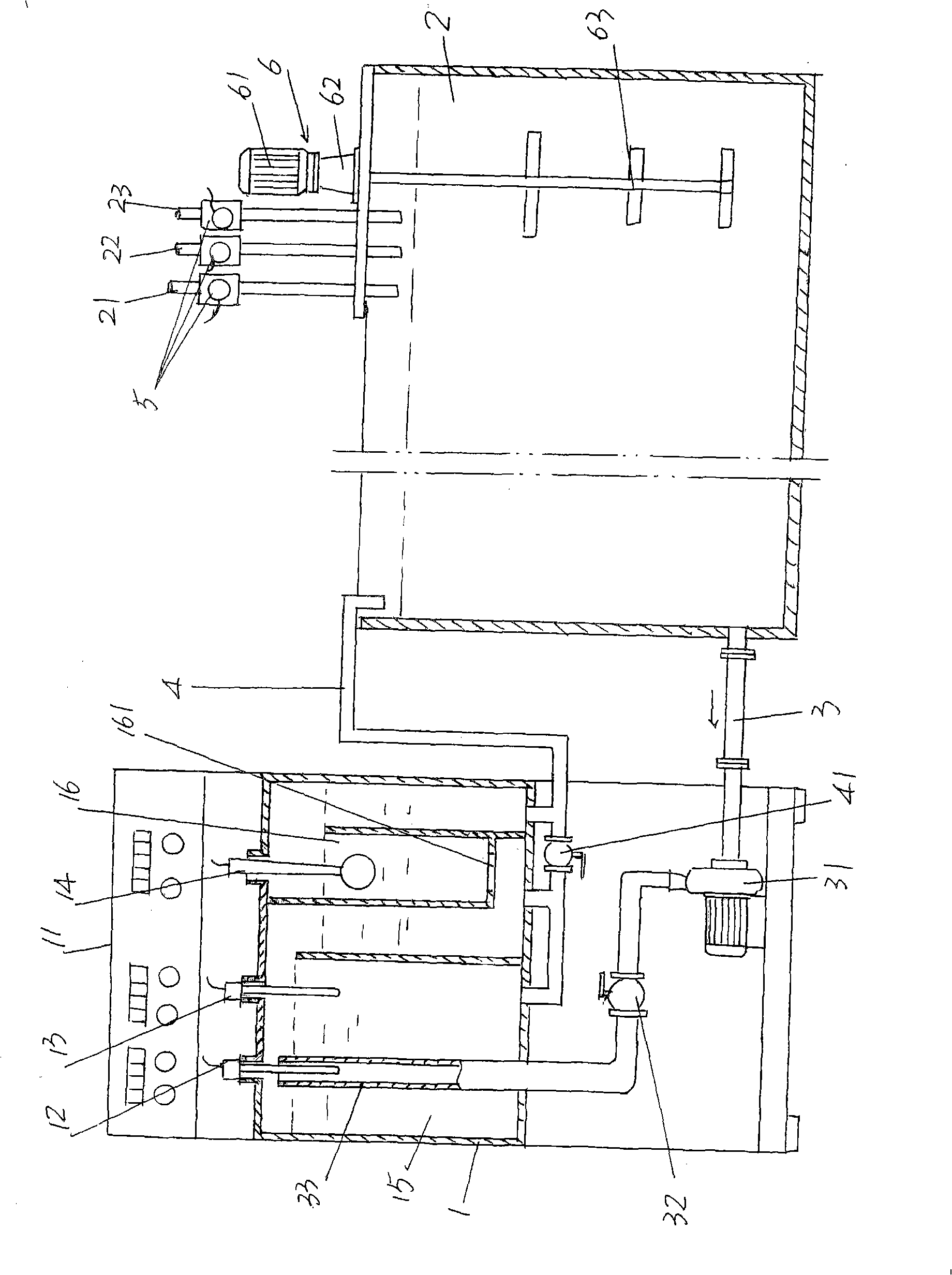

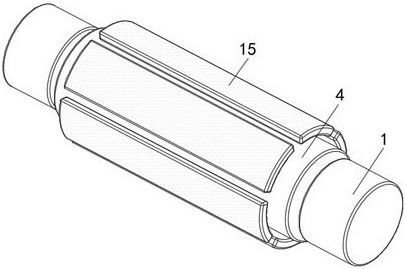

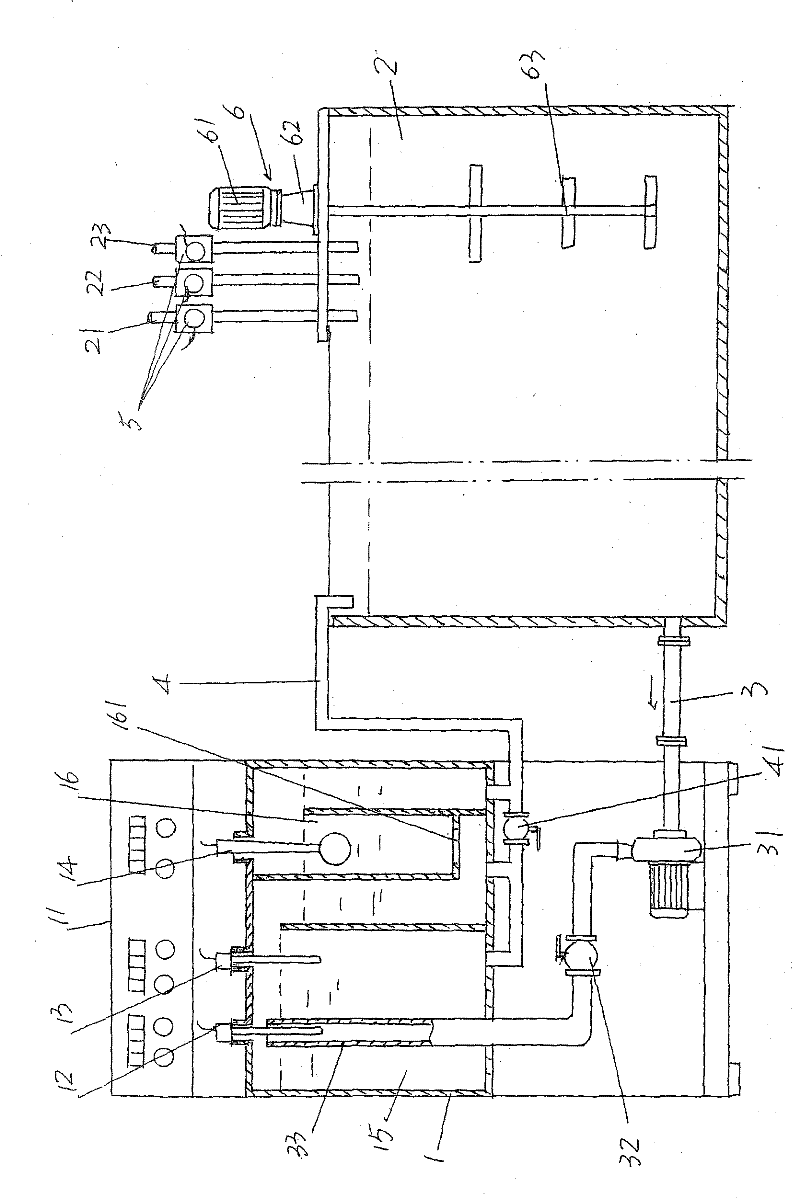

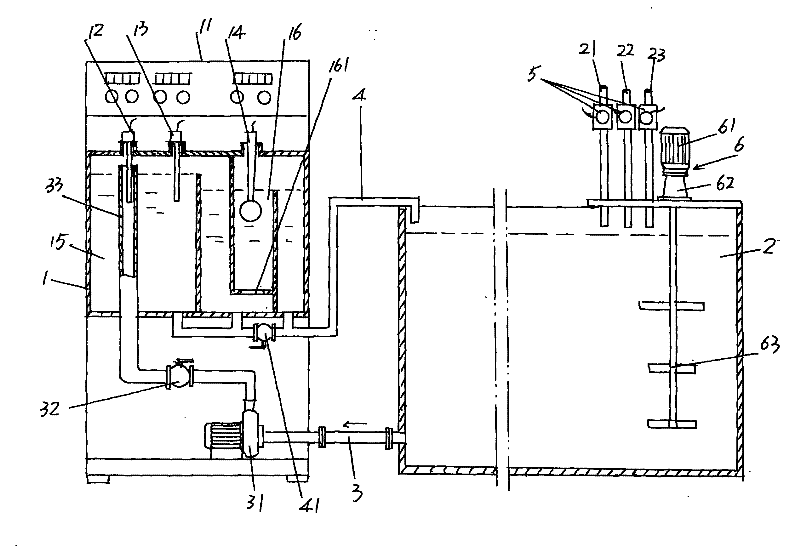

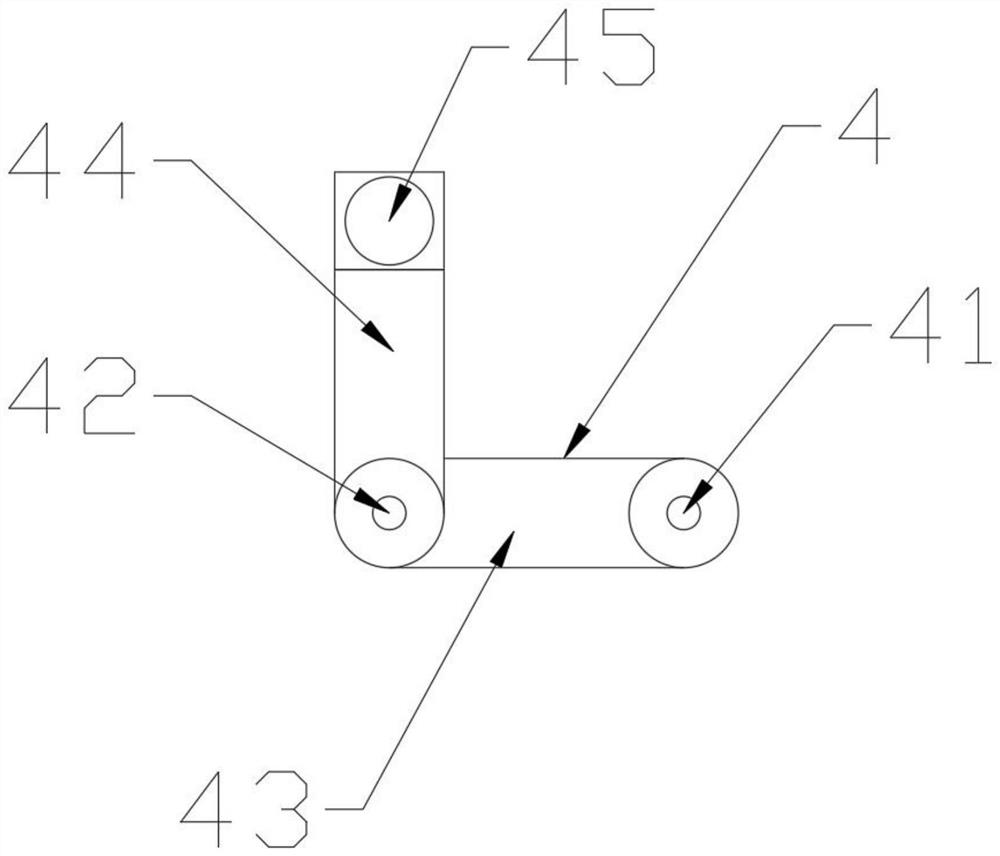

Flexible circuit board etching liquid concentration control device

InactiveCN101538715ATimely and accurate measurementGuaranteed etching effectControlling ratio of multiple fluid flowsMaterial analysis by observing immersed bodiesFlexible circuitsEngineering

The invention relates to a flexible circuit board etching liquid concentration control device belonging to the technical field of etching liquid detection and control devices and comprising a testing box with a box cavity, an etching pool, a liquid inlet pipe and a liquid return pipe. The testing box is provided with a controller as well as an oxidant probe, a hydrochloric acid probe and a hydrometer which are respectively and electrically connected with the controller and extend into the testing box; the etching pool is provided with an oxidant adding pipe, a hydrochloric acid inlet pipe and a water inlet pipe; the oxidant adding pipe, the hydrochloric acid inlet pipe and the water inlet pipe are respectively provided with a control valve; the control valves are electrically connected with the controller; one end of the liquid inlet pipe is connected with the etching pool, the middle is provided with a conveying pump and a valve, and the other end extends into the testing box; and one end of the liquid return pipe is connected with the etching pool and the other end is connected with the testing box. The invention has the characteristic that the oxidant probe is inserted into the pipe cavity of the liquid inlet pipe. The invention has the advantage of ensuring the etching effect of the etching pool to FPC boards.

Owner:苏州市飞莱克斯电路电子有限公司

Molybdenum aluminum molybdenum etching solution

The invention relates to a molybdenum aluminum molybdenum etching solution. Based on a total weight, the molybdenum aluminum molybdenum etching solution comprises: 35-45% of phosphoric acid, 1-3% of nitric acid, 8-12% of glacial acetic acid, 0.5-1.0% of additives and 39-55.5% of deionized water. The additives comprise organic polybasic phosphonic acid substance, amine substance and salt substance.The molybdenum aluminum molybdenum etching solution provided by the invention can meet the customers' requirements for etching angle and etching amount, improves the product's excellent and good rate, at the same time greatly lowers the phosphoric acid content, and reduces the problem of uneven local etching caused by excessive phosphoric acid concentration.

