Patents

Literature

34results about How to "Etching is effective" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gradient method preprocessing technique for depositing CVD diamond film on hard metal surface

InactiveCN101220462AQuality improvementGuaranteed StrengthChemical vapor deposition coatingEtchingHard metal

The invention provides a pretreatment process for a CVD diamond film deposited on a hard alloy surface by adopting a gradient method in view of the problems of low intensity of the seamed edges and sharp corners, affecting the product performance and even the corrosion of seamed edges and sharp corners and so on caused by the faster removal of Co on the seamed edges and the sharp corners than Co on a face in the pretreatment process of the existing CVD diamond films deposited on a hard alloy surface; the main process procedures are provided in sequence as follows: polishing (1) arrow cleaning(2) arrow etching of WC (3) arrow cleaning(4) arrow first etching of Co(5) arrow cleaning(6) arrow drying (7) arrow glue spreading (8) arrow second etching of Co(9) arrow cleaning(10) arrow sol(11) and seeding with diamond powder (12), particularly, the gluing technique of the procedures ensures that the hard alloy surface meets the deposit demands of the CVD diamond films after being pretreated and at the same time, the Co content of the seamed edges and the sharp corners of the hard alloy product and the removal Co content on the face are caused to be basically consistent, which ensures the intensity of the seamed edges and the sharp corners and improves the performance of the CVD diamond films.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

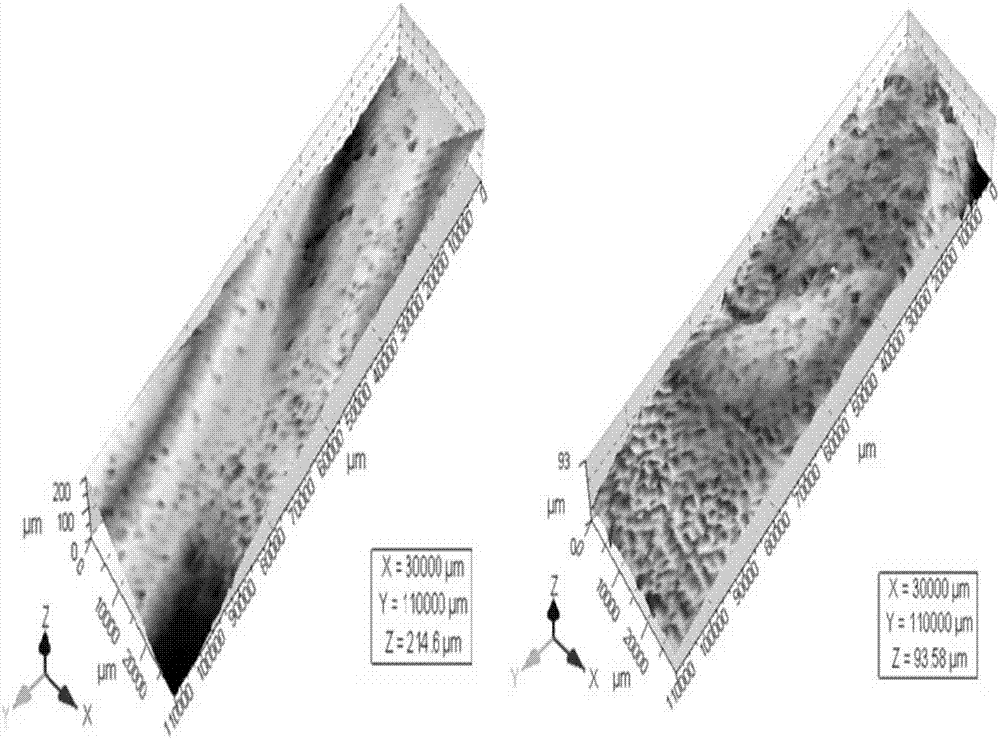

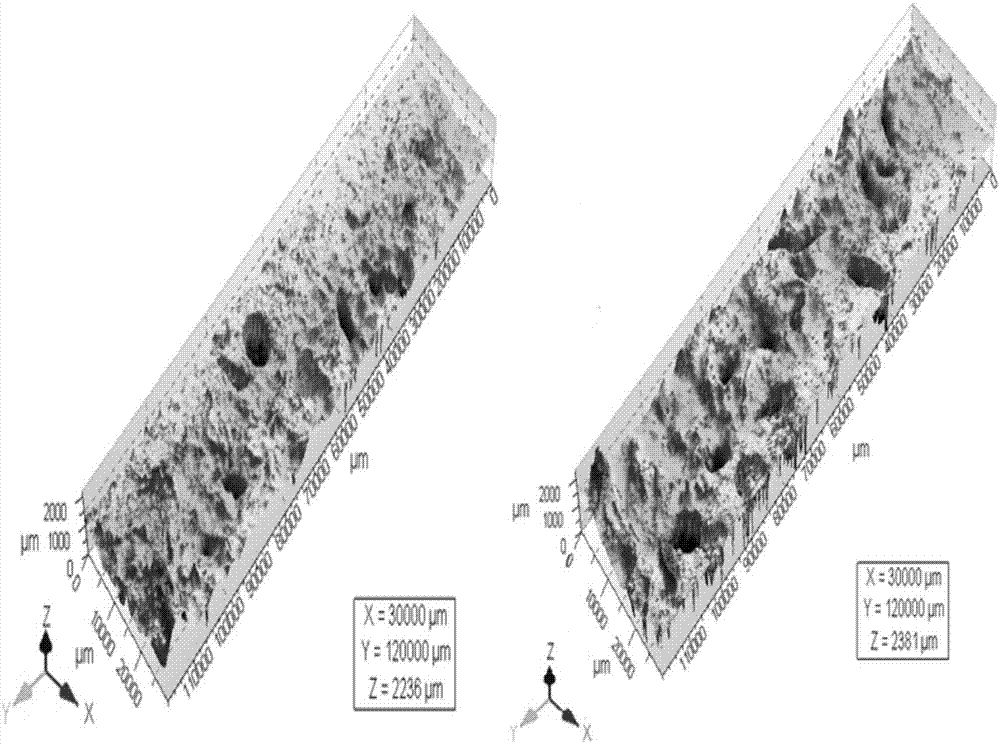

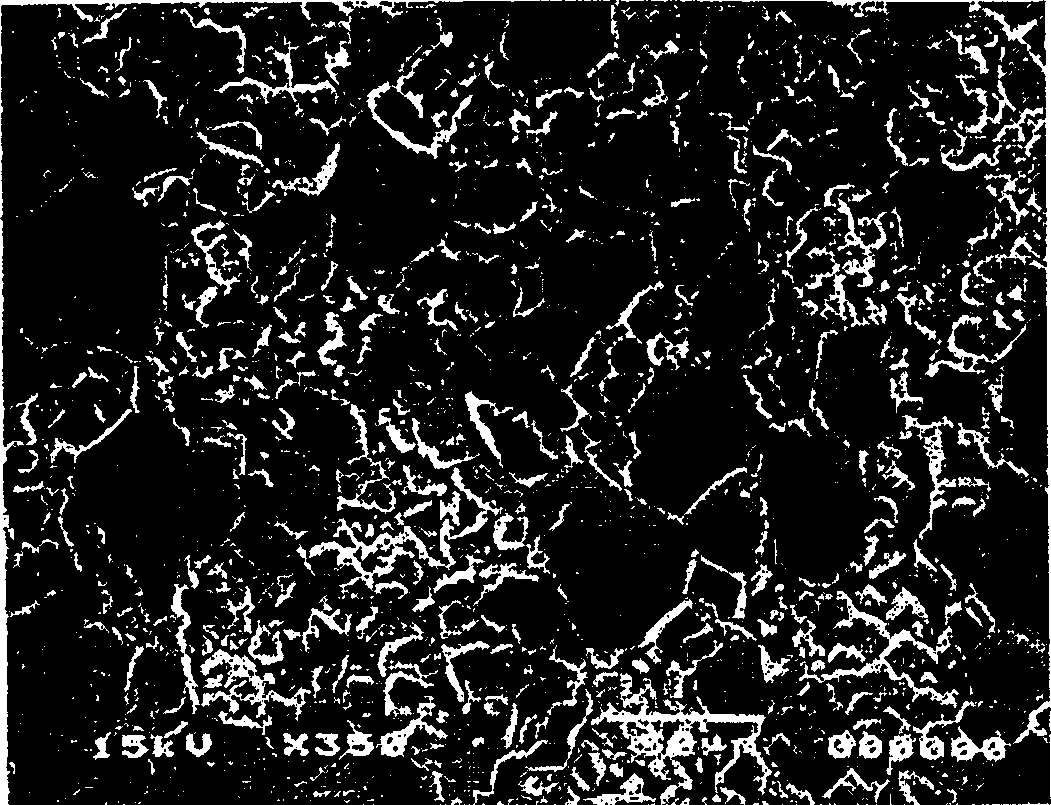

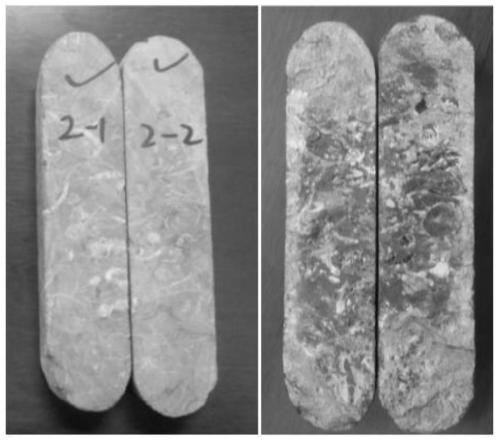

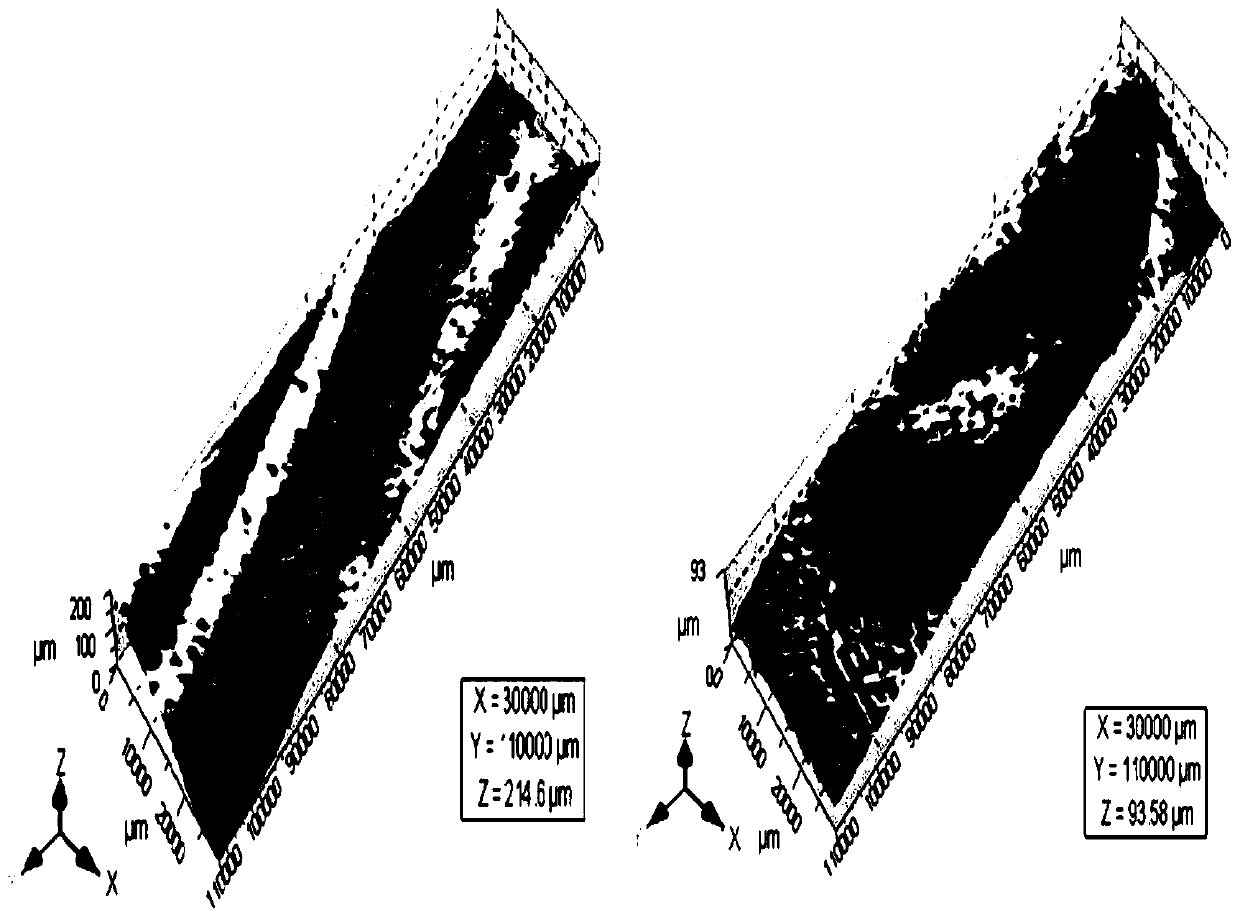

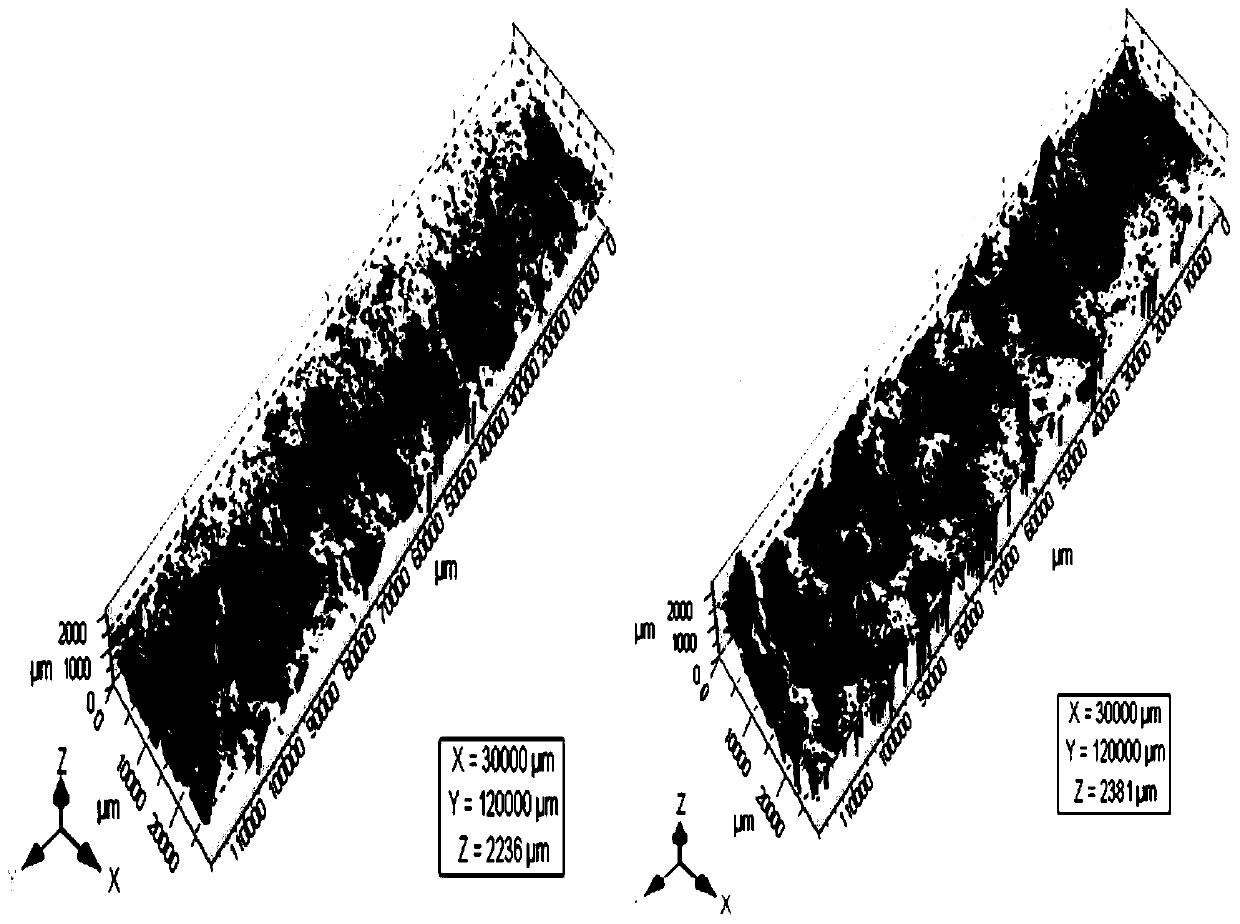

Evaluation method of acid fracturing effect of carbonate rock

The invention provides an evaluation method of an acid fracturing effect of carbonate rock. The method comprises the following steps of performing appearance scanning on a rock core sample to obtain the initial surface roughness degree, performing acid etching treatment on the rock core sample by using acid liquid to be tested; performing appearance scanning again to obtain the surface roughness degree after acid etching after the acid etching treatment is completed, working out the surface roughness degree difference value of the surface roughness degree of the rock core sample after the acid etching and the initial surface roughness degree, and comparing the obtained surface roughness difference value with a threshold value so as to evaluate the acid fracturing effect of the acid liquid to be tested. The acid fracturing effect is evaluated through the appearance features of the surface of the rock core sample before and after the acid etching, so that the data reference and theoretical basis can be provided for the subsequent acid liquid screening, acidification fracturing design and optimization and carbonate rock acidification yield increase record recognition.

Owner:CHINA PETROLEUM & CHEM CORP +1

Etching method and semiconductor device fabrication method

InactiveCN101154582AReduce etch rateImprove the selection ratioElectric discharge tubesSemiconductor/solid-state device manufacturingResistMicrowave