Owner:SHENZHEN CAPCHEM TECH CO LTD

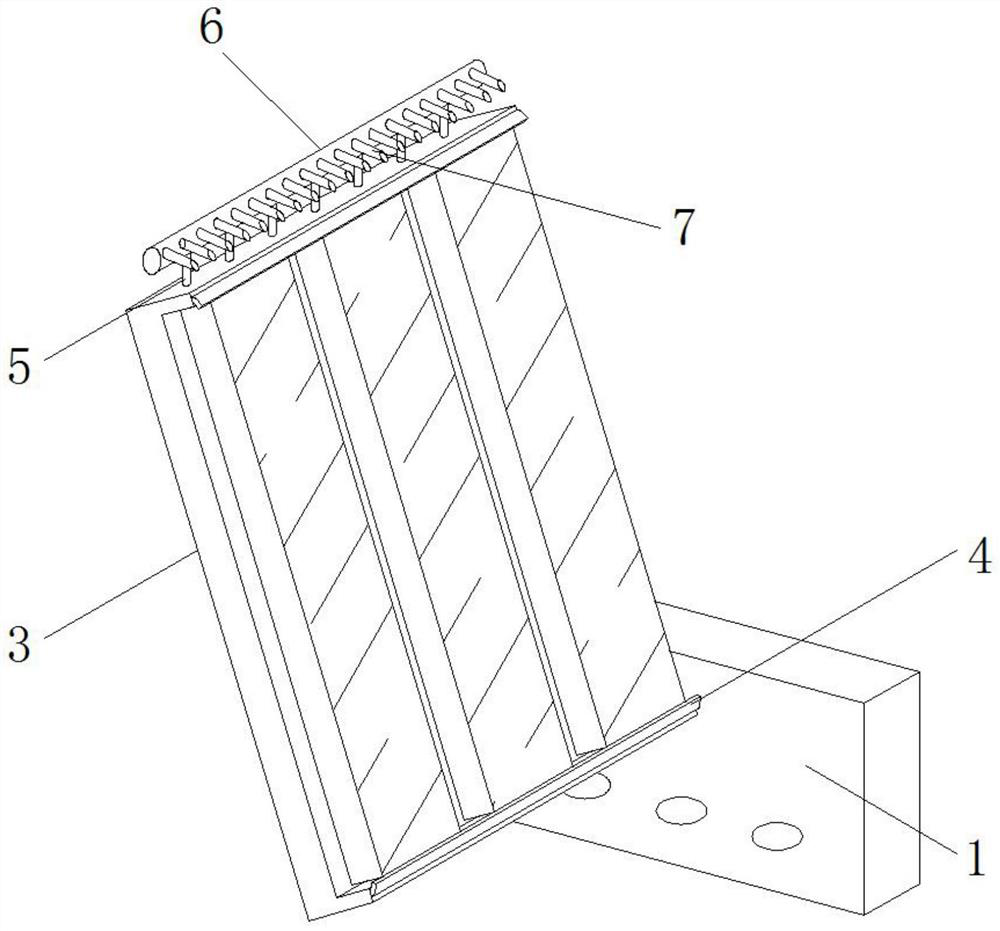

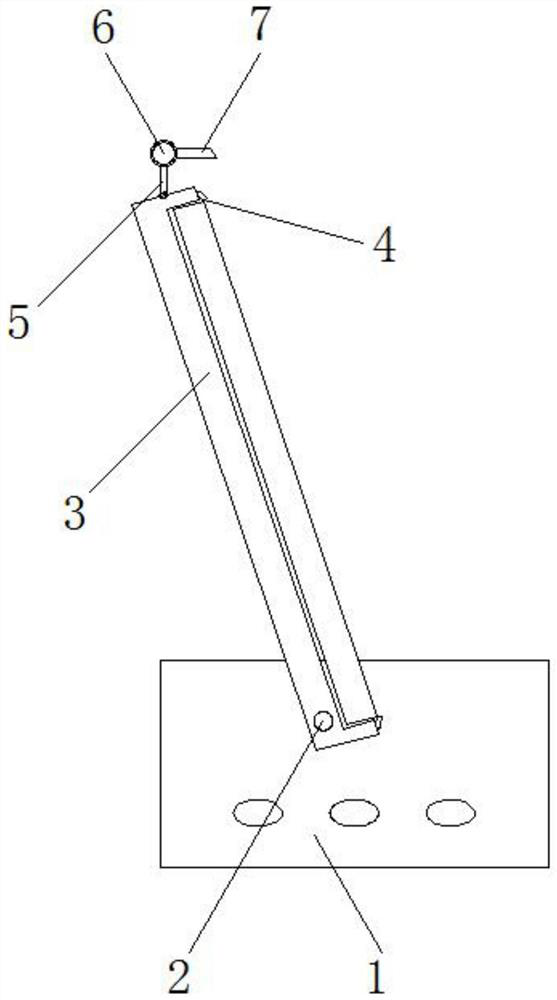

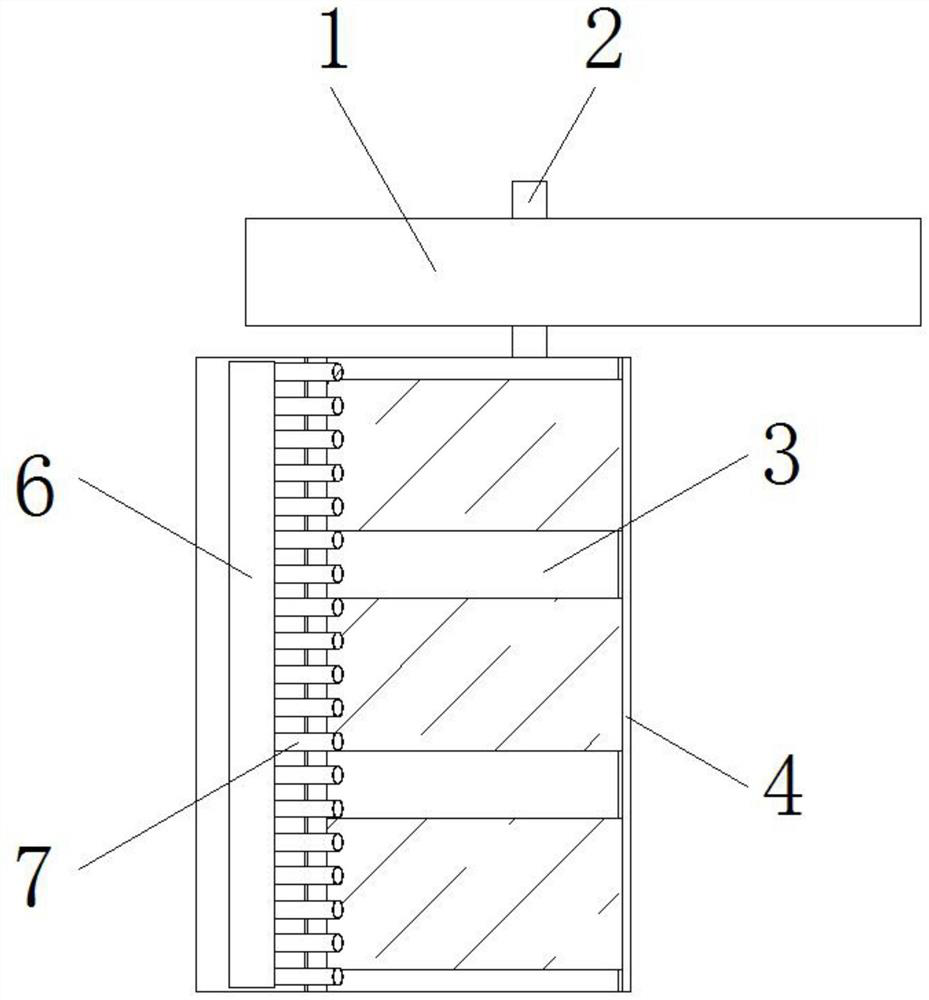

Waterfall flow type special jig for chemical etching and preparation method of ultrathin glass

The invention discloses a waterfall flow type special jig for chemical etching and a preparation method of ultrathin glass. The waterfall flow type special jig comprises a mounting base, a rotating shaft is rotatably connected into the mounting base, a supporting frame is fixedly connected to the front end of the rotating shaft, PVC cover plates are connected to the right ends of the upper side and the lower side of the supporting frame in a clamped mode, supporting rods distributed at equal intervals are fixedly connected to the upper end of the supporting frame, and spraying pipes are mounted at the upper ends of the supporting rods; nozzles distributed at equal intervals are fixedly connected to the right end of the spraying pipe. According to the waterfall flow type special jig for chemical etching and the preparation method of the ultrathin glass, a waterfall flow type chemical etching method is adopted, no pressure is needed on the glass, the glass cannot be broken due to stress, the recovery ratio is high, waste liquid is minimum, the utilization rate of acid liquid is high, a large amount of cost is saved, a conveying belt is used for conveying in the whole process, the apparent effect is good, and rework is not needed; the yield is very high, turnover operation is not needed, the fragment risk is reduced, the etching capacity is improved, and the sealing performance of the upper end and the lower end of the glass is ensured.

Owner:赣州帝晶光电科技有限公司

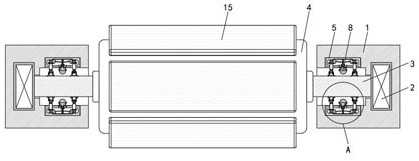

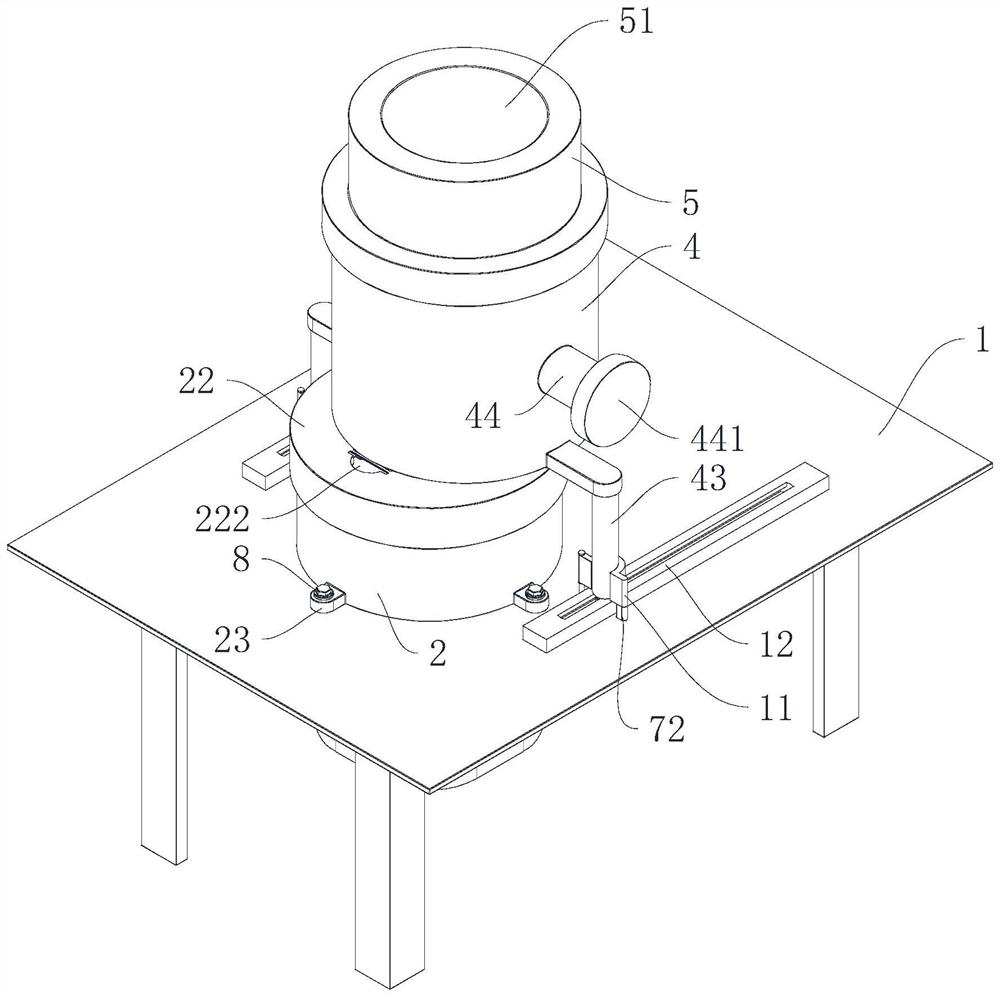

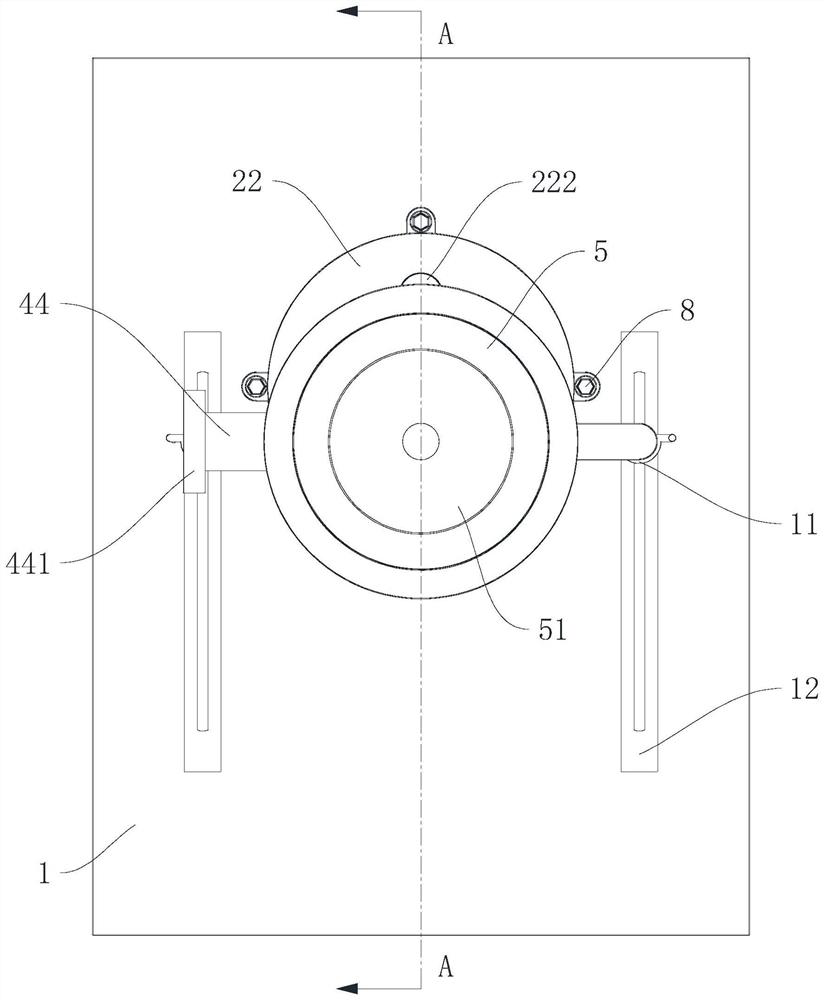

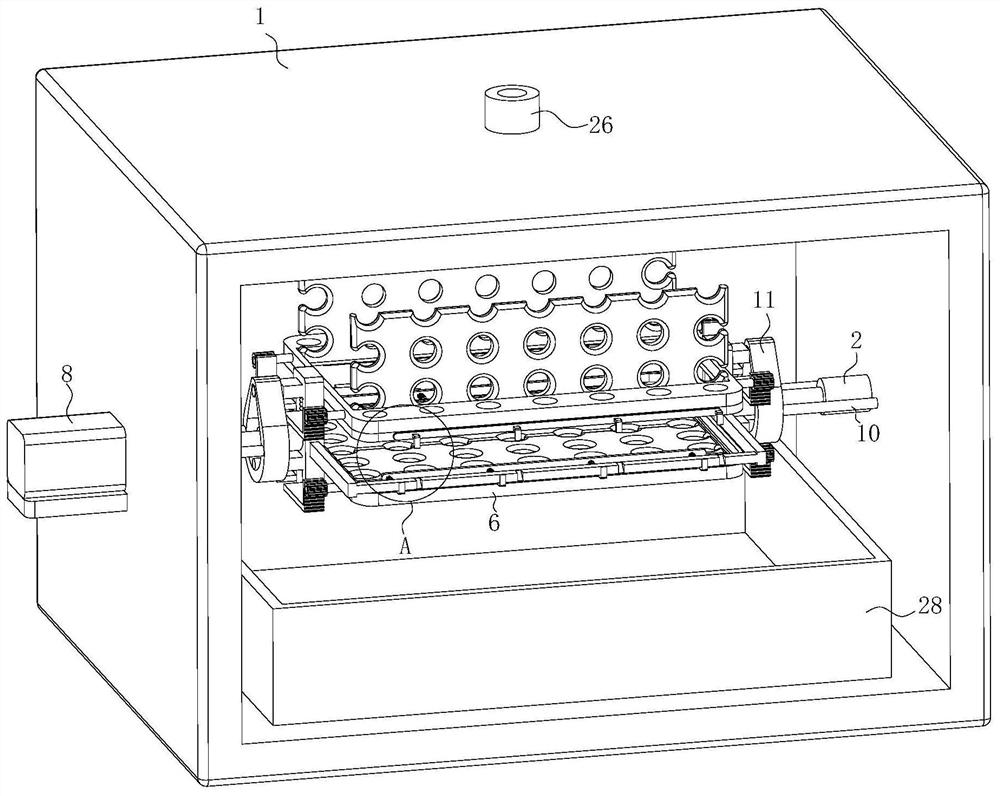

Etching device for manufacturing integrated optoelectronic device

ActiveCN114171442AImprove etching effectFix jitterFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention provides an etching device for manufacturing an integrated optoelectronic device, which comprises a main body, a driving mechanism is arranged in the main body, a driving shaft is arranged on the driving mechanism, an etching device is arranged on the driving shaft, a fixing component is arranged on the inner wall of the main body, and the fixing component is arranged on the inner wall of the main body. An offset sensing assembly, a linkage assembly and a correction assembly are arranged on the fixing part; the deviation induction assembly comprises an induction air cushion, a movable part, an induction main rod and a guide part. According to the etching device for manufacturing the integrated optoelectronic device, by arranging the correction assembly, once the etching device shakes, the etching device inevitably drives the driving shaft to synchronously shake, and the correction main rod is utilized to drive the correction piece to be in contact with the driving shaft, so that the driving shaft which deviates due to shaking is corrected; therefore, the problem of jittering of the etching device is fundamentally solved, the etching effect of the etching device on the integrated optoelectronic device is improved, and meanwhile, the reliability of the equipment is effectively improved.