Owner:TOKYO ELECTRON LTD

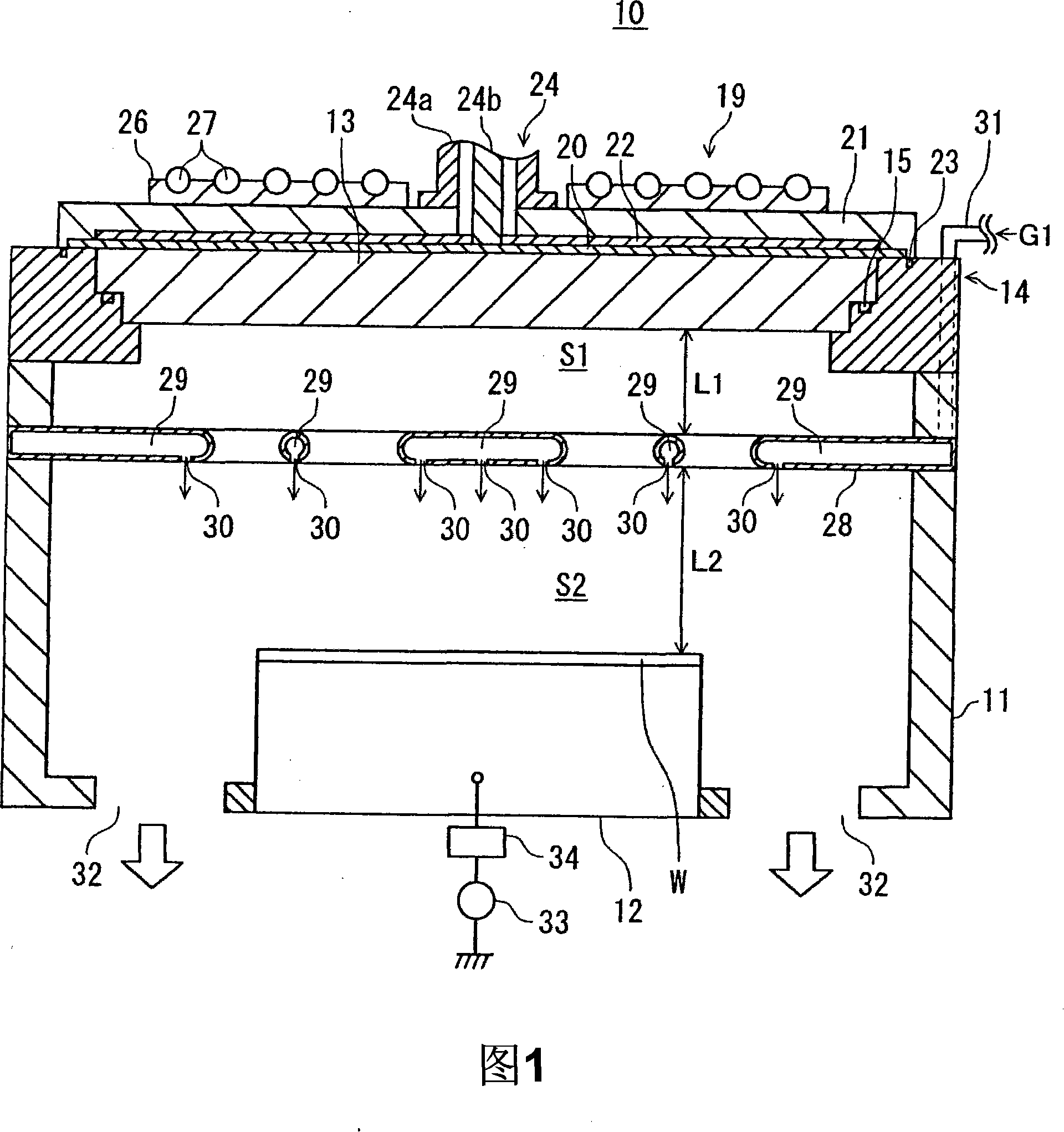

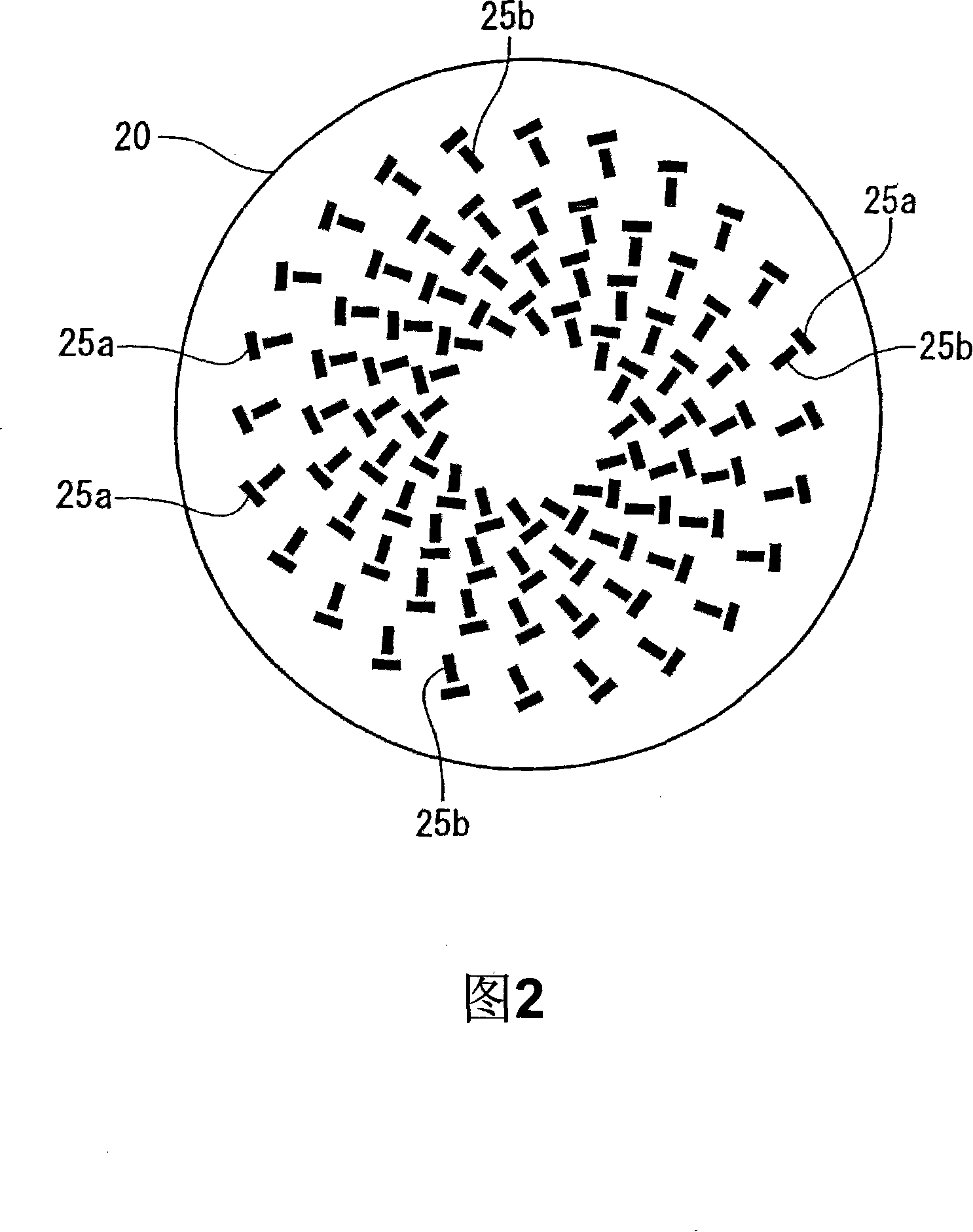

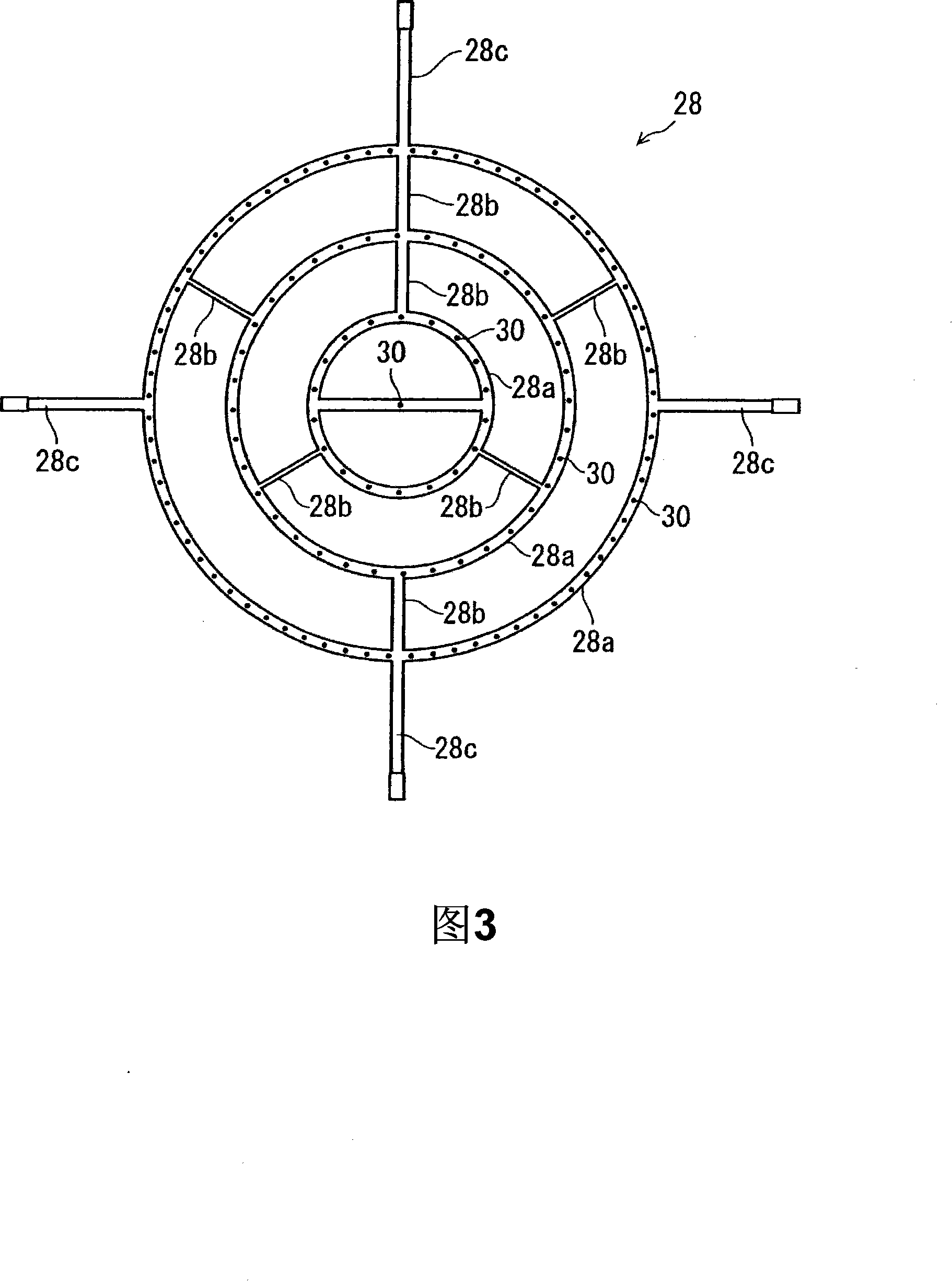

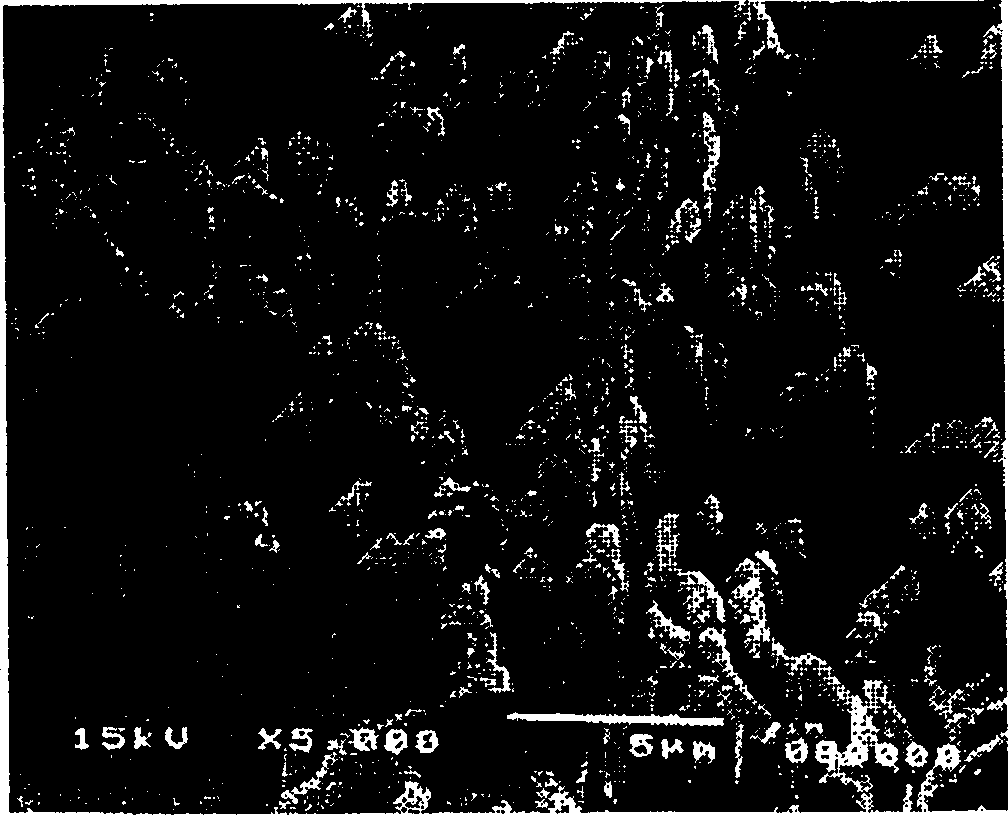

Ceramic parts formed micro crowning on its surface and its mfg. method

InactiveCN1369465AEasy to fixImprove mechanical durabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSurface layerMetallurgy

The present invention provides a ceramic component capable of controlling and preventing gas release, having an excellent immobilization effect on other substances attached and deposited on the surface, and less prone to peeling off of other substance particles when used in a thin film forming device, and a manufacturing method thereof. The ceramic part of the present invention is formed on the surface of a dense ceramic base material with a purity of 95% by weight or more, or on the surface of crystal grains near it, forming a plurality of protrusions with a diameter smaller than the diameter of the crystal grains, or with a purity of 95% by weight. The above-mentioned dense ceramics are used as the base material, and the surface layer is a ceramic with a concave-convex structure with a micropore whose diameter is 0.5 to 50 times the average particle size of the ceramic forming the base material and has a large-diameter portion in the depth direction. part. In the ceramic part, the surface of a dense ceramic substrate with a purity of more than 95% by weight and a density of more than 90% of the theoretical density is eroded in an acidic etching solution to form multiple ceramic particles on the surface of the substrate or its vicinity. protruding part to manufacture.

Owner:TOSHIBA CERAMICS CO

Etching liquid for silver alloy

The present invention relates to an etching liquor for silver alloy, it includes 1-60 weight portions of ammonium compound, 1-60 weight portions of hydrogen peroxide and 0-96 weight portions of water, According to the requirements said etching liquor also can include 1-10 weight portions of sulfuric acid or organic acid so as to can obtain optimum control of etching rate.

Owner:RITDISPLAY

Etching process for semiconductors

InactiveCN102893378AFast etchEtching is effectiveSemiconductor/solid-state device manufacturingPhotovoltaic energy generationMicro structureSemiconductor materials

A process for etching semiconductors, such as II-VI or III-V semiconductors is provided. The method includes sputter etching the semiconductor through an etching mask using a nonreactive gas, removing the semiconductor and cleaning the chamber with a reactive gas. The etching mask includes a photoresist. Using this method, light-emitting diodes with light extracting elements or nano / micro-structures etched into the semiconductor material can be fabricated.

Owner:3M INNOVATIVE PROPERTIES CO

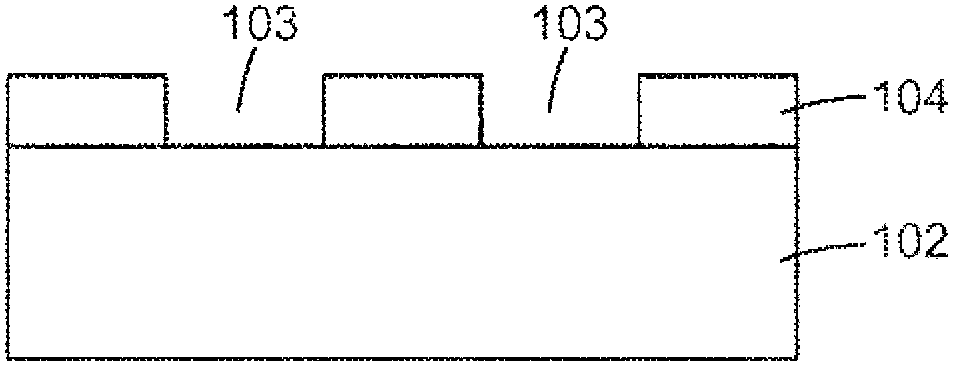

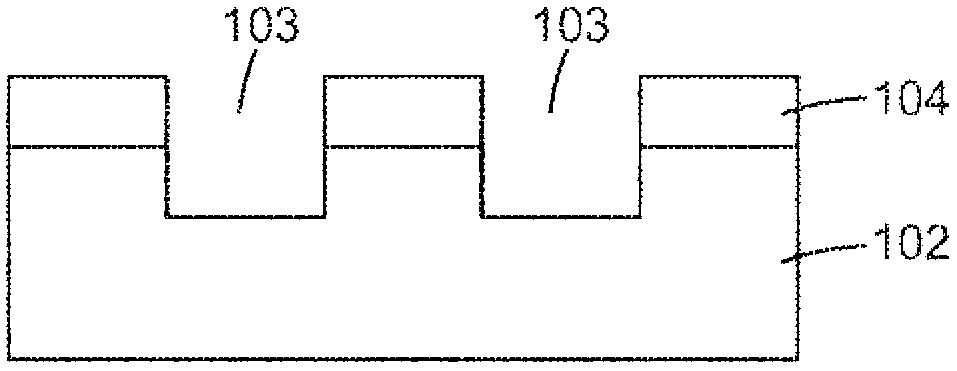

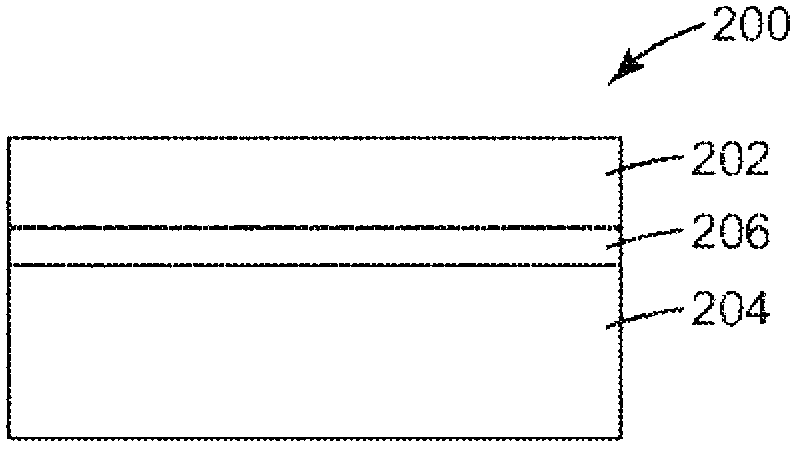

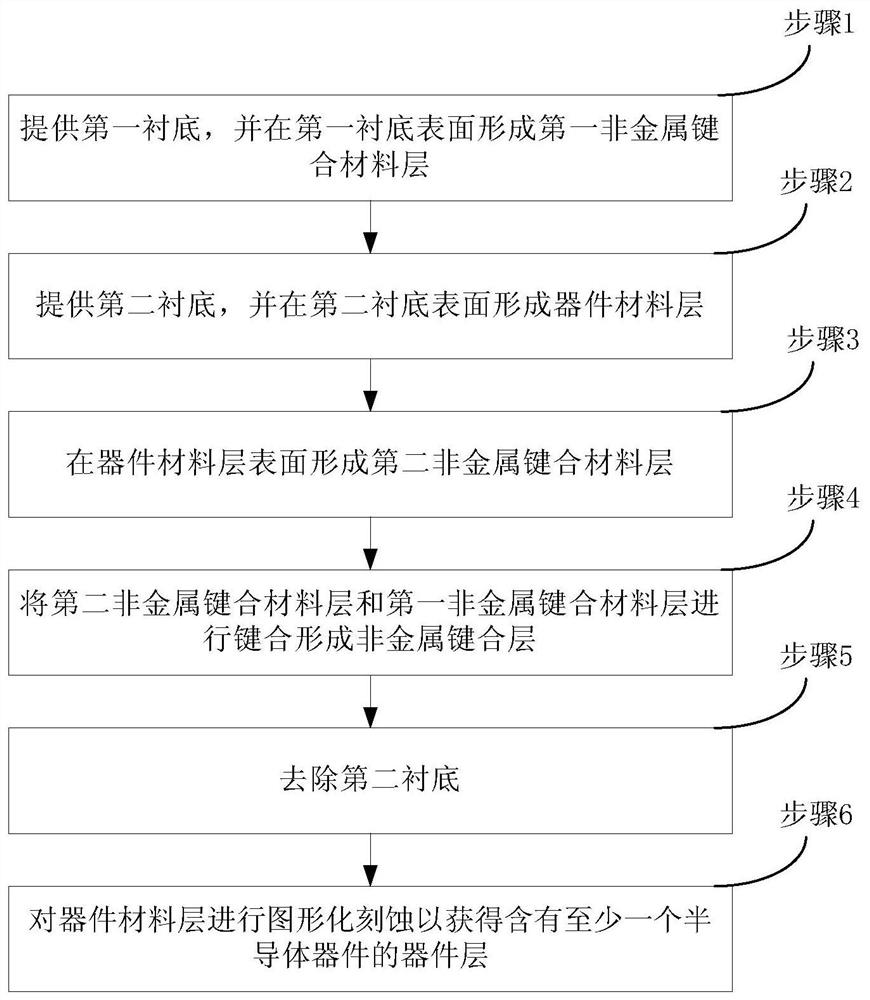

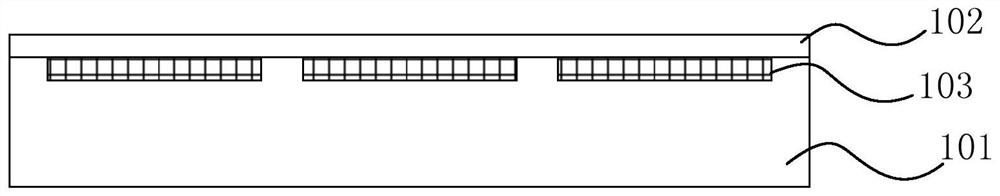

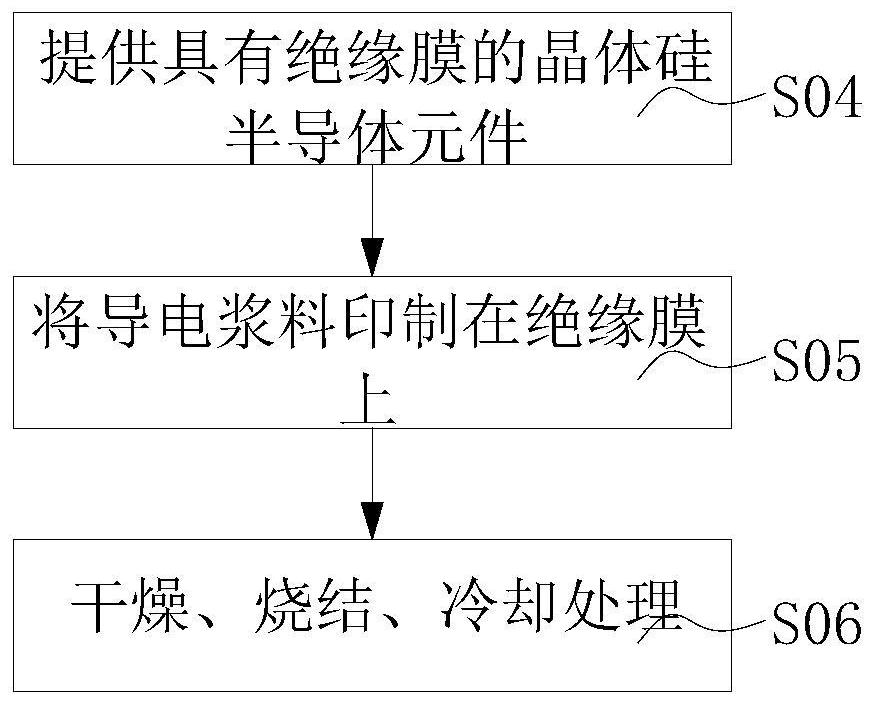

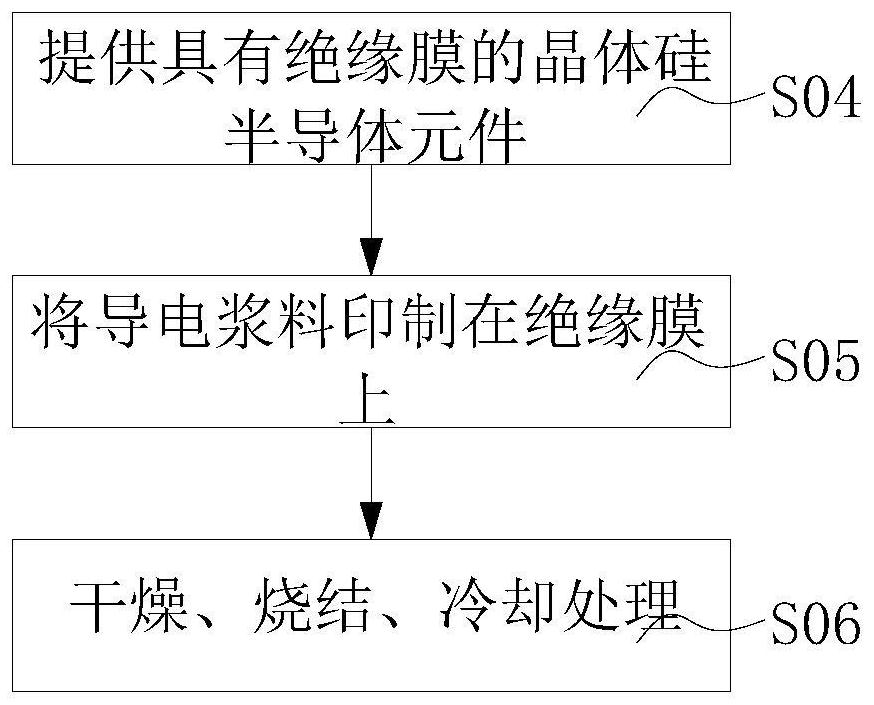

Preparation method of integrated semiconductor device and integrated semiconductor device

InactiveCN113451151ASolve the leakEtching is effectiveSolid-state devicesSemiconductor/solid-state device manufacturingEtchingDevice material

The invention discloses a preparation method of an integrated semiconductor device and the integrated semiconductor device. The method comprises the steps of providing a first substrate, and forming a first nonmetal bonding material layer on the surface of the first substrate, providing a second substrate, and forming a device material layer on the surface of the second substrate, forming a second non-metal bonding material layer on the surface of the device material layer, bonding the second non-metal bonding material layer and the first non-metal bonding material layer to form a non-metal bonding layer, removing the second substrate, and performing graphical etching on the device material layer to obtain a device layer containing at least one semiconductor device. Through the non-metal bonding mode, the problem of electric leakage caused by overflowing of graphical etching metal and cleaning of metal particle residues after metal bonding is avoided, through the non-metal bonding mode, an effective etching high selection ratio is formed, a process window is increased, and feasibility is improved.