Owner:GUILIN TRYIN TECH CO LTD

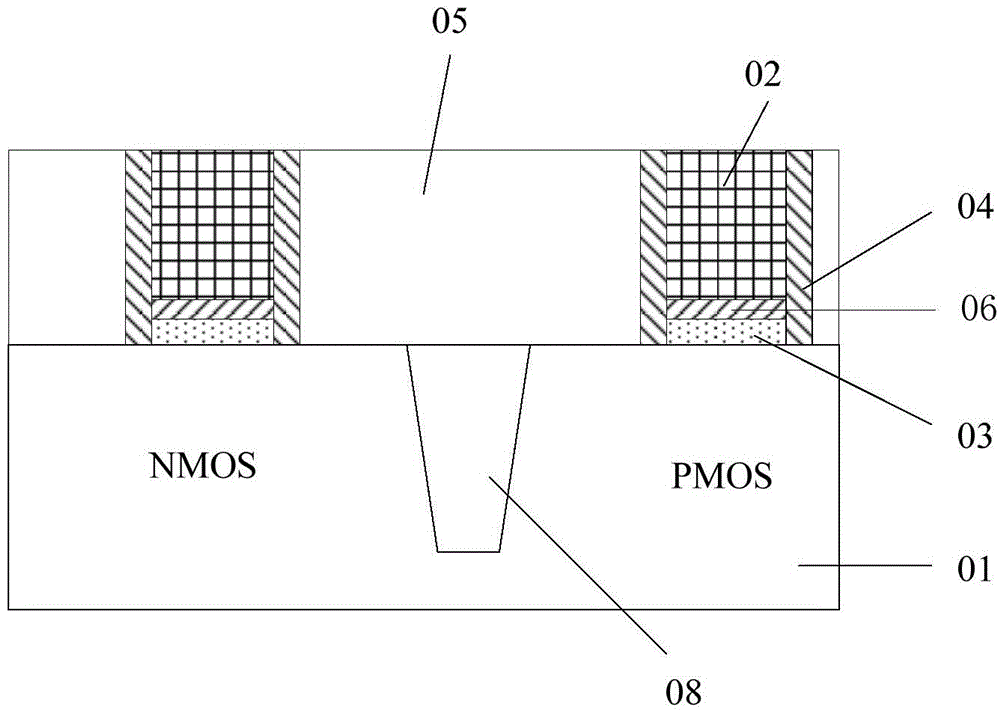

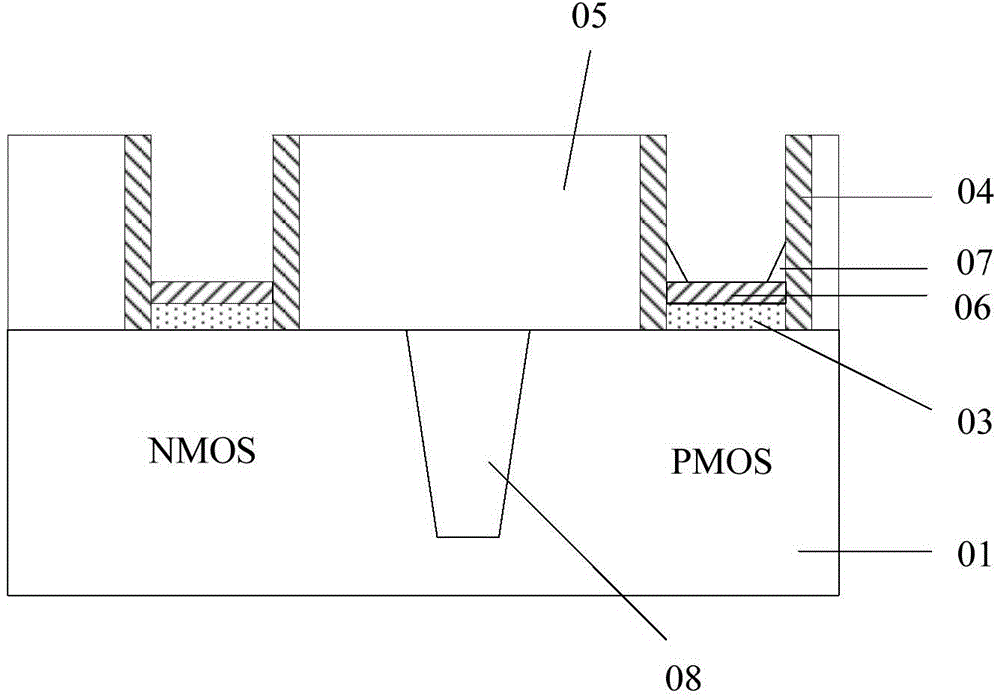

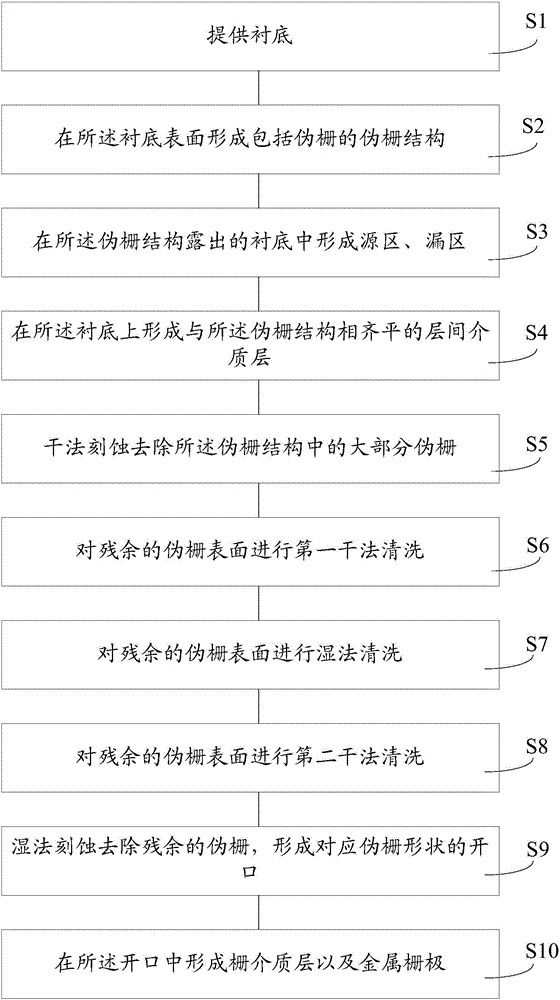

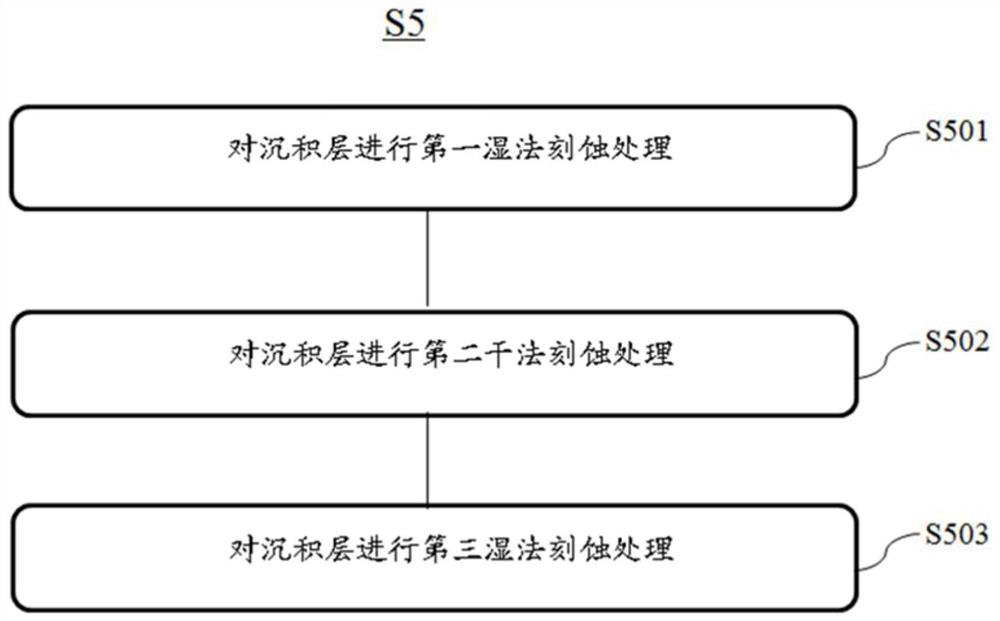

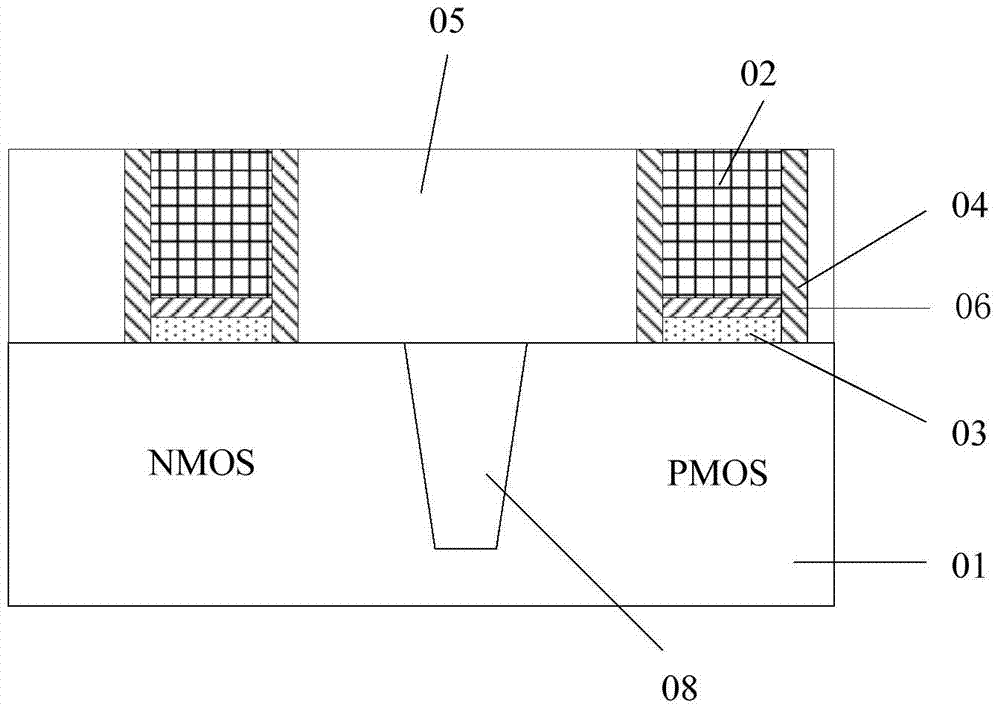

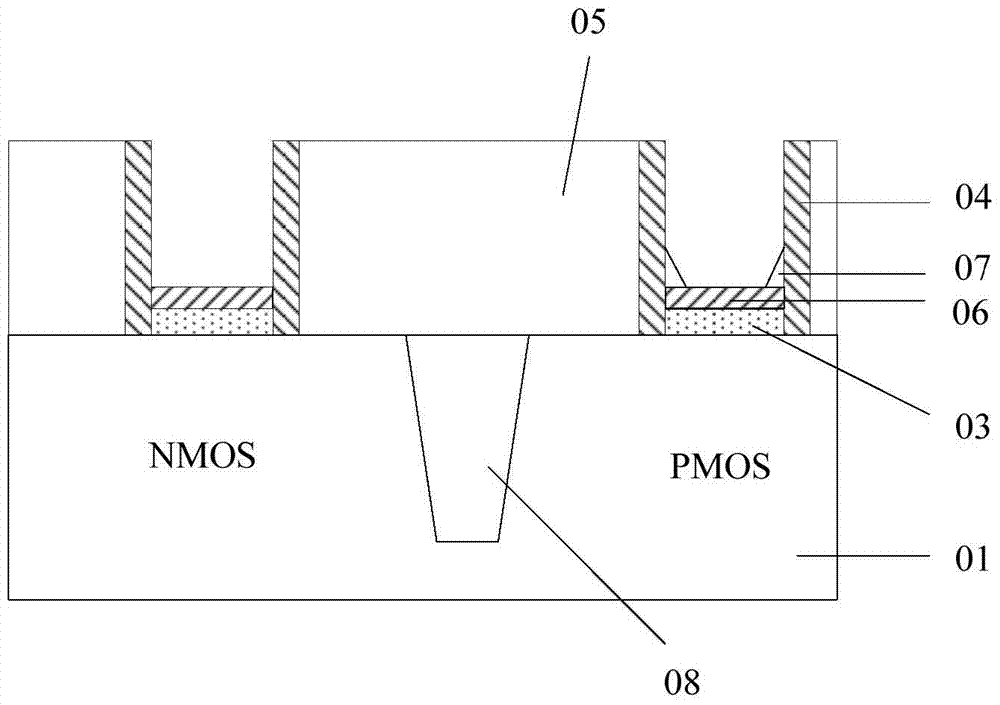

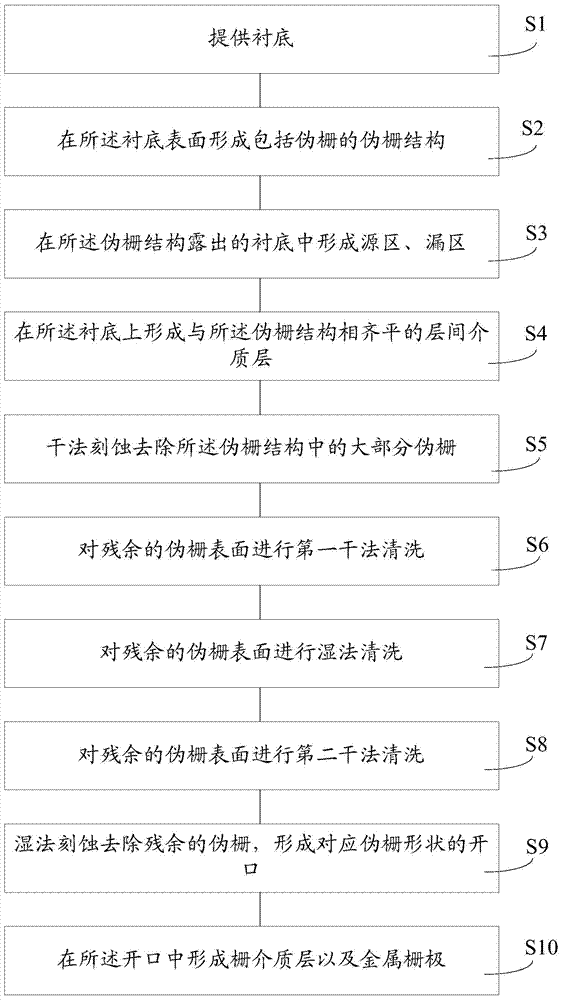

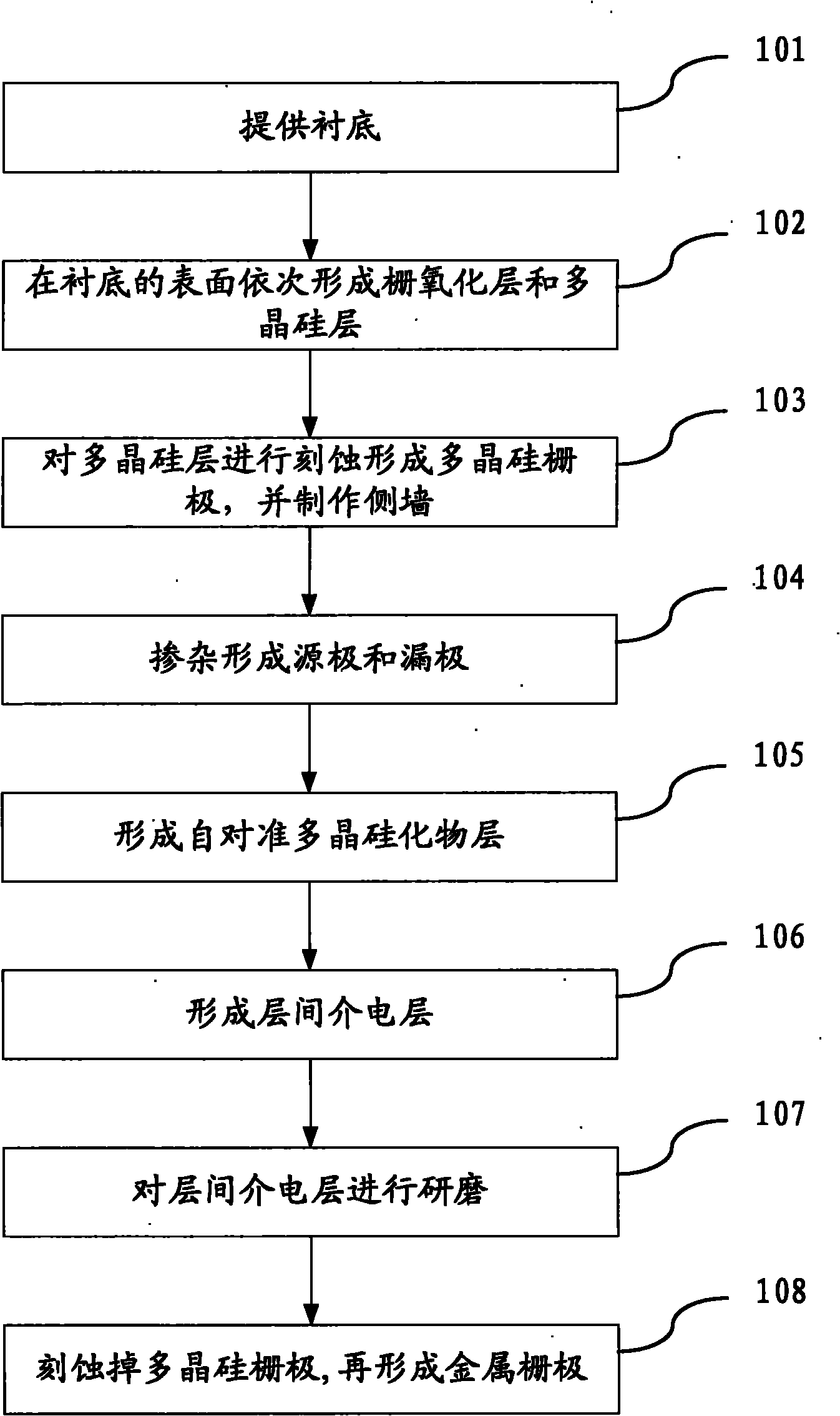

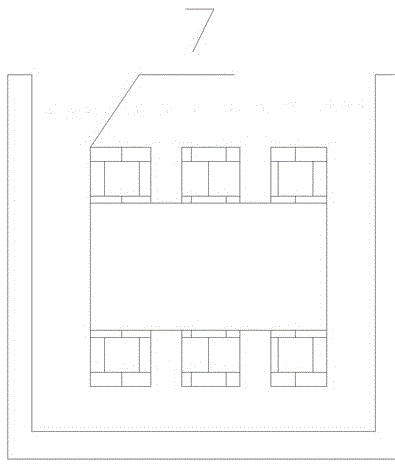

Transistor forming method

ActiveCN104701170AImprove etching effectAvoid pollutionSemiconductor/solid-state device manufacturingSemiconductor devicesMedia layerDry etching

The invention provides a transistor forming method. The method includes providing a substrate; forming a false grid structure comprising a false grid on the surface of the substrate; forming a source region and a leak region on the substrate exposed in the false grid structure; forming an interlayer medium layer aligned with the false grid structure on the substrate; removing majority of the false grid of the false grid structure by dry etching; performing first dry washing on the surface of the remained false grid; performing wet washing on the surface of the remained false grid; performing second dry washing on the surface of the remained false grid; removing the remained false grid by wet etching, and forming an opening corresponding to the false grid in the shape; forming a grid medium layer and a metal grid electrode in the opening. By means of the first dry washing, the wet washing and the second dry washing, the contaminant remained on the surface of the false grid is removed after the false grid is formed by dry etching, and the performance of a transistor is optimized.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Preparation method of anti-dazzle glass

The invention discloses a preparation method of anti-dazzle glass. The preparation method of the anti-dazzle glass comprises the following steps: (1) preparation of etchant, (2) glass pretreatment, and (3) etching treatment. By the treatment method, the quality of the glass is improved effectively, the smoothness of particles on the surface of the glass is improved, the transmittance and the anti-dazzle effect are improved, the treatment efficiency and the yield are high, and thus, the anti-dazzle glass has quite high promotion and use value.

Owner:安徽凤阳亚欧玻璃工艺品有限公司

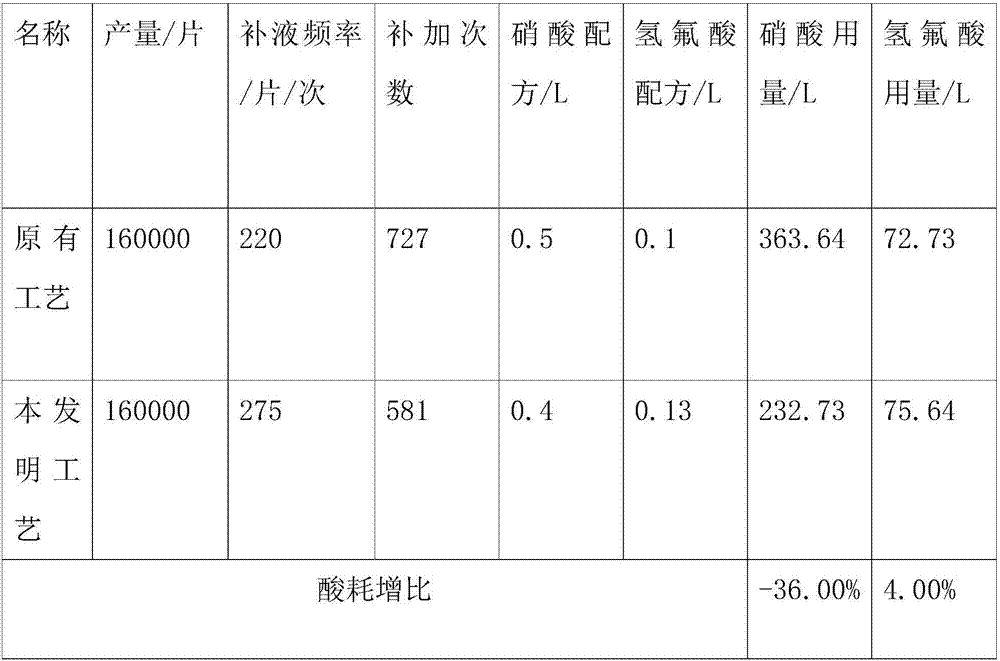

Etching process of solar energy cell chips capable of reducing NOx emissions

InactiveCN107090595AReduce appearanceLow efficiencyAfter-treatment detailsFinal product manufactureAcid etchingCell chip

The invention relates to the technical field of cell chip etching, in particular to an etching process of solar energy cell chips capable of reducing NOx emissions. The etching process comprises the following steps of (1), evenly attaching deionized water to the upper surface of a to-be-etched silicon chip to form water film; (2), adjusting the flatness of rollers in an etching tank so as to enable all the rollers to remain absolutely horizontal; (3), adding optimization etching liquid into the etching tank; (4), putting the to-be-etched silicon chip into the etching tank for etching. By forming a layer of the deionized water film on the upper surface of the silicon chip, the etching process can greatly weaken the negative effects on the appearance and efficiency of the silicon chip; after the acid etching liquid can not diffuse to the upper surface of the silicon chip, waste of the etching liquid is reduced, so is the dosage of nitric acid; therefore, the emissions of NOx are reduced, and the effects of environment protection and NOx treatment cost reduction are achieved on the premise that the efficiency of etching silicon chips and etching effects are guaranteed.

Owner:TONGWEI SOLAR HEFEI

Flexible circuit board etching liquid concentration control device

InactiveCN101538715BTimely and accurate measurementGuaranteed etching effectSemiconductor/solid-state device manufacturingFlexible circuitsEngineering

The invention relates to a flexible circuit board etching liquid concentration control device belonging to the technical field of etching liquid detection and control devices and comprising a testing box with a box cavity, an etching pool, a liquid inlet pipe and a liquid return pipe. The testing box is provided with a controller as well as an oxidant probe, a hydrochloric acid probe and a hydrometer which are respectively and electrically connected with the controller and extend into the testing box; the etching pool is provided with an oxidant adding pipe, a hydrochloric acid inlet pipe anda water inlet pipe; the oxidant adding pipe, the hydrochloric acid inlet pipe and the water inlet pipe are respectively provided with a control valve; the control valves are electrically connected with the controller; one end of the liquid inlet pipe is connected with the etching pool, the middle is provided with a conveying pump and a valve, and the other end extends into the testing box; and one end of the liquid return pipe is connected with the etching pool and the other end is connected with the testing box. The invention has the characteristic that the oxidant probe is inserted into thepipe cavity of the liquid inlet pipe. The invention has the advantage of ensuring the etching effect of the etching pool to FPC boards.

Owner:苏州市飞莱克斯电路电子有限公司

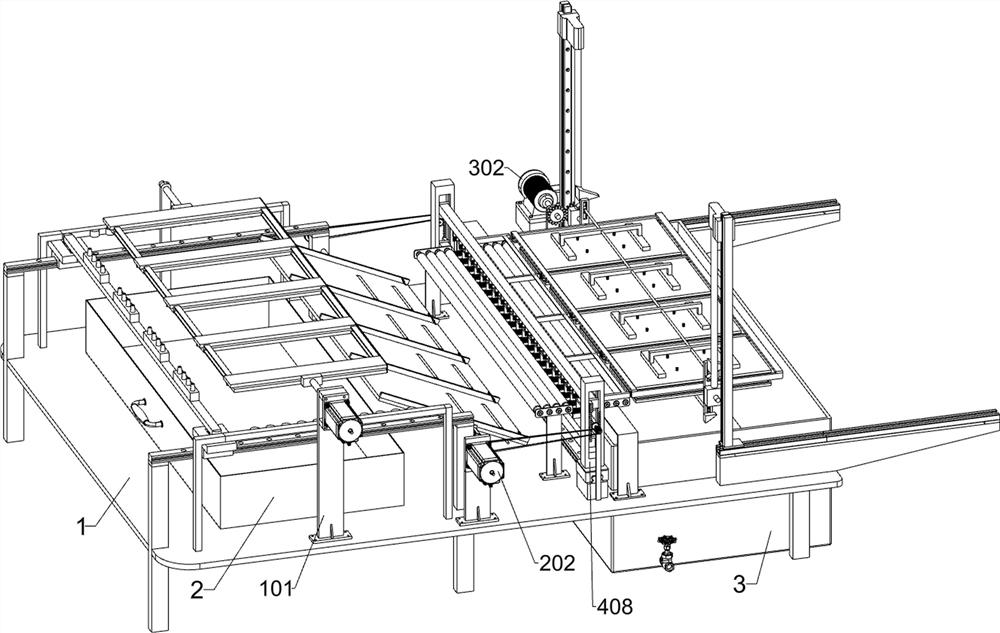

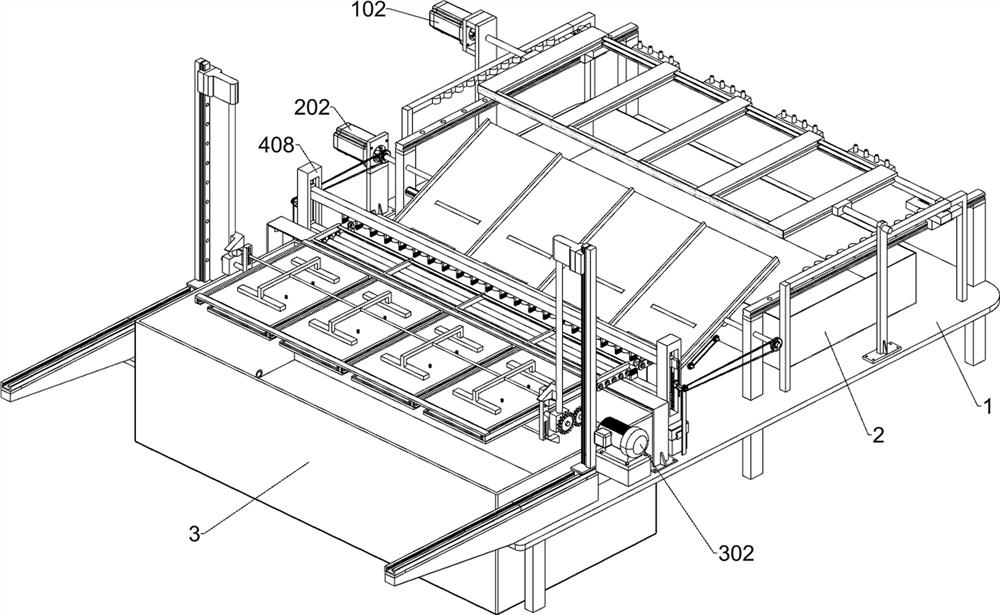

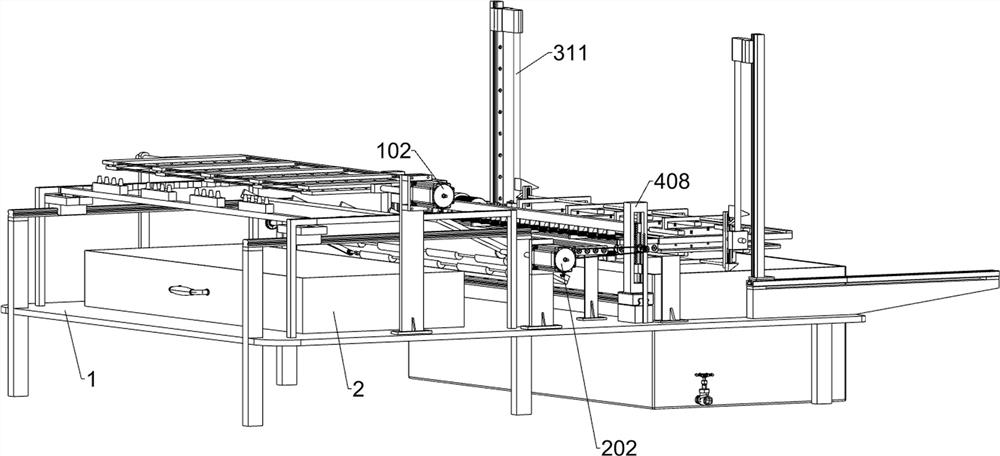

Copper foil removing equipment for UWB positioning base station substrate production

PendingCN114423162AAvoid damageReduce adverse effectsPrinted circuit liquid treatmentInsulating layers/substrates workingMetallurgyEngineering

The invention relates to the technical field of electronics, in particular to copper foil removing equipment for UWB positioning base station substrate production. The technical problem is that a copper foil on a substrate has impurity particles during pressing, after the copper foil is etched and removed, the impurity particles fall into blind holes of the substrate, and additional processing steps need to be added for processing, so that the production cost is increased. According to the technical scheme, the copper foil removing equipment for UWB positioning base station substrate production comprises a bottom frame, a collecting box and the like; a collecting box is connected to the left portion of the bottom frame. When the device is used, residual glue residues in the blind holes of the substrate are cleaned through the air jet, the damage to the substrate is avoided, meanwhile, the adverse effect of the glue residues on etching is avoided, only the lower surface of the substrate is etched through overturning each time, the upper surface is sealed and protected, and the production efficiency is improved. Impurity particles are prevented from falling into the blind holes of the substrate after the copper foil is etched and removed when the copper foil is pressed, and additional processing steps are avoided.

Owner:HANGZHOU CCRFID MICROELECTRONICS

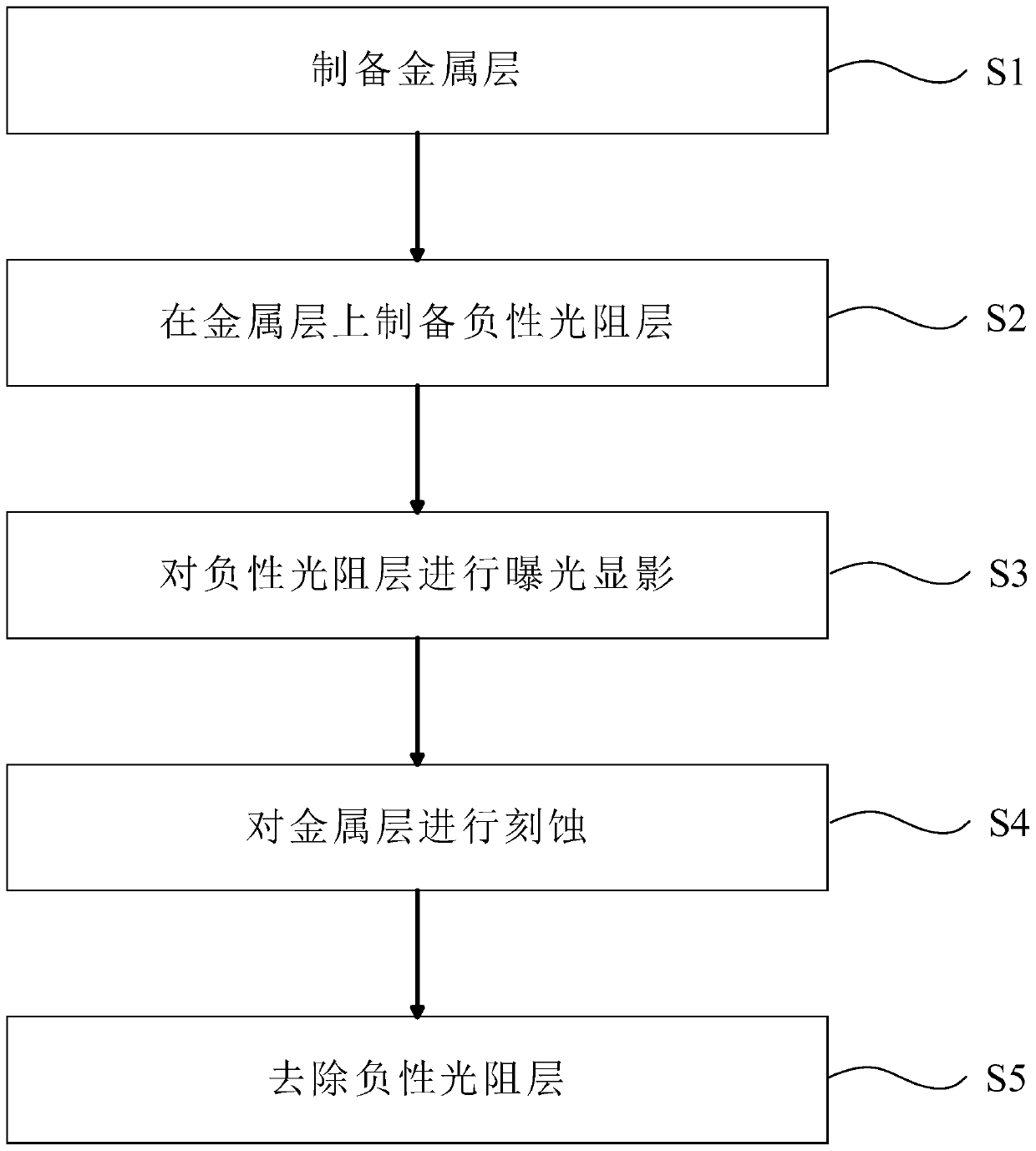

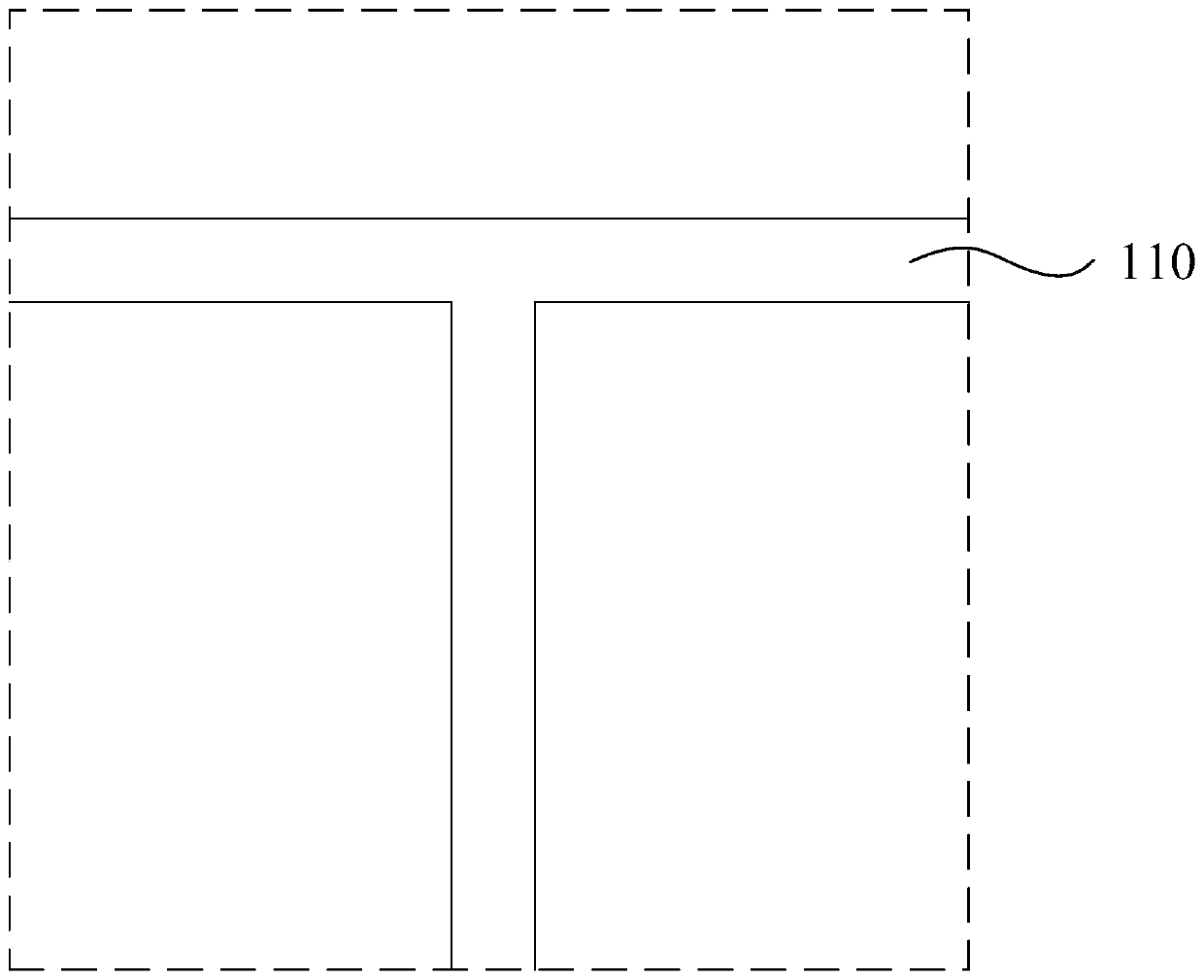

Array substrate and preparation method thereof

ActiveCN110828381AGuaranteed etching effectImprove dark state light leakageSolid-state devicesSemiconductor/solid-state device manufacturingPhysical chemistryDisplay device

The invention provides an array substrate and a preparation method thereof. The preparation method comprises the steps of preparing a metal layer, preparing a negative photoresist layer on the metal layer, exposing and developing the negative photoresist layer, etching the metal layer, and removing the negative photoresist layer. According to the preparation method, the metal layer is patterned byusing a negative photoresist, and the characteristic of light retention of the negative photoresist is utilized. During exposure, the negative photoresist exposure amount at the corresponding position of the corner in the pattern is enough. During development, the negative photoresist at the corresponding position of the corner in the pattern can be completely dissolved in the developing solutionwithout residues. The etching effect of the corner in the metal in the subsequent metal etching process is ensured, and the problem that the corner in the metal is rounded due to insufficient photoresist exposure is avoided. Therefore, the phenomenon of dark-state light leakage of a display device is improved, and the contrast ratio of a product is improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