Owner:格芯致显杭州科技有限公司

Etching solution for silver alloy

An etching liquid for silver alloy contains proportionally hydrogen peroxide, ammonium compound or one of sulfuric acid, nitric acid and organic acid, and water. The etched silver alloy is also disclosed.

Owner:RITDISPLAY

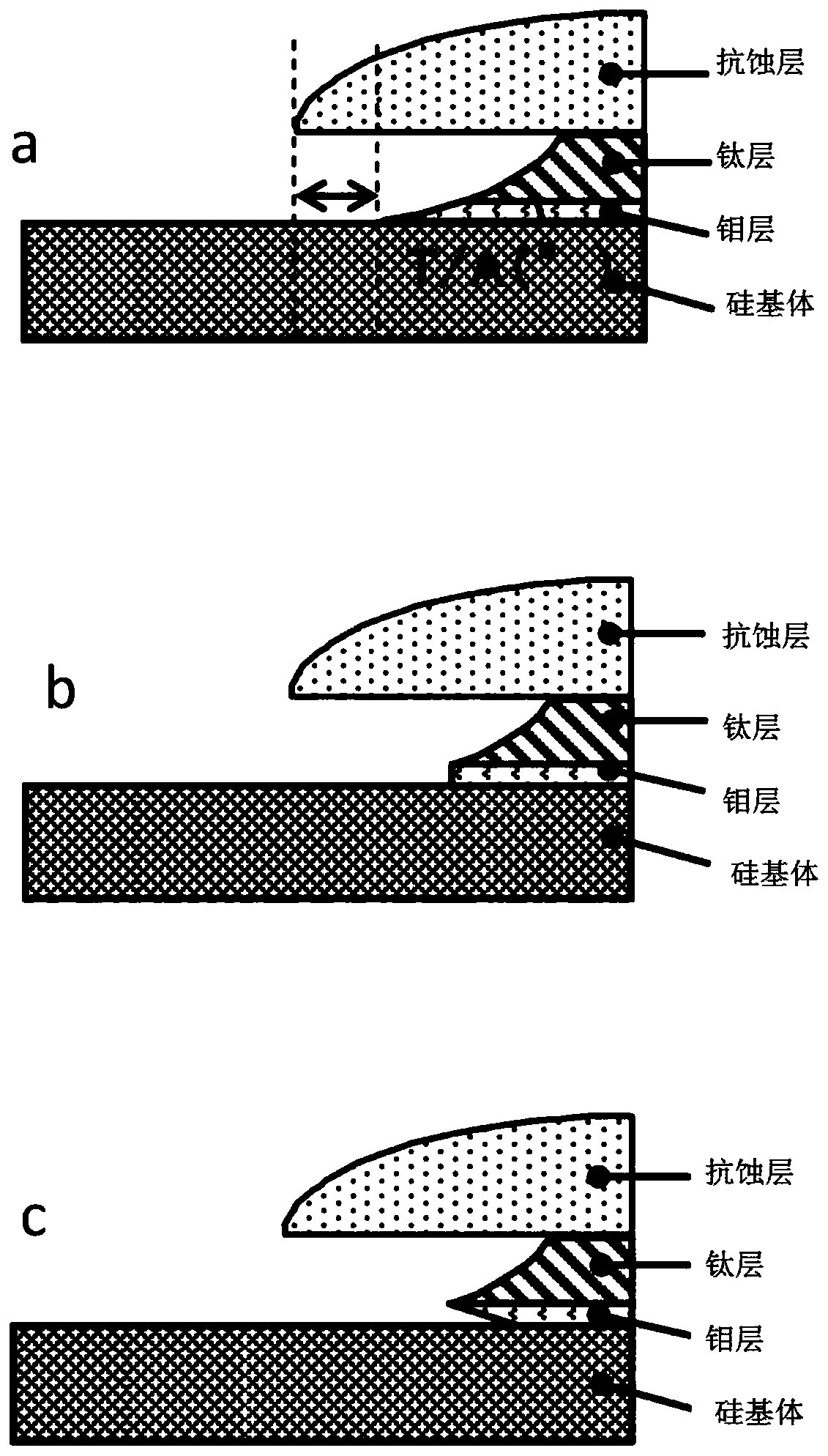

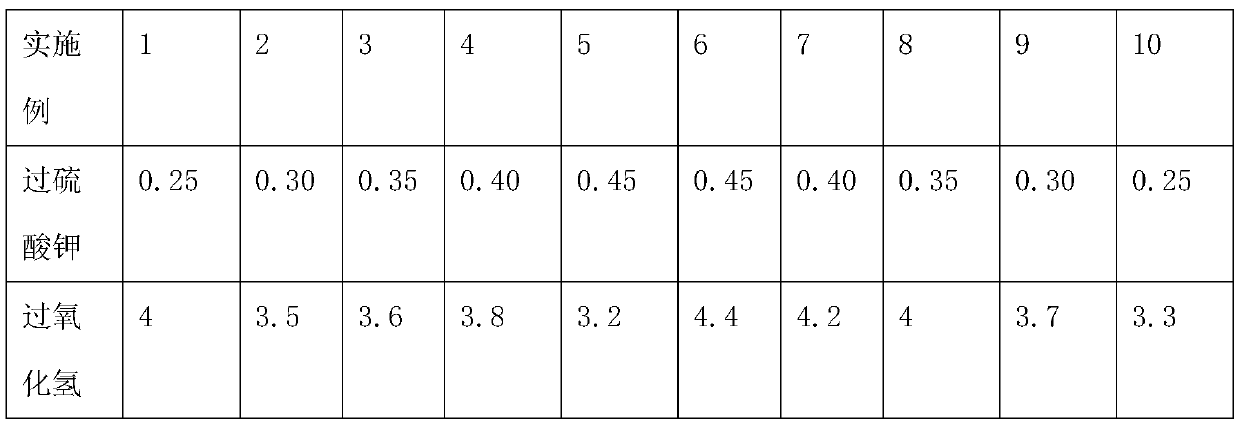

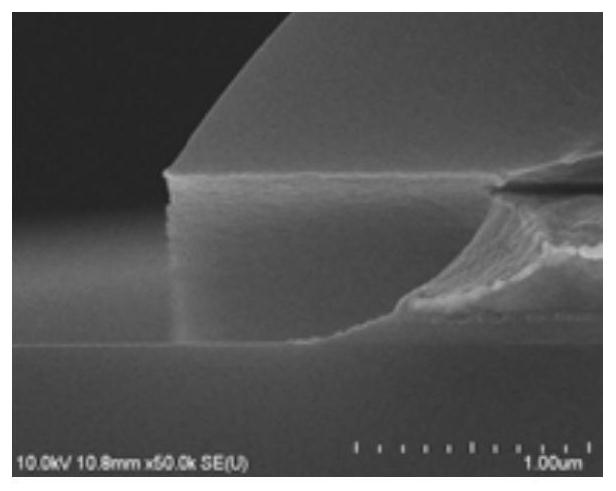

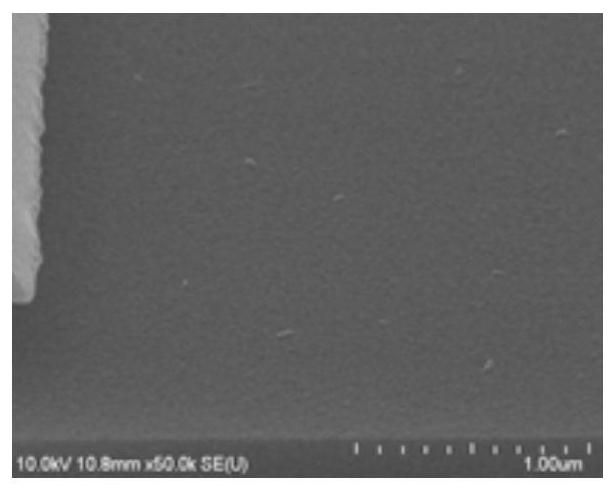

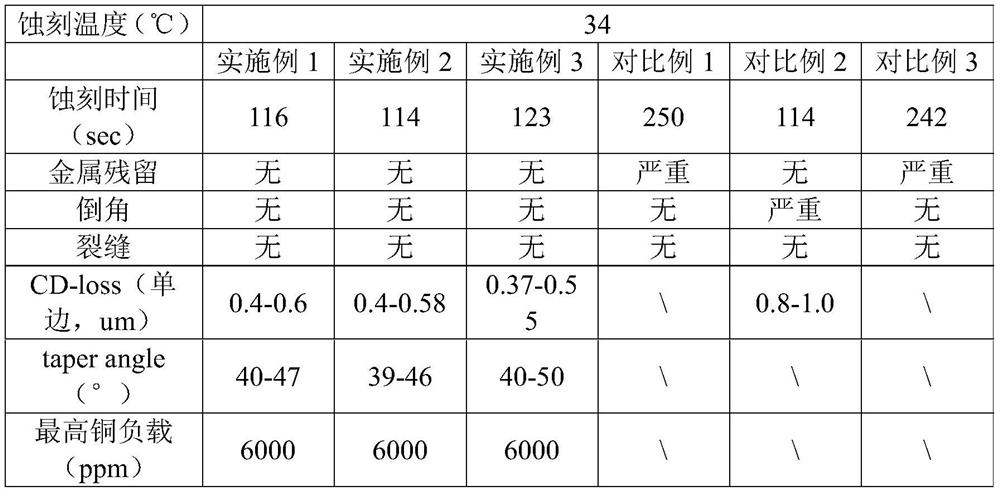

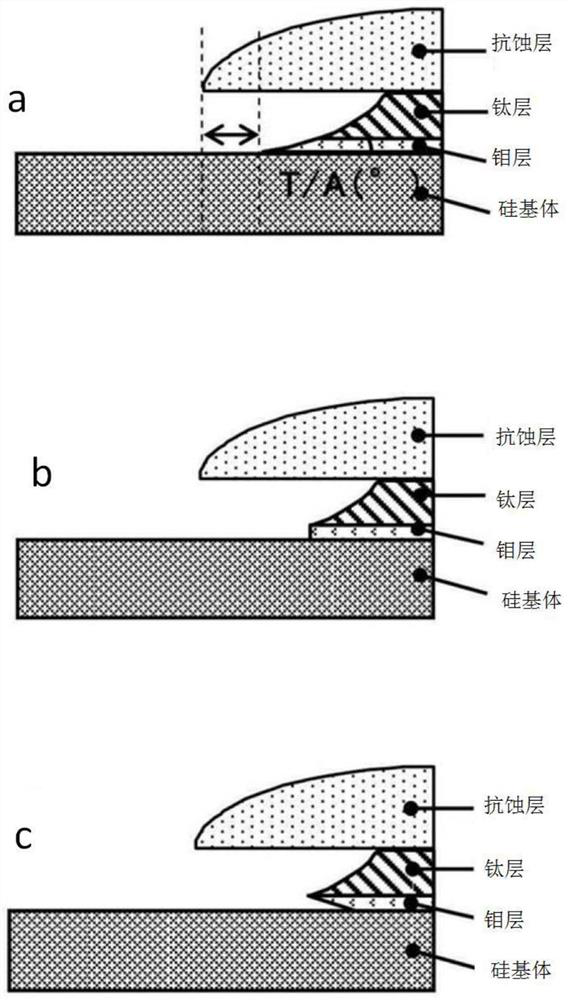

Molybdenum/titanium alloy film etching solution composition and application thereof

ActiveCN111041489AAvoid deterioration of etching effectAvoid large side corrosionSolid-state devicesSemiconductor devicesH2O2 - Hydrogen peroxideTitanium alloy

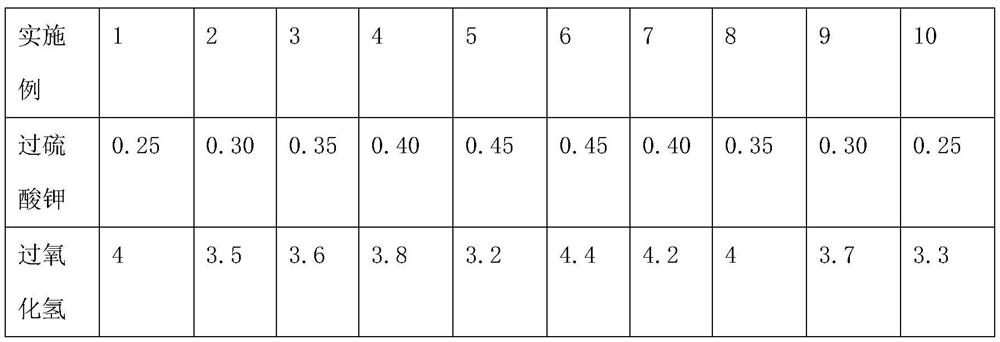

The invention discloses a molybdenum / titanium alloy film etching solution composition and application thereof. The etching liquid composition is prepared from 0.25 to 0.45 weight percent of persulfate, 3 to 4 weight percent of hydrogen peroxide, 0.05 to 0.08 weight percent of fluoride, 5 to 10 weight percent of ammonium dihydrogen phosphate, 1.0 to 2.5 weight percent of tartaric acid, 0.3 to 0.5 weight percent of additive 2-chloro-5-chloromethylthiazole for preventing side surface corrosion, 2 to 5 weight percent of ethylenebis(nitrilodimethylene)tetraphosphonic acid complexing agent and deionized water, and the pH is 5.0 to 6.0. The components do not play roles independently, but cooperate with one another as a whole to etch an etching profile with a proper taper angle, and it can be guaranteed that no molybdenum is left under the condition that corresponding CD Loss is controlled. And meanwhile, excessive side corrosion is avoided, and the situation that the performance cannot meet the application requirement due to molybdenum undercutting and other defects is avoided.

Owner:易安爱富武汉科技有限公司

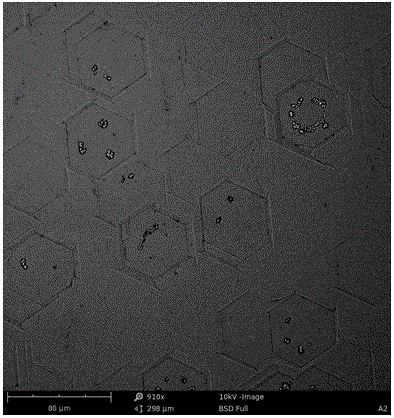

Method for etching c-plane sapphire

ActiveCN104651948AEtching is effectiveImprove etching effectAfter-treatment detailsHydrofluoric acidEtching

The invention discloses a method for etching c-plane sapphire. The method comprises the following steps: firstly immersing c-plane sapphire in a mixed solution consisting of hydrofluoric acid and water at 25 DEG C for 20 minutes, then taking out the c-plane sapphire, sequentially performing alcohol washing, supersonic washing and drying to obtain c-plane sapphire treated by hydrofluoric acid; then immersing the c-plane sapphire treated by the hydrofluoric acid in a mixed acid consisting of concentrated sulfuric acid and concentrated phosphoric acid for 20 minutes, naturally cooling, taking out the c-plane sapphire and sequentially performing alcohol washing, supersonic washing and drying to obtain c-plane sapphire treated by the mixed acid; and finally putting the c-plane sapphire treated by the mixed acid in a melting solution of flaky NaOH at the temperature of 325-340 DEG C for 10 minutes, taking out the c-plane sapphire and sequentially performing alcohol washing, supersonic washing and drying to finish the etching of the c-plane sapphire. The method for etching the c-plane sapphire disclosed by the invention has the advantages of good etching effect, good uniformity, good quality, high yield and the like.

Owner:西双版纳承启科技有限公司

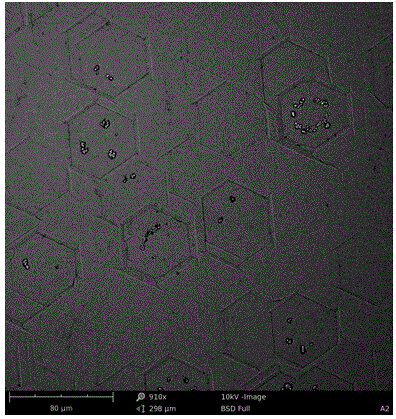

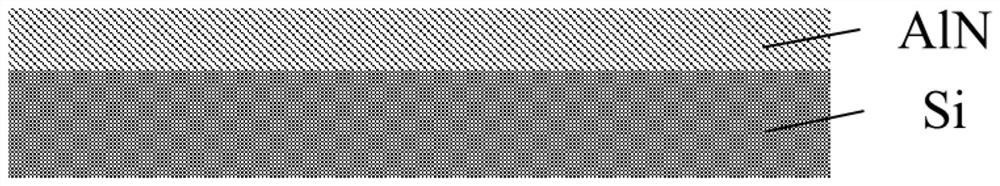

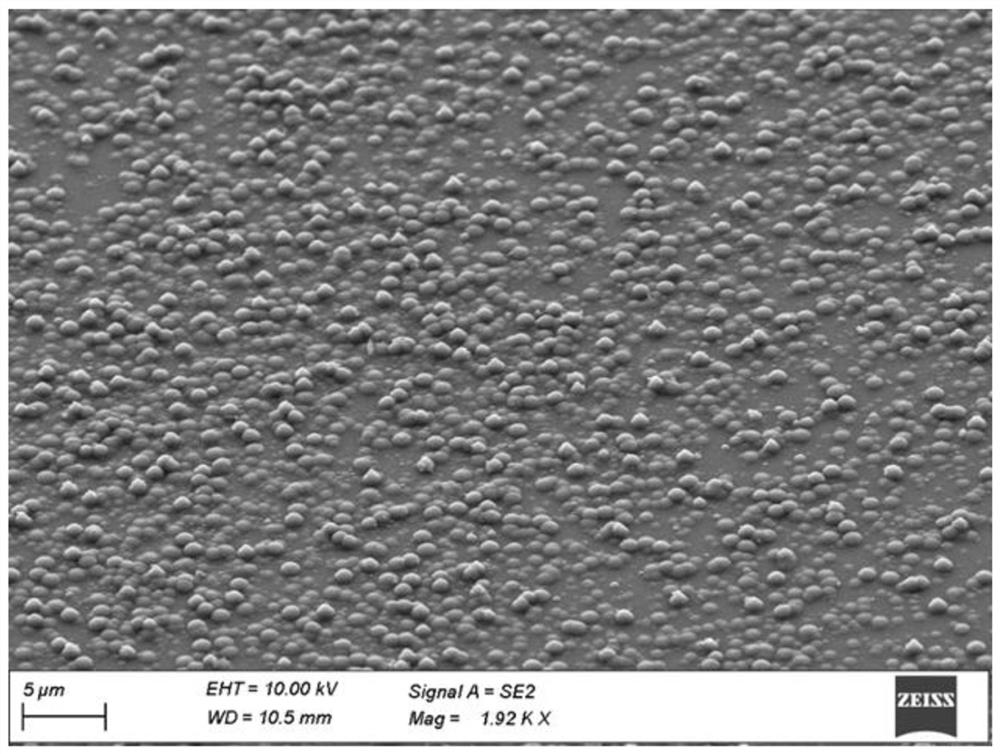

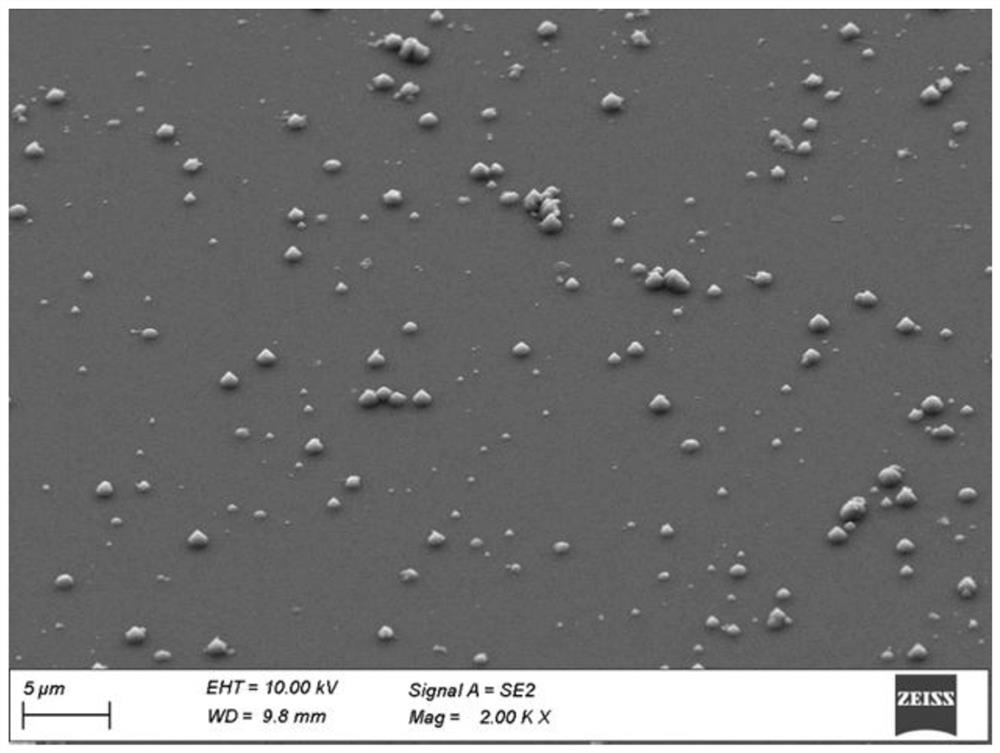

High-selectivity etching solution for aluminum nitride and silicon

ActiveCN114369461AAccelerated destructionEtching is effectiveSemiconductor/solid-state device manufacturingSurface treatment compositionsHigh selectivityChlorosilane

The invention discloses a high-selectivity etching solution for aluminum nitride and silicon. The etching solution comprises the following main components in percentage by mass: 5-40% of alkali, 0.2-0.5% of fluoride, 0.1-0.5% of organochlorosilane, 1-5% of silicate and the balance of water. The etching solution can be used for quickly cleaning the aluminum nitride layer, no crystal lattice remains, and the selection ratio of the etching solution to the Si substrate can reach more than 1000.