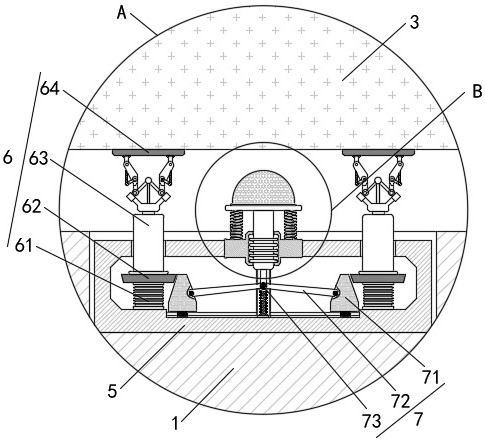

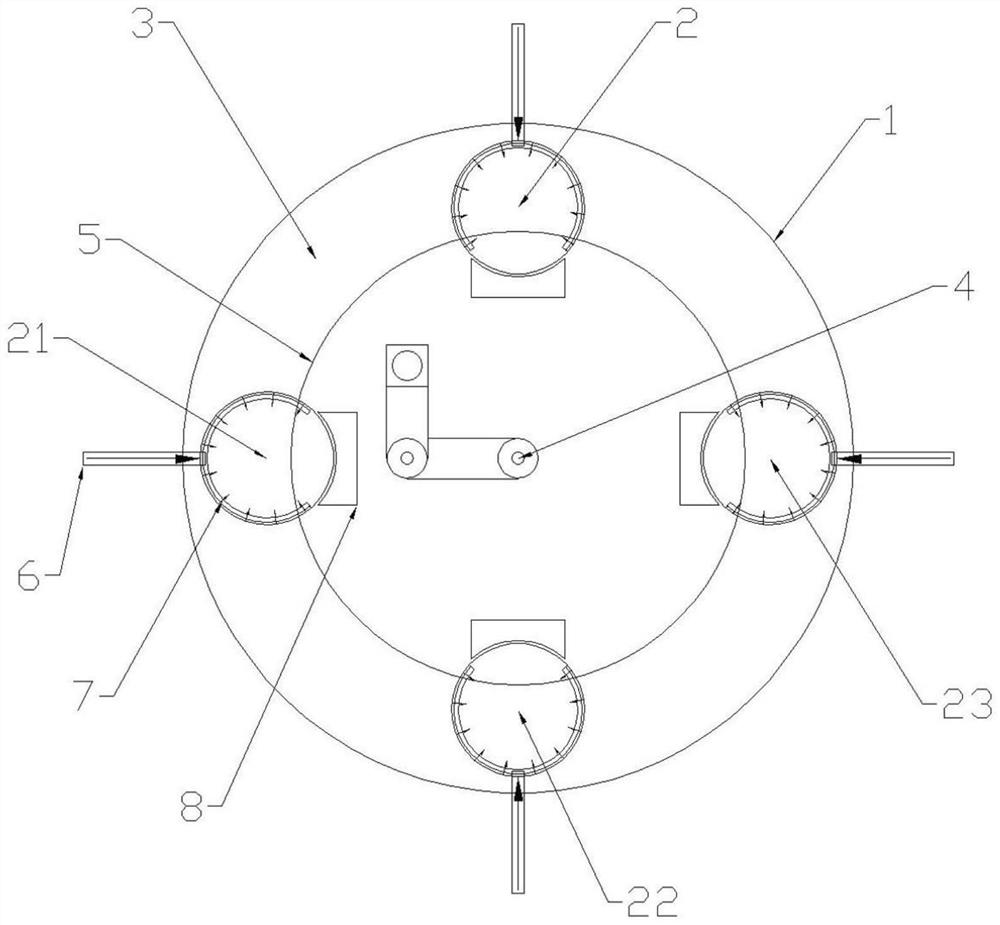

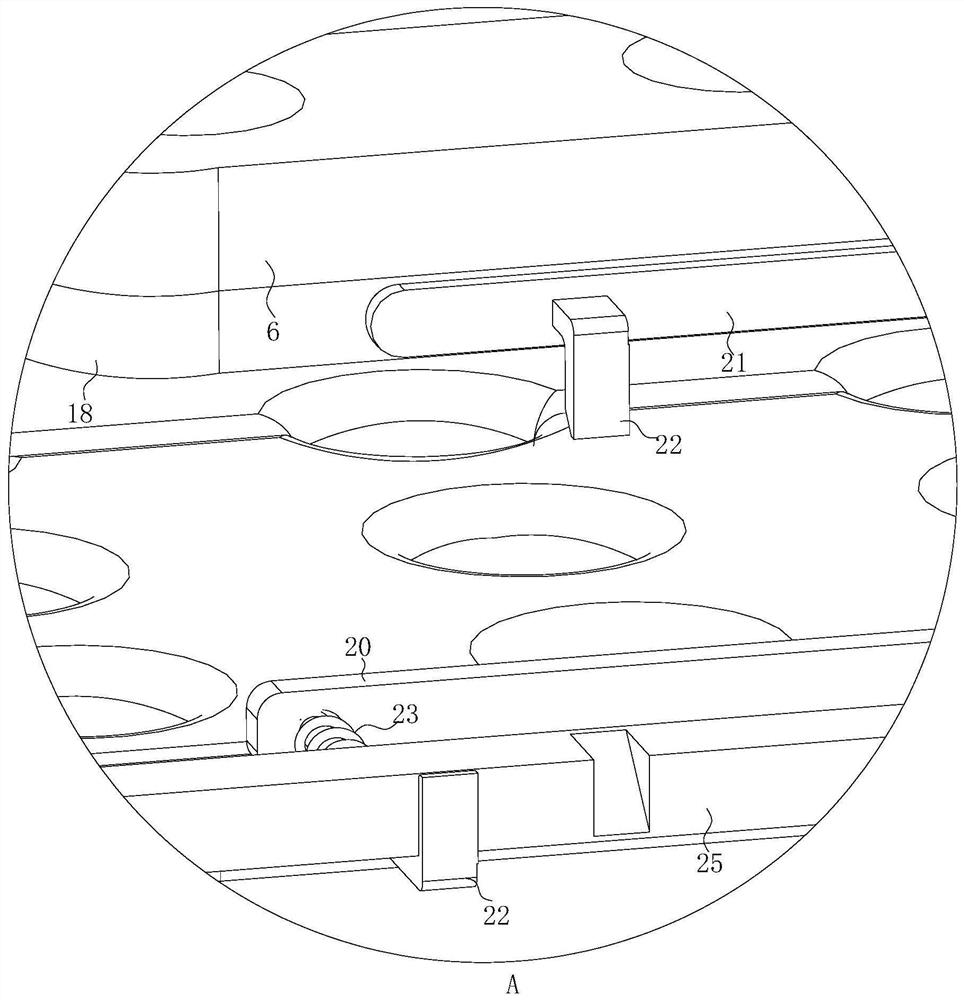

Method for quickly and freely depositing or etching atomic layer and chamber structure

PendingCN114864370AGuaranteed depositionGuaranteed etching effectElectric discharge tubesSemiconductor/solid-state device manufacturingCircular discReciprocating motion

The invention belongs to the technical field of atomic layers, and provides a method for quickly and freely depositing or etching an atomic layer and a chamber construction.The chamber structure comprises a disc chamber, a plurality of source reaction chambers which are annularly arranged at equal intervals are arranged in the disc chamber, and transmission chambers are arranged outside the source reaction chambers; at least one substrate transmission device rotating around the circle center of the disc cavity is arranged in the middle of the disc cavity; according to the invention, the deposition or etching reaction is carried out through the rotary reciprocating motion of the substrate carrying transmission device, the deposition or etching rate is improved while the deposition or etching effect is ensured, and the deposition or etching efficiency can be improved by setting different cavity numbers and operation programs according to the types of deposition or etching materials. And automatic and intelligent deposition or etching of various materials is realized.

Owner:江苏鹏举半导体设备技术有限公司

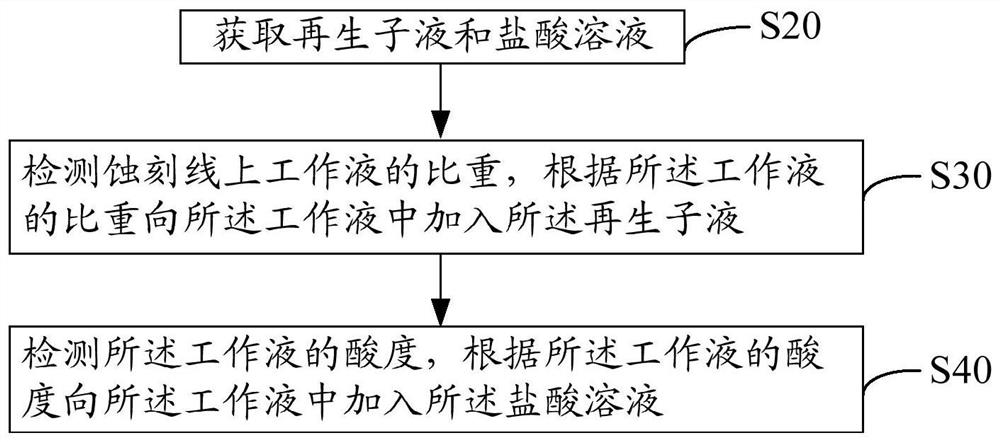

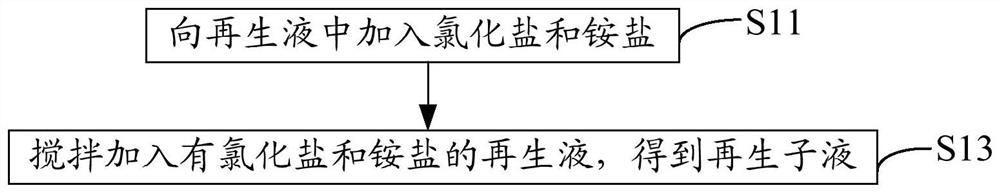

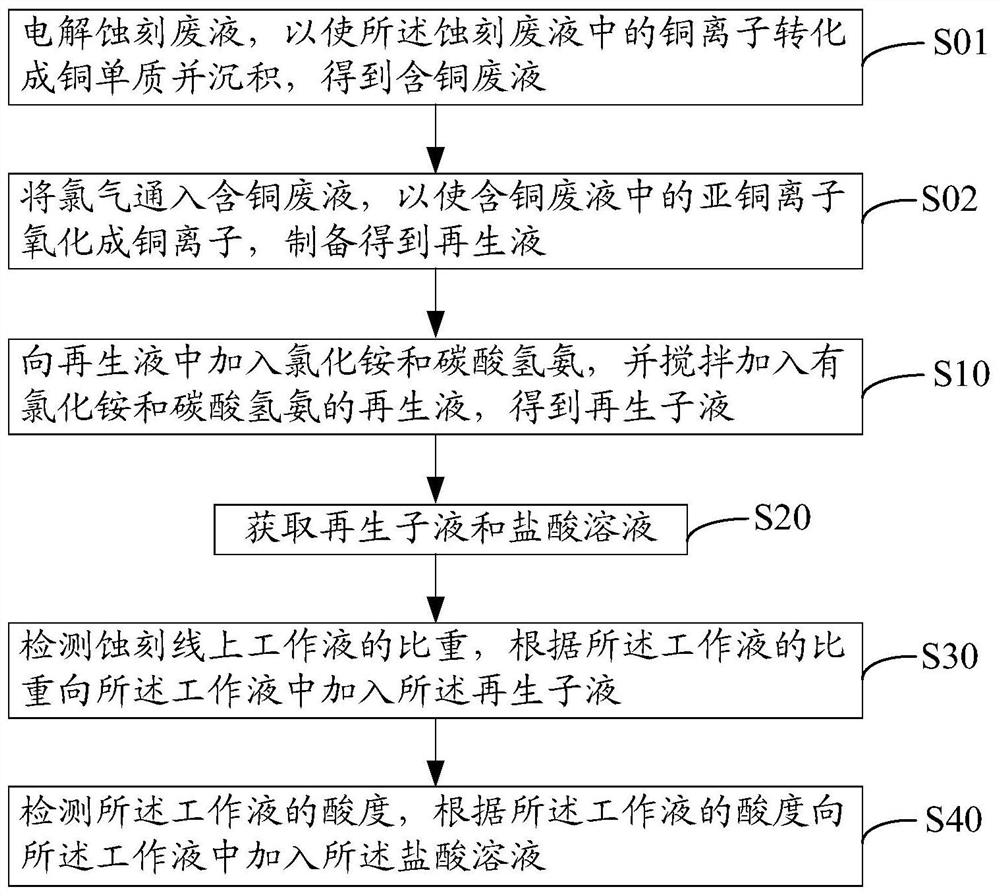

Regenerated sub-solution reuse method

ActiveCN111809184APrevent precipitationGuaranteed etching effectAmmonium chloride mixtureAcidity/alkalinity

The invention discloses a regenerated sub-solution reuse method comprising the following steps: obtaining a regenerated sub-solution and a hydrochloric acid solution; detecting the specific gravity ofa working solution above an etching line, and adding the regenerated sub-solution to the working solution according to the specific gravity of the working solution; and detecting the acidity of the working solution, and adding the hydrochloric acid solution to the working solution according to the acidity of the working solution. That is, the technical scheme of the invention avoids precipitationof ammonium chloride in the regenerated sub-solution and ensures the etching effect of the added regenerated sub-solution.