Owner:湖北兴福电子材料股份有限公司

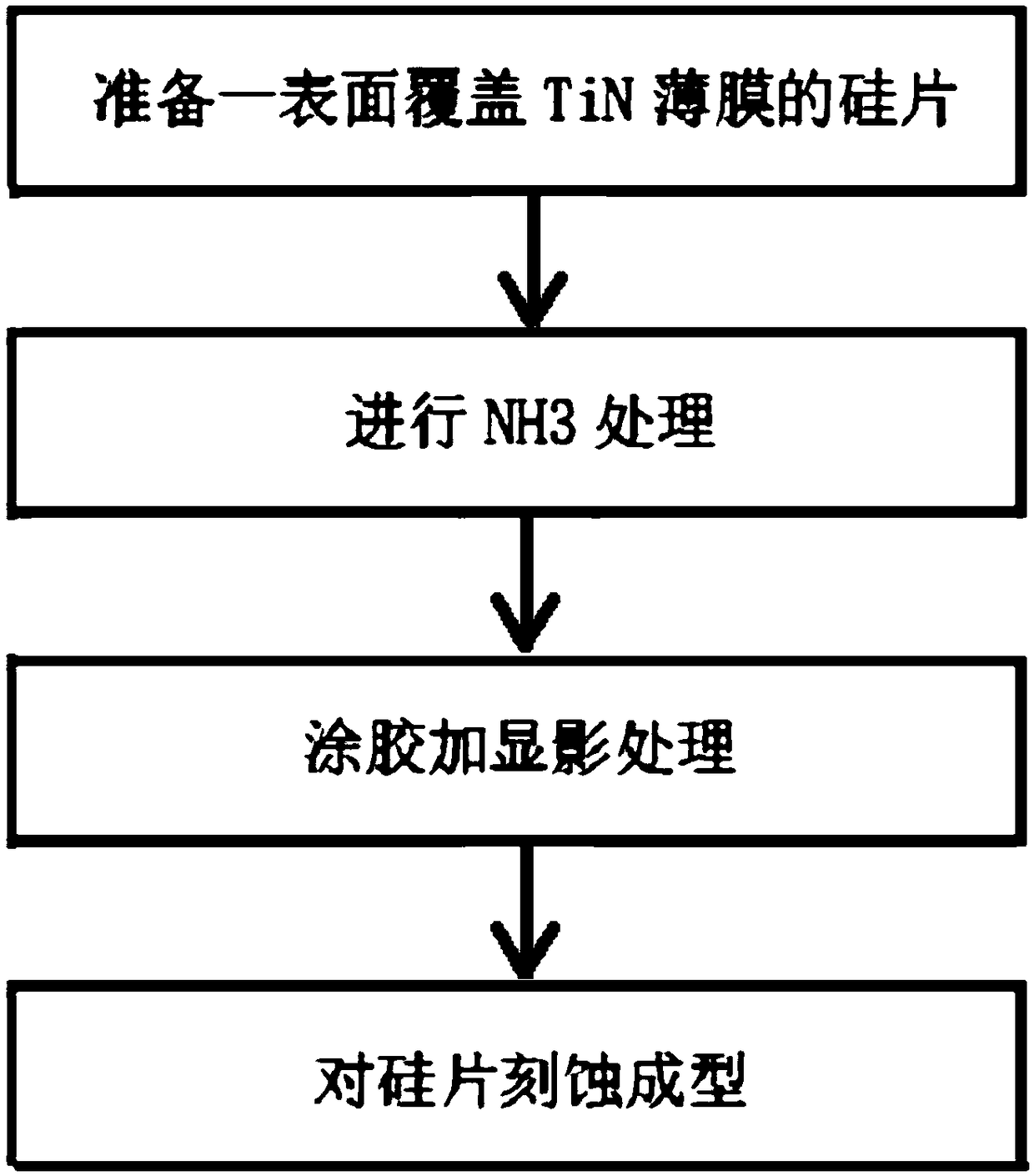

TiN Thin Film Etching Method

InactiveCN109166797AEtching is effectiveDoes not affect propertiesDecorative surface effectsSemiconductor/solid-state device manufacturingEtchingTin thin films

The invention discloses a TiN thin film etching method, comprising the following steps: step 1, carrying out NH3 treatment on a silicon wafer covered with the TiN thin film; 2, coating the NH3-treatedsilicon wafer with glue and carrying out development treatment on the silicon wafer; 3, etch and molding that silicon wafer. The invention can effectively etch the TiN film without affecting the characteristics of the lower film.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

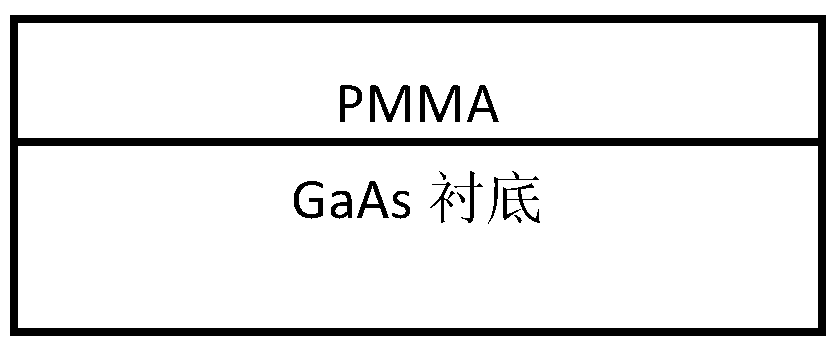

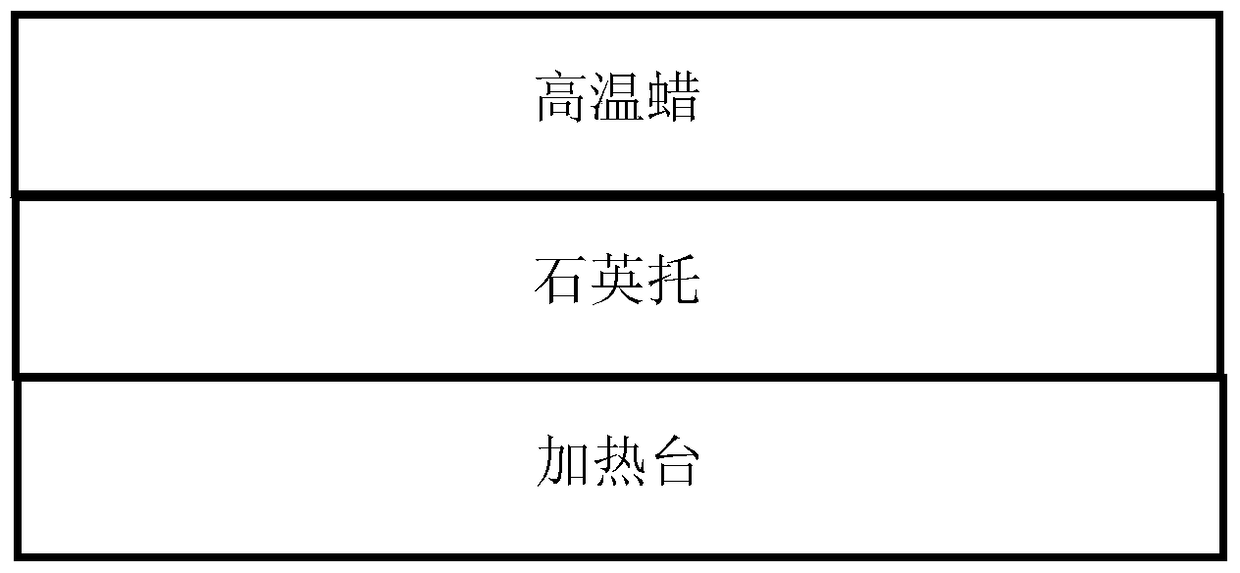

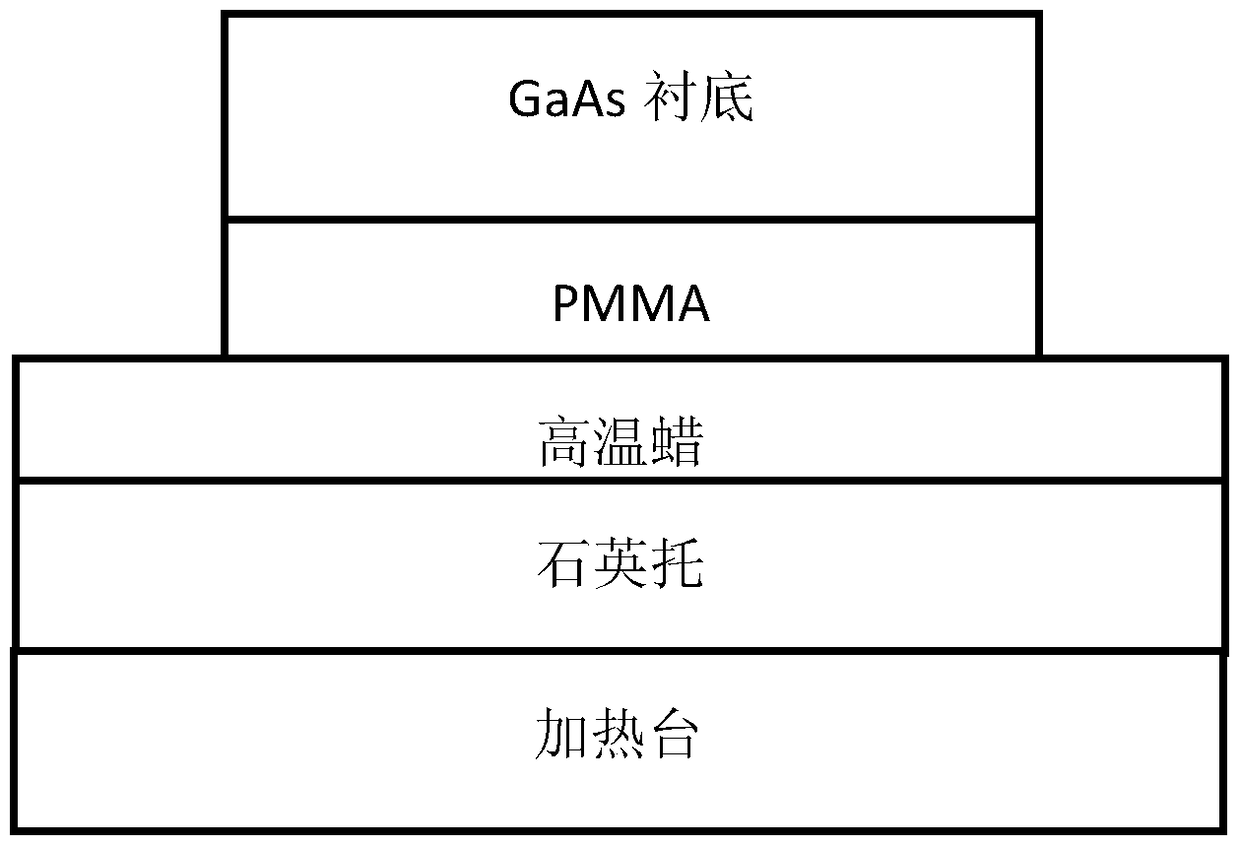

A method for reducing the pollution of plasma etching machine cavity in GAAS back hole process

ActiveCN105070656BNo miscibility problemsStrong adhesionElectric discharge tubesSemiconductor/solid-state device manufacturingAdhesiveDissolution

The invention discloses a method for reducing plasma etching machine cavity pollution in GaAs back hole process. The method comprises the following steps: uniformly coating an electron beam photoresist on the front face of a substrate, pasting the front face of the substrate onto a quartz tray using a liquid wax, pasting the quartz tray, to which the substrate is pasted, to a thinning glass sheet, performing thinning process, taking the quartz tray together with the substrate down from the thinning glass sheet, uniformly coating the photoresist and then baking the sheet, forming a back hole pattern, forming a back hole, and removing the photoresist and the liquid wax to enable the substrate sheet to be separated from the quartz tray; and the liquid wax is composed of a certain amount of a Crystalbond 509 strong adhesive and an amount of acetone capable of dissolving the Crystalbond 509 strong adhesive. The liquid wax is adopted to replace a traditional high-temperature wax, a mutual dissolution problem cannot be generated, the liquid wax also has excellent adhesivity, and the problems of the sputtered high-temperature wax due to plasma bombardment and metal pollution of a plasma etching machine cavity inner wall are solved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

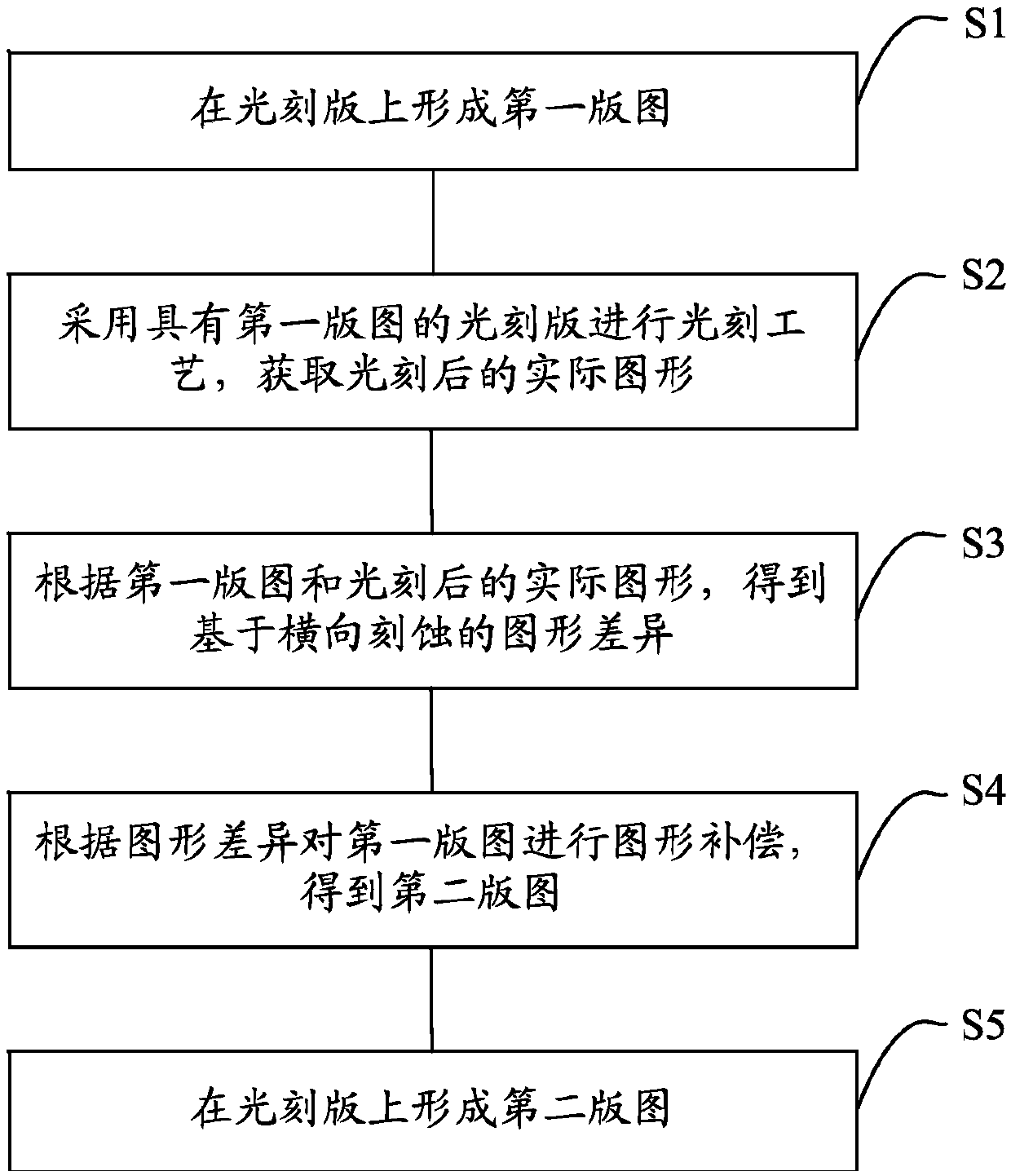

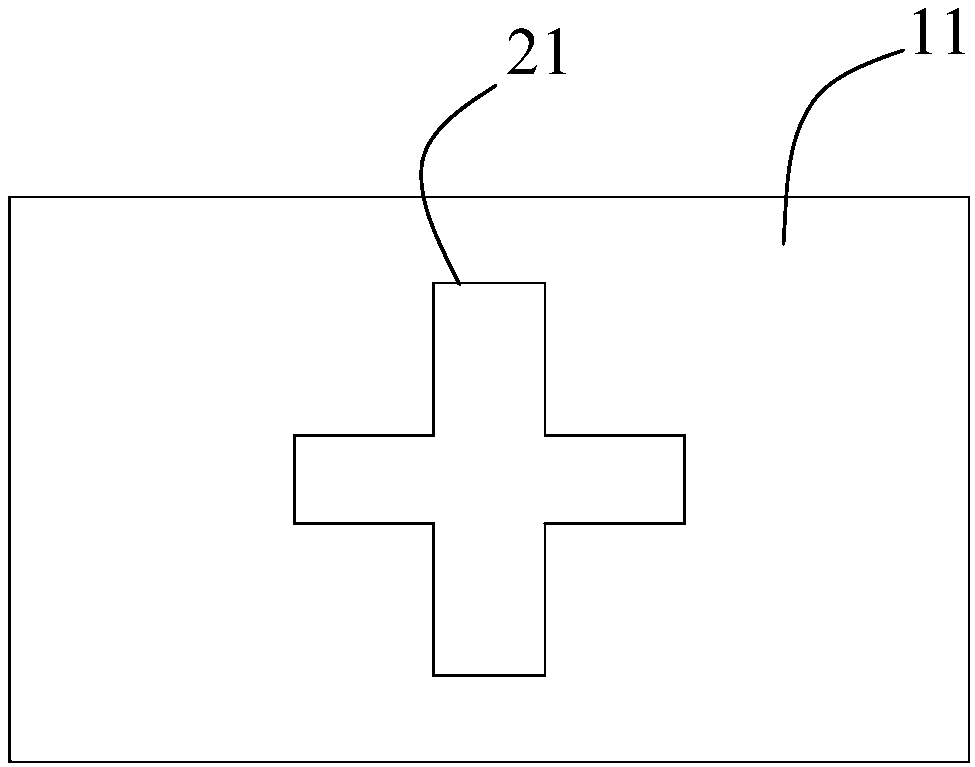

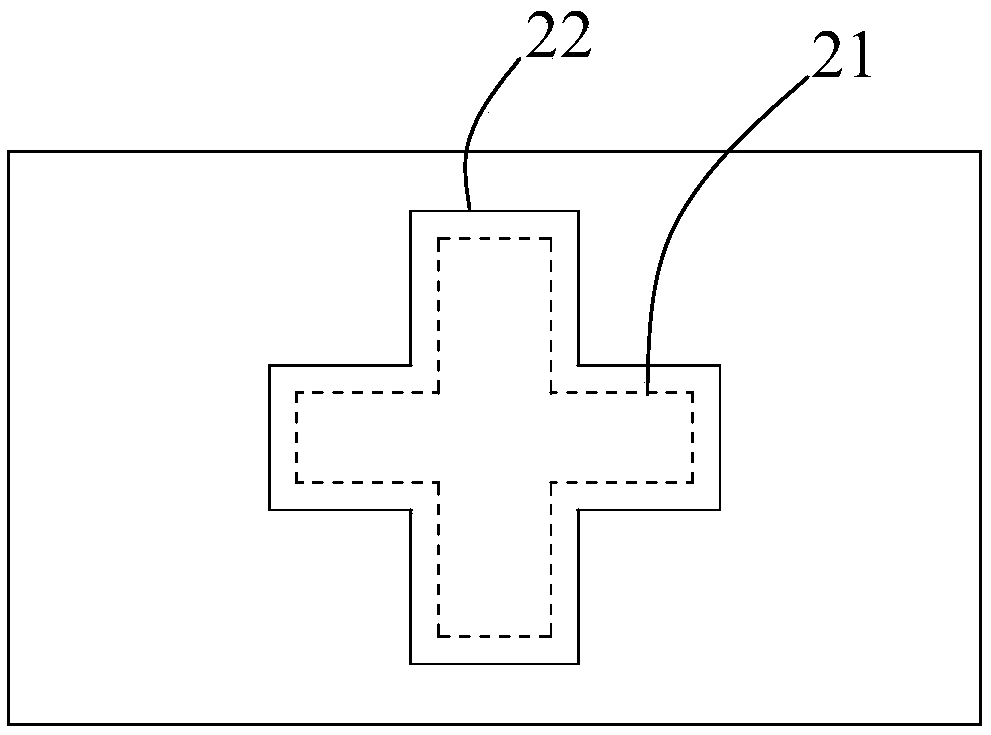

Lithographic plate based on pattern compensation and making method thereof

InactiveCN109634053AEtching is effectiveApplicable processOriginals for photomechanical treatmentLithographic artistEngineering

The invention discloses a lithographic plate based on pattern compensation and a making method thereof. The making method includes the following steps: S1, forming a first layout on a lithographic plate; S2, using the lithographic plate with the first layout to carry out a lithographic process to obtain an actual pattern after lithography; S3, obtaining the pattern difference based on transverse etching according to the first layout and the actual pattern after lithography; S4, making pattern compensation for the first layout according to the pattern difference to obtain a second layout; and S5, forming the second layout on the lithographic plate. The original layout is compensated and corrected according to the pattern difference between the original layout and the actual pattern, the pattern size of transverse etching in the etching process is compensated into the lithographic plate layout, and an ideal target pattern can be formed by etching. The lithographic plate is applicable tothe process flow of various electronic devices.

Owner:SUZHOU SUNA PHOTOELECTRIC

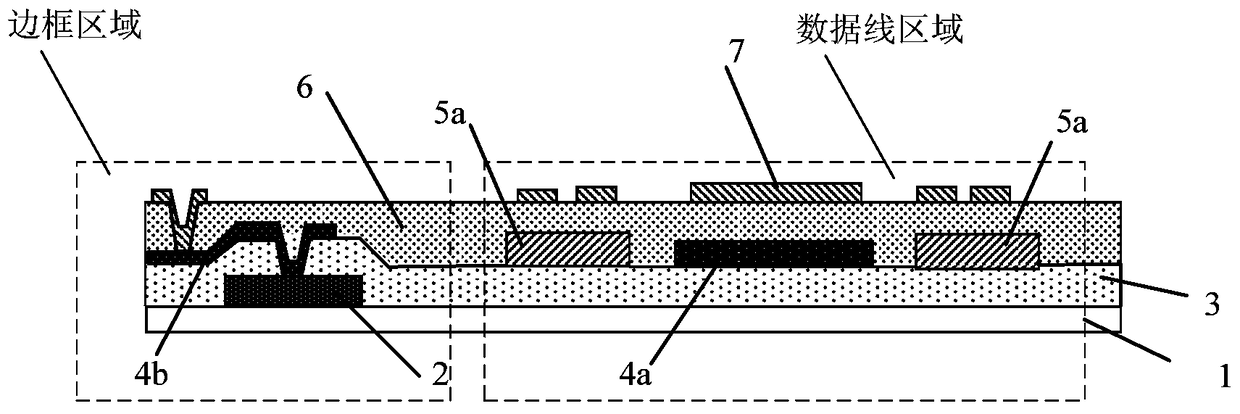

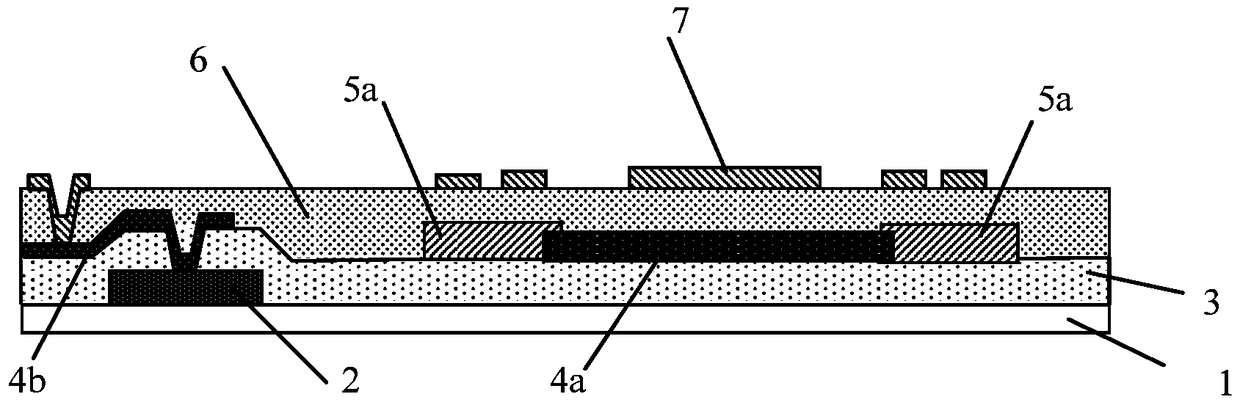

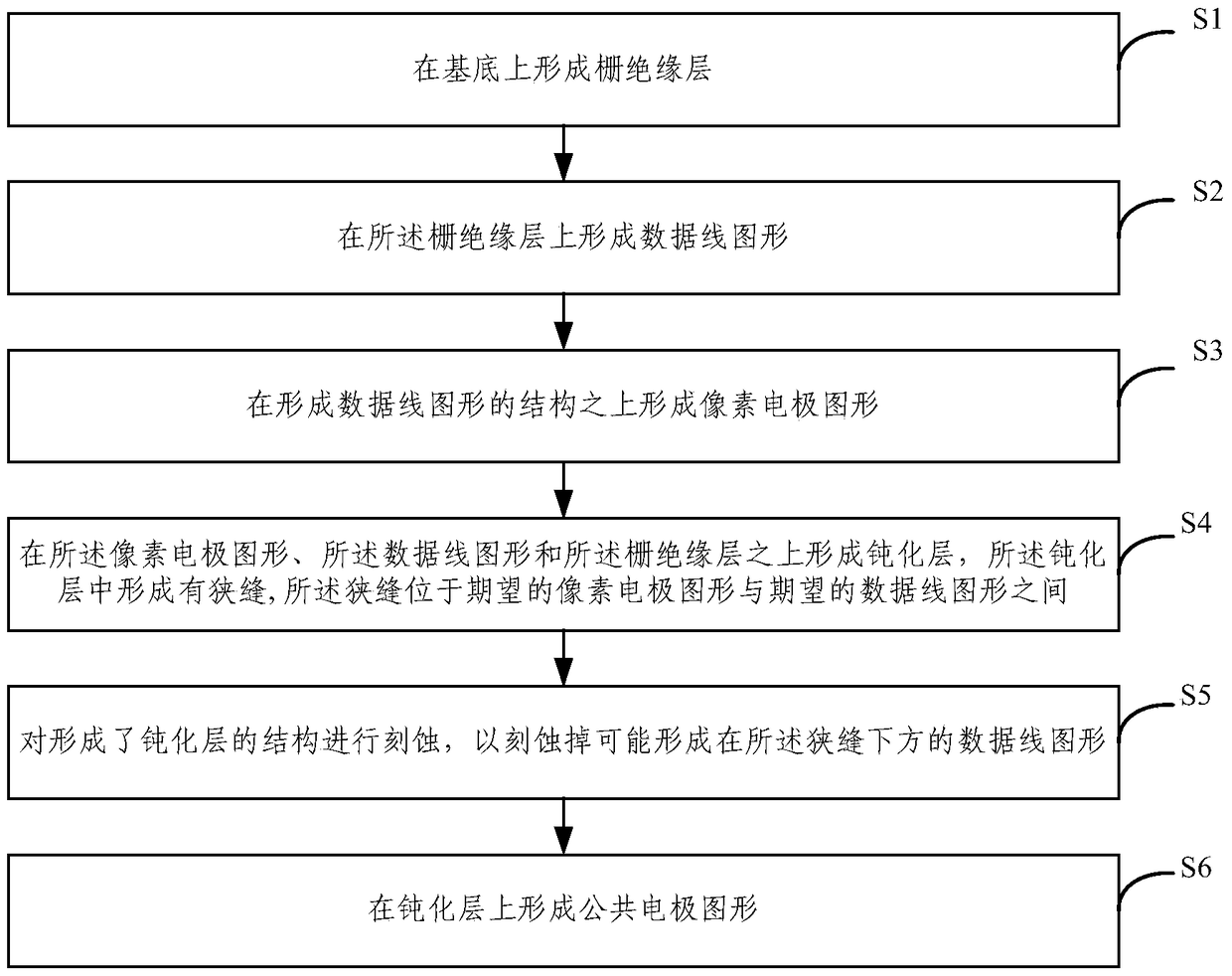

Array substrate, manufacturing method thereof, and display device

ActiveCN104779201BEtching is effectiveSolid-state devicesSemiconductor/solid-state device manufacturingDisplay device

The invention provides an array substrate and a manufacturing method thereof as well as a display device. The manufacturing method comprises the following steps: forming a grilling insulation layer; forming a data cable figure on the grilling insulation layer; forming a pixel electrode figure on the structure of the formed data cable figure; forming a passivation layer on the data cable figure and the grilling insulation layer; forming a slot in the passivation layer, wherein the slot is formed between the supposed pixel electrode figure and the supposed data cable figure; etching the structure of the formed passivation layer to eliminate the data cable figure formed under the slot; forming a common electrode figure on the passivation layer. According to the manufacturing method, the data cable figure can be prevented from being connected with the pixel electrode figure.

Owner:BOE TECH GRP CO LTD +1

A method for evaluating acid fracturing effect of carbonate rocks

The invention provides an evaluation method of an acid fracturing effect of carbonate rock. The method comprises the following steps of performing appearance scanning on a rock core sample to obtain the initial surface roughness degree, performing acid etching treatment on the rock core sample by using acid liquid to be tested; performing appearance scanning again to obtain the surface roughness degree after acid etching after the acid etching treatment is completed, working out the surface roughness degree difference value of the surface roughness degree of the rock core sample after the acid etching and the initial surface roughness degree, and comparing the obtained surface roughness difference value with a threshold value so as to evaluate the acid fracturing effect of the acid liquid to be tested. The acid fracturing effect is evaluated through the appearance features of the surface of the rock core sample before and after the acid etching, so that the data reference and theoretical basis can be provided for the subsequent acid liquid screening, acidification fracturing design and optimization and carbonate rock acidification yield increase record recognition.

Owner:CHINA PETROLEUM & CHEM CORP +1

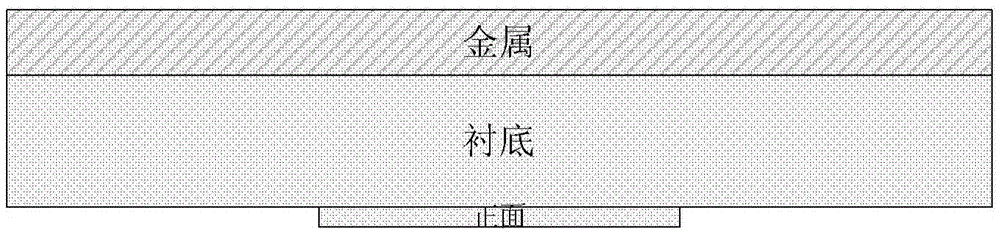

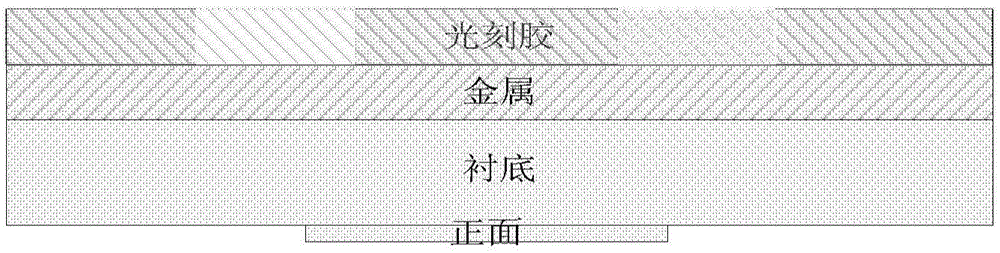

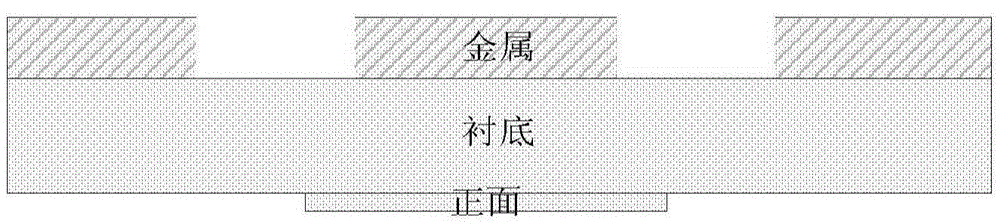

A method for reducing the pollution of plasma etching machine cavity in back hole process

ActiveCN103730348BAchieve cleaningReduce the difficulty of cleaningElectric discharge tubesSemiconductor/solid-state device manufacturingPlasma etcherPhotoresist

The invention discloses a method for reducing plasma etcher cavity pollution in a back hole process. The method comprises the steps of sputtering or evaporating a metal mask layer on the back of a SiC substrate; enabling the metal mask layer to be coated with photoresist, and drying the photoresist; performing photoetching on the photoresist to form a photoresist pattern; utilizing the formed photoresist pattern to corrode the metal mask layer, and forming a metal mask graph; performing plasma bombardment on the back of the SiC substrate of the formed metal mask graph in a plasma etcher, sputtering the photoresist on the metal mask layer to an inner wall of a cavity of the plasma etcher, and forming a photoetching layer on the inner wall of the cavity of the plasma etcher; utilizing the formed metal mask graph to etch the SiC back in the plasma etcher, and forming a back hole until the back hole is communicated with SiC front source metal. By utilizing the method, the pollution to the inner wall of the plasma etcher cavity caused by a metal mask in the back hole process is reduced, and using efficiency of the plasma etcher is improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

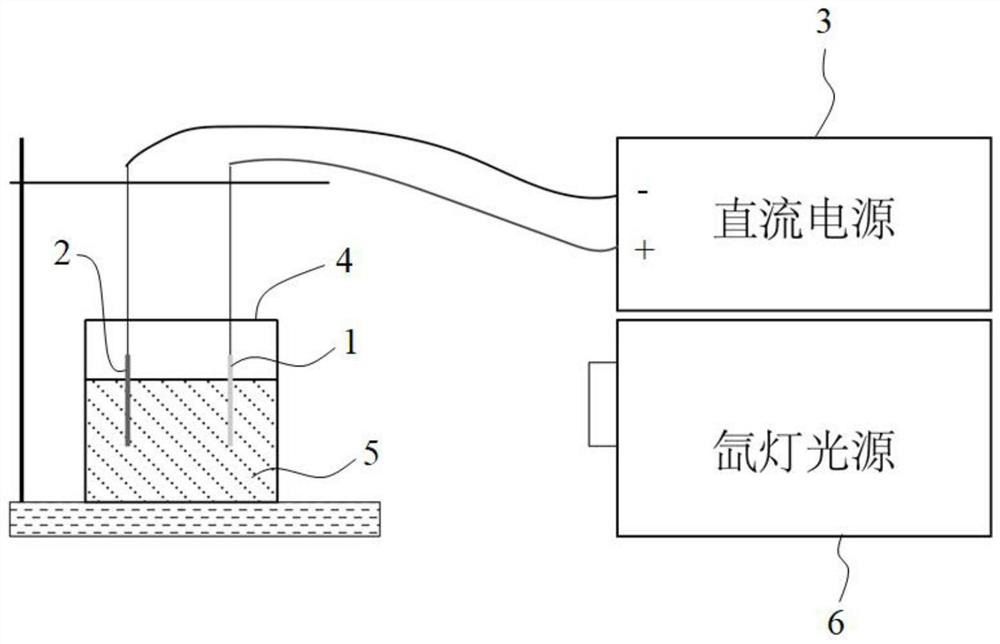

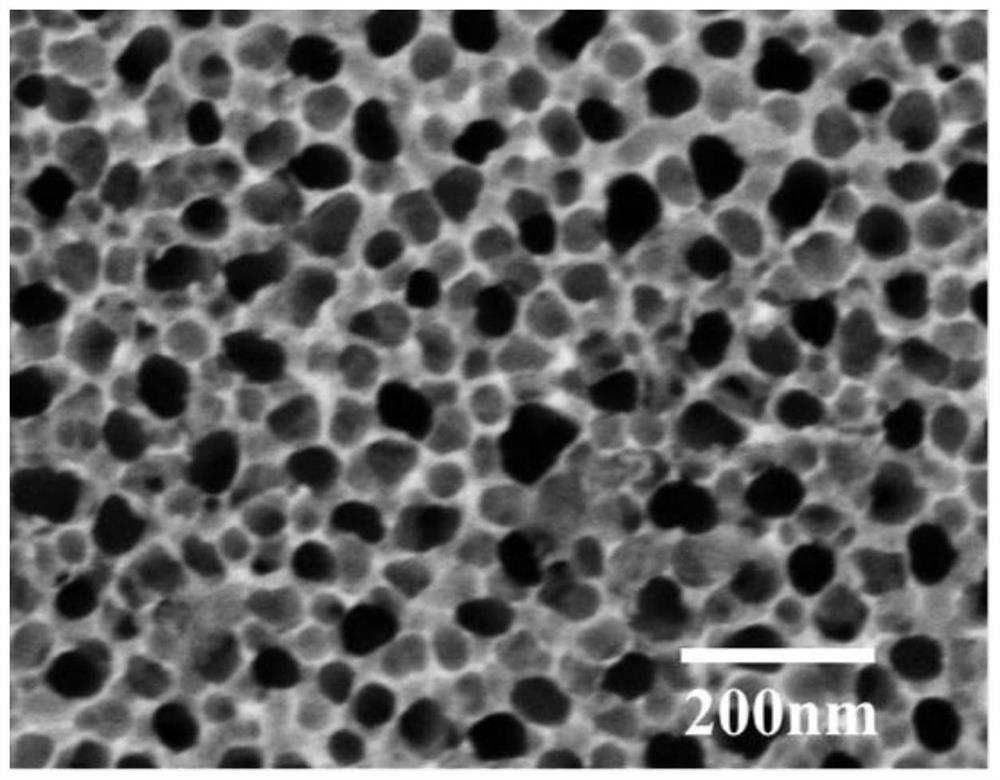

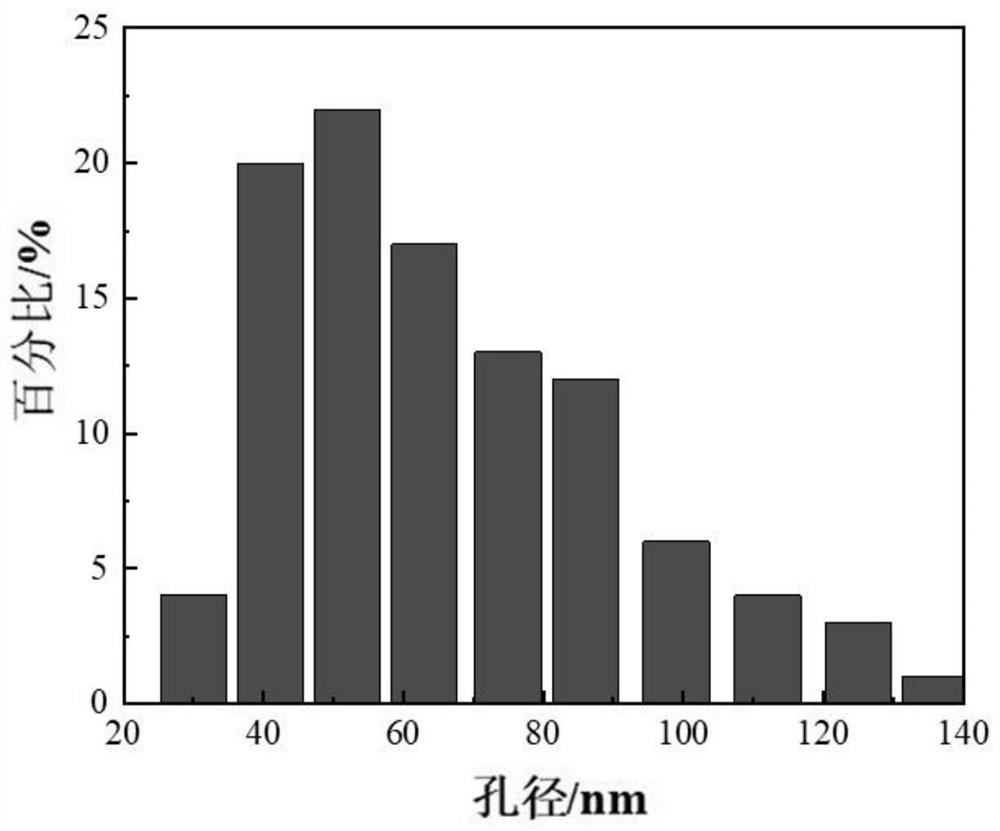

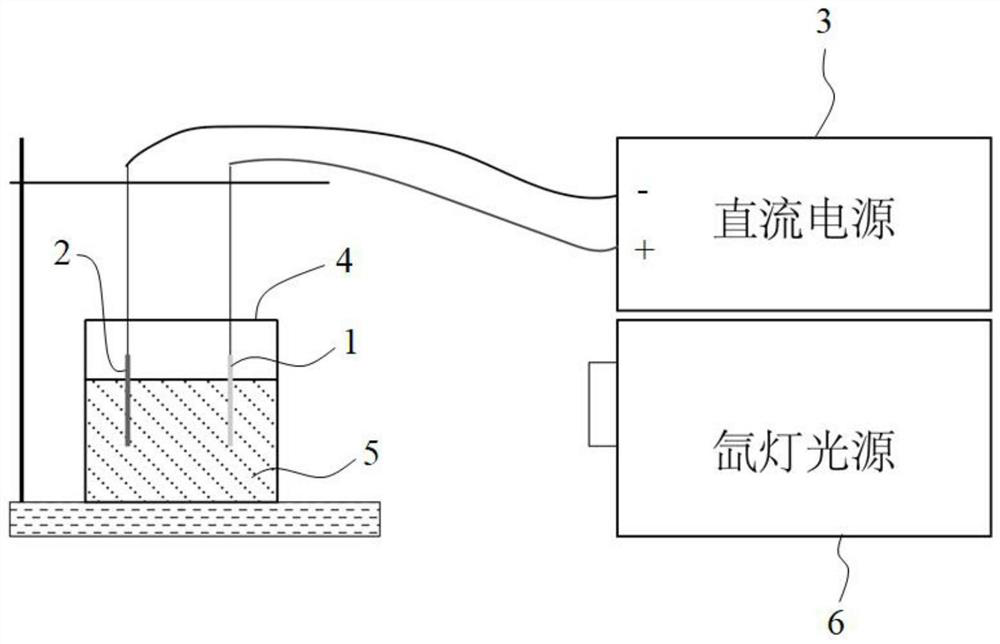

Etching solution for photoelectrochemical etching of gallium nitride

ActiveCN112779013BEtching is effectiveAvoid damageFinal product manufactureSemiconductor/solid-state device manufacturingPhotoelectrochemical etchingPhotoelectrochemistry