Owner:深圳市祺鑫环保科技有限公司

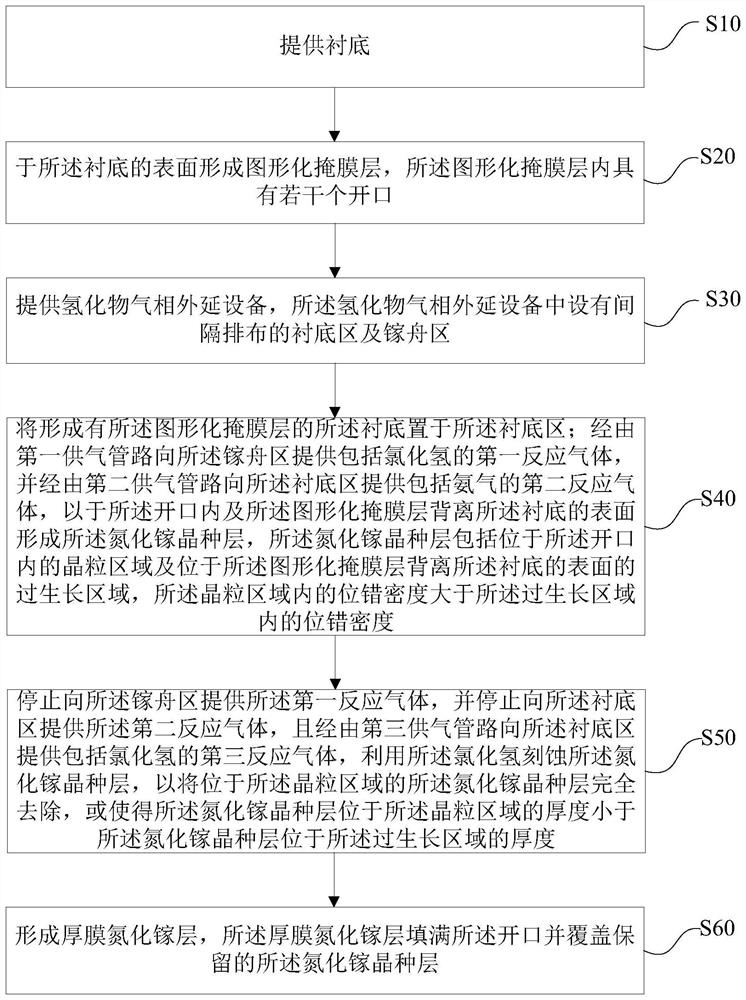

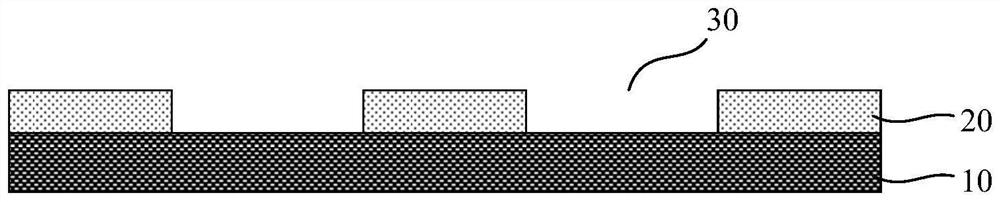

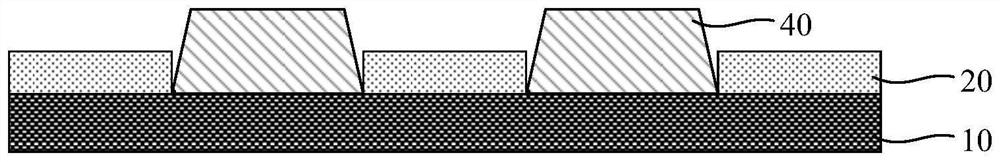

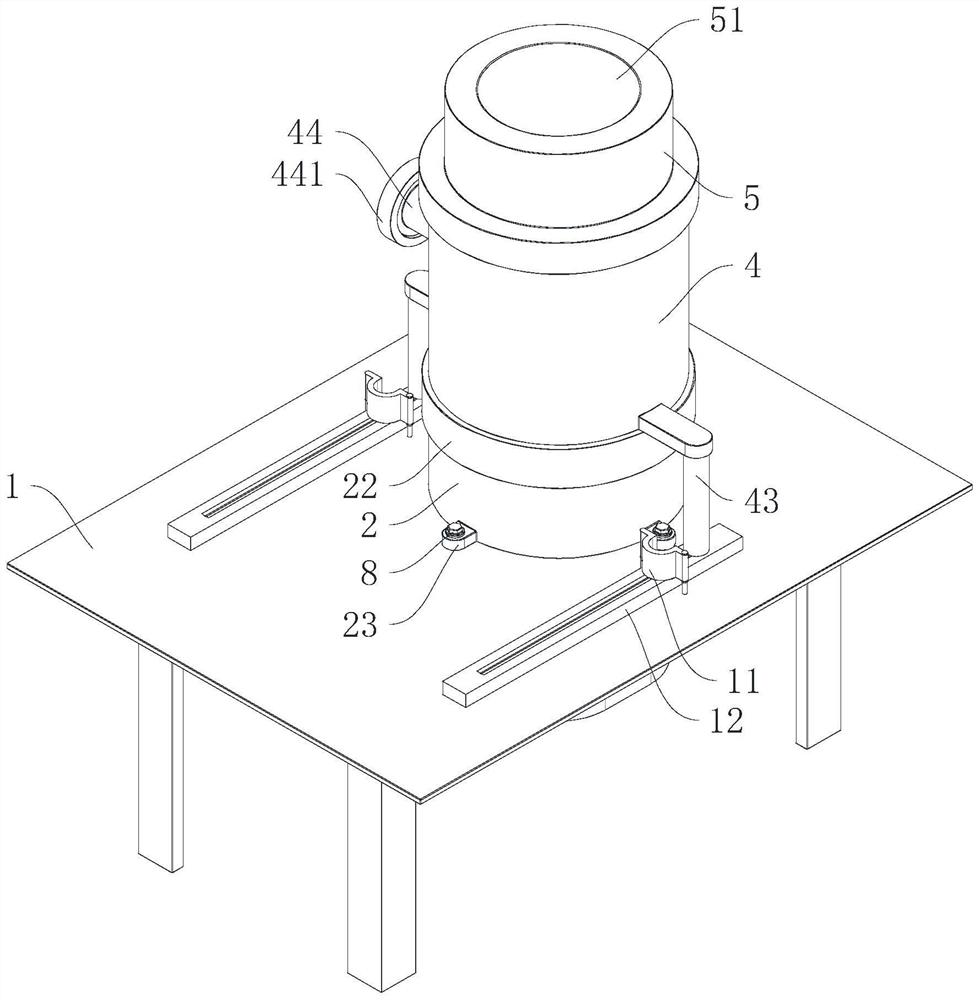

Semiconductor structure, self-supporting gallium nitride layer and preparation method thereof

PendingCN114743862AImprove crystal qualityAvoid problems that affect performance and make it difficult to meet requirementsFinal product manufactureSolid-state devicesSemiconductor structureGallium nitride

The invention relates to a semiconductor structure, a self-supporting gallium nitride layer and a preparation method of the self-supporting gallium nitride layer. Forming a patterned mask layer on the surface of the substrate; providing a hydride vapor phase epitaxy apparatus; placing the substrate on which the patterned mask layer is formed in a substrate region; providing a first reaction gas containing hydrogen chloride for the gallium boat region through a first gas supply pipeline, and providing a second reaction gas containing ammonia gas for the substrate region through a second gas supply pipeline to form a gallium nitride seed crystal layer; and stopping providing the first reaction gas to the gallium boat region, stopping providing the second reaction gas to the substrate region, and providing a third reaction gas containing hydrogen chloride to the substrate region through a third gas supply pipeline so as to completely remove the gallium nitride seed crystal layer in the crystal grain region, or the thickness of the gallium nitride seed layer in the grain area is smaller than that of the gallium nitride seed layer in the overgrowth area; and forming a thick-film gallium nitride layer. The method can save the raw material cost and improve the quality of the thick-film gallium nitride layer.

Owner:镓特半导体科技(上海)有限公司

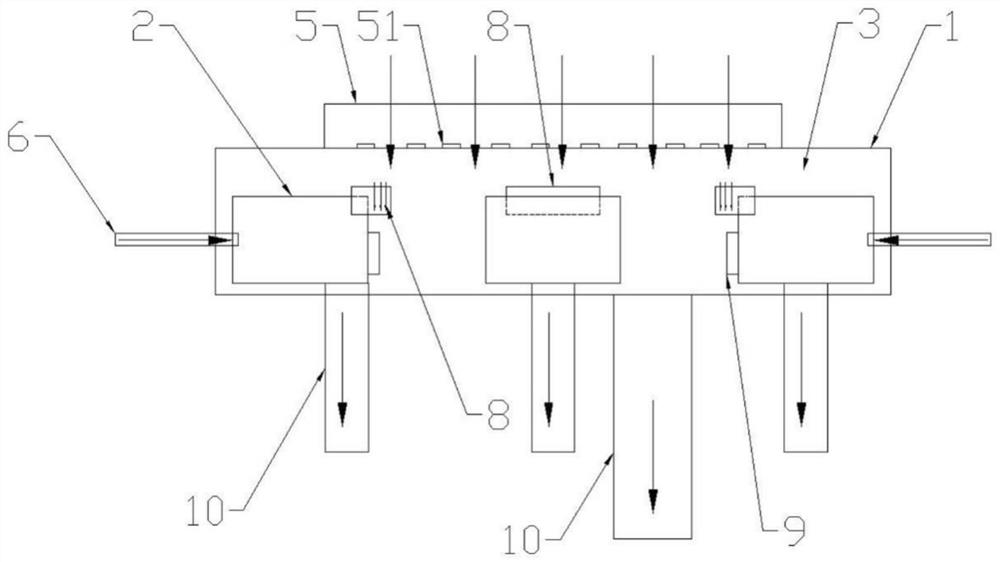

Etching device

PendingCN114042421AImprove etching efficiencyGuaranteed etching effectChemical/physical/physico-chemical stationary reactorsFeed devicesPhysicsEngineering

The invention provides an etching device. The etching device comprises a base, a containing part, a rotating disc, a translation part and a jet part; a fixing base is arranged on the base and provided with a containing cavity and a top cover, and a through hole is formed in the top cover; the rotating disc is arranged in the containing cavity and connected with a rotating driving assembly; the translation part is slidably arranged on the containing part and provided with a reaction cavity and an air inlet hole; and the jet part is arranged on the translation part and provided with a liquid inlet channel. During use, etching liquid is input into the reaction cavity through the liquid inlet channel, the internal pressure of the reaction cavity is reduced, external gas enters the reaction cavity through the gas inlet hole and reacts with the etching liquid, and a product with etching capability is formed. The translation part is moved until the reaction cavity is communicated with the through hole, so that the product flows into the containing cavity; and meanwhile, the rotating driving assembly is started, and the rotating disc drives a to-be-etched object to rotate. According to the etching device provided by the embodiment of the invention, a product can be prevented from reacting with the external environment, the etching efficiency can be improved by the structure of the etching device, and the etching effect is also ensured.

Owner:江西华兴四海机械设备有限公司

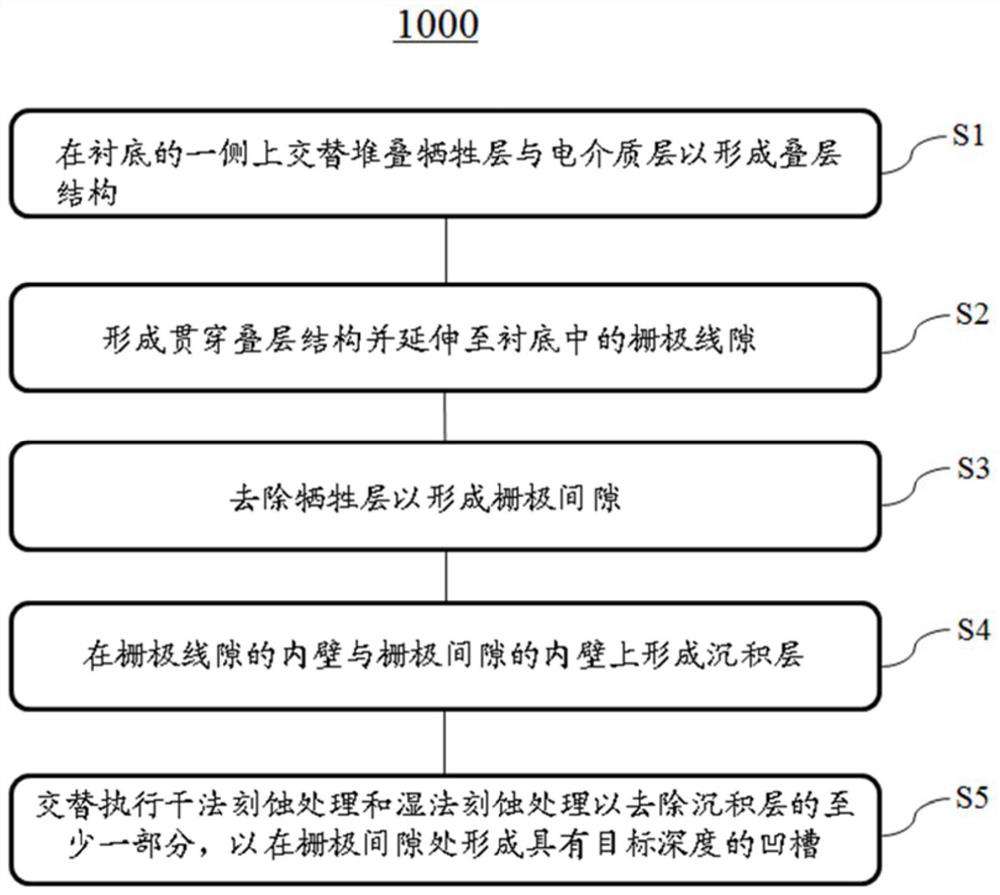

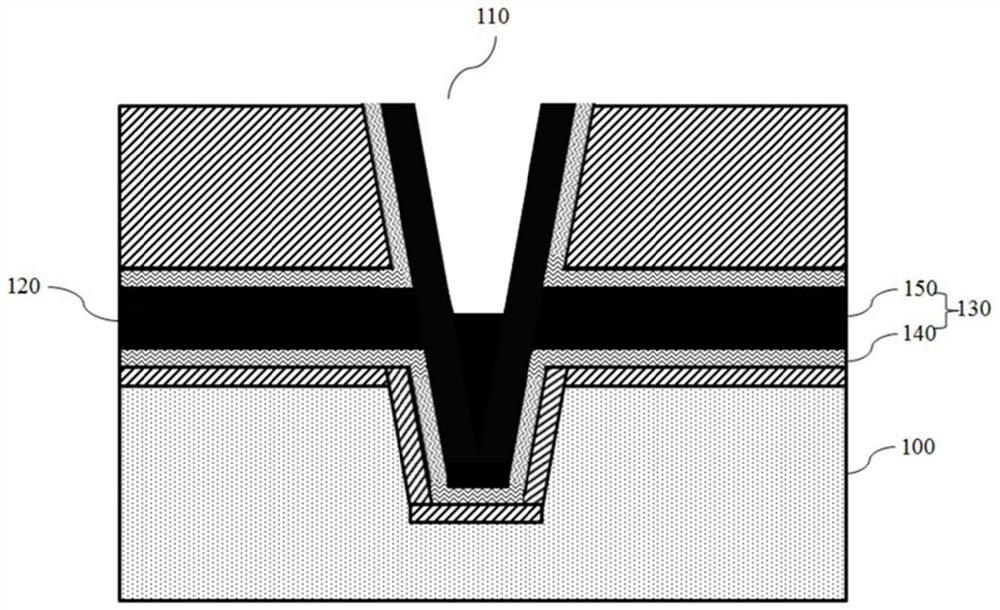

Preparation method of three-dimensional memory

ActiveCN113035700BEfficient removalInfluence subsequent process stepsSolid-state devicesSemiconductor devicesEngineeringDielectric layer

The present application provides a method for preparing a three-dimensional memory, the method comprising: alternately stacking sacrificial layers and dielectric layers on one side of a substrate to form a stacked structure; a gate line gap; removing the sacrificial layer to form a gate gap; forming a deposition layer on an inner wall of the gate line gap and an inner wall of the gate gap; and alternately performing a dry etching process and a wet etching process to remove the deposition layer At least a portion of the gate gap to form a groove having a target depth at the gate gap.