The invention discloses an etchant for photoelectrochemically etching gallium nitride. The etchant is composed of amino acid or its derivatives dissolved in a solvent. The invention uses amino acid or its derivatives as an etchant to photoelectrochemically etch gallium nitride, which can effectively etch gallium nitride, and the etching process has low equipment requirements, convenient operation, simple process and environmental protection, which is beneficial to The damage to the surface of the material is small.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

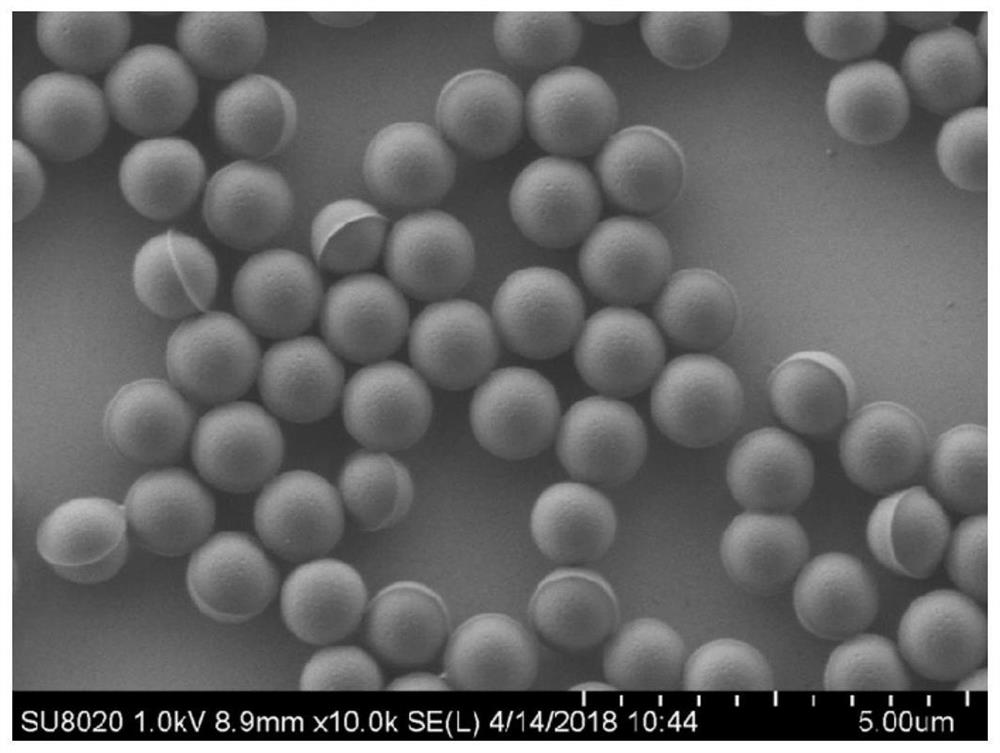

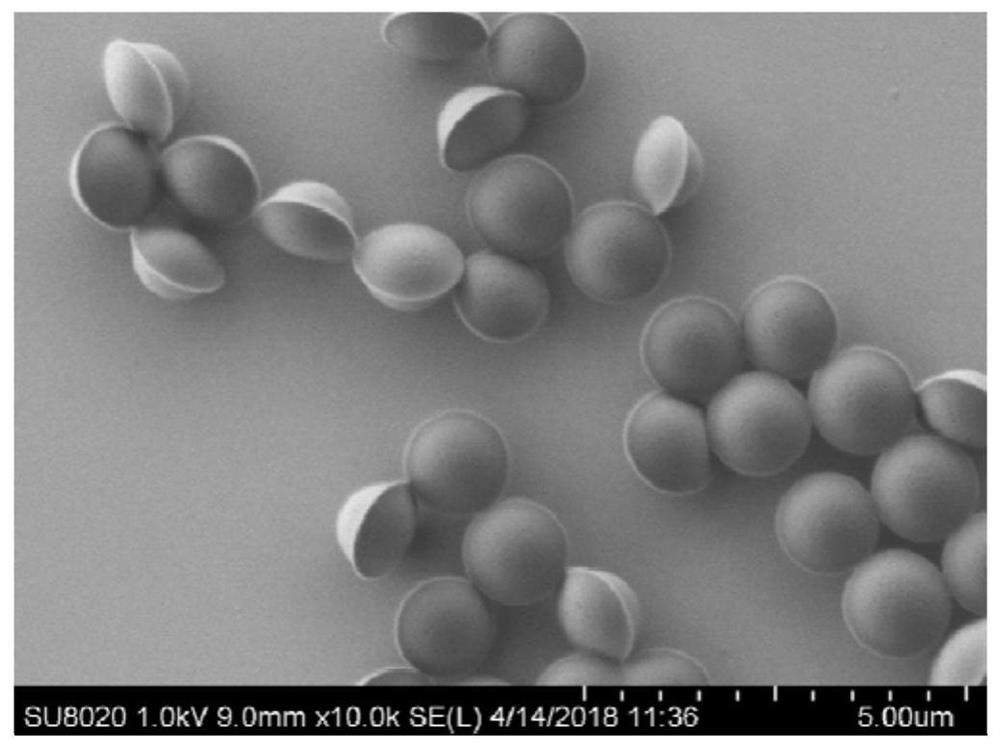

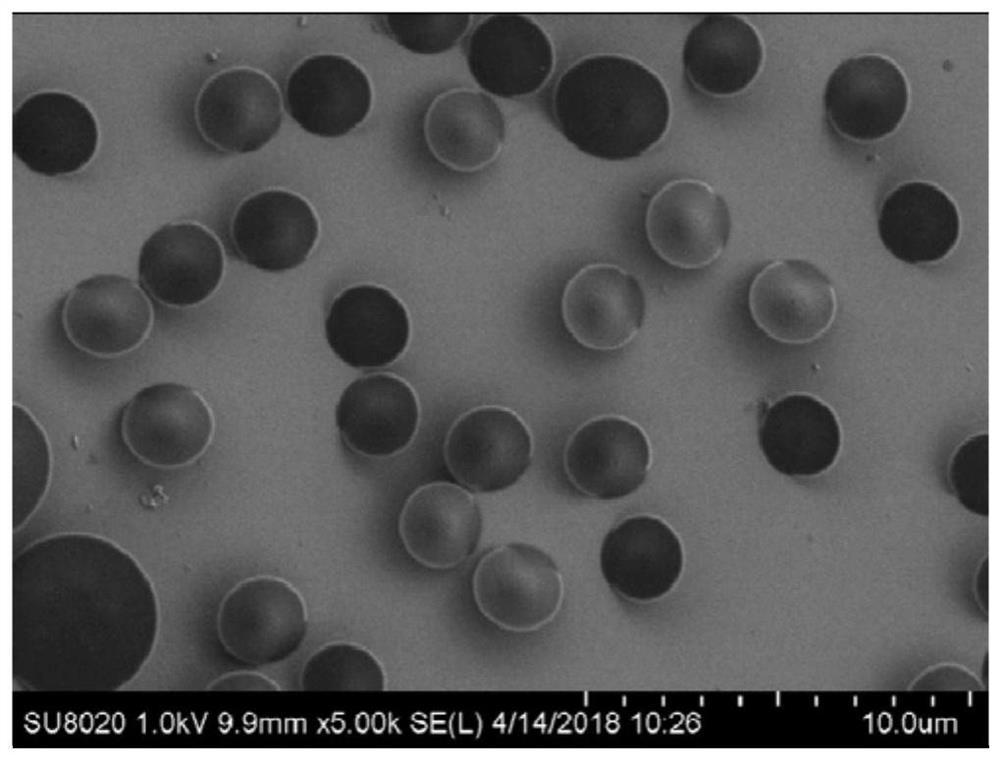

A method for preparing a large number of uniform non-spherical janus particles

Owner:SHAANXI NORMAL UNIV

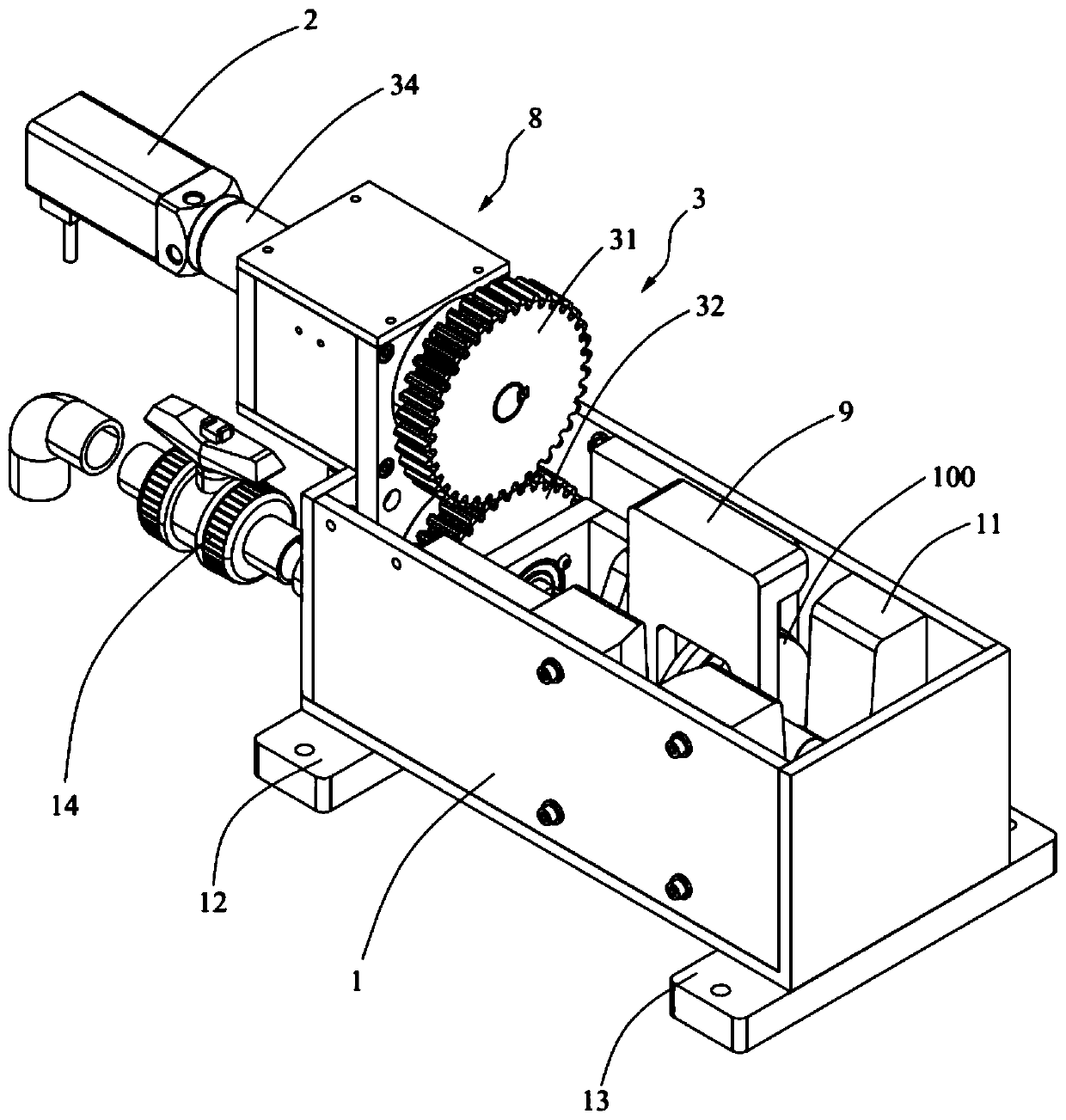

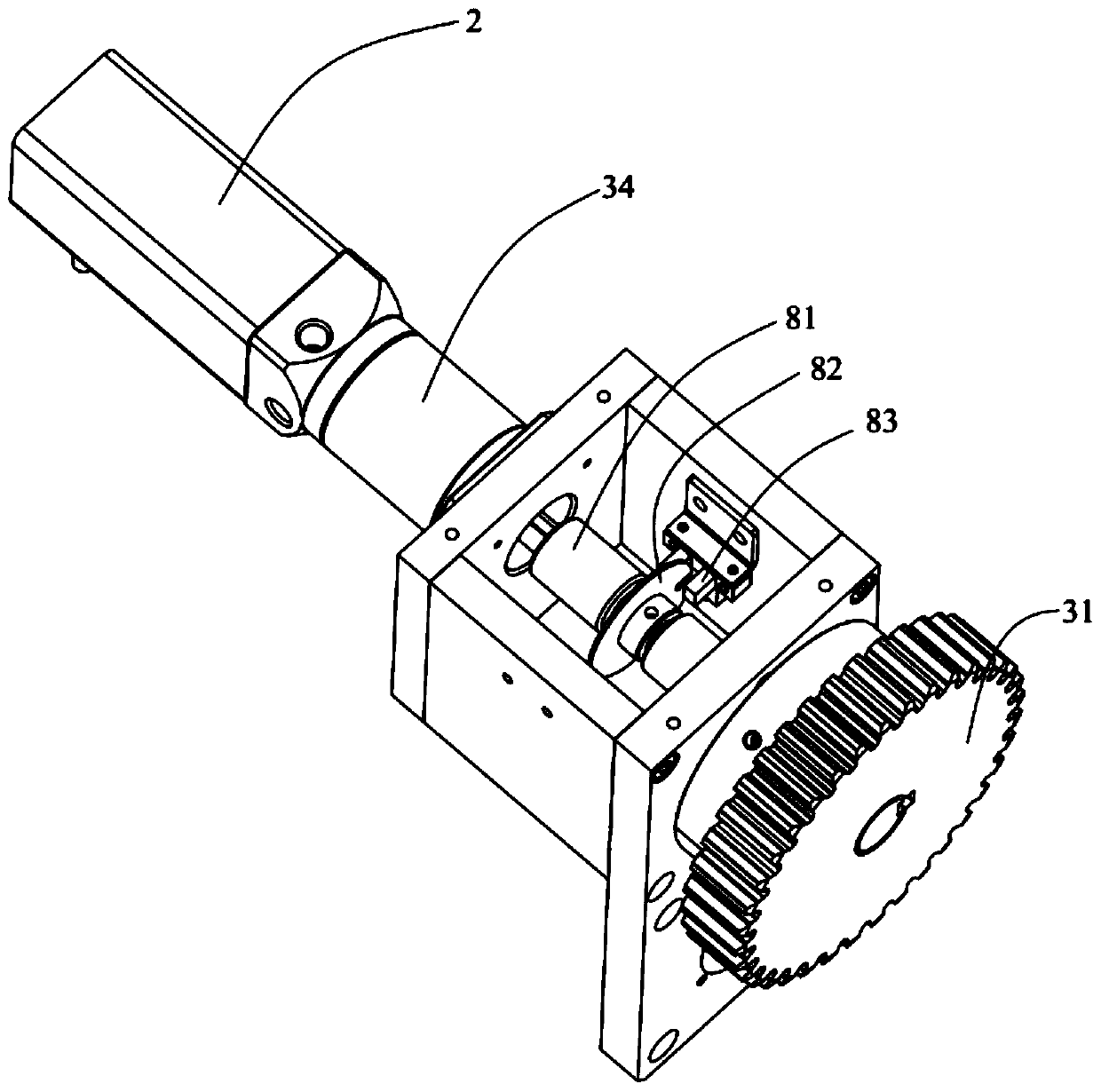

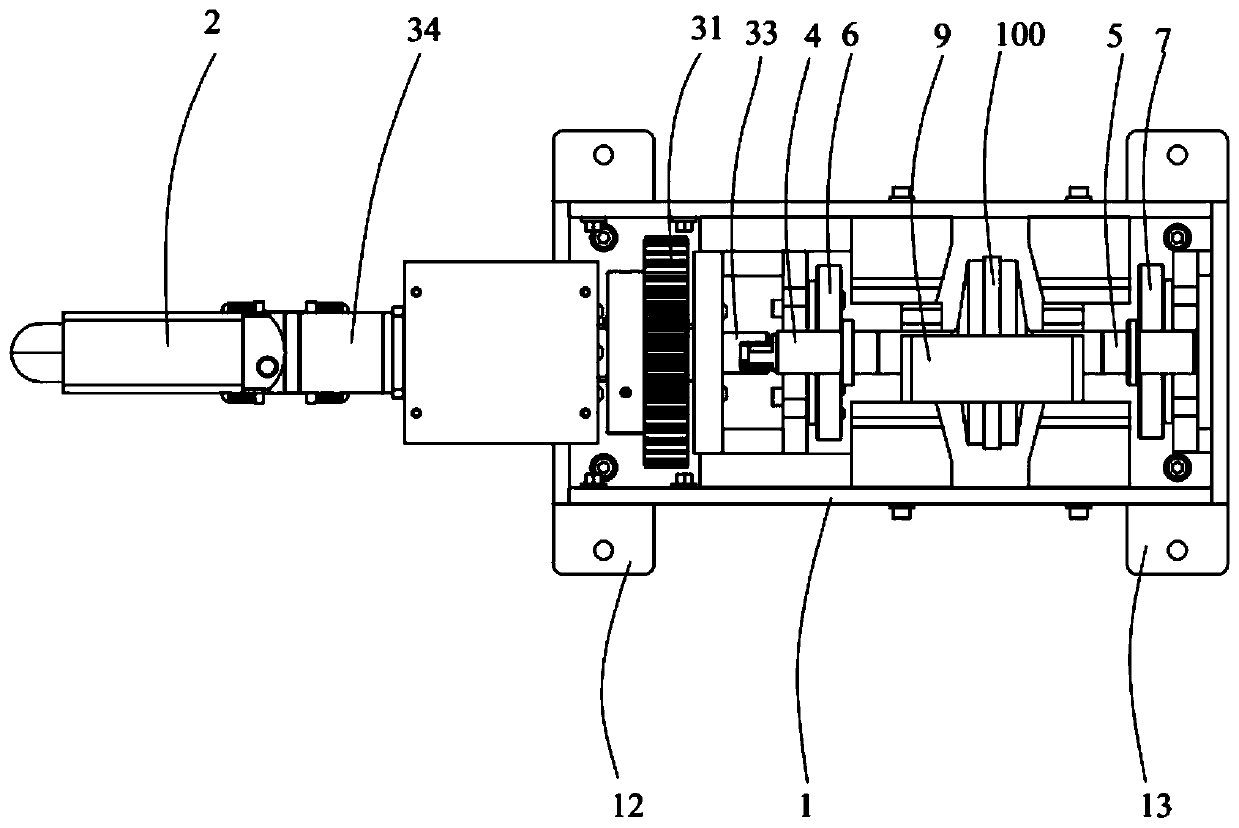

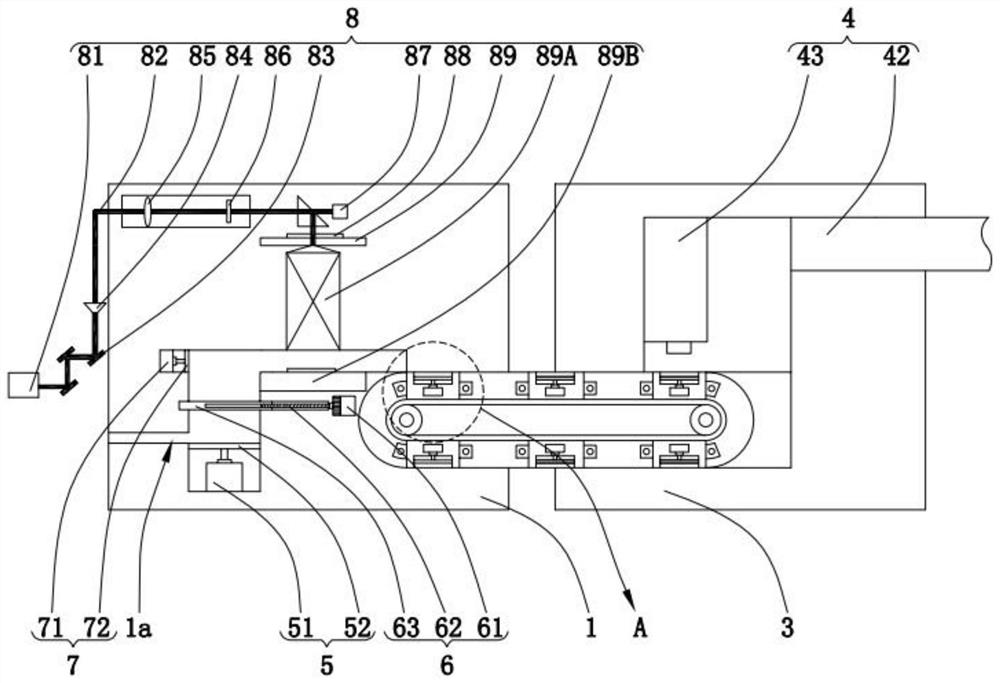

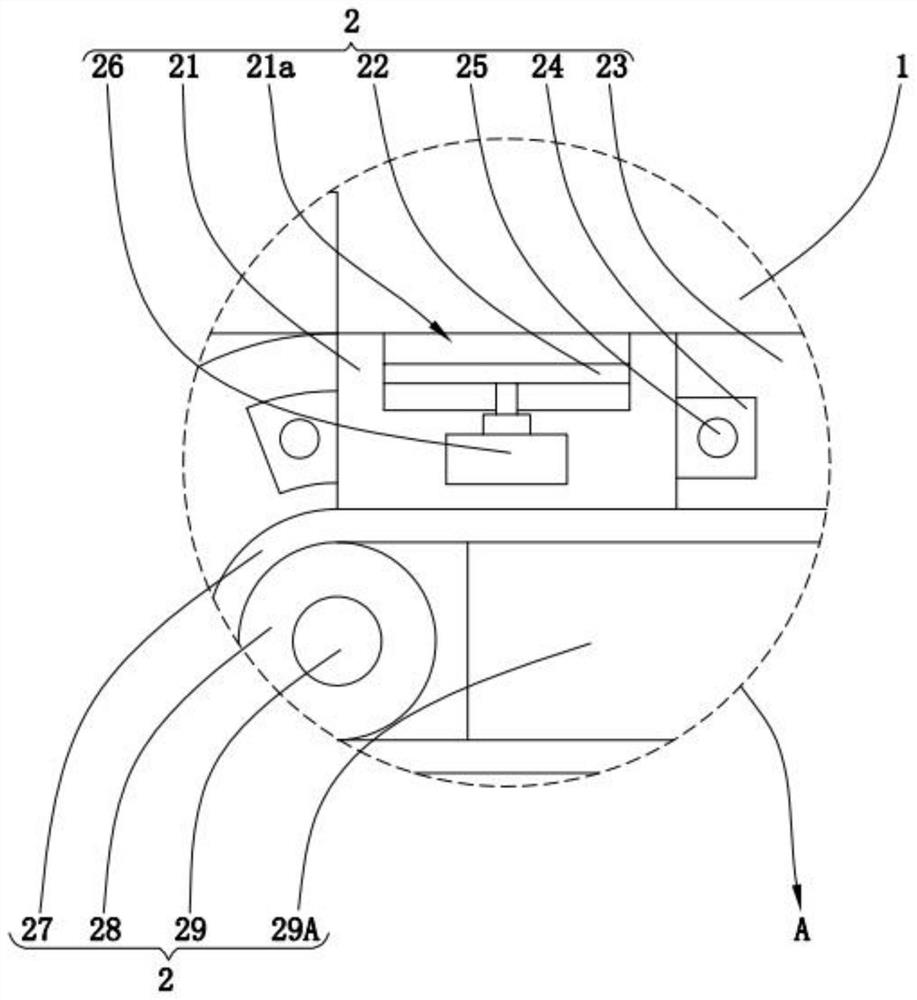

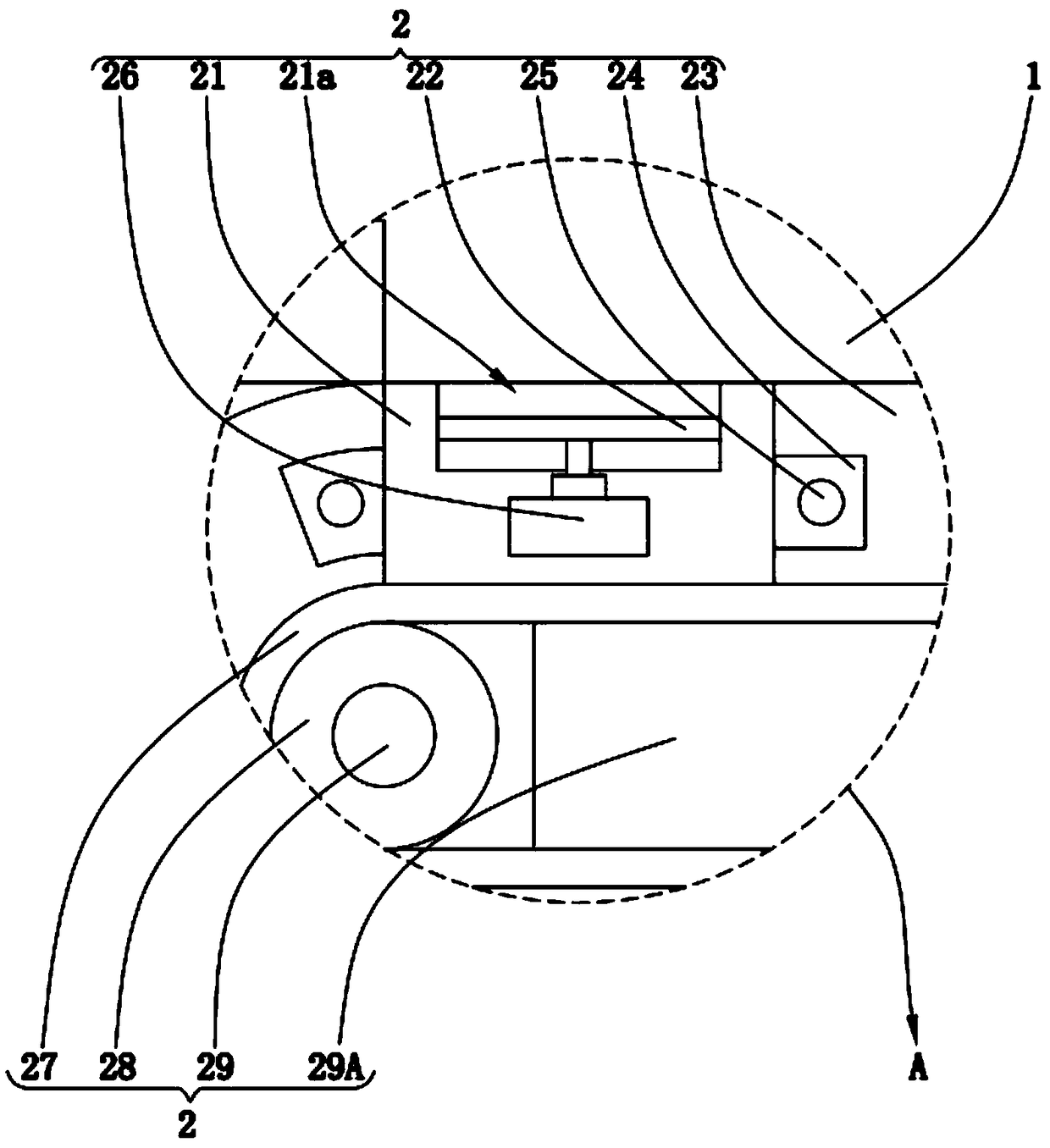

Etching device

PendingCN110764375AUniform etchingEtching is effectivePhotosensitive material processingEtchingEngineering

The invention belongs to the technical field of anvil block production and processing, and discloses an etching device. The etching device comprises a box body used for containing etching liquid, an opening being formed in one side of the box body; a driving member, which is arranged on the box body; and a transmission assembly, of which one end is connected to the output end of the driving member, and the other end is detachably connected to a workpiece to be etched. The driving member is configured to drive the workpiece to be etched to rotate through the transmission assembly to make the peripheral surface of the workpiece to be etched covered with etching liquid. Compared with the prior art, the etching device realizes uniform and effective etching of the workpiece to be etched in therotary motion process of the workpiece to be etched through mutual cooperation of the driving member and the transmission assembly; etching effect is good, and the quality of a finished product is improved; and meanwhile, the time of the etching process in the production process of the workpiece to be etched is shortened, and semi-automatic production is realized, so that the working efficiency is improved.

Owner:SBT ULTRASONIC TECH CO LTD

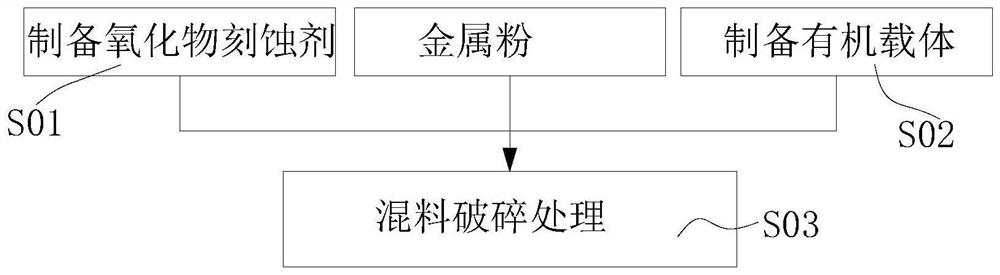

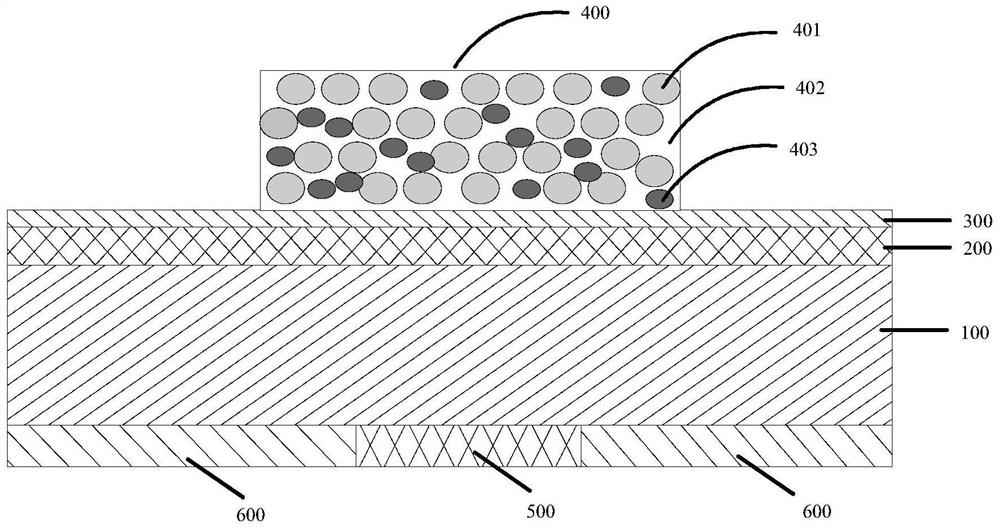

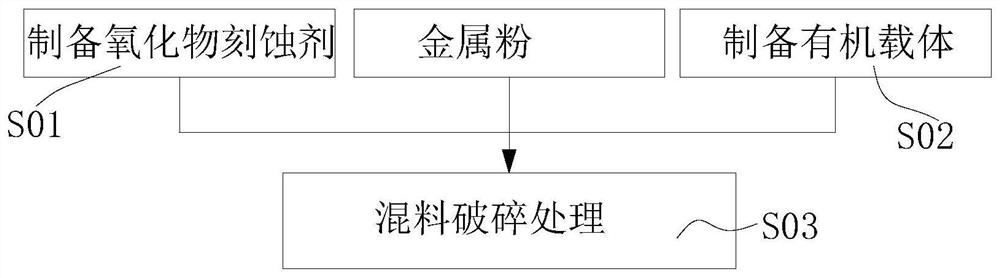

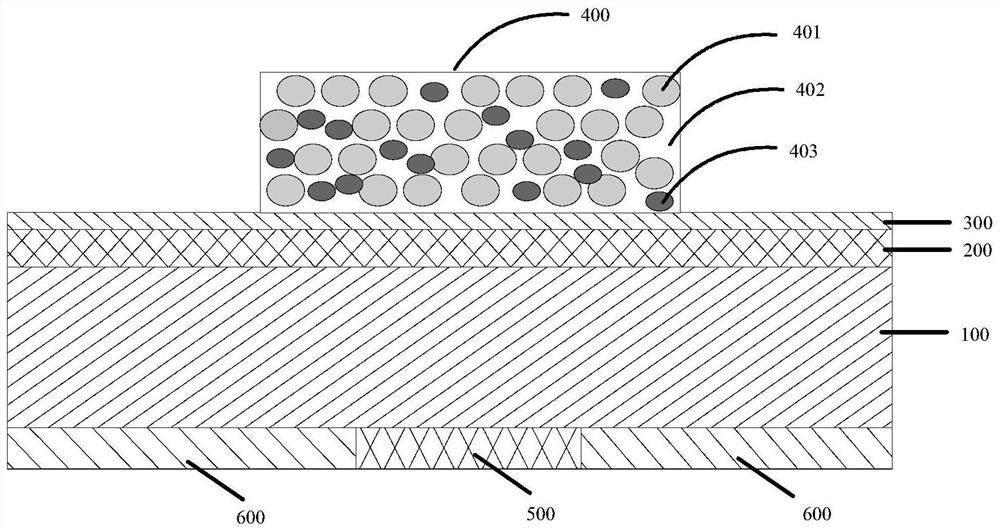

Front conductive paste for crystalline silicon solar cell, preparation method thereof, and solar cell

ActiveCN110603606BIncrease contact resistanceImprove conductivityNon-conductive material with dispersed conductive materialCrystalline siliconOhmic contact

The present invention provides a front conductive paste for crystalline silicon solar cells. In parts by weight, the front conductive paste for crystalline silicon solar cells includes the following raw material components: 80.0-93.0 parts of metal powder; 6.0-15.0 parts of organic carrier; 1.0-5.0 parts of material etchant; wherein, the oxide etchant contains at least PbO, B 2 o 3 , MgO and WO 3 , and the MgO and WO 3 The weight ratio is 0.1:15~6:1; B 2 o 3 and WO 3 The weight ratio of 0.1:15~6:1; WO 3 The weight ratio with PbO is 1:50-15:25. During the sintering process, the front conductive paste can make metal powder and silicon form good ohmic contact, greatly reduce resistance, and finally obtain a front electrode with low contact resistance, good conductivity and strong adhesion.

Owner:SOLTRIUM ADVANCED MATERIALS TECH LTD SHENZHEN

A kind of etching method of c-plane sapphire

ActiveCN104651948BEtching is effectiveImprove etching effectAfter-treatment detailsHydrofluoric acidEtching

The invention discloses a method for etching c-plane sapphire. The method comprises the following steps: firstly immersing c-plane sapphire in a mixed solution consisting of hydrofluoric acid and water at 25 DEG C for 20 minutes, then taking out the c-plane sapphire, sequentially performing alcohol washing, supersonic washing and drying to obtain c-plane sapphire treated by hydrofluoric acid; then immersing the c-plane sapphire treated by the hydrofluoric acid in a mixed acid consisting of concentrated sulfuric acid and concentrated phosphoric acid for 20 minutes, naturally cooling, taking out the c-plane sapphire and sequentially performing alcohol washing, supersonic washing and drying to obtain c-plane sapphire treated by the mixed acid; and finally putting the c-plane sapphire treated by the mixed acid in a melting solution of flaky NaOH at the temperature of 325-340 DEG C for 10 minutes, taking out the c-plane sapphire and sequentially performing alcohol washing, supersonic washing and drying to finish the etching of the c-plane sapphire. The method for etching the c-plane sapphire disclosed by the invention has the advantages of good etching effect, good uniformity, good quality, high yield and the like.

Owner:西双版纳承启科技有限公司

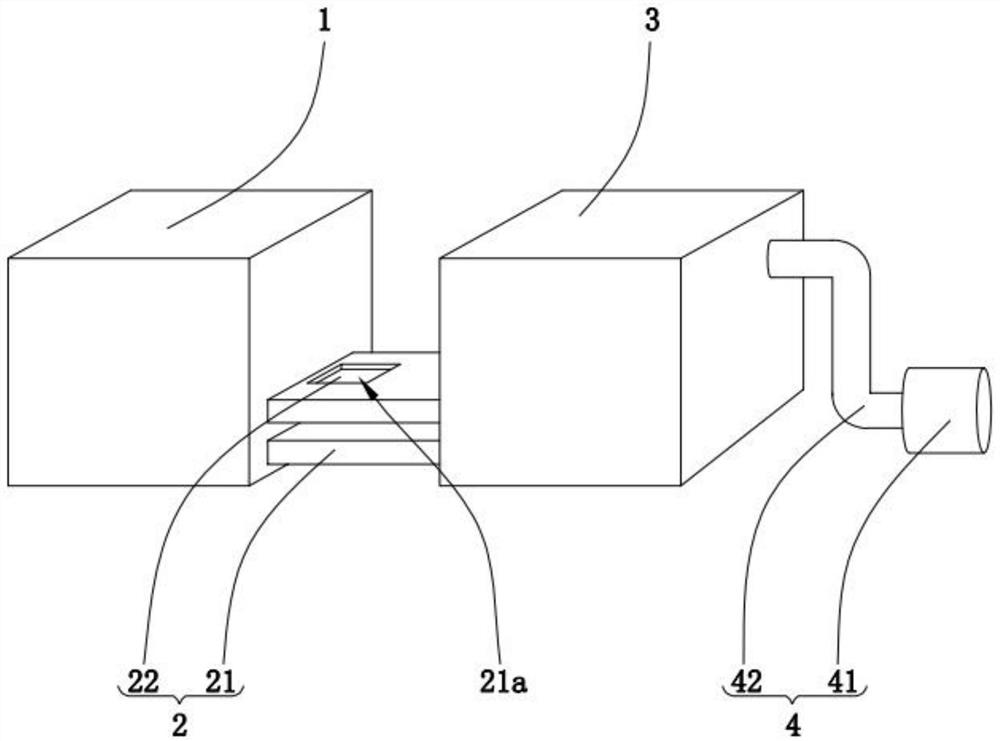

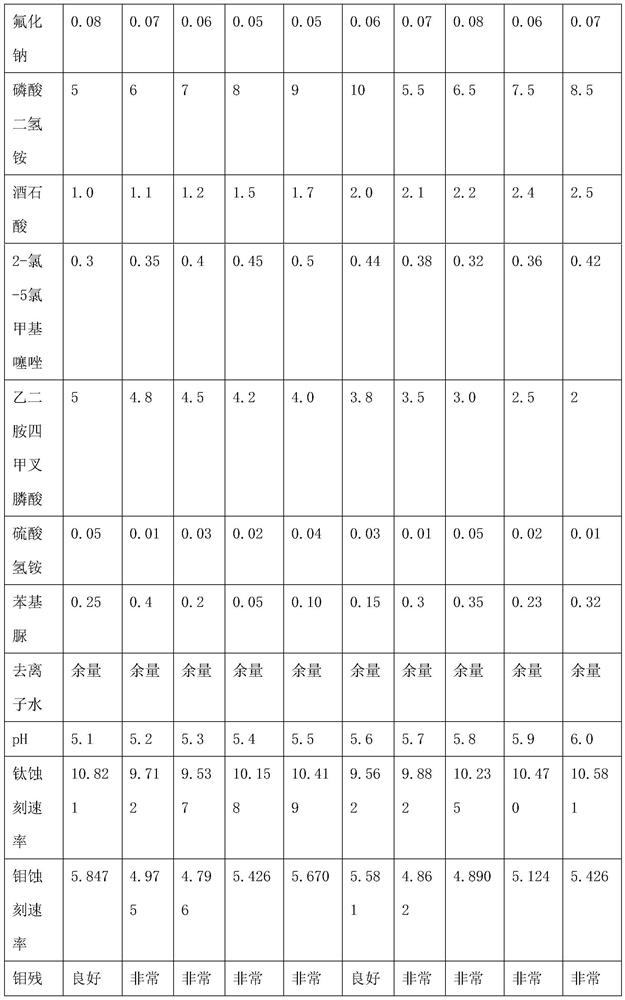

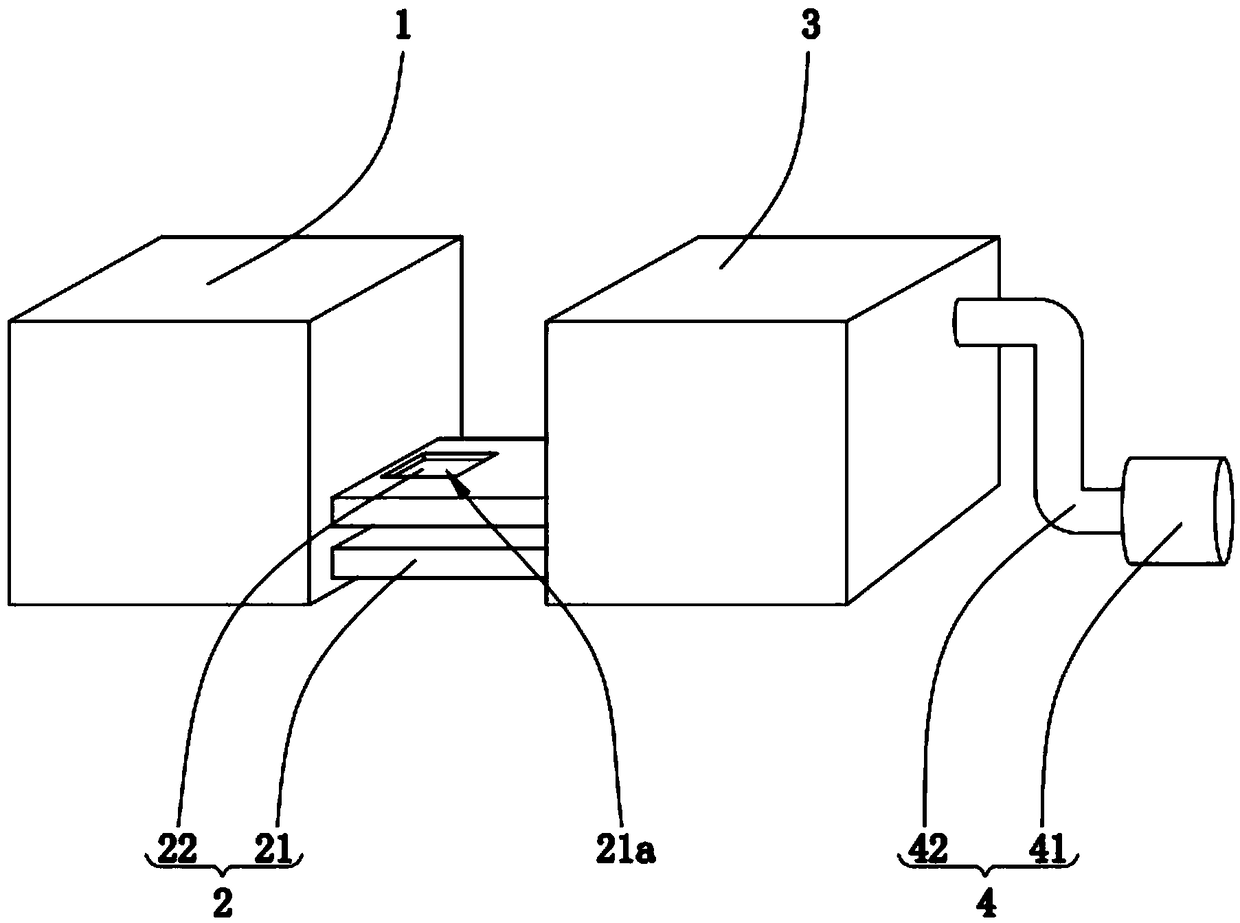

A Diffraction Grating Etching Machine

ActiveCN108802882BEtching is effectiveEffective projectionDiffraction gratingsPhotomechanical exposure apparatusEngineeringSilica gel