Owner:YANGTZE MEMORY TECH CO LTD

Method of forming a transistor

ActiveCN104701170BImprove etching effectGood for shape protectionSemiconductor/solid-state device manufacturingSemiconductor devicesStructural phaseEngineering

Owner:SEMICON MFG INT (SHANGHAI) CORP

Etching solution for photoelectrochemical etching of gallium nitride

ActiveCN112779013BEtching is effectiveAvoid damageFinal product manufactureSemiconductor/solid-state device manufacturingPhotoelectrochemical etchingPhotoelectrochemistry

The invention discloses an etchant for photoelectrochemically etching gallium nitride. The etchant is composed of amino acid or its derivatives dissolved in a solvent. The invention uses amino acid or its derivatives as an etchant to photoelectrochemically etch gallium nitride, which can effectively etch gallium nitride, and the etching process has low equipment requirements, convenient operation, simple process and environmental protection, which is beneficial to The damage to the surface of the material is small.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Efficient etching machine for new energy photovoltaic wafer

ActiveCN114038939AFast etchPrevent slipping outFinal product manufactureSemiconductor/solid-state device manufacturingEtchingWafering

The invention discloses an efficient etching machine for a new energy photovoltaic wafer in the technical field of etching machines. The efficient etching machine comprises a protective shell, the inner side of the protective shell is provided with a placement mechanism for clamping and placing the photovoltaic wafer, and the left and right sides of the placement mechanism are connected with a conversion mechanism for driving the placement mechanism to rotate and convert the photovoltaic wafer; the photovoltaic wafer is stably supported by the placement mechanism when double-sided etching is carried out on the photovoltaic wafer every time, and after one side of the photovoltaic wafer is etched, the placement mechanism is rotated by matching with the conversion mechanism, and the placement mechanism is closed firstly to make the photovoltaic wafer clamped stably, so that the photovoltaic wafer is prevented from sliding out in the rotating process; and after conversion, the conversion mechanism opens the middle part of the placement mechanism, so that the placement mechanism is prevented from interfering with etching liquid to etch the photovoltaic wafer, the etching effect of the etching liquid on the photovoltaic wafer is ensured, and the two surfaces of the photovoltaic wafer are quickly etched.

Owner:泰州君之华新能源科技有限公司

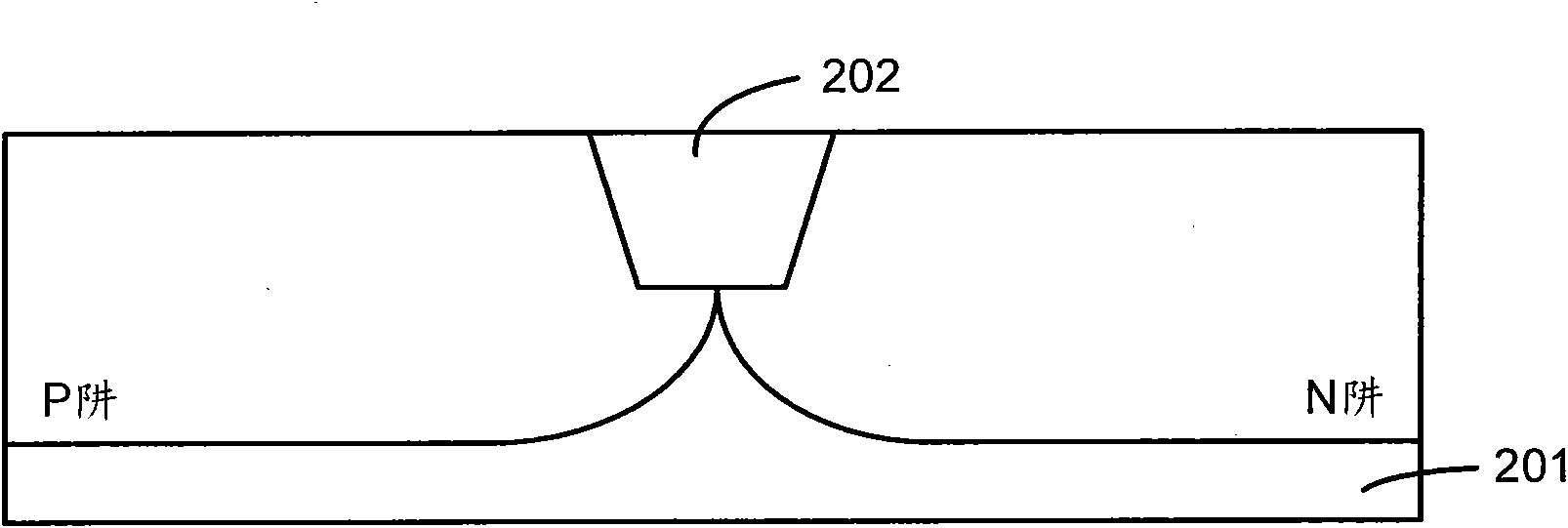

Method for producing semiconductor device

InactiveCN102376572AQuality assuranceQuality improvementSolid-state devicesSemiconductor/solid-state device manufacturingDielectric layerSemiconductor

The invention provides a method for producing a semiconductor device. The method comprises the following steps of: providing a substrate; forming a polycrystalline silicon layer on the surface of the substrate; forming a mask layer on the surface of the polycrystalline silicon layer; patterning the mask layer and the polycrystalline silicon layer to form a polycrystalline silicon grid and a barrier layer which is located on the surface of the polycrystalline silicon grid; and producing side walls at two sides of the polycrystalline silicon grid; doping at two sides of the polycrystalline silicon grid to form a source electrode and a drain electrode; forming self aligned polycide layers on the surface of the substrate and the surface of the barrier layer; forming interlayer dielectric layers on the surfaces of the polycide layers and the surfaces of the side walls; removing the interlayer dielectric layers to the polycrystalline silicon grid by a chemical and mechanical grinding method; removing the polycrystalline silicon grid to form a groove for obtaining a metal grid; and doping in the groove to form the metal grid. According to the method provided by the invention, etching speeds of different polycrystalline silicon grids are basically the same and the etching effect is guaranteed, so that the quality of the subsequently formed metal grid is ensured.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Processing method of ogs capacitive touch screen cover glass

ActiveCN103226425BGuaranteed edge strengthIncrease productivityInput/output processes for data processingCapacitanceGlass cover

The invention relates to a touch screen cutting method for an electronic product, and mainly relates to an OGS (one glass solution) capacitive touch screen cover glass processing method. The OGS capacitive touch screen cover glass processing method comprises the following steps: step 1: manufacturing a protective layer with the thickness of 20-30 mm on a large OGS toughened glass plate, and sequentially drying the protective layer by roasting, exposing and developing the protective layer and toughening a membrane of the protective layer; and step 2: immersing the large OGS toughened glass plate processed in the step 1 into an etching solution with the temperature of 21-25 DEG C for etching the large OGS toughened glass plate into small OGS toughened glass plates. By the OGS capacitive touch screen cover glass processing method, the large OGS toughened glass plate can be etched into the single small OGSs, without a repairing process after the etching process; and the etched single small OGSs are high in size precision and high in qualified rate.

Owner:深圳华视光电有限公司

Preparation method of silicon thin film surface antireflection structure

InactiveCN102694076BGuaranteed etching effectImprove performanceFinal product manufactureVacuum evaporation coatingEtchingSilicon thin film

The invention relates to a preparation method of a silicon thin film surface antireflection structure, and the method comprises the following steps of: 1, preparation of a silicon thin film: firstly sequentially packaging a silicon target with the purity of 99.9999%, a silver target with the purity of 99.999% and a cheap silicon wafer base into a vacuum chamber, then vacuumizing the vacuum chamber, then introducing argon into the vacuum chamber, and finally depositing a polycrystalline silicon thin film with the thickness of 0.3-5Mum on the base; 2, deposition of silver nano particles: continuously depositing silver nano particles on the polycrystalline silicon thin film obtained in the step one, wherein the thickness of the deposited silver nano particle layer is 2-20nm; 3, catalytic etching of precious metal silver nano particles; and 4, removal of the silver nano particles: soaking a black silicon thin film obtained in the step three with a salpeter solution with the mass fraction of 20-40% for 10-30 minutes at room temperature, so as to remove the silver nano particles reserved on the black silicon thin film, then washing with distilled water and ethyl alcohol successively, and drying with cold air. The silicon thin film surface antireflection structure disclosed by the invention is of a porous structure and has the characteristics of low cost, good antireflection effect and high stability.

Owner:SHENYANG UNIV

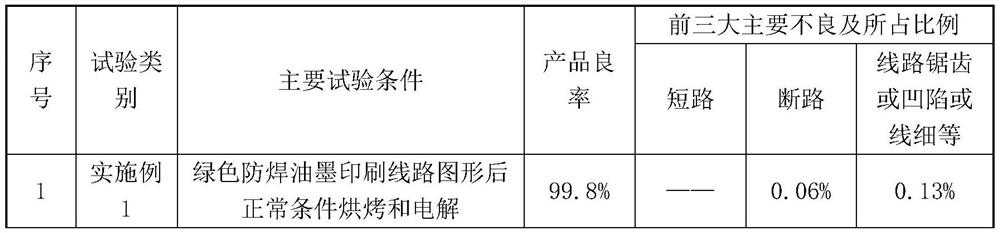

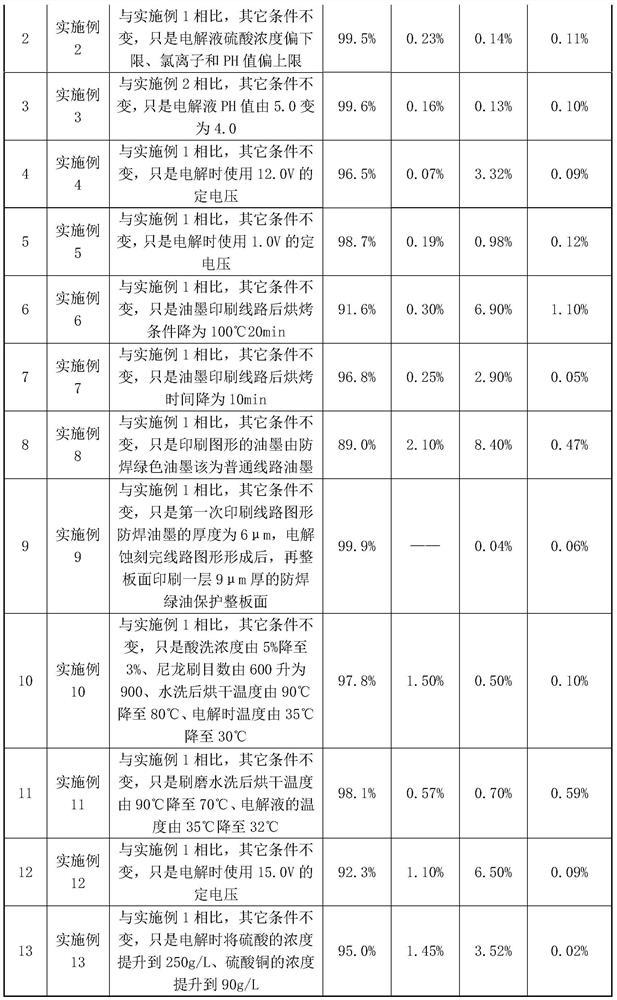

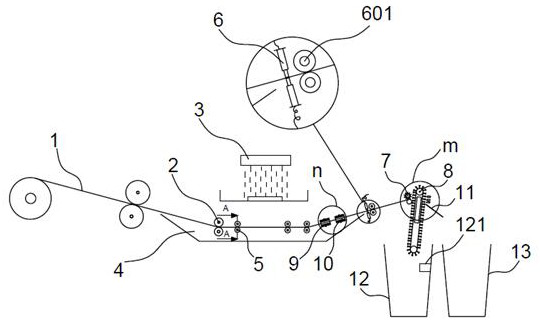

Production process method of PCB

PendingCN113950194AIncrease incomeImprove working environmentInsulating layers/substrates workingEtchingEngineering

The invention relates to the technical field of circuit board manufacturing, in particular to a production process method of a PCB, which comprises an etching method for forming a circuit pattern, and the etching method is electrolytic etching. According to the production process method of the PCB, chemical etching in a traditional PCB production process is replaced with electrolytic etching, the method is green, environmentally friendly and free of pollution, the production cost is greatly saved, the workshop operation environment is improved, and the strict acceptance standard of clean and civilized production is met.

Owner:KUNSHAN DONGWEI MACHINERY CO LTD

Shark's Metal Magnetic Line Marker Making Device

ActiveCN107466940BReduce harmNot easy to corrode and rustAntifouling/underwater paintsPaints with biocidesWire rodEngineering

The invention discloses a metal magnetic line marker manufacture device for sharks, and belongs to the technical field of artificial marker production. The device comprises an etching machine by which a line marker body can be etched, the etching machine is connected with a dowel drilling group by which the tail end of the segmented line marker body can be drilled, an etching tank is arranged below the etching machine, the interior of the etching tank is provide with a guide pulley group and shaping wheel groups; a spraying machine, a drying machine, a glue dispensing machine and a cutting hob are sequentially connected between the shaping wheel groups and the dowel drilling group, one side of the dowel drilling group is provided with the cutting hob, and the other side is provided with drilling machines; a line marker collecting barrel is arranged below the dowel drilling group; and a scrap guiding board is arranged below the drilling machines. According to the device provided by the invention, line material waste produced in a whole process is less, the surface of parts of the device is sprayed with an abrasion resistant layer, precision of the parts of the device is not easy to reduce in a long-term usage process, marker serial numbers for etching are clear, production is rapid, energy consumption is low, batched production can be realized, and after manufactured line markers are injected into shark bodies, influences on shark activity are small.

Owner:ZHEJIANG OCEAN UNIV

A mixed additive for eliminating internal stress of electrolytic copper foil and method for producing low-stress copper foil

The invention relates to a mixed additive for removing internal stress of an electrolytic copper foil and a method for producing a low-stress copper foil and belongs to the technical field of production of a high-precision electrolytic copper foil. The mixed additive for removing internal stress of the electrolytic copper foil comprises gelatin, hydroxyethyl cellulose and liquid additive. The method for producing the low-stress copper foil by using the mixed additive comprises the steps of preparing high-purity cathode copper and sulfuric acid into mixed solution of sulfuric acid and copper sulfate at 60-95 DEG C under the condition of stirring in the presence of air, wherein Cu<2+> is 85-100g / L and H2SO4 is 100-120g / L; adjusting the temperature of electrolyte to 45-60 DEG C and the flow to 50-70m<3> / h; adding 20-50mg / L of Cl<->, adding the mixed additive, with a drum titanium tube which continuously rotates as a cathode and arc titanium as an anode, carrying out copper electrolytic deposition and lastingly stripping to obtain 12-70 microns copper foil under the condition of the direct current of which the current density is 55-70A / dm<2>. The thickness of the copper foil is controlled by adjusting the rotation speed of the cathode; and the obtained copper foil has excellent performances.

Owner:SHANDONG JINBAO ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com