The invention relates to the technical field of lithography, and specifically relates to a diffraction grating etcher. The diffraction grating etcher includes a first fixed housing, a transmission mechanism, a second fixed housing, an etching mechanism, a feeding mechanism, a sealing mechanism, an adjusting mechanism and a lithography mechanism, wherein the lithography mechanism is arranged in thefirst fixed housing, and can effectively project on a silica gel plate to form a model; the etching mechanism is arranged in the second fixed housing, and can effectively use the projected silica gelplate to perform etching to manufacture a real product; the transmission mechanism is arranged between the first fixed housing and the second fixed housing, and can transmit the projected silica gelplate in the first fixed housing into the second fixed housing for etching while maintaining the sealing properties of the first fixed housing and the second fixed housing, so as to realize continuousproduction; and in the first fixed housing, the feeding mechanism is used to perform feeding, and at the same time the sealing mechanism is used to maintain the sealing state, and when the sealing mechanism is opened, the sealing mechanism can guarantee that no external light enters and can guarantee the sealing properties during the feeding process.

Owner:温州豪正实业有限公司

Laminated metal and metal oxide etching liquid composition and use method thereof

ActiveCN113046747AImproved etch topography and linewidth lossFix damageSurface treatment compositionsLiquid compositionCorrosion inhibitor

The invention provides a laminated metal and metal oxide etching solution composition and a use method thereof. The laminated metal and metal oxide etching solution composition comprises the following raw materials by mass of: 5% to 20% of hydrogen peroxide, 1% to 10% of inorganic acid, 0.01% to 1% of a fluorine ion source, 1% to 10% of a complexing agent, 1% to 10% of an alkali compound, 0.01% to 1% of a metal corrosion inhibitor, and the balance of a solvent. According to the laminated metal and metal oxide etching liquid composition and the use method thereof provided by the invention, not only the laminated metal and metal oxide can be effectively etched, but also the etching morphology is good, the etching precision is high, and the requirements of customers can be effectively met.

Owner:四川和晟达电子科技有限公司 +1

A kind of molybdenum/titanium alloy film etchant composition and application thereof

ActiveCN111041489BAvoid deterioration of etching effectAvoid large side corrosionSolid-state devicesSemiconductor devicesEthylenediamineSulfate

The invention discloses a molybdenum / titanium alloy thin film etchant composition and application thereof. The etchant composition comprises 0.25-0.45wt% persulfate, 3-4wt% hydrogen peroxide, 0.05-0.08wt% fluoride, 5-10wt% ammonium dihydrogen phosphate, 1.0-2.5wt% tartaric acid, 0.3-0.5wt% side corrosion prevention additive 2-chloro-5 chloromethylthiazole, 2-5wt% ethylene di Amine tetramethylene phosphonic acid complexing agent and deionized water; pH 5.0‑6.0. The various components do not play their roles independently, but cooperate with each other as a whole to make the etching have an etching profile with an appropriate taper angle, and under the condition of controlling the corresponding CD Loss, it can ensure that there is no molybdenum residue. At the same time, excessive side corrosion is avoided, and defects such as molybdenum undercuts are avoided, resulting in performance that cannot meet the application.

Owner:易安爱富武汉科技有限公司

Diffraction grating etcher

ActiveCN108802882AEtching is effectiveEffective projectionDiffraction gratingsPhotomechanical exposure apparatusEngineeringDiffraction grating

The invention relates to the technical field of lithography, and specifically relates to a diffraction grating etcher. The diffraction grating etcher includes a first fixed housing, a transmission mechanism, a second fixed housing, an etching mechanism, a feeding mechanism, a sealing mechanism, an adjusting mechanism and a lithography mechanism, wherein the lithography mechanism is arranged in thefirst fixed housing, and can effectively project on a silica gel plate to form a model; the etching mechanism is arranged in the second fixed housing, and can effectively use the projected silica gelplate to perform etching to manufacture a real product; the transmission mechanism is arranged between the first fixed housing and the second fixed housing, and can transmit the projected silica gelplate in the first fixed housing into the second fixed housing for etching while maintaining the sealing properties of the first fixed housing and the second fixed housing, so as to realize continuousproduction; and in the first fixed housing, the feeding mechanism is used to perform feeding, and at the same time the sealing mechanism is used to maintain the sealing state, and when the sealing mechanism is opened, the sealing mechanism can guarantee that no external light enters and can guarantee the sealing properties during the feeding process.

Owner:温州豪正实业有限公司

Gradient method preprocessing technique for depositing CVD diamond film on hard metal surface

InactiveCN100543177CQuality improvementGuaranteed StrengthChemical vapor deposition coatingEdge surfaceEtching

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

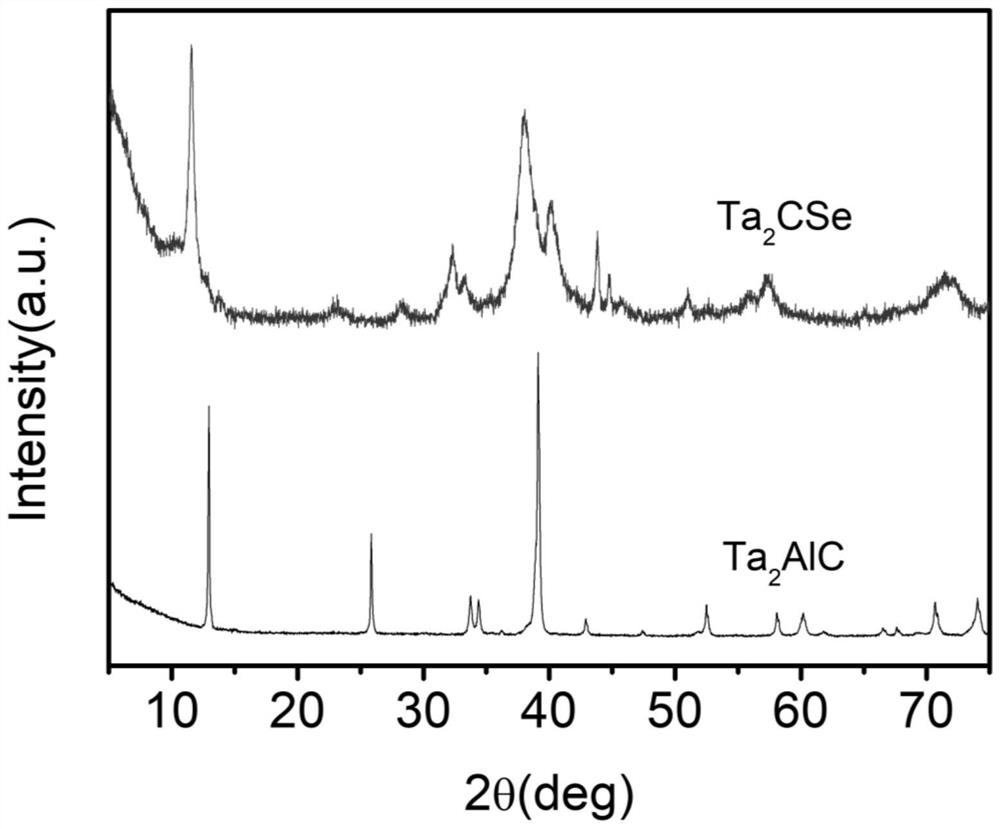

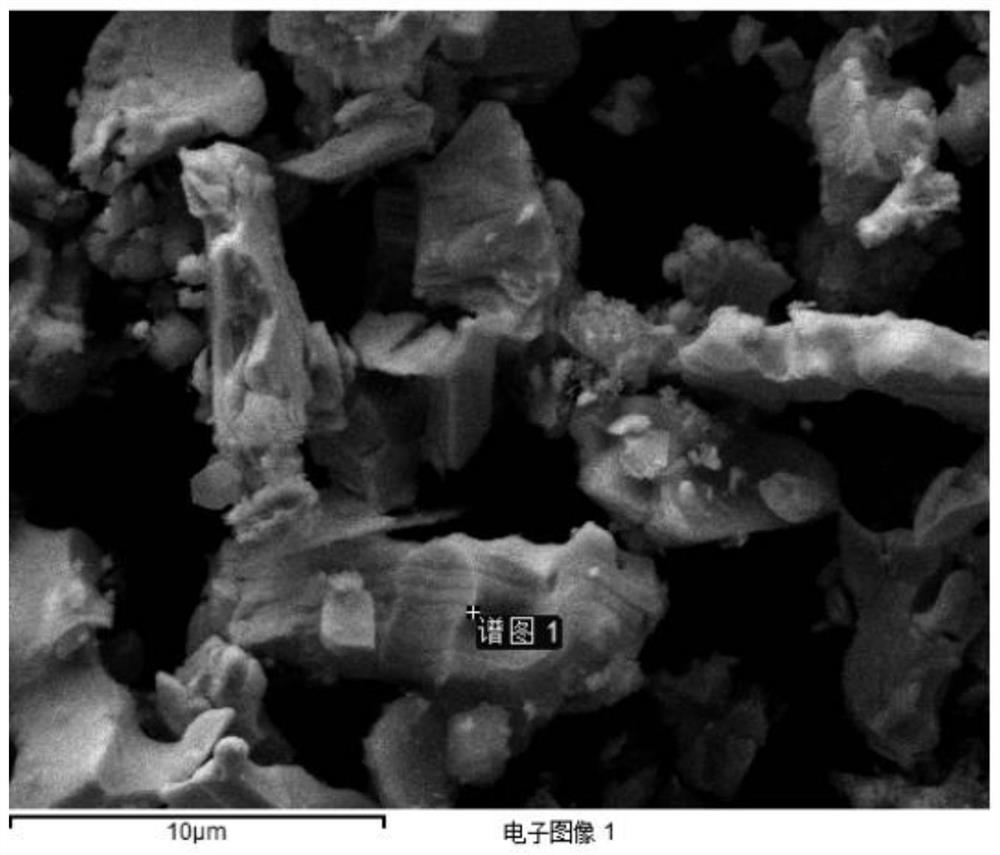

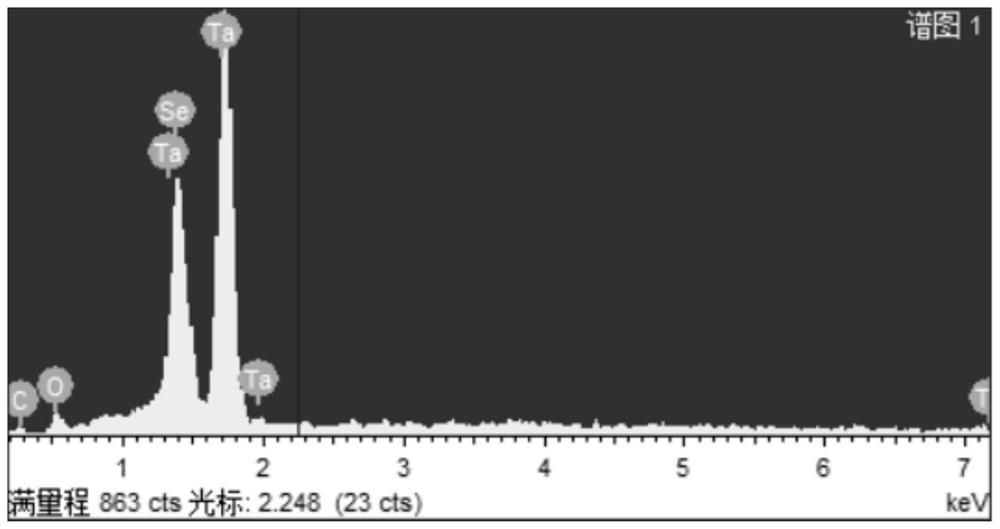

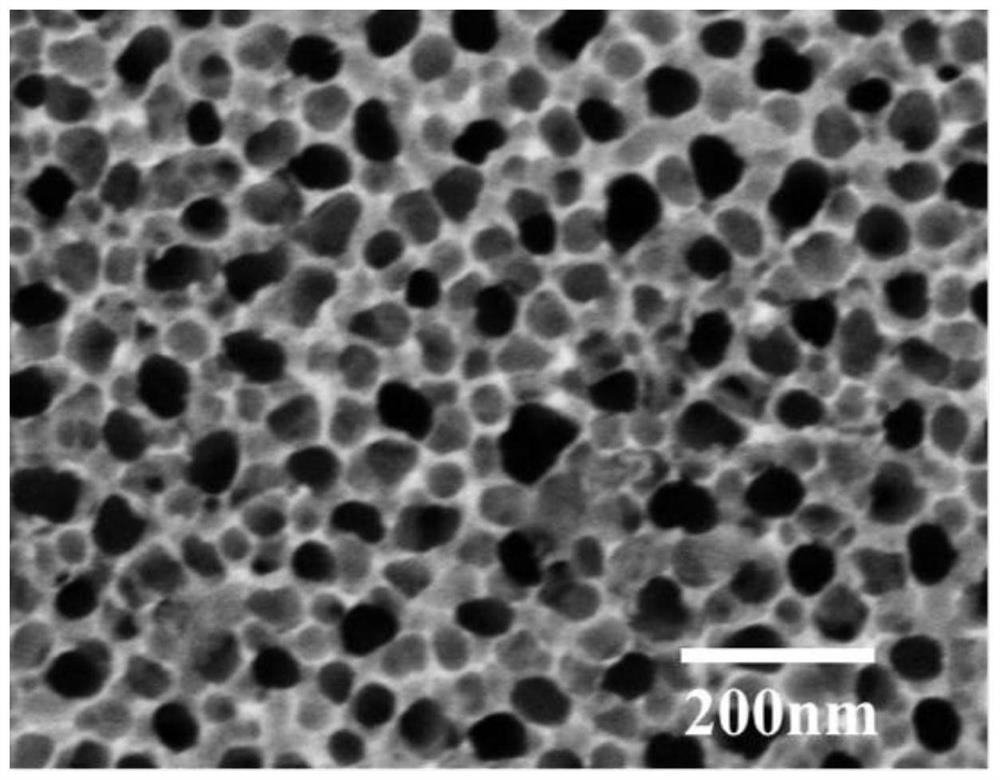

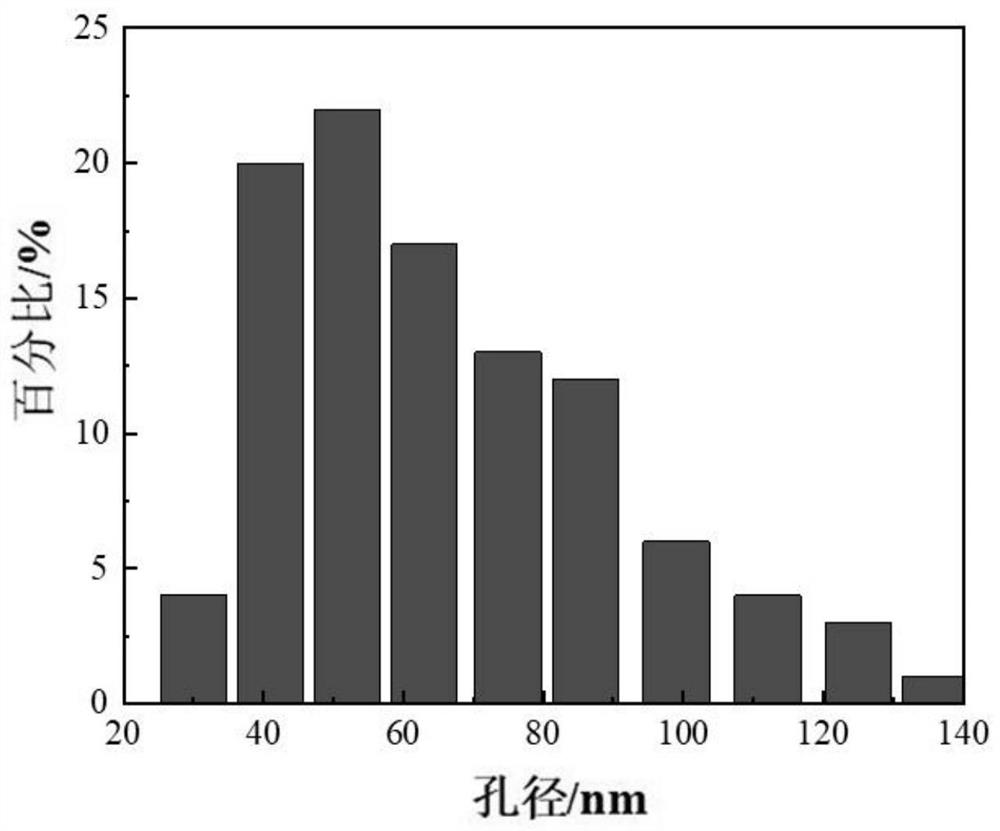

Etching method of MXene material

PendingCN114408873AEasy to prepareFacilitating functional applications and large-scale preparationSelenium/tellurium compounds with other elementsChalcogenideInorganic salts

The invention belongs to the technical field of two-dimensional nano materials, and particularly relates to an etching method of an MXene material. The invention relates to an etching method of an MXene material, which comprises the following steps: mixing a precursor MAX phase material, chalcogenide or nitrogen elementary substance element powder or related alloy phase thereof and inorganic salt, and reacting at high temperature. The method disclosed by the invention is simple, efficient and environment-friendly, multiple defects caused by using a hydrofluoric acid (HF) solution with high toxicity and high risk as an etching agent to prepare MXene are avoided, chemical modification of the surface of the MXene material is realized, physical and chemical properties of the MXene material can be effectively regulated and controlled through end group modification, and functional application and large-scale preparation of MXene are expected to be further promoted.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

Front conductive paste for crystalline silicon solar cell, preparation method thereof, and solar cell

ActiveCN110557965BLower resistanceStrong adhesionNon-conductive material with dispersed conductive materialConductive pasteElectrical resistance and conductance

The present invention provides a front conductive paste for crystalline silicon solar cells. In parts by weight, the front conductive paste for crystalline silicon solar cells includes the following raw material components: 80.0-93.0 parts of metal powder; 6.0-15.0 parts of organic carrier; 1.0-5.0 parts of material etchant; wherein, the oxide etchant contains at least Pb 3 o 4 , CuO and Li 2 O, and the CuO and Pb 3 o 4 The weight ratio of CuO and Li is 0.02 to 2.5, and the CuO and Li 2 The weight ratio of O is 0.025-3. During the sintering process, the front conductive paste can make metal powder and silicon form good ohmic contact, greatly reduce resistance, and finally obtain a front electrode with low contact resistance, good conductivity and strong adhesion.

Owner:SOLTRIUM ADVANCED MATERIALS TECH LTD SHENZHEN

Etching solution for photoelectrochemical etching of gallium nitride

ActiveCN112779013AEtching is effectiveAvoid damageFinal product manufactureSemiconductor/solid-state device manufacturingPhotoelectrochemical etchingPhotoelectrochemistry

The invention discloses an etching solution for photoelectrochemical etching of gallium nitride. The etching solution is formed by dissolving amino acid or derivatives thereof in a solvent. According to the invention, the amino acid or the derivative of the amino acid is used as an etching agent for photoelectrochemical etching of the gallium nitride, the gallium nitride can be effectively etched, and the etching process is low in equipment requirement, convenient to operate, simple in process, green, environmentally friendly and small in damage to the surface of a material.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